Low-density cement paste for well cementation operation, and cement composition for well cementation operation

A low-density, cement slurry technology, applied in the field of oil well drilling engineering, can solve problems such as high density and inability to meet leakage prevention requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

[0026] The low-density cement slurry (formula B) for well cementing of this embodiment is composed of 170.5 parts by weight of water, cement composition for well cementing, fluid loss reducer, early strength agent and drag reducer, and cement for well cementing The composition is composed of the following components in parts by weight: 100 parts of G-grade oil well cement, 40 parts of lightening materials, and 15 parts of microsilicon; wherein the lightening materials include power plant floating beads and glass microspheres, and the weight of power plant floating beads and glass microspheres The ratio is 7:1; the dosages of fluid loss reducer, early strength agent and drag reducer are respectively 2%, 2.5% and 0.2% of the cement composition for well cementing operations. The particle size of power plant floating beads is 31.724~287.748μm, and the density is 0.7~0.9g / cm 3 , the particle size of the glass beads is 15-125 μm. The density of the low-density cement slurry of this...

experiment example 1

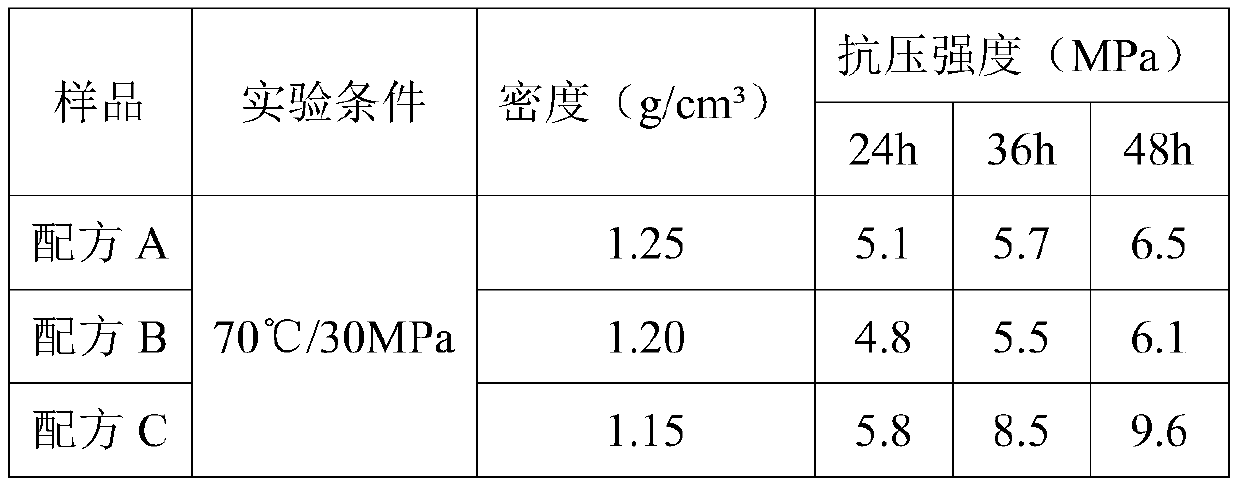

[0033] The low-density cement slurry formulations A, B, and C were used for cementing operations to perform compressive strength tests, and the test results are shown in Table 1 below:

[0034] Table 1 Compressive strength test

[0035]

[0036] Through the experiment of the compressive strength of cement stone in Table 1, it can be seen that the density of the low-density cement slurry for cementing operation of the present invention is as low as 1.15-1.25g / cm 3 , At the same time, the compressive strength of 24h, 36h, and 48h is strong, so that the strength of cement stone is increased while the density is reduced, which can not only solve the problem of leakage, but also ensure the quality of cementing.

experiment example 2

[0038] Floating beads are thin-walled bead-shaped particles screened from fly ash floats, which have the characteristics of light weight, heat insulation, acid and alkali resistance, non-toxic, non-combustible and odorless. When using floating beads to prepare cement slurry, the floating beads only need a small amount of water to wet the surface to make the cement slurry have a certain fluidity, thereby reducing the amount of slurry water added. At present, the floating beads commonly used in oil fields are divided into artificial floating beads and power plant floating beads. The pressure bearing capacity of power plant floating beads is higher than that of artificial floating beads.

[0039] In order to compare the pressure bearing capacity of artificial floating beads and power plant floating beads, artificial floating beads and power plant floating beads were used as lightening materials to make a density of 1.15g / cm 3 For cement slurry (formula C), put the slurry in a hig...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com