Air cushion type space-reserved drift and fill type mining device and method

A space-reserved, air-cushioned technology, used in safety devices, ground mining, mining equipment, etc., can solve the problems of affecting the stability of the backfill body, large damage to the backfill body, and poor comprehensive benefits, so as to improve blasting efficiency and mining efficiency. , less damage, and the effect of increasing productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to make the technical problems, technical solutions and advantages to be solved by the present invention clearer, the following will describe in detail with reference to the drawings and specific embodiments.

[0031] Aiming at the shortcomings and deficiencies of the existing route mining technology, the present invention provides an air cushion type reserved space route mining device and method.

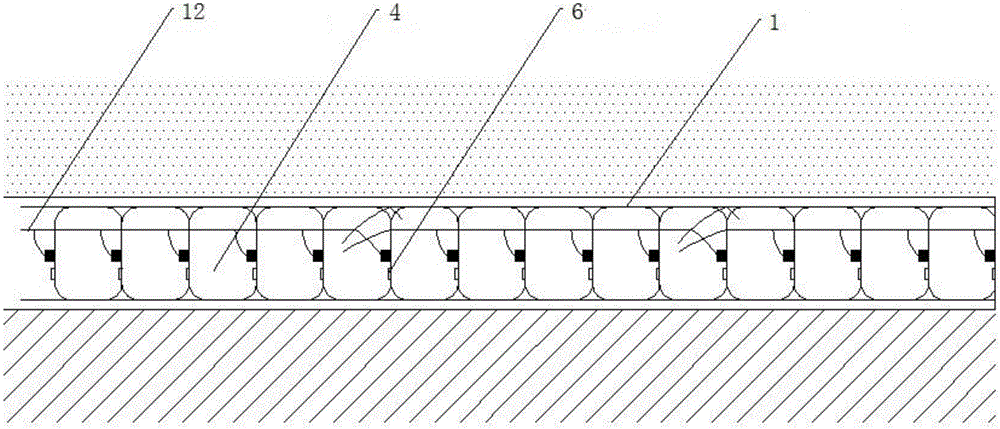

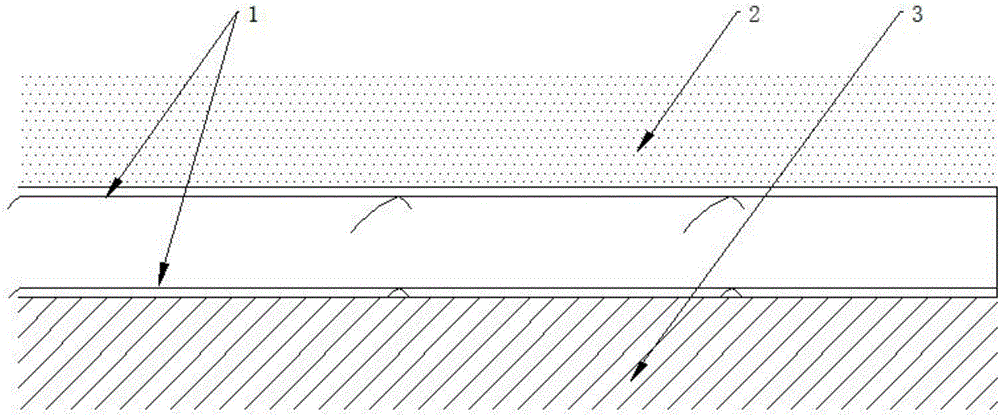

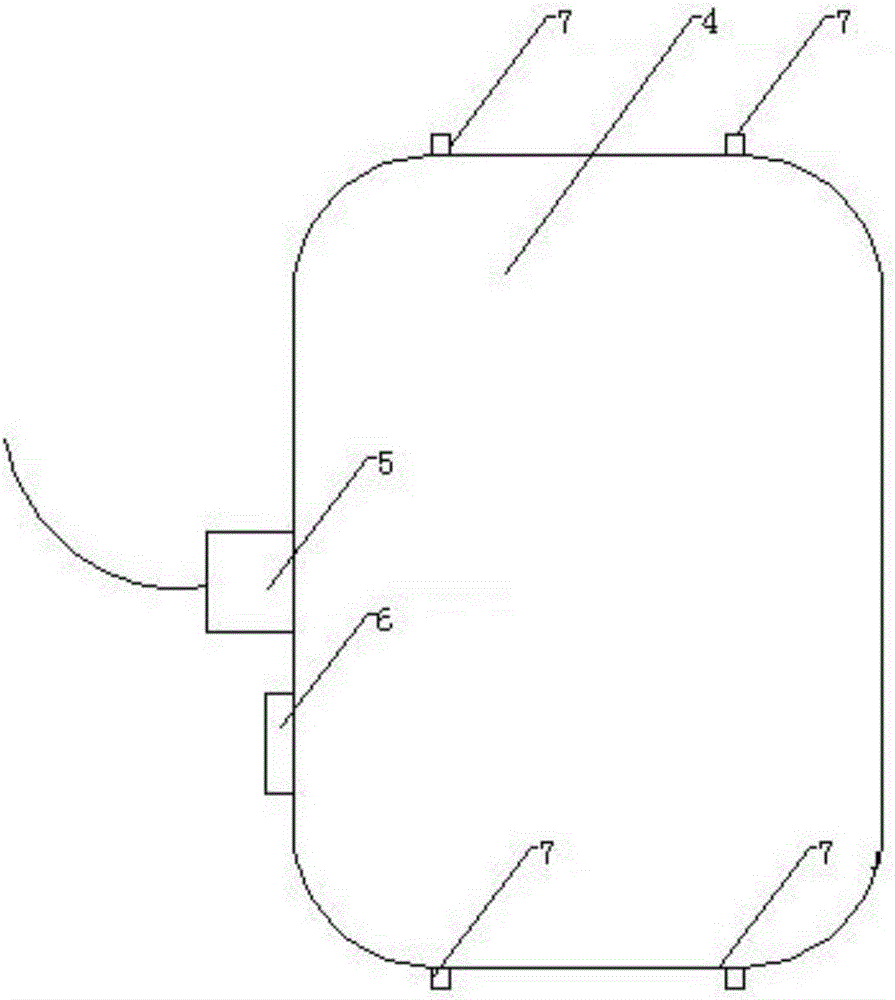

[0032] likefigure 1 and figure 2 As shown, the device includes an air cushion, a fixing mechanism and auxiliary equipment, such as image 3 and Figure 4 As shown, the air cushion includes an air bag 4, an inflation and deflation valve 5, a safety valve 6 and a buckle 7; An air bag 4 is provided with an inflation and deflation valve 5, a safety valve 6 and four buckles 7, the air cushion is connected to the fixed rope 1 through the buckles 7, and the clamping ball is arranged on the fixed rope 1, and the fixed rope 1 passes through the expansion screw Fixed on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com