Method for extracting coalbed gases from coal mines by upper and lower combination

A technology for coal bed methane and coal seam, which is applied in the field of coal bed methane combined upper and lower coal mine drainage, can solve problems such as poor gas drainage effect, and achieve the effects of reducing the number of moving houses, shortening the construction period, and shortening the drainage time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

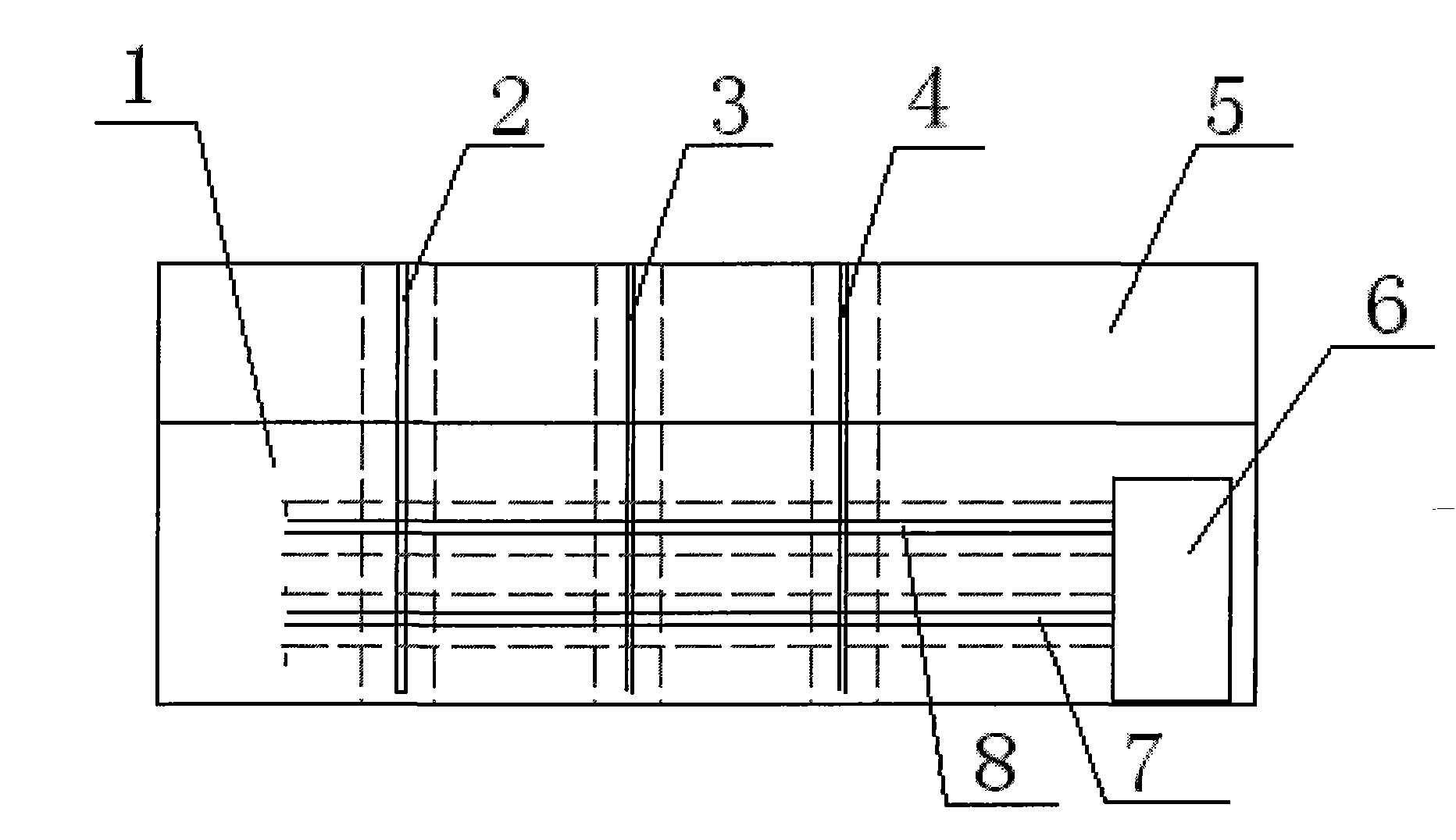

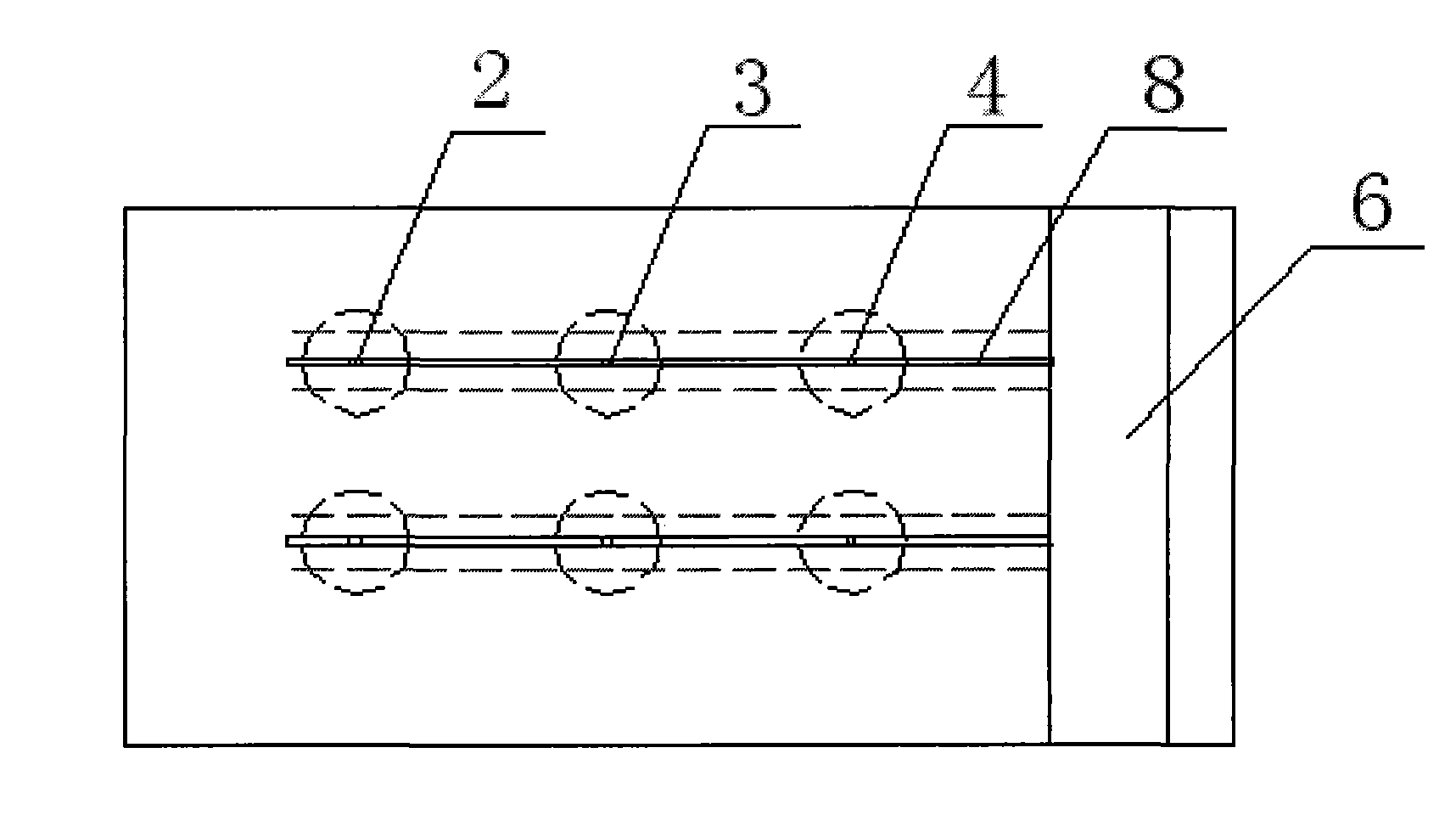

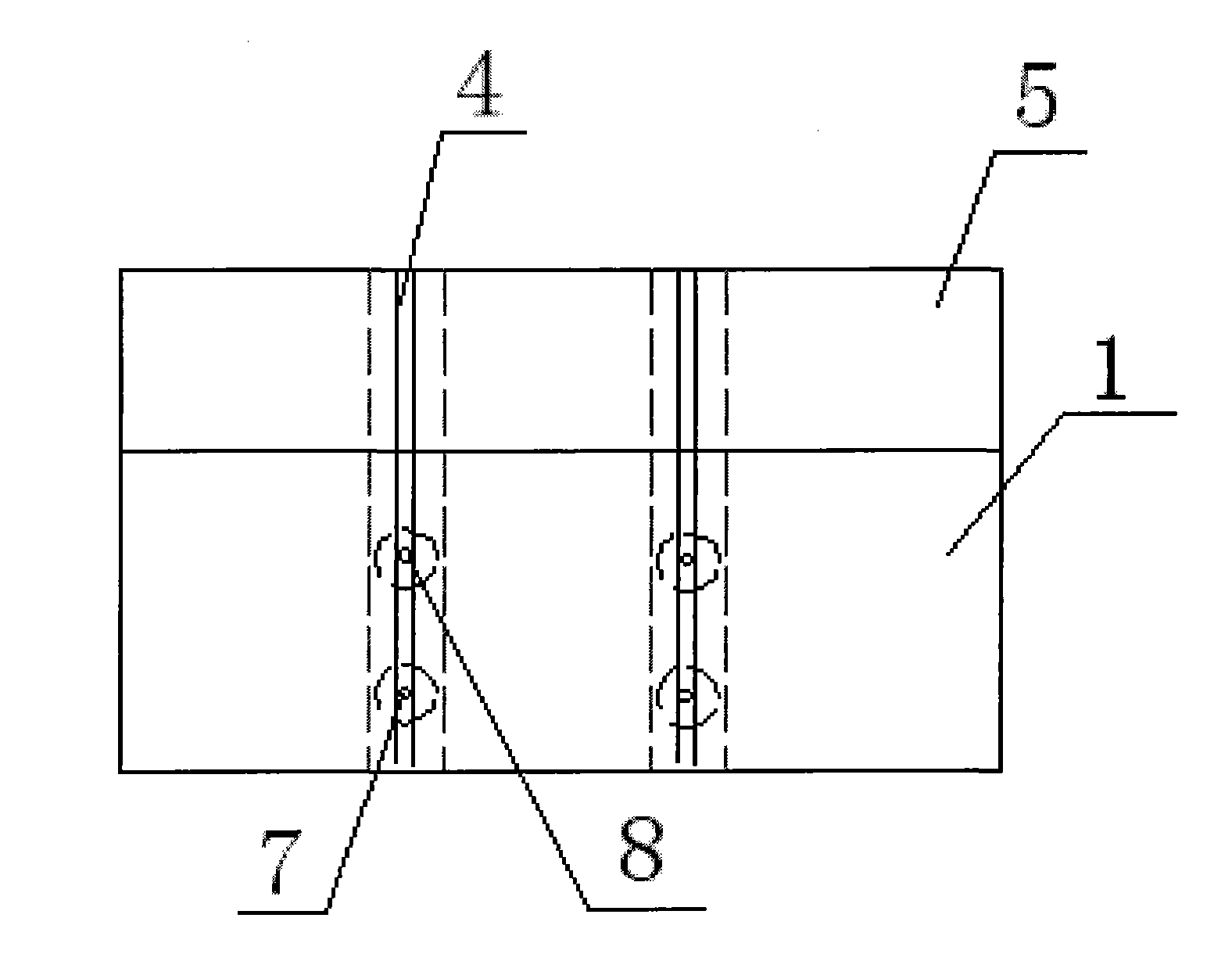

[0016] Such as figure 1 , 2 Shown in , 3, utilize drilling rig to construct directional long boreholes 8,7 in the downhole, two boreholes are arranged vertically, then construct drainage wells 2,3,4 on the ground, make described drainage wells 2, 4 by precise positioning 3 and 4 pass through downhole directional long boreholes 8 and 7 respectively so that the borehole and the extraction well can be connected precisely. The directional long borehole 3 is effectively sealed, and then the construction area around the drainage wells 2, 3, and 4 (the dotted line in the figure) and the directional long boreholes 8, 7 are sealed on the ground using ground drilling and fracturing equipment and technology. All the coal seams in the construction area (dotted line in the figure) are fractured, so that the relatively small area produced by the fracturing of surface drainage drilling 2, 3, and 4 can be expanded to a larger area around the long borehole 3 area, thereby significantly incre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com