Production process of wear-resistant, stain-resistant and corrosion-resistant stainless steel plate

A technology of stainless steel plate and production process, which can be used in the direction of pretreatment surface, coating, device for coating liquid on the surface, etc., which can solve the problems of poor corrosion resistance and fouling resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] see Figure 1-10 As shown, this embodiment is a production process for wear-resistant, stain-resistant and corrosion-resistant stainless steel plates, including the following steps:

[0040] Step 1: Polish the surface of the stainless steel plate with sandpaper;

[0041] Step 2: Put the polished stainless steel plate into lye for 15 minutes, take it out, wash it with deionized water 3 times, and dry it; the lye is a mixed aqueous solution of sodium carbonate and sodium hydroxide, wherein sodium carbonate , The concentration of sodium hydroxide is 3g / mL;

[0042] Step 3: Place the dried stainless steel plate on the conveyor belt 204 of the feeding mechanism 200 of the surface treatment equipment, start the conveying motor 202, and the conveying motor 202 drives the conveyor belt 204 to rotate through the transmission roller 203, so as to move the stainless steel plate to the surface The processing mechanism 100 conveys;

[0043] Step 4: Inject protective paint into th...

Embodiment 2

[0048] see Figure 1-10 As shown, this embodiment is a production process for wear-resistant, stain-resistant and corrosion-resistant stainless steel plates, including the following steps:

[0049] Step 1: Polish the surface of the stainless steel plate with sandpaper;

[0050] Step 2: Put the polished stainless steel plate into lye for 20 minutes, take it out, wash it with deionized water 5 times, and dry it; the lye is a mixed aqueous solution of sodium carbonate and sodium hydroxide, wherein sodium carbonate , The concentration of sodium hydroxide is 5g / mL;

[0051] Step 3: Place the dried stainless steel plate on the conveyor belt 204 of the feeding mechanism 200 of the surface treatment equipment, start the conveying motor 202, and the conveying motor 202 drives the conveyor belt 204 to rotate through the transmission roller 203, so as to move the stainless steel plate to the surface The processing mechanism 100 conveys;

[0052] Step 4: Inject protective paint into th...

Embodiment 3

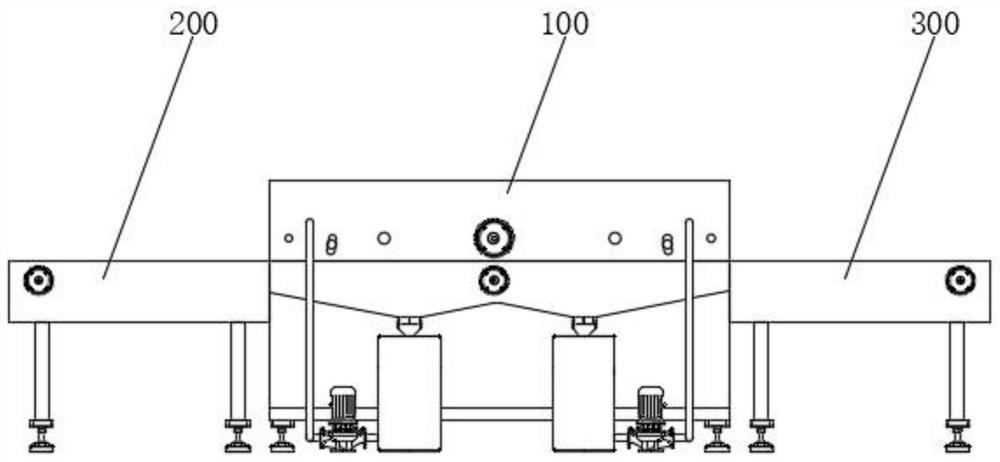

[0057] see Figure 1-10 As shown, the present embodiment is a surface treatment device, including a surface treatment mechanism 100, a feeding mechanism 200, and an unloading mechanism 300. One end of the surface treatment mechanism 100 is equipped with a feeding mechanism 200, and the other end of the surface treatment mechanism 100 is One end is equipped with a blanking mechanism 300, and the structures of the loading mechanism 200 and the blanking mechanism 300 are the same;

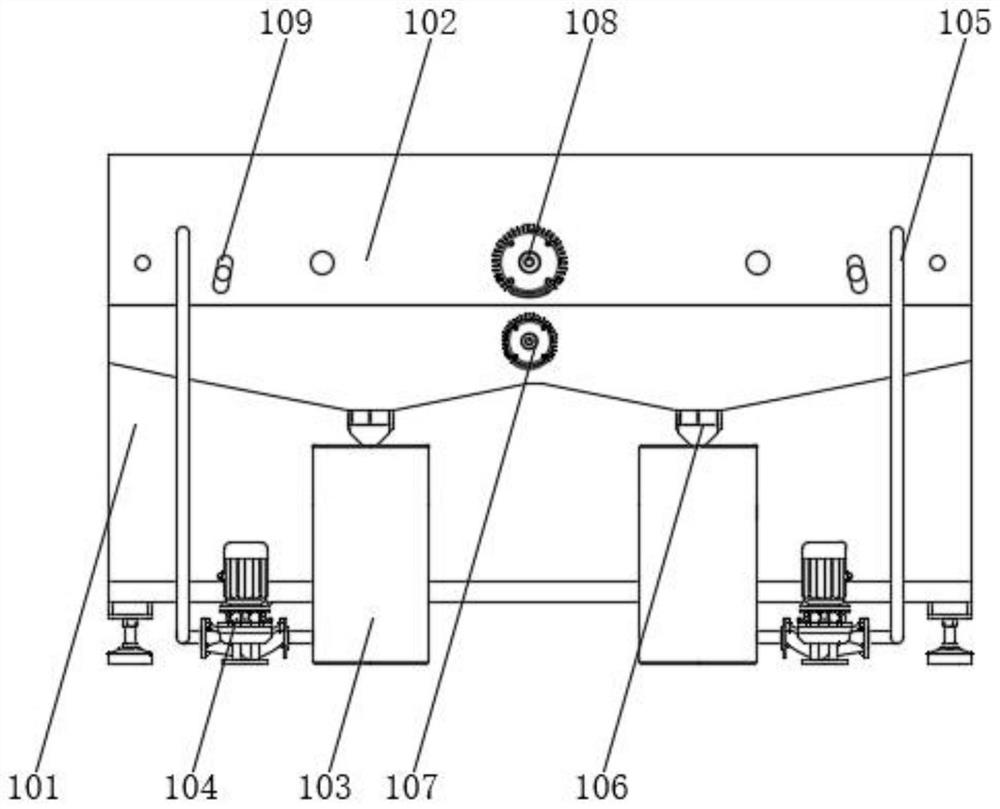

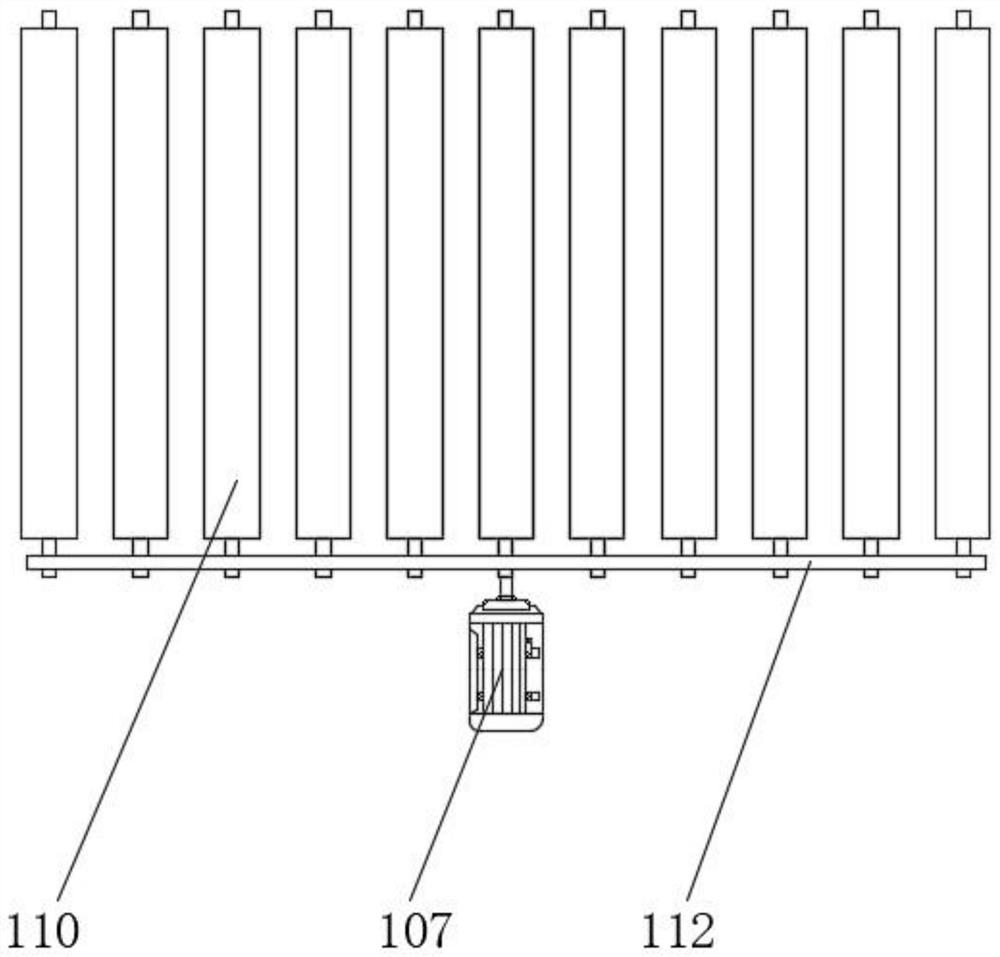

[0058] The surface treatment mechanism 100 includes a first installation box 101, a second installation box 102, a material storage box 103, a paint delivery pump 104, a delivery pipeline 105, a recovery bucket 106, a material transfer motor 107, a drive motor 108, an adjustment hole 109, Conveying roller 110, transmission gear 111, toothed belt 112, loading box 113, discharge nozzle 114, connecting shaft 115, feeding roller 116, transmission sprocket 117, transmission chain 118, hopper 119, discharge...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com