Manufacturing method for bar-type array tellurium-zinc-cadmium detector

A technology for cadmium zinc telluride and detectors, which is applied in the field of preparation of strip array cadmium zinc telluride detectors, can solve the problems of edge defects of lithography images, sag lithography electrode patterns, uneven thickness of wafers, and the like, and saves the preparation. time, overcoming sag, reducing the effect of processing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] Step 1: CdZnTe crystal ingot grown by the vertical Bridgman method is oriented along the direction to cut out a size of 12×10mm 2 , a rectangular single wafer with a thickness of 0.5 mm.

[0018] Step 2: After the wafer is mechanically polished and chemically polished, the Au electrode is evaporated on the {111}Cd surface of the wafer by thermal evaporation, and a photoresist is coated on the electrode to protect the Au electrode from subsequent processing. Destroyed; four 1×8 strip array patterns were simultaneously photolithographically etched on the {111} Te surface of a single wafer, and Au electrodes were prepared by thermal evaporation.

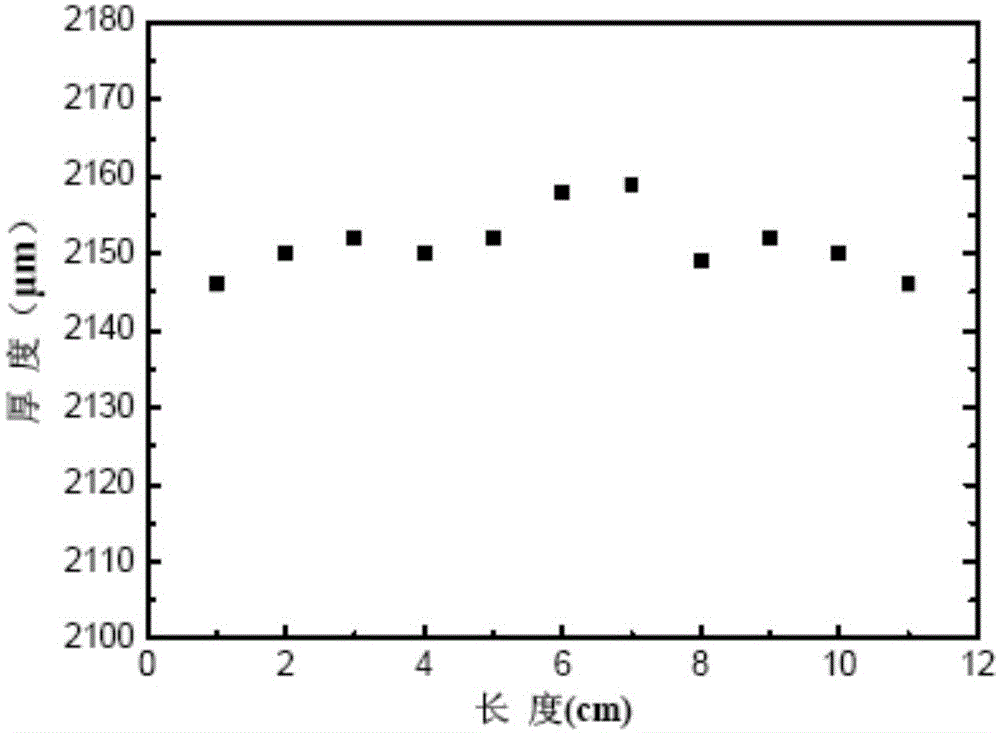

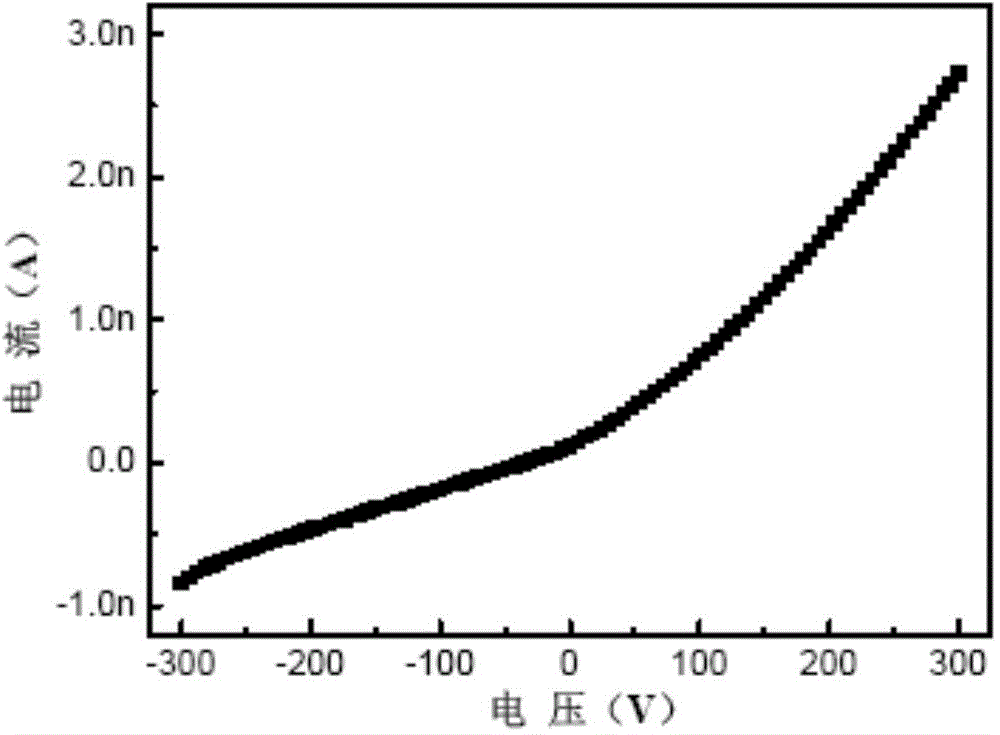

[0019] Step 3: Uniformly coat a layer of photoresist on the surface of the photolithography electrode of the single wafer to protect the strip array electrode from being washed and damaged by the cutting fluid during scribing and cutting. A dicing machine is used to slit along the outer contour of the strip array electrode patt...

Embodiment 2

[0025] Step 1: CdZnTe crystal ingot grown by the vertical Bridgman method is oriented along the direction to cut out a size of 20×20mm 2 , a rectangular single wafer with a thickness of 5 mm.

[0026] Step 2. After the wafer is mechanically polished and chemically polished, AuCl with a concentration of 10-50g / L is used on the {111}Cd surface of the wafer. 3 The Au electrode is prepared by the chemical method of aqueous solution, and the photoresist is evenly coated on the electrode to protect the Au electrode from being damaged in the subsequent processing; six 1×32 pixels are simultaneously photolithographically etched on the {111} Te surface of the wafer Array patterns, and use AuCl with a concentration of 10-50g / L 3 Preparation of Au electrodes by chemical method in aqueous solution.

[0027] Step 3: Uniformly coat a layer of photoresist on the surface of the photolithography electrode of the single wafer to protect the strip array electrode from being washed and damaged...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com