Self-cleaning device suitable for conveying belt for small metal part hardening and tempering

A conveying device and conveying belt technology, which is applied to cleaning devices, transportation and packaging, conveyor objects, etc., can solve problems such as poor scraping effect, and achieve the effect of increasing the contact area, expanding the setting range, and improving the cleaning effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Below in conjunction with specific embodiment, content of the present invention is described in further detail:

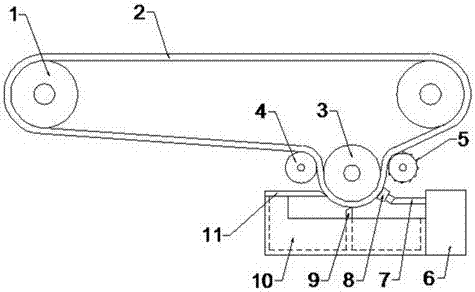

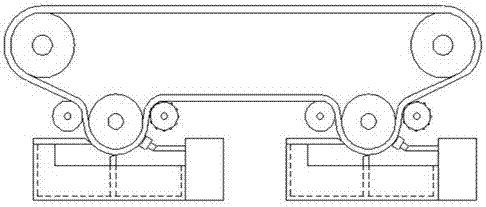

[0019] Such as Figure 1-2 Shown, a kind of self-cleaning device that is applicable to the conveyer belt of small-sized metal parts tempering, comprises conveying device and is arranged on the 1-2 cleaning device of conveying device lower end; Wherein conveying device comprises a pair of drive shafts 1, is arranged on The reversing shaft 3 below the transmission shaft 1, the conveyor belt 2 arranged around the transmission shaft 1 and the reversing shaft 3; the two sides of the reversing shaft 3 have a pair of symmetrically arranged limit shafts 4 outside the conveyor belt 2; the cleaning device includes The water spray assembly, the wiper 9 and the scraper assembly arranged in turn along the conveying direction of the lower layer of the conveyor belt 2; Below the shaft 3, the upper end is wedge-shaped and contacts the end surface of the conveyor belt 2; th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com