Split type tri-cone drill

A three-cone, split-type technology, applied in the direction of drill bits, drilling equipment, earthwork drilling and mining, etc., can solve the problems of three-cone bit rock-breaking efficiency and low tooth scraping efficiency, and achieve good lubrication environment and tooth scraping efficiency Improve and prevent the effect of mud bag

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with accompanying drawing.

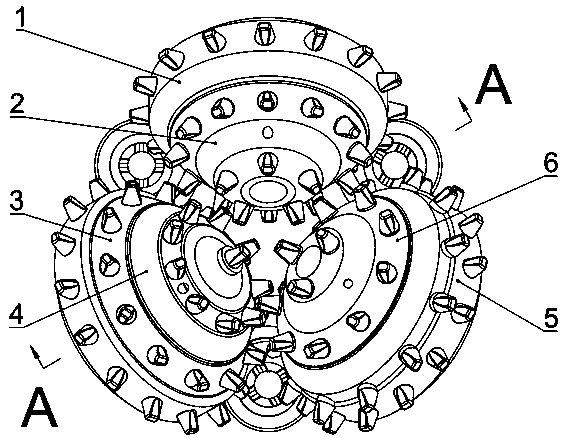

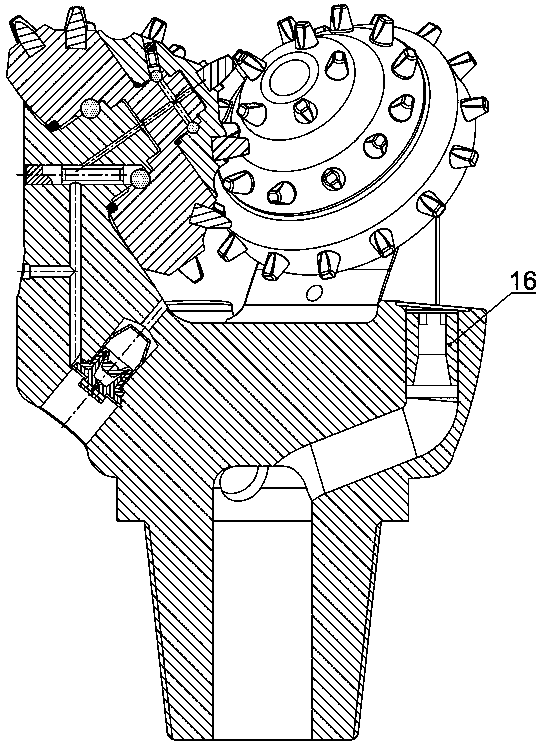

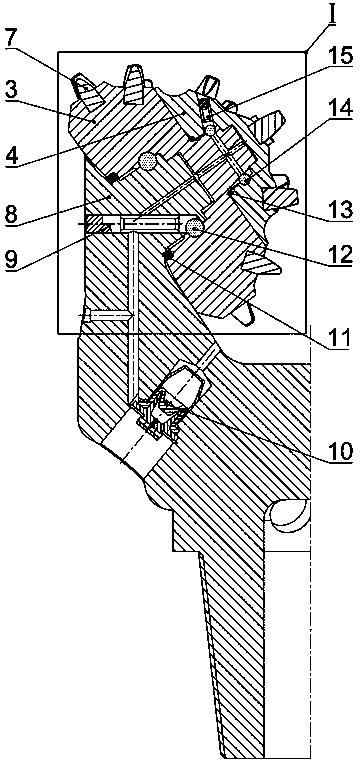

[0023] Referring to the accompanying drawings, the split-type three-cone bit is characterized in that: the split-type three-cone bit is mainly composed of the first cone set, the second cone set, the third cone set, teeth 7, tooth palms 8, oil storage compensation The pressure balance system 10 and the nozzle 16 are characterized in that: the oil storage compensation pressure balance system 10 is installed at the lower end of the back of the palm 8; the nozzle 16 is arranged on the drill body; the teeth 7 are arranged on the second The cloth tooth surfaces of the first gear group, the second gear group, and the third gear group; the tooth palm 8 is provided with the tooth palm journal oil guide hole 17, the plug pin hole a18, and the tooth palm oil guide hole 19. Oil hole 20; the first gear set includes the first gear lower body 3 and the first gear upper body 4, the first ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com