Copolymer, preparation method thereof, application of the copolymer as plugging agent, oil-based drilling fluid and application of oil-based drilling fluid

A technology of oil-based drilling fluid and copolymer, applied in the field of oil-based drilling fluid

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0036] As previously mentioned, the second aspect of the present invention provides a method for preparing a copolymer, the method comprising the steps of:

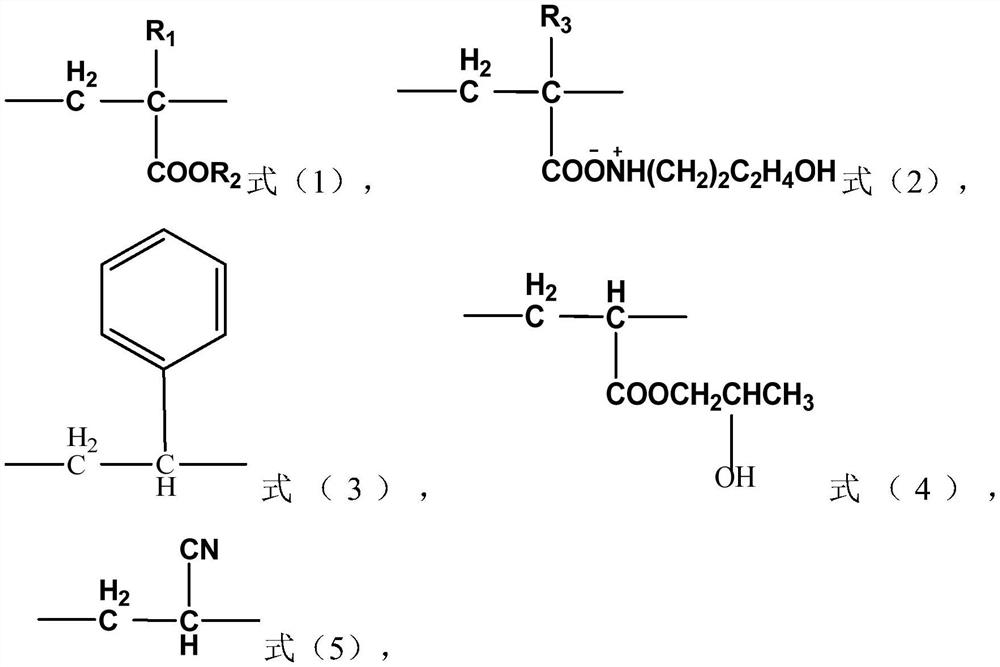

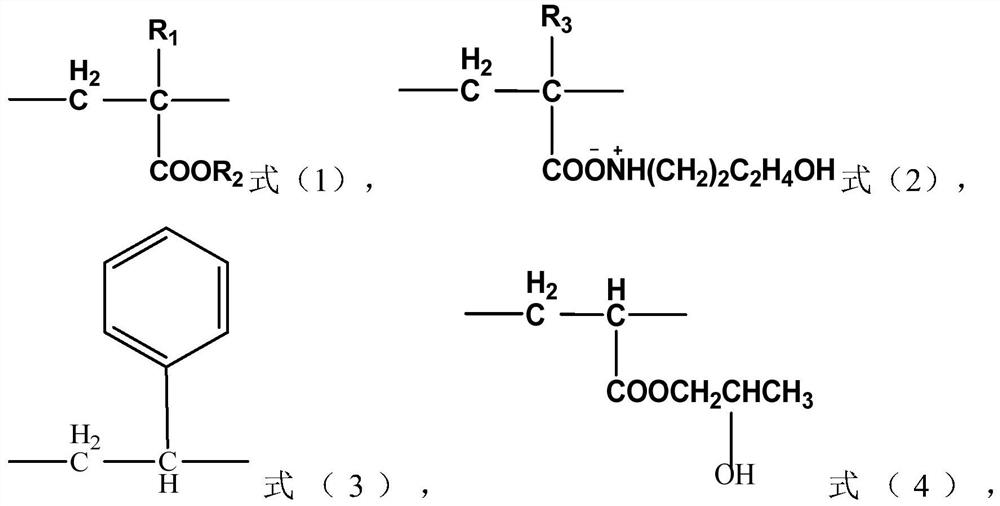

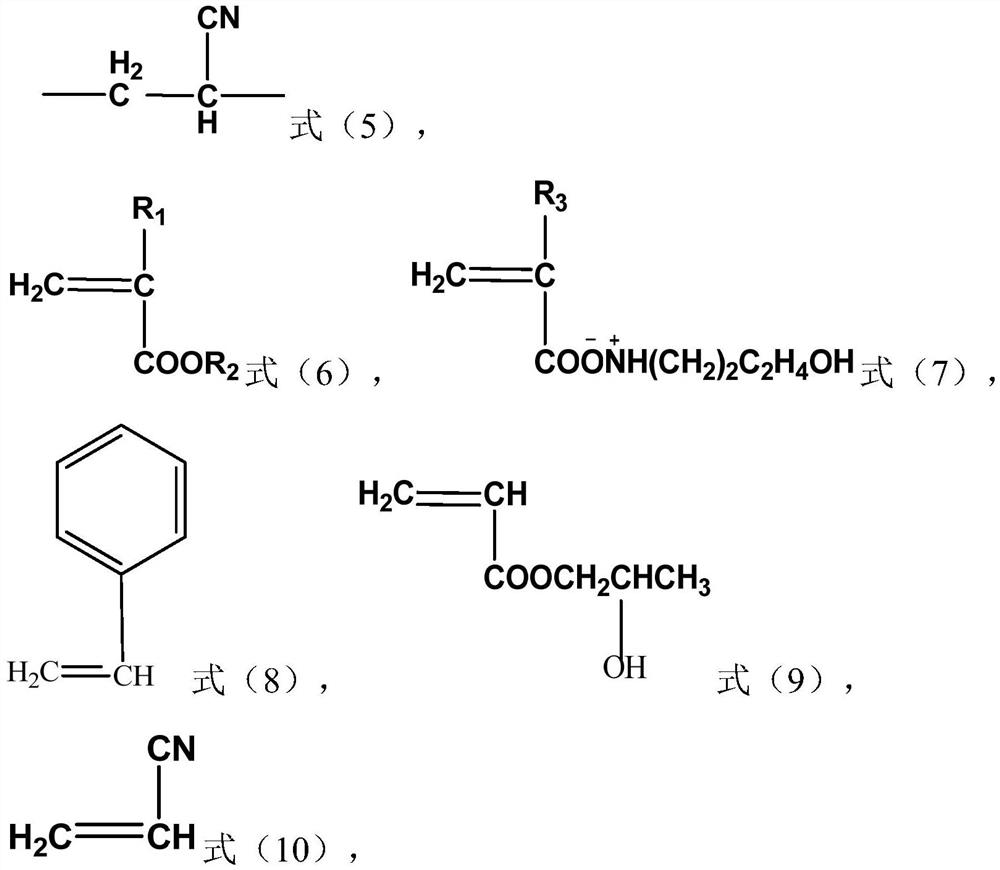

[0037] In the presence of initiator, emulsifier and aqueous solvent, monomer A, monomer B, monomer C, monomer D and monomer E are subjected to emulsion polymerization; the monomer A is represented by formula (6) The monomer of structure, described monomer B is the monomer that has the structure shown in formula (7), and described monomer C is the monomer that has the structure shown in formula (8), and described monomer D is the monomer that has formula ( 9) The monomer of the shown structure, the monomer E is a monomer having the structure shown in formula (10); wherein, the monomer A, the monomer B, the monomer C, the monomer D and the monomer E The dosage makes in the prepared copolymer, the unit number of structural unit A is 2-20, the unit number of structural unit B is 1-30, the unit number of structural unit C is 1...

Embodiment approach

[0060] According to a preferred embodiment provided by the present invention, the preparation method of the copolymer specifically includes the following steps:

[0061] At room temperature, first mix monomer A, monomer B, monomer C, monomer D and monomer E, and then mix with the first emulsifier to obtain the outer phase; mix the aqueous solvent with the second emulsifier to obtain the inner phase ; The external phase is sheared in a high-speed shear emulsifier, and the internal phase is added to continue shearing during the shearing process, and an initiator is added to continue shearing to obtain an emulsion; then, under an inert atmosphere, under a water bath condition, the emulsion polymerization;

[0062] The monomer A is a monomer having a structure shown in formula (6), the monomer B is a monomer having a structure shown in formula (7), and the monomer C is a monomer having a structure shown in formula (8). A monomer, the monomer D is a monomer having a structure show...

Embodiment 1

[0087] This example is used to illustrate the copolymer of the present invention and its preparation method and plugging agent.

[0088] At normal temperature, each monomer styrene (monomer C), butyl acrylate (monomer A, R 1 for H, R 2 for -CH 2 CH 2 CH 2 CH 3 ), acrylonitrile (monomer E), 2-hydroxypropyl acrylate (monomer D), monomer B (R 3 Methyl) were mixed in a weight ratio of 4:4:1:0.5:0.5, Span 80 was added in an amount of 0.3wt% of the total amount of each monomer, and stirred at 50 rpm for 12 minutes to obtain an external phase.

[0089] At room temperature, take 100 g of deionized water, add Tween 80 in an amount of 4 wt% of the total amount of deionized water, and stir at 50 rpm for 12 minutes to obtain an internal phase.

[0090] At room temperature, pour the external phase into an emulsifier placed in an ice bath, shear at a high speed at 12000 rpm, pour the internal phase into the shearing process, and shear for 2 minutes; then add 0.3 wt% azobisisobutyroni...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com