Patents

Literature

36results about How to "Easy scraping" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

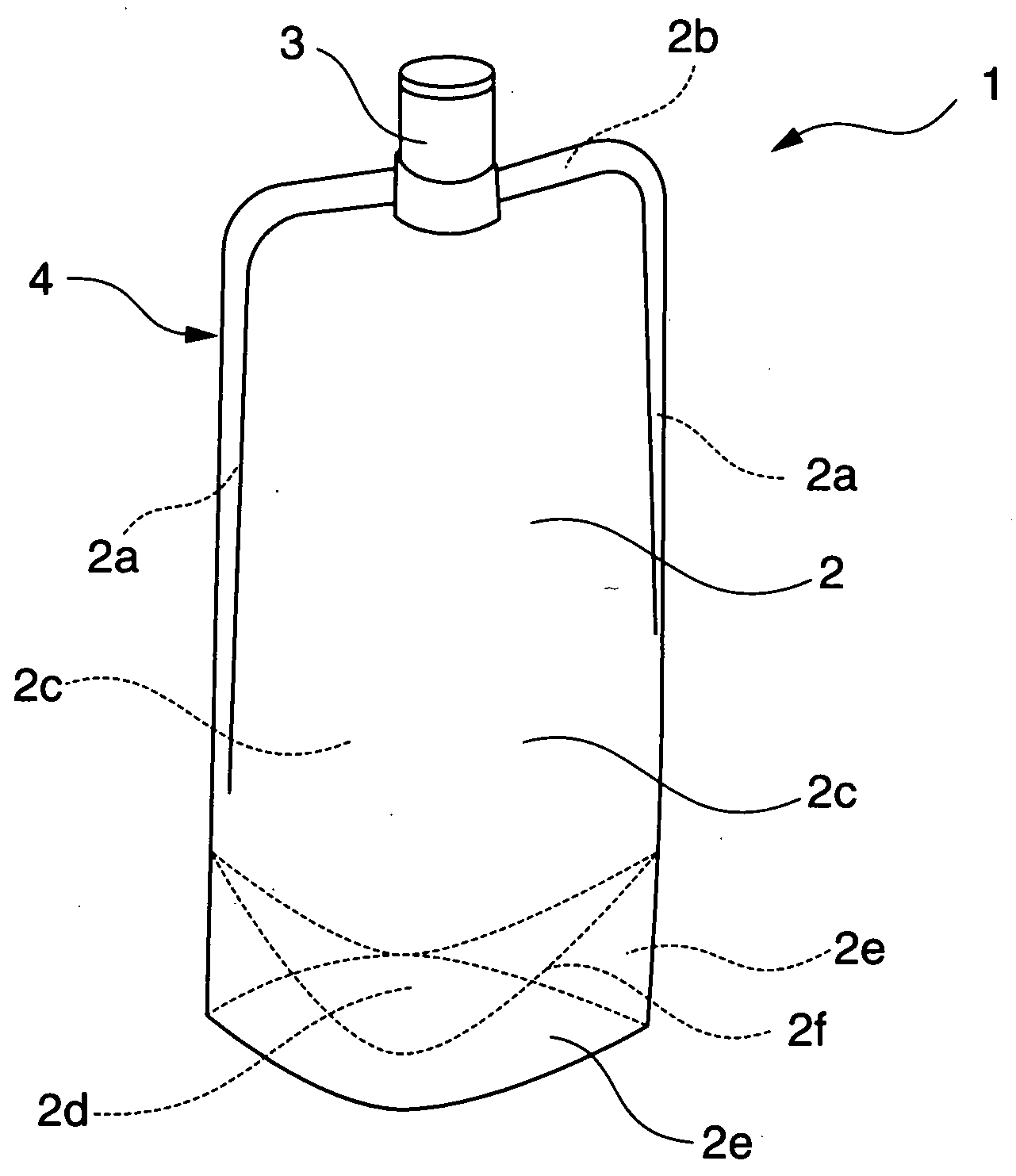

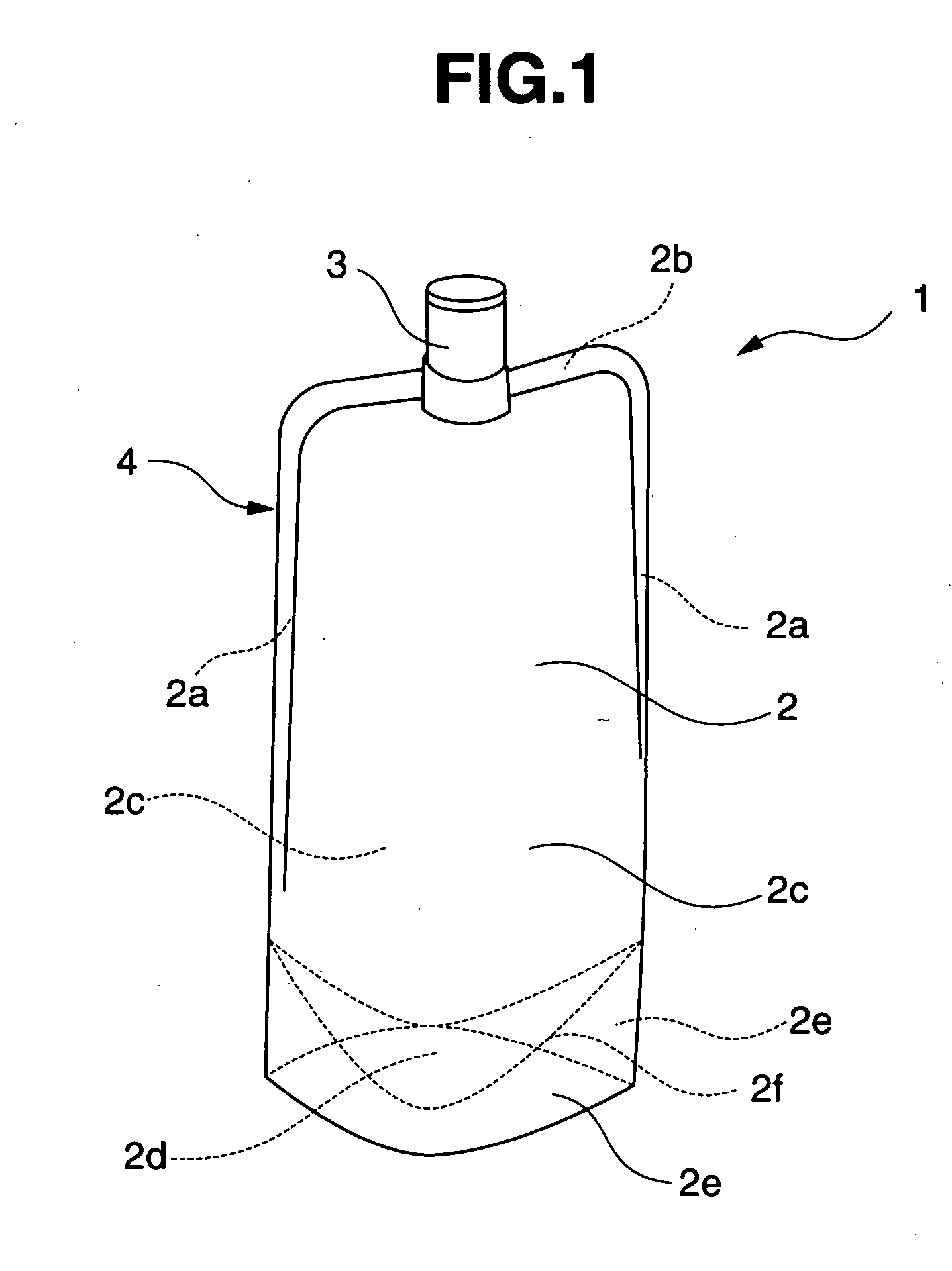

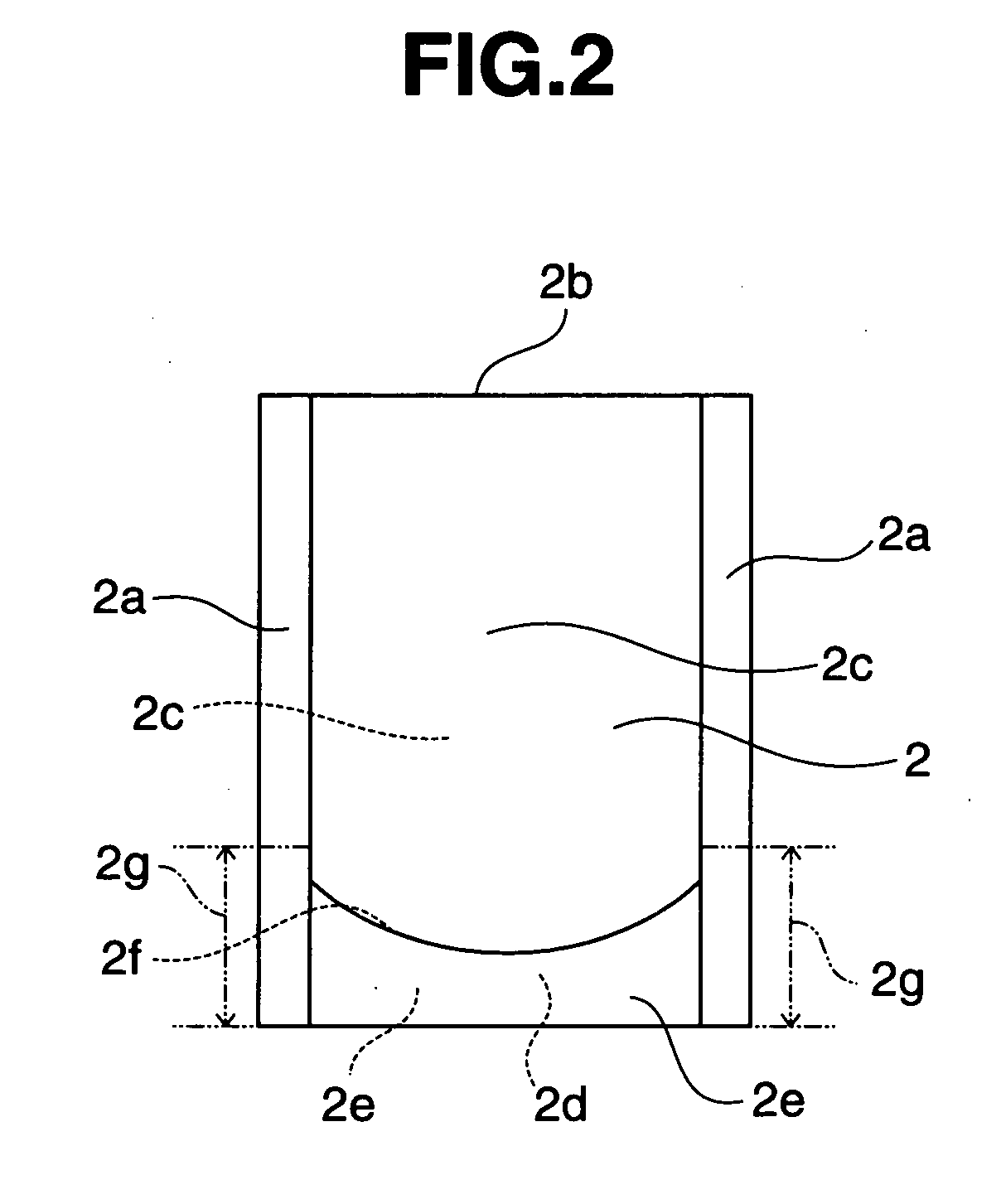

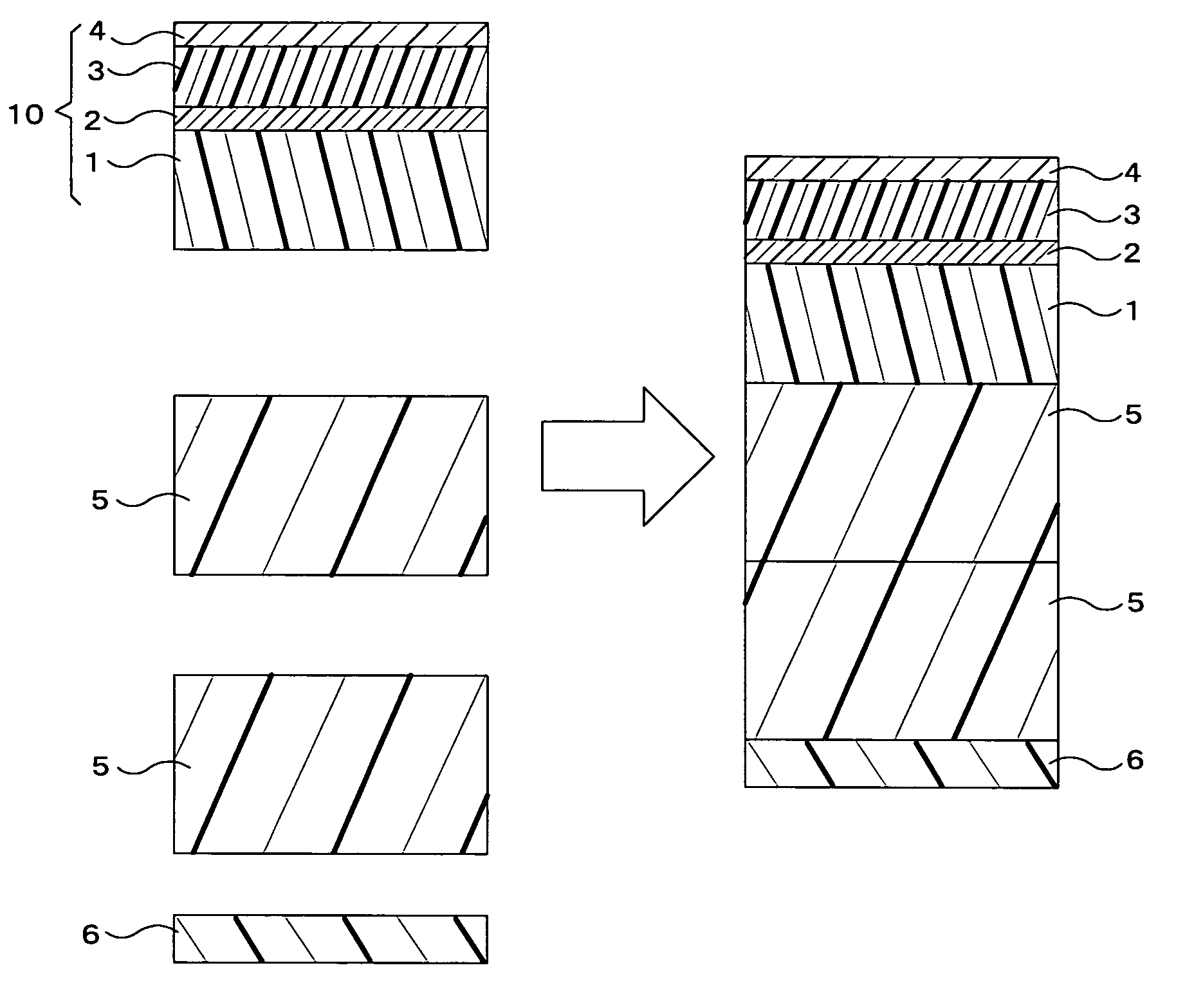

Self-standing bag and method of manufacturing the bag

Owner:FUJIMORI KOGYO CO LTD

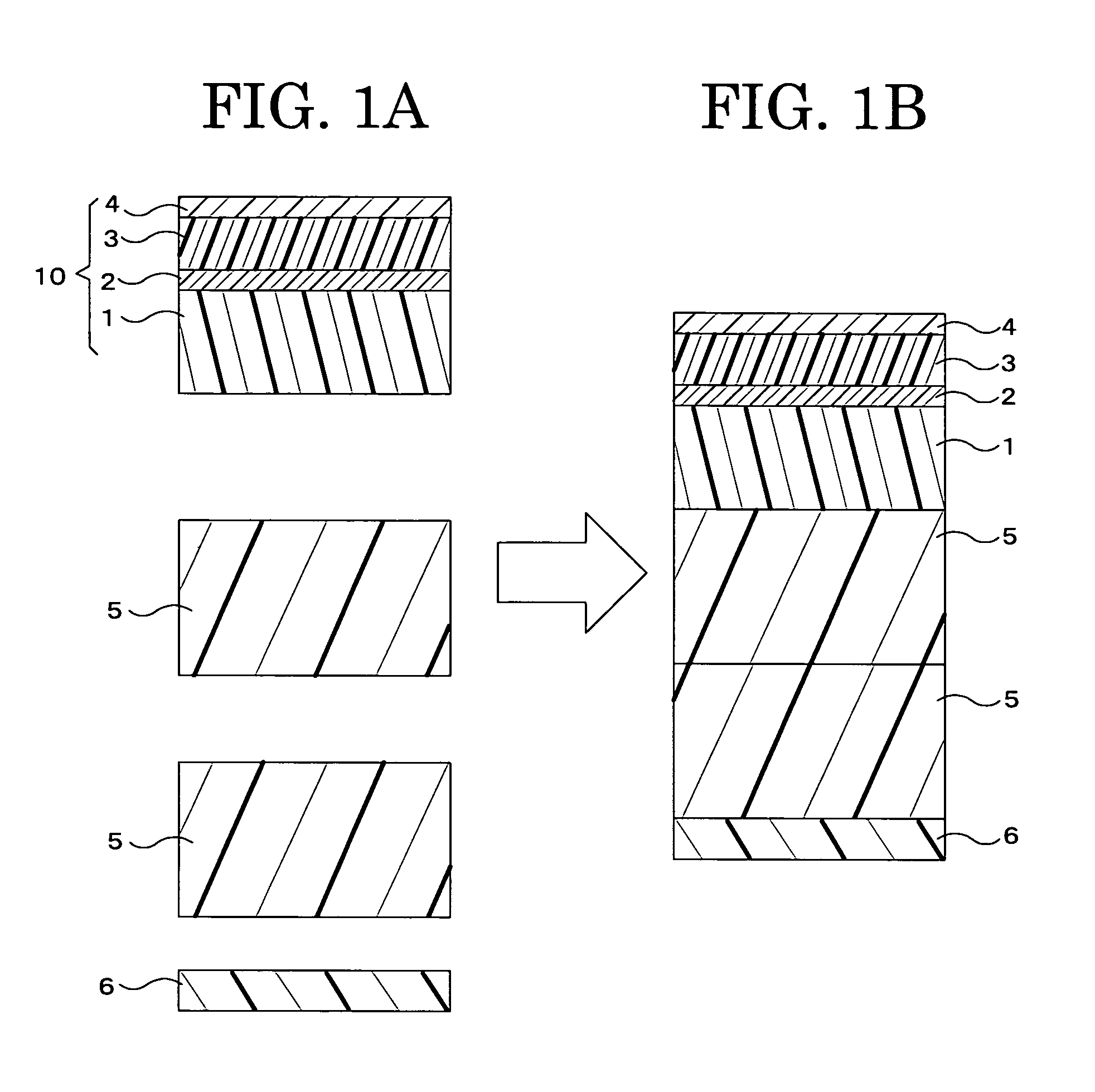

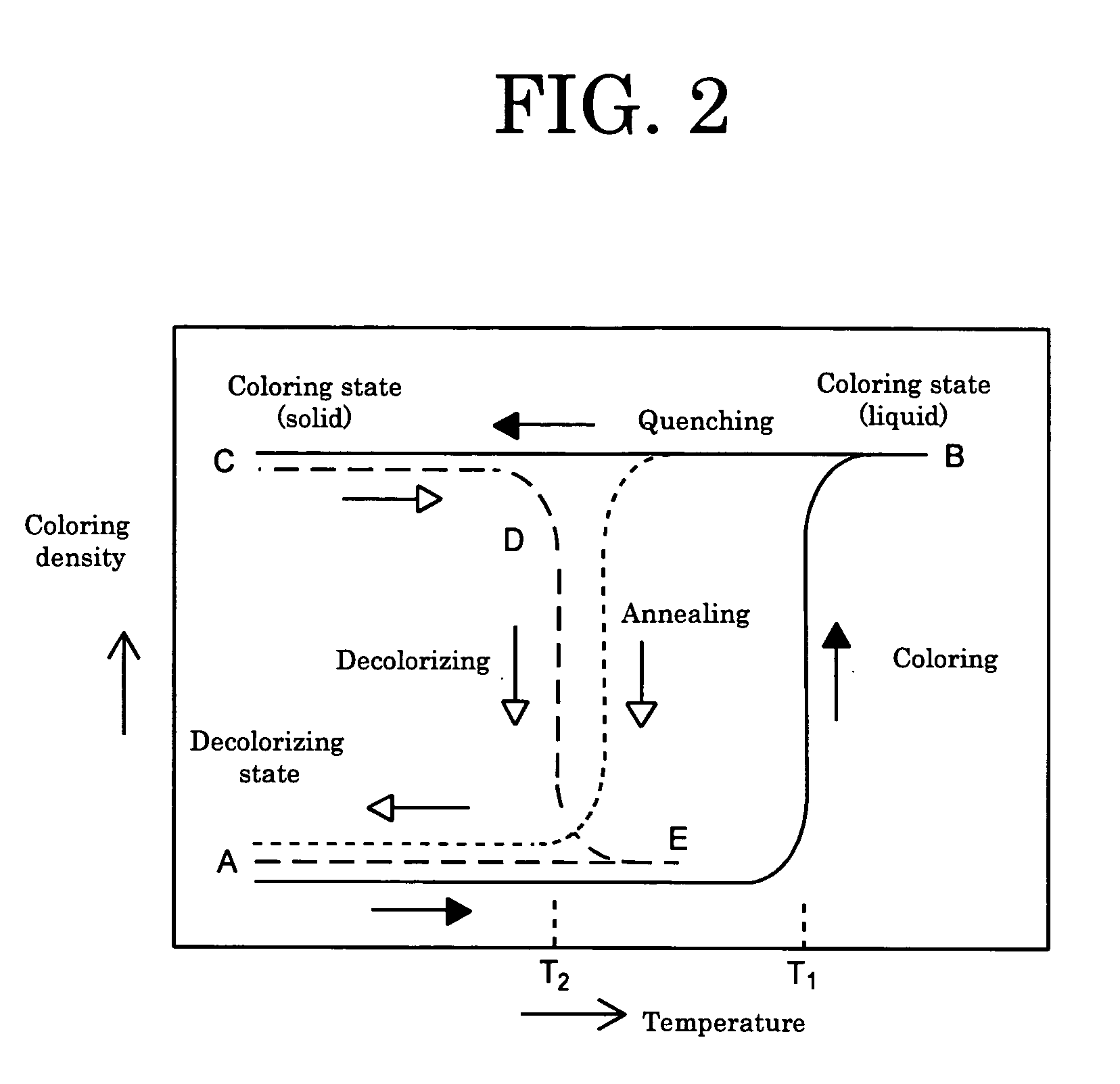

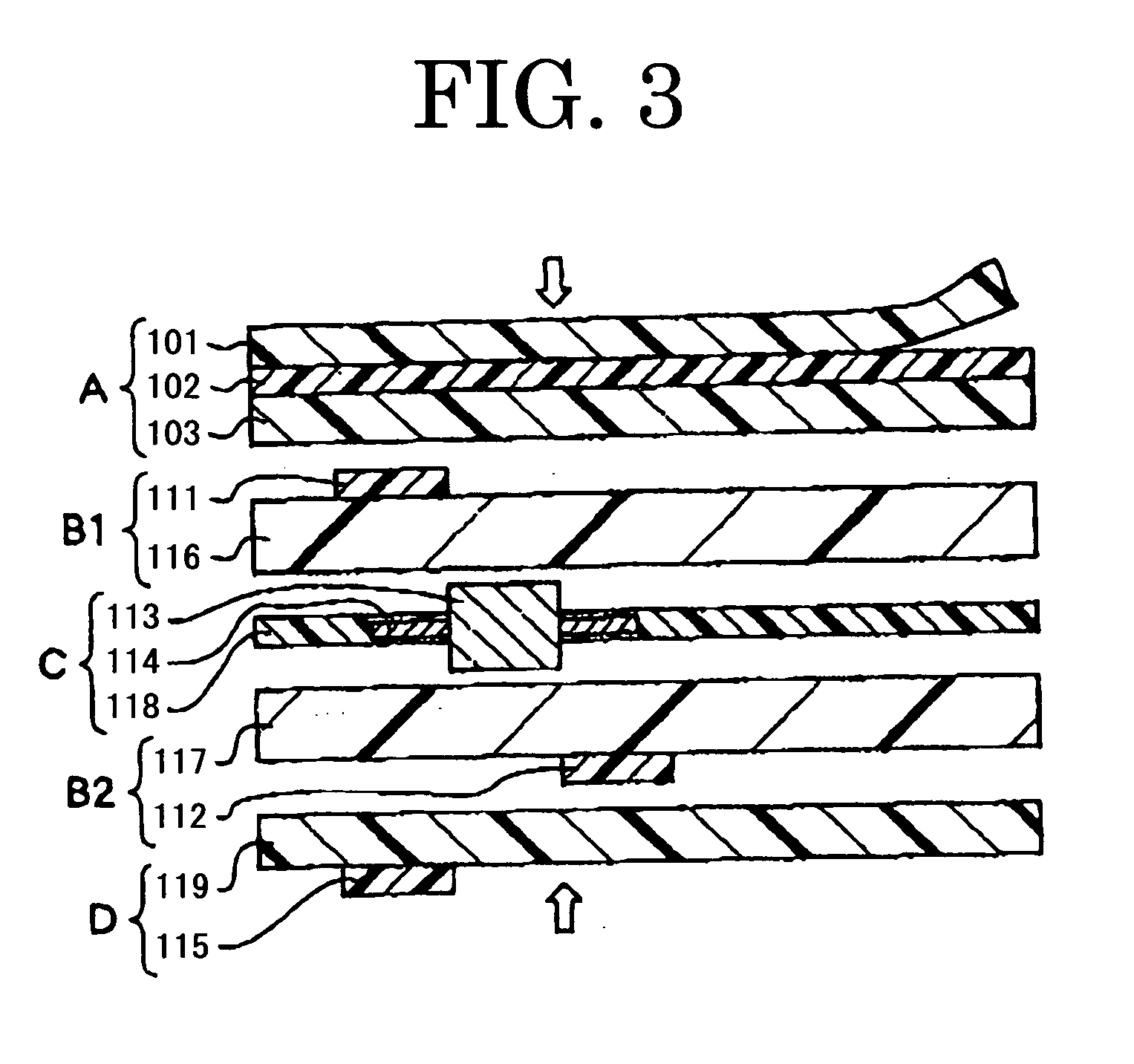

Information recording-displaying card, image processing method using same, and image processor

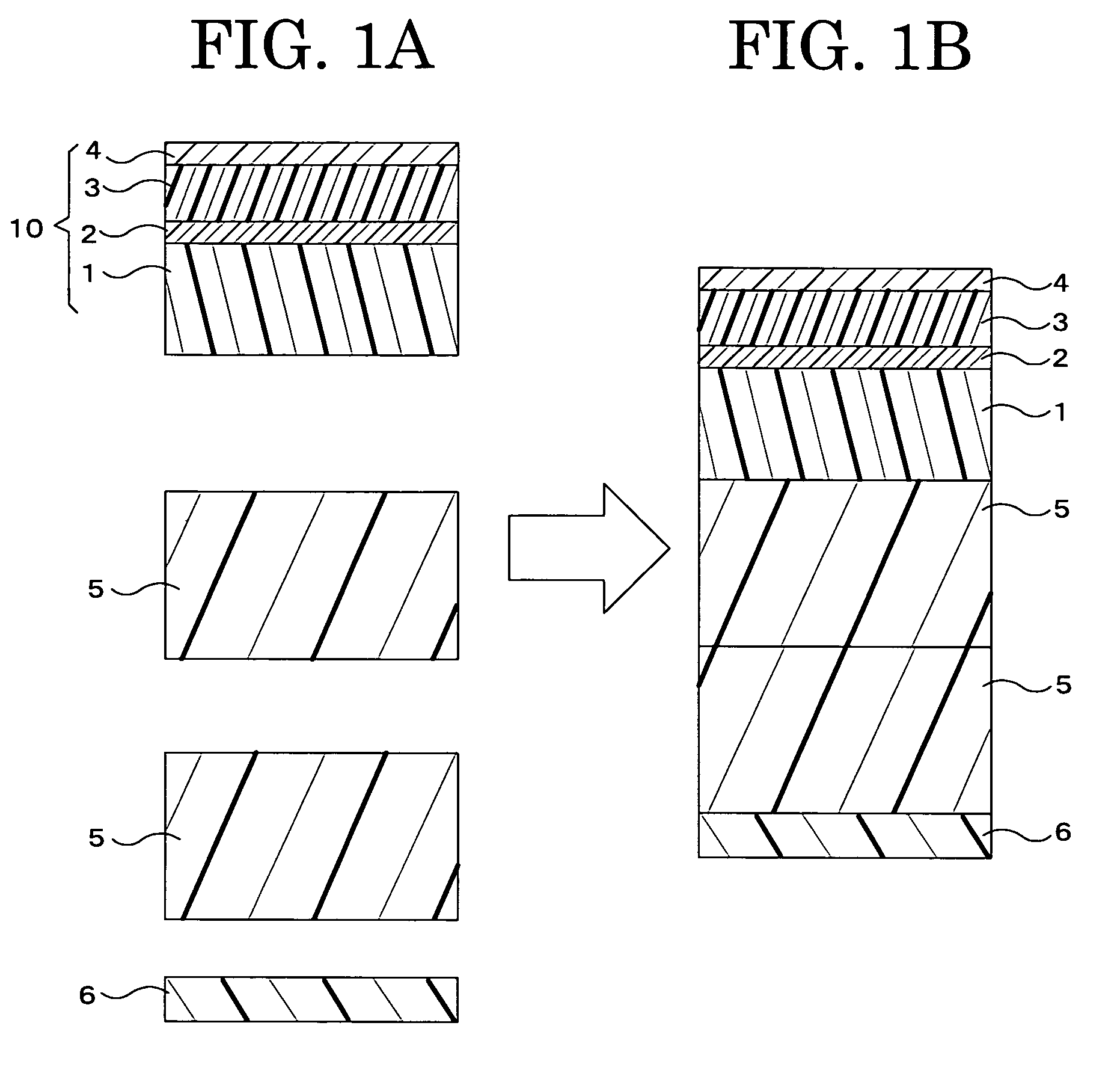

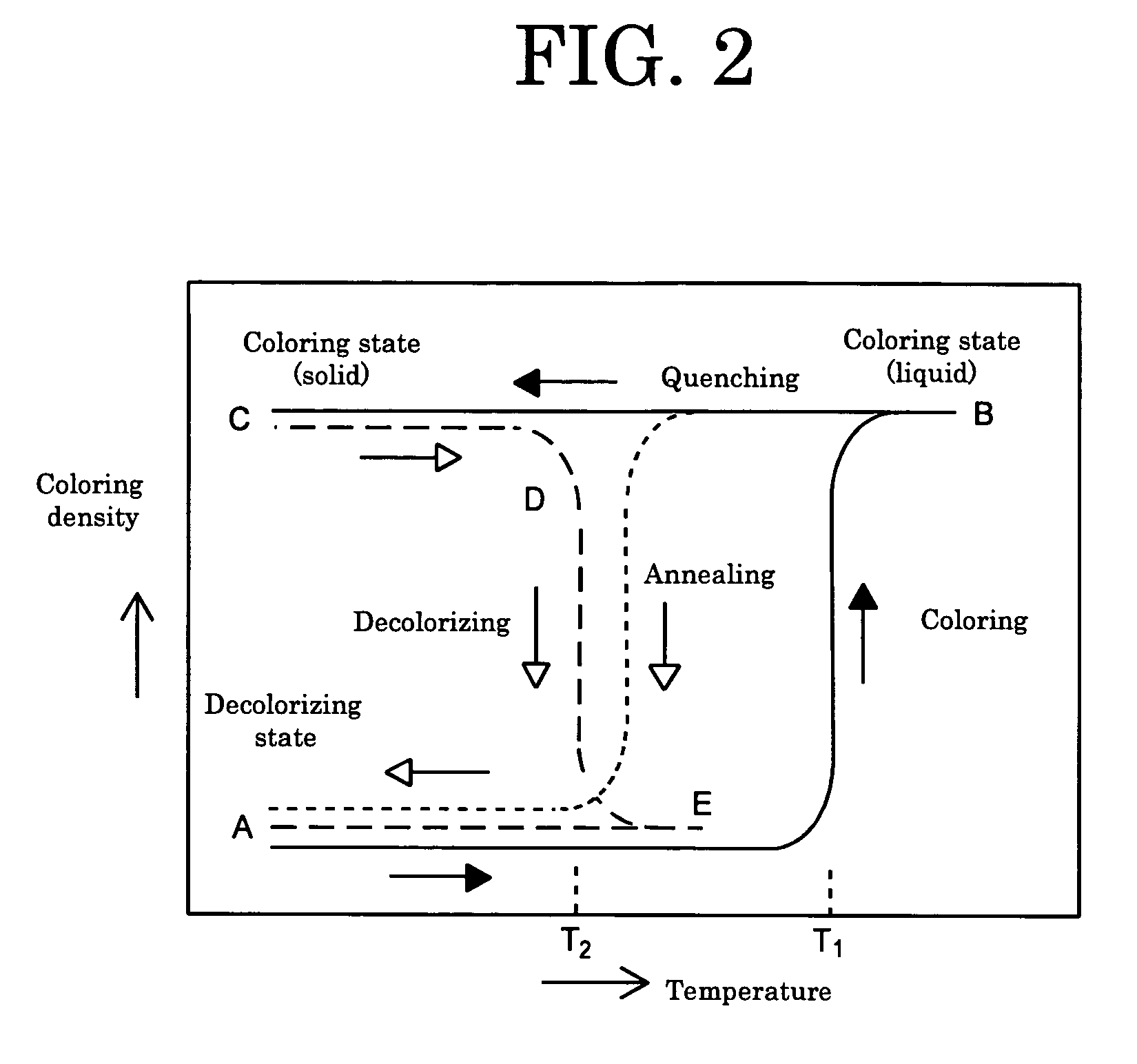

InactiveUS6969695B2Easy embossingImprove machinabilityDecorative surface effectsSynthetic resin layered productsImaging processingChemical compound

An information recording-displaying card, includes: core sheet; and over sheet bonded to core sheet, including: a support including an amorphous polyester resin, and a reversible thermosensitive recording layer on the support, including: an electron-donating coloring compound, and an electron-accepting compound. The reversible thermosensitive recording layer is capable of forming coloring state and decolorizing state, with difference in at least one of the following: heating temperature, and cooling rate after heating. The over sheet is embossable in upper portion thereof, functions as image displaying section, and meets the following conditions (A), (B) and (C): (A) (over sheet's upper limit temperature for erasing−30° C.)>(over sheet's temperature of storage elasticity E′ (1.0 E+08) Pa), (B) 10 μm or less of surface waviness WCM, and (C) 1.0 E+02 Pa≦(storage elasticity E′ of reversible thermosensitive over sheet at 180° C.)≦5.0 E+07 Pa.

Owner:RICOH KK

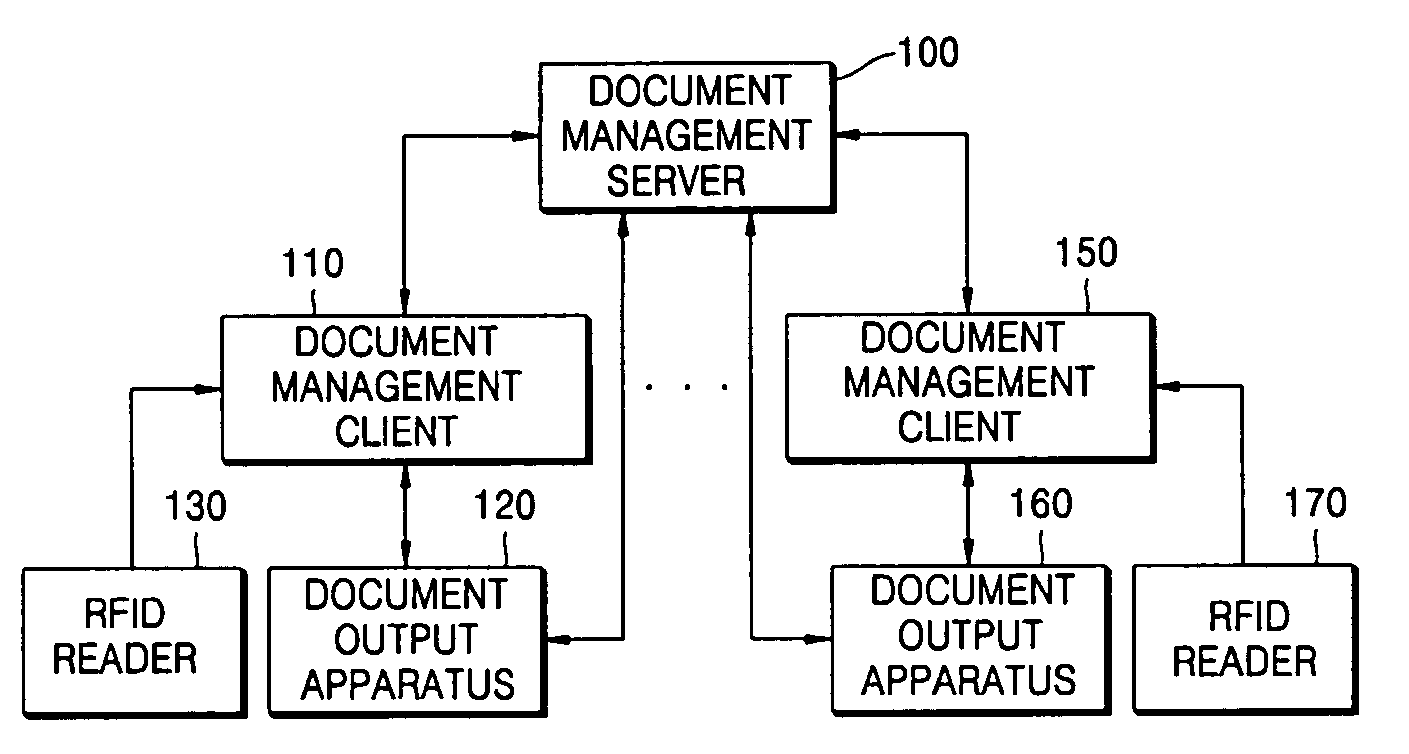

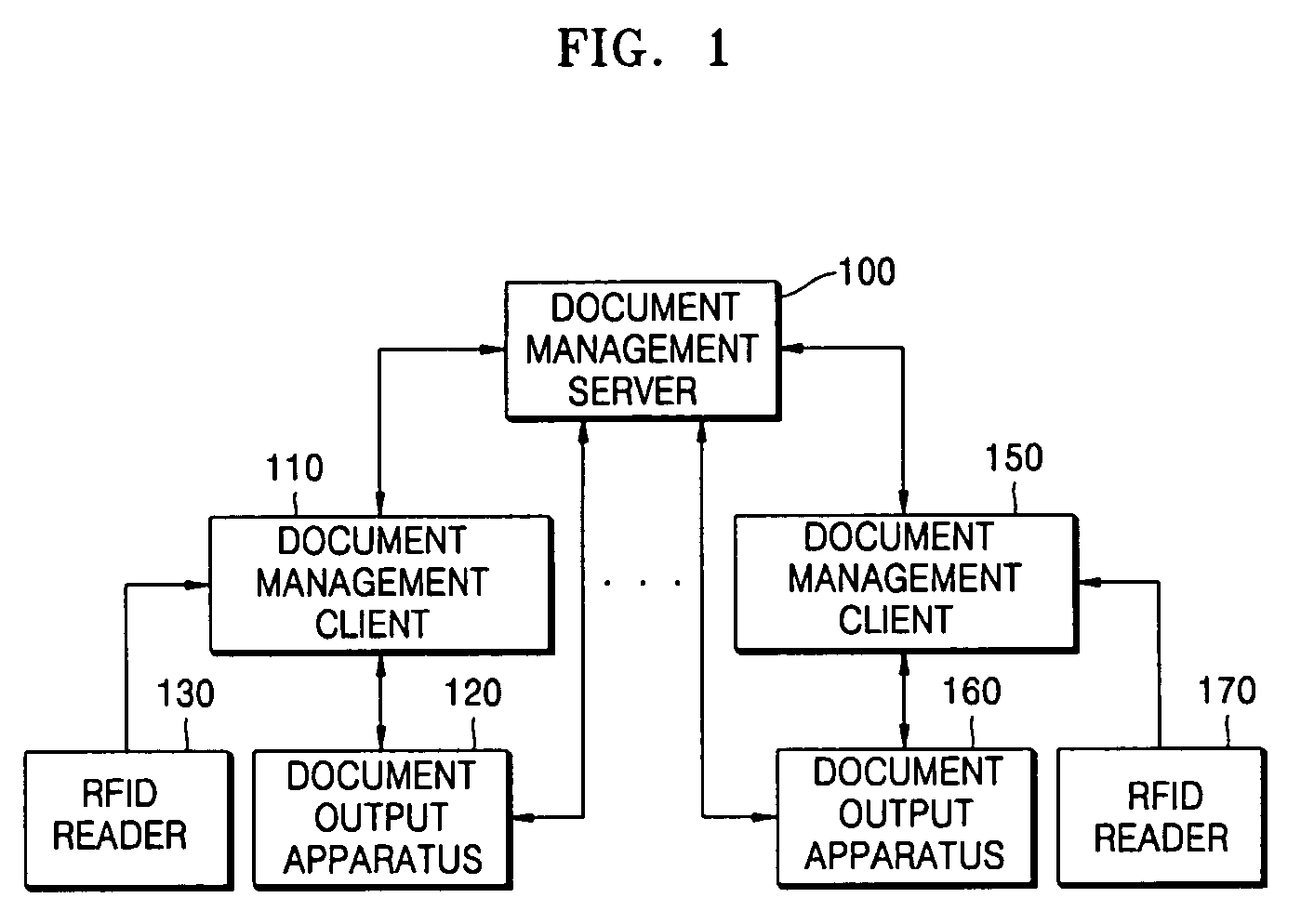

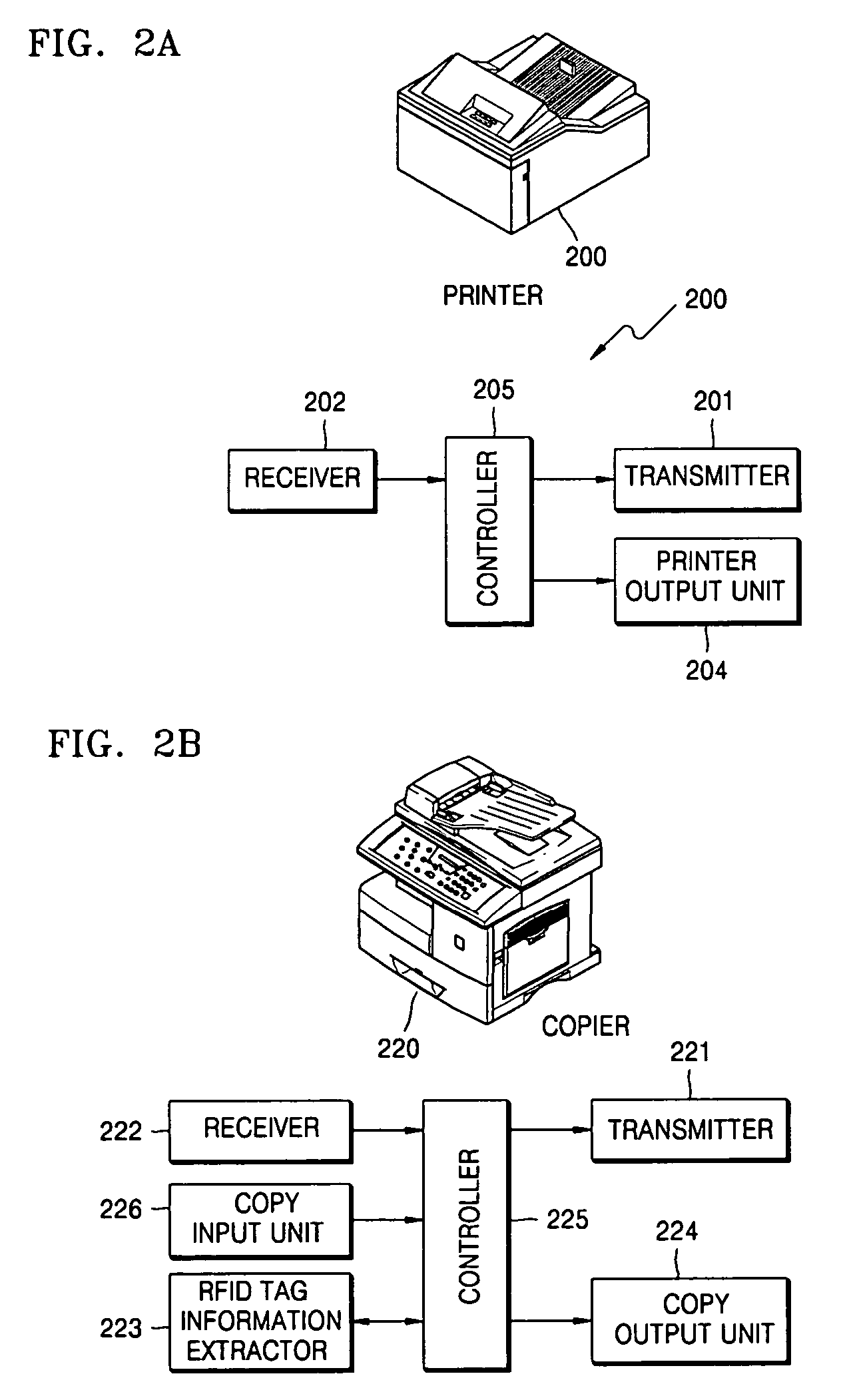

Method and apparatus for managing online and offline documents with RFID technology

InactiveUS7327259B2Easy scrapingElectric signal transmission systemsMultiple keys/algorithms usageOnline and offlineDocument preparation

Provided are a method and an apparatus for managing online and offline documents using RFID technology. The method includes: pre-registering online and offline documents using radio frequency identification tag information stored in at least one of the online and offline documents to be output; determining whether the pre-registered online and offline documents are authorized to be output; and if it is determined that the pre-registered online and offline documents are authorized to be output, generating documents of the online and offline documents to be output and storing new radio frequency identification tag information in radio frequency identification tags attached to the documents to be output.

Owner:ELECTRONICS & TELECOMM RES INST

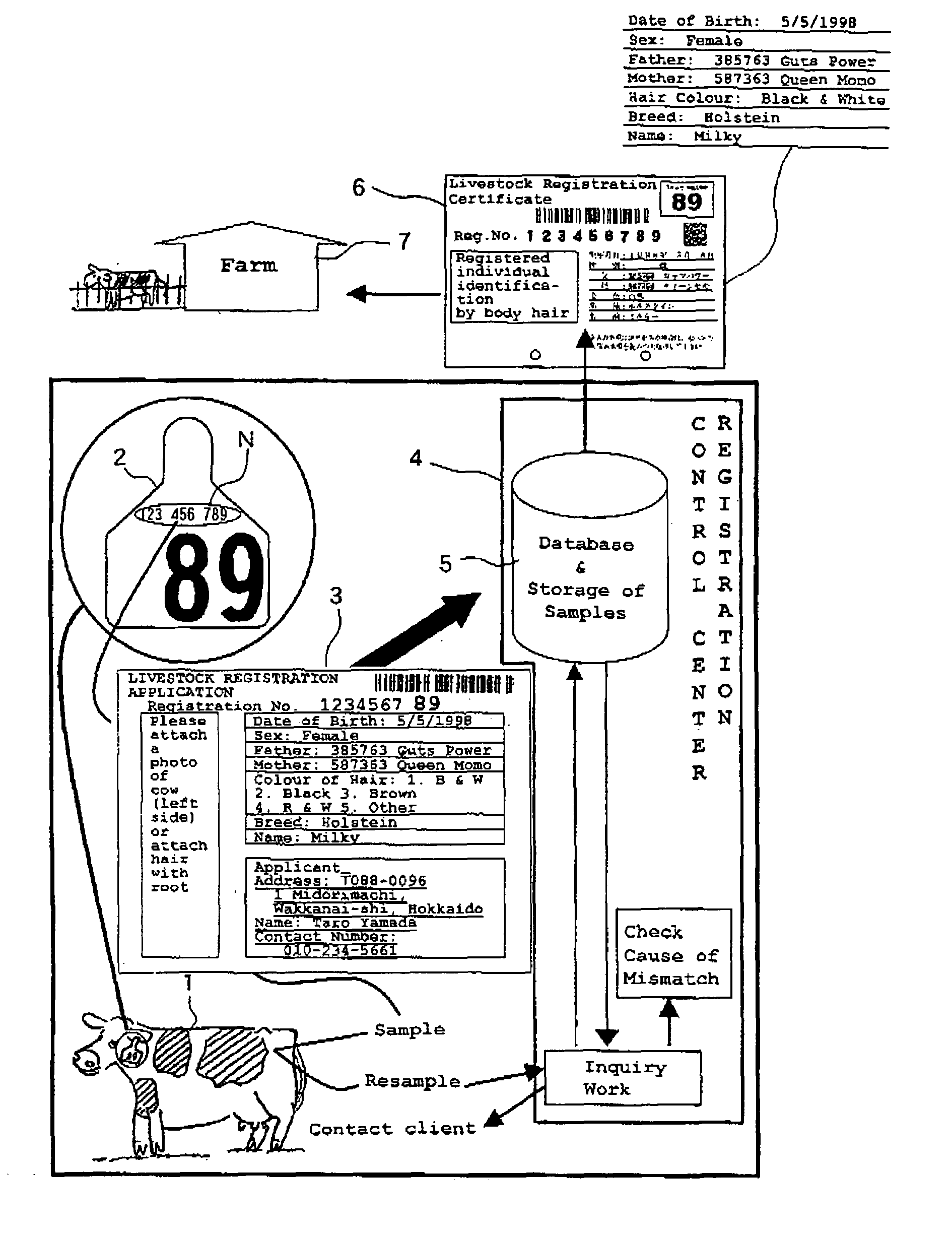

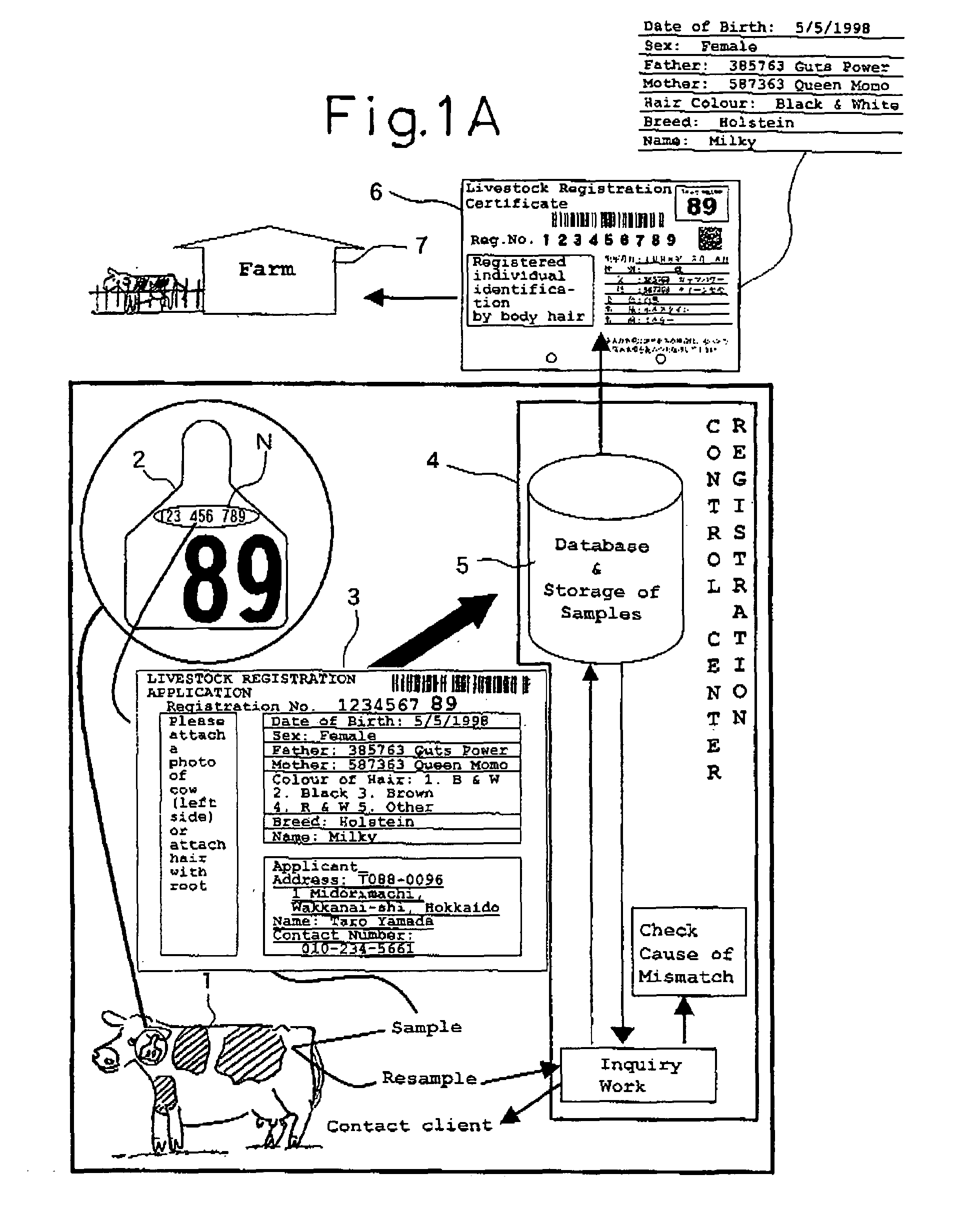

Animal registration management system capable of animal identification

InactiveUS6892671B1Low costFast and accurate analysisStampsAnimal housingAnimal scienceManagement system

An animal registration management system which enables the individual identification of an animal correctly, quickly, and at a low cost using an animal identifier. This system is an animal registration management system which enables individual identification of an animal by an identifier printed or recorded with an animal registration number belonging to a predetermined management organization, wherein when an animal breeder registers an animal at a management organization, it first obtains an identifier, then reports an animal registration number included in the identifier to the management organization together with individual information unique to the animal which the breeder desires to register, then the management organization registers the reported animal registration number and the individual information in its database and issues an animal registration certificate linking the animal registration number and the individual information. The report can be made by an animal registration application form attached to the identifier.

Owner:SURGE MIYAWAKI

Information recording-displaying card, image processing method using same, and image processor

InactiveUS20050170961A1Excellent in embossabilityEasy scrapingDecorative surface effectsSynthetic resin layered productsRecording layerHeating temperature

An information recording-displaying card, includes: core sheet; and over sheet bonded to core sheet, including: a support including an amorphous polyester resin, and a reversible thermosensitive recording layer on the support, including: an electron-donating coloring compound, and an electron-accepting compound. The reversible thermosensitive recording layer is capable of forming coloring state and decolorizing state, with difference in at least one of the following: heating temperature, and cooling rate after heating. The over sheet is embossable in upper portion thereof, functions as image displaying section, and meets the following conditions (A), (B) and (C): (A) (over sheet's upper limit temperature for erasing−30° C.)>(over sheet's temperature of storage elasticity E′ (1.0 E+08) Pa), (B) 10 μm or less of surface waviness WCM, and (C) 1.0 E+02 Pa≦(storage elasticity E′ of reversible thermosensitive over sheet at 180° C.)≦5.0 E+07 Pa.

Owner:RICOH KK

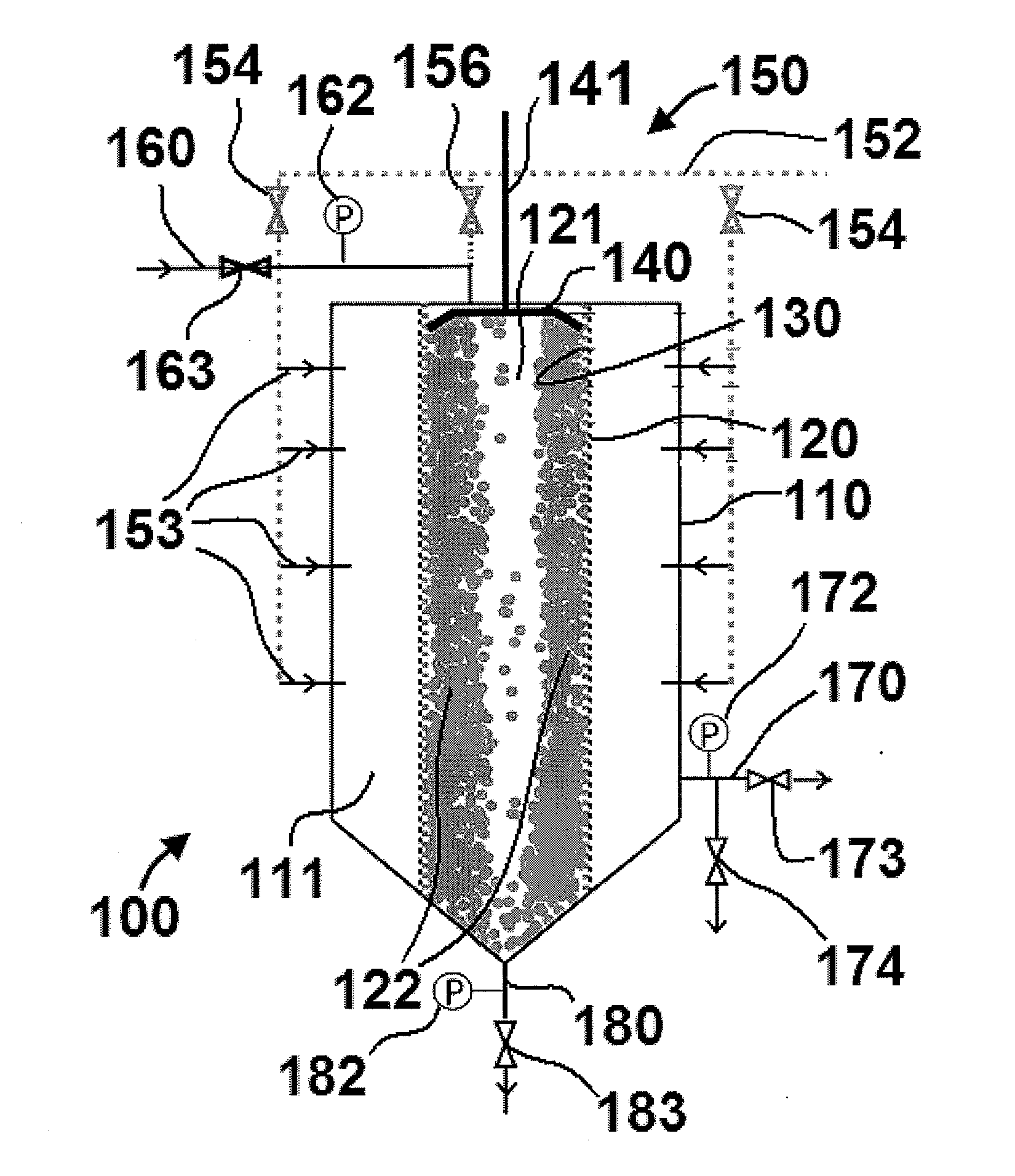

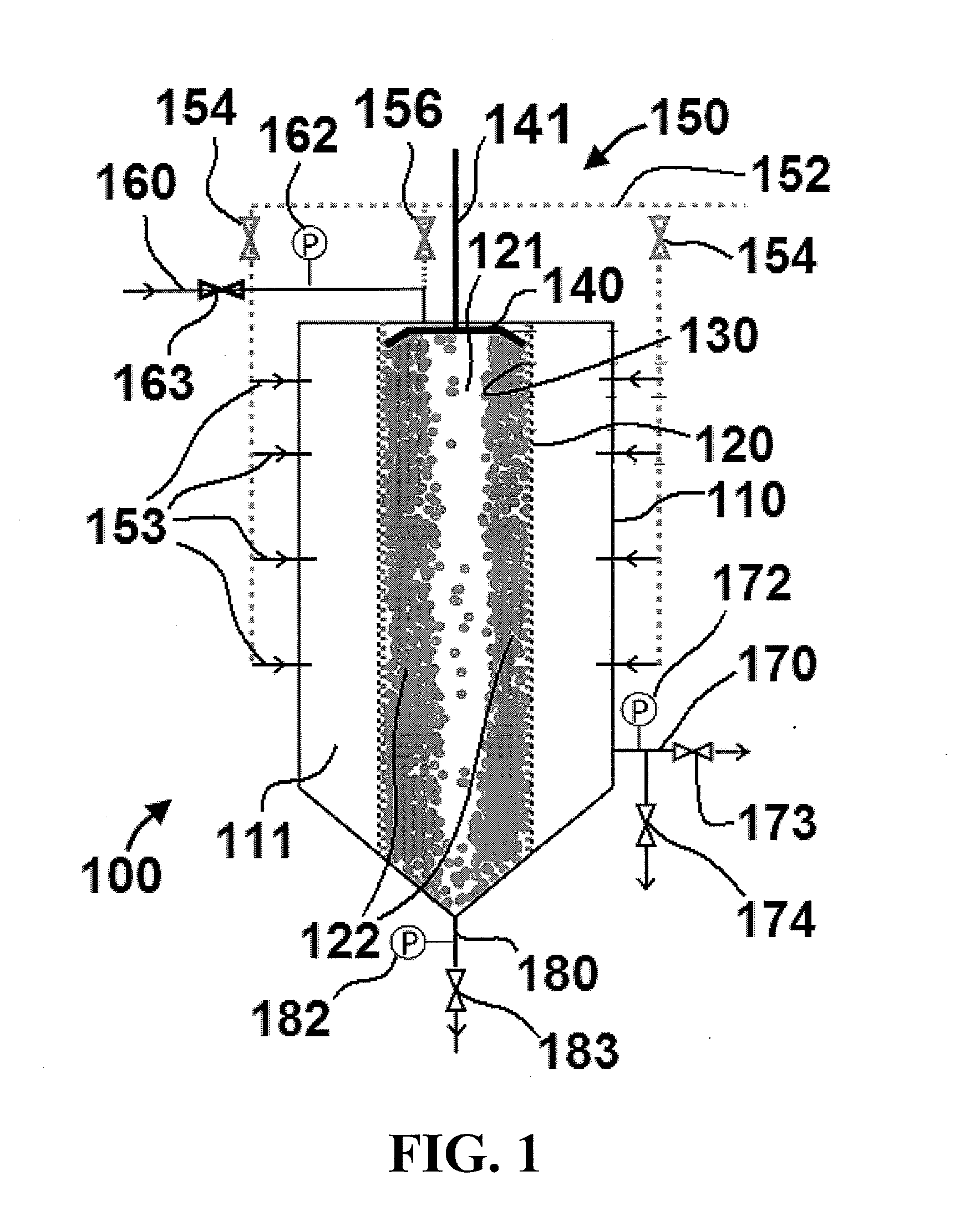

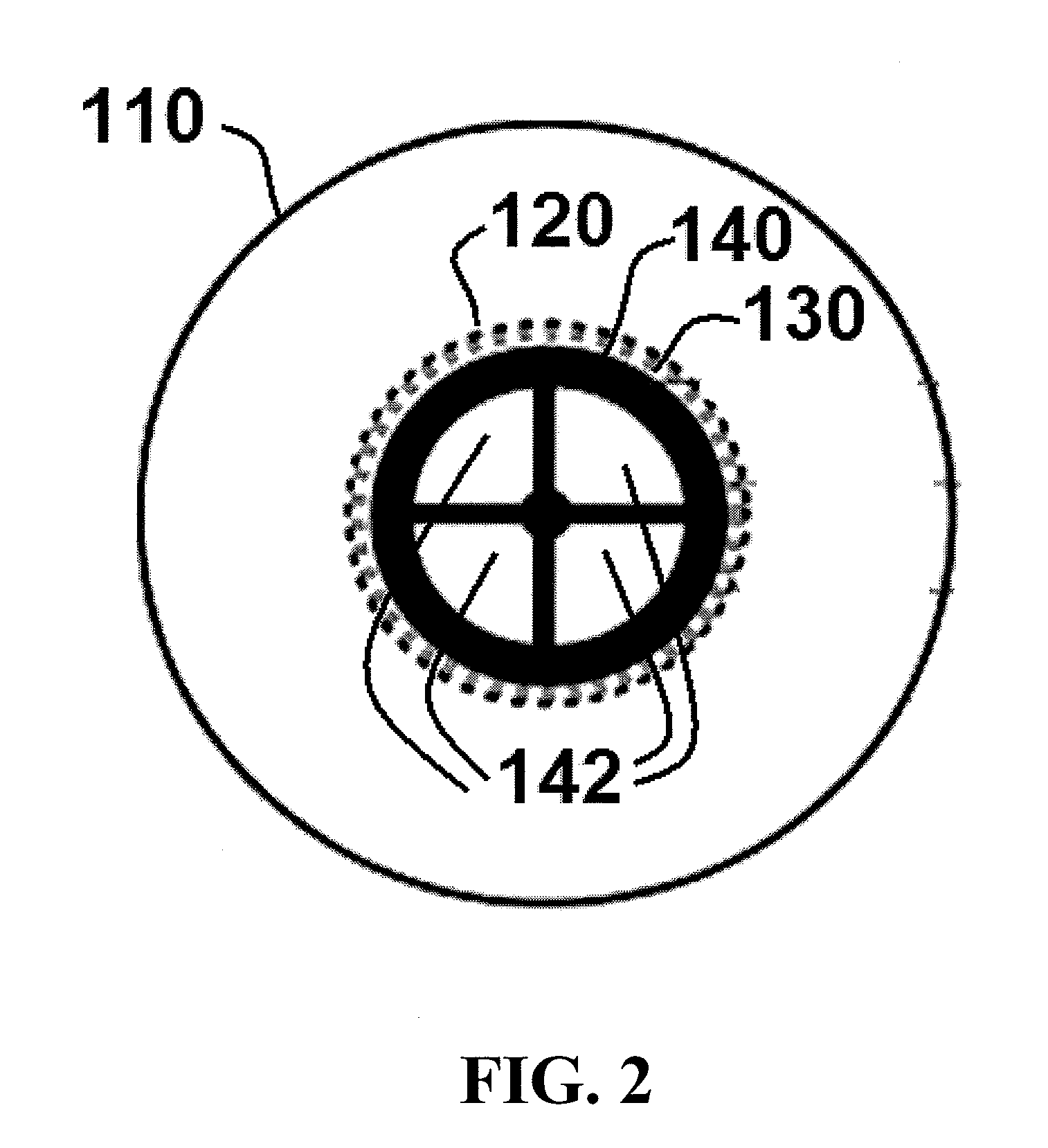

Algae filtration systems and methods

InactiveUS20110253605A1Easy scrapingEasy to removeSemi-permeable membranesAlgae productsFiltrationPiston

Owner:ARIZONA STATE UNIVERSITY

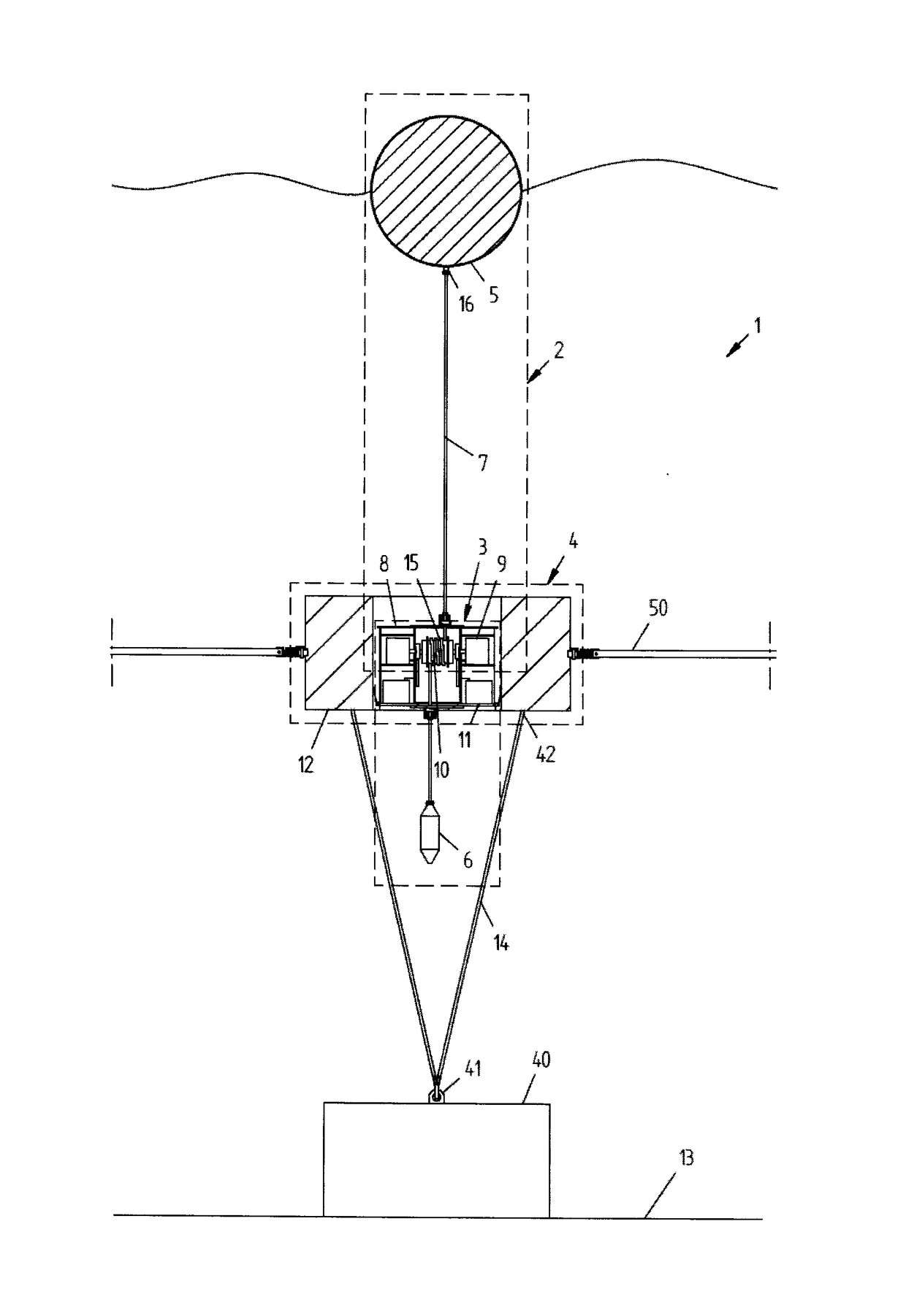

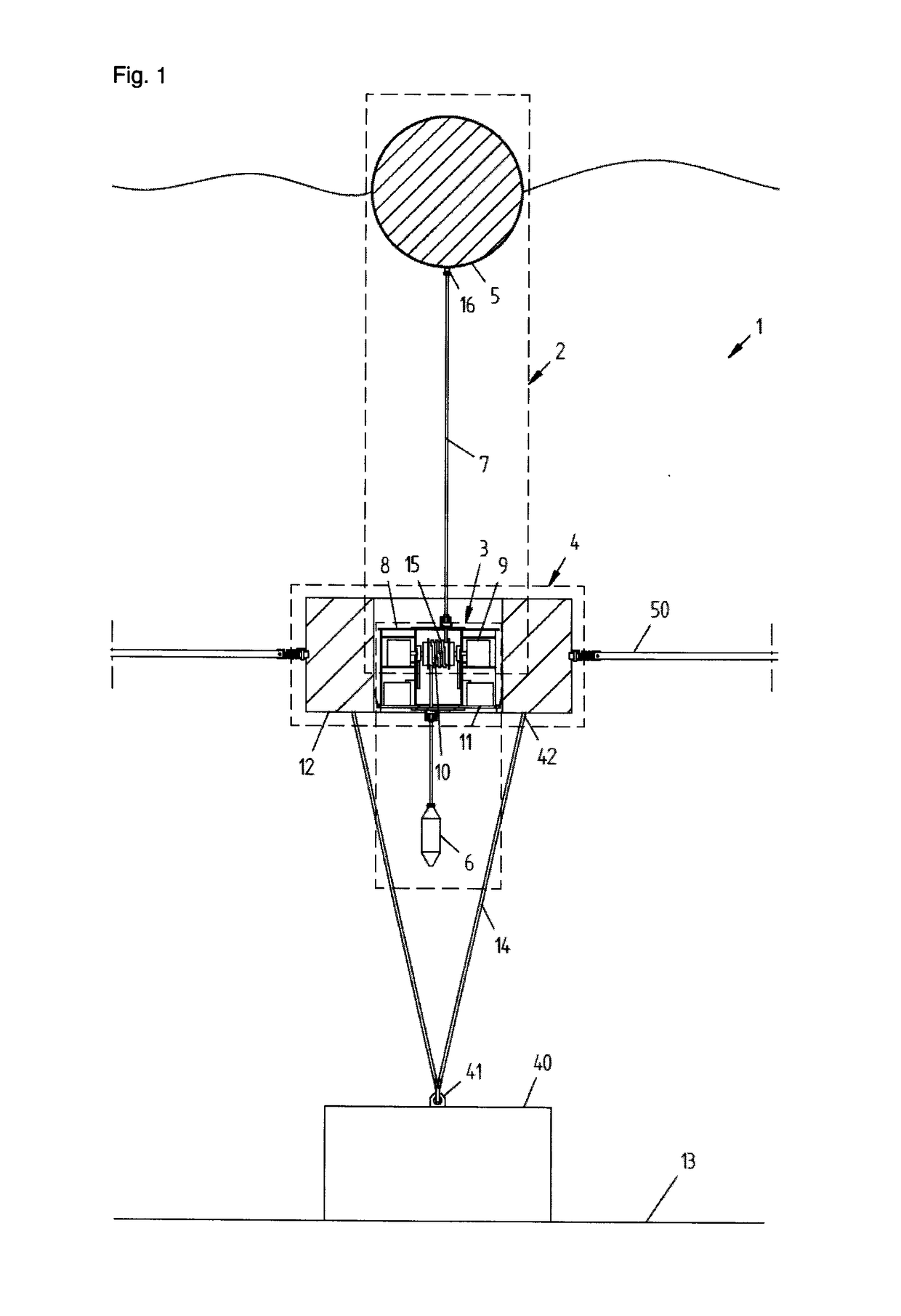

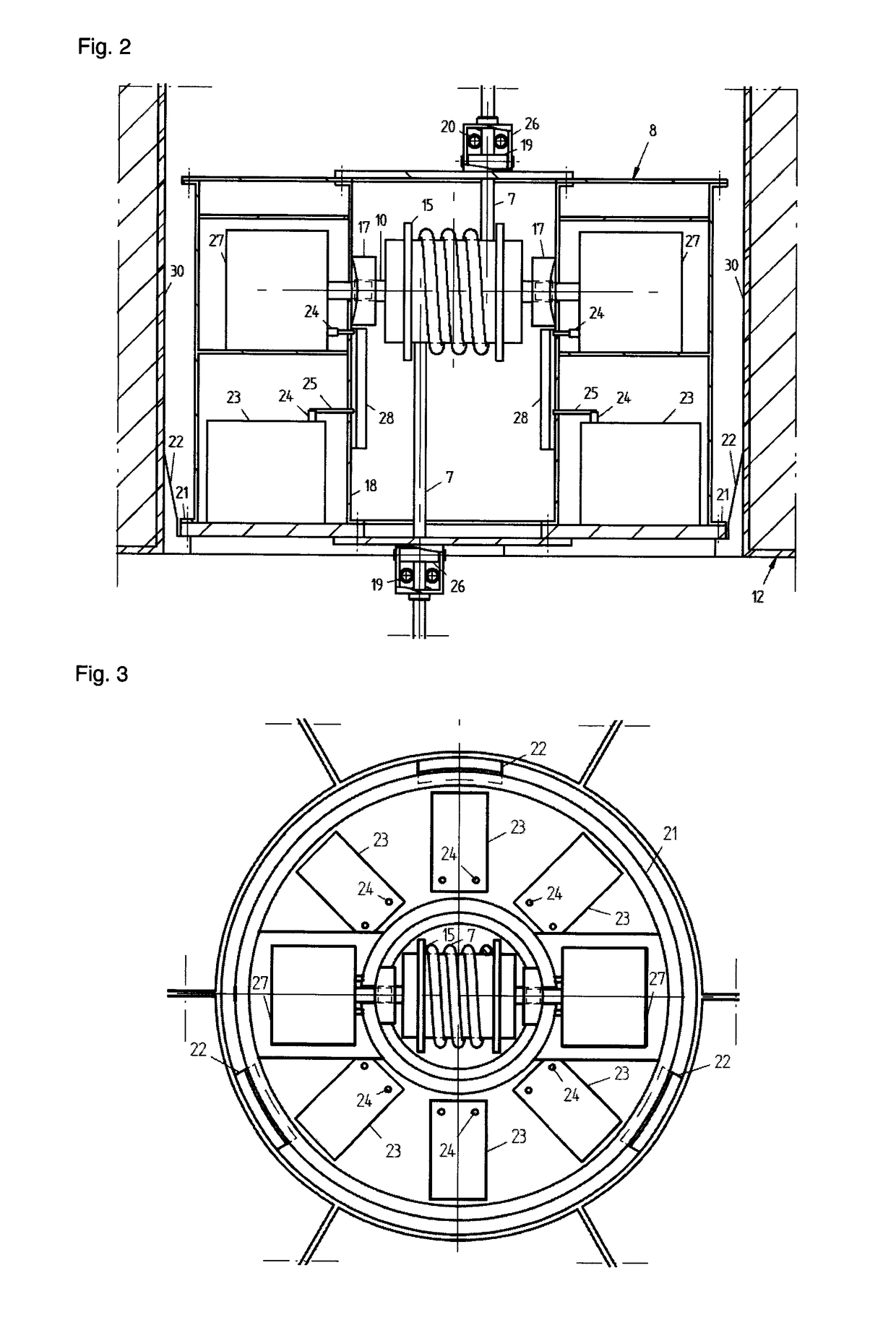

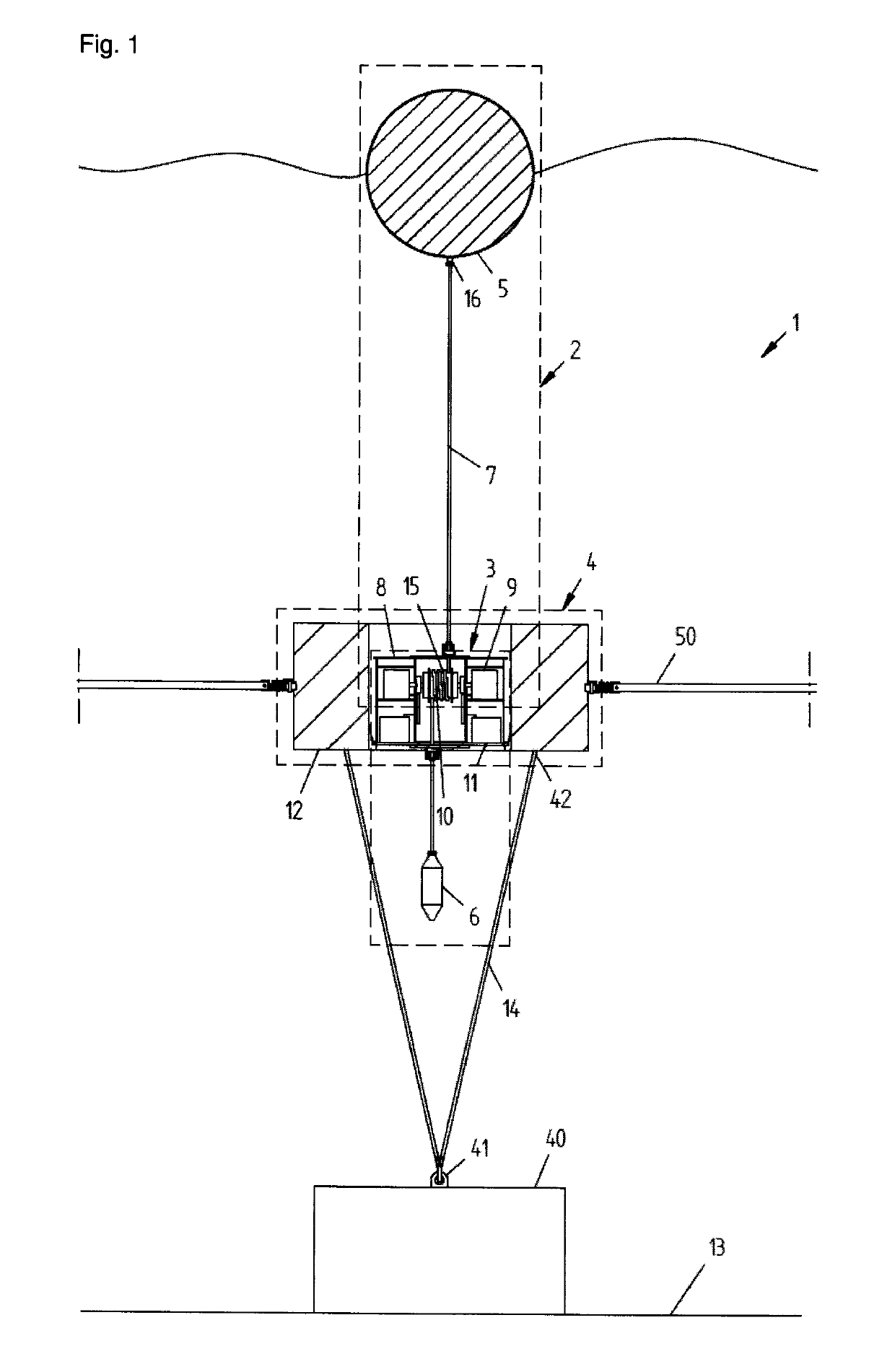

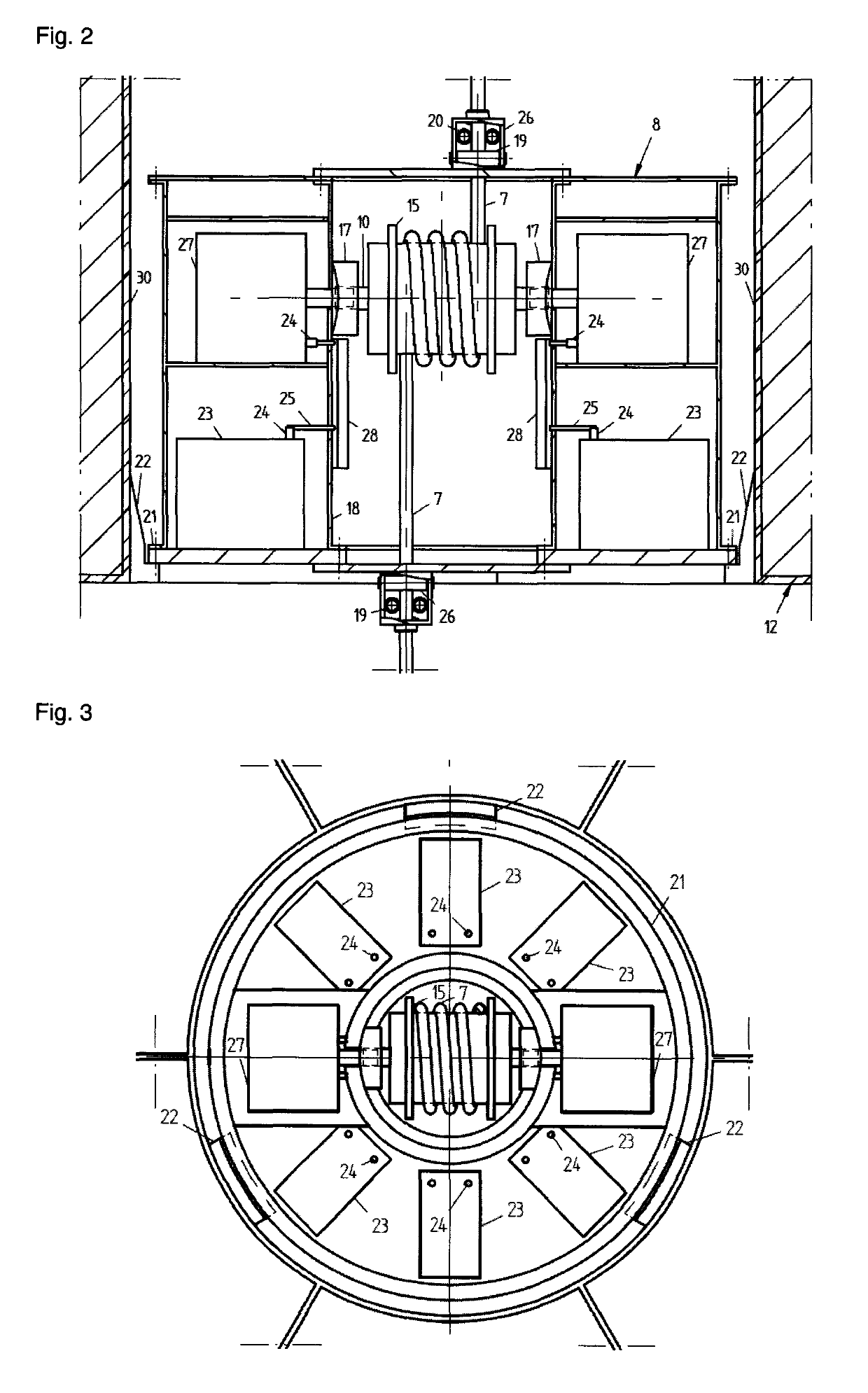

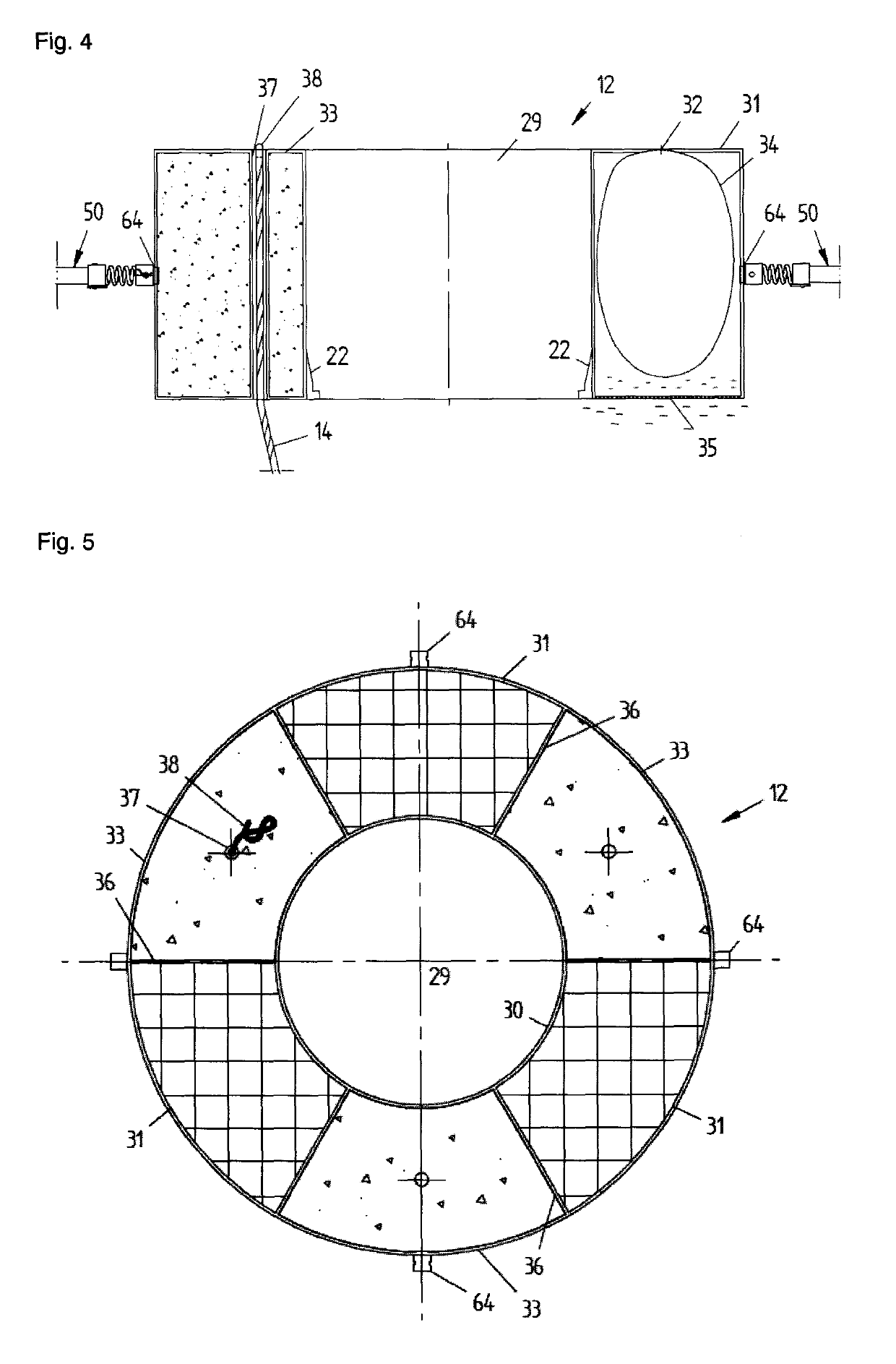

Wave power station

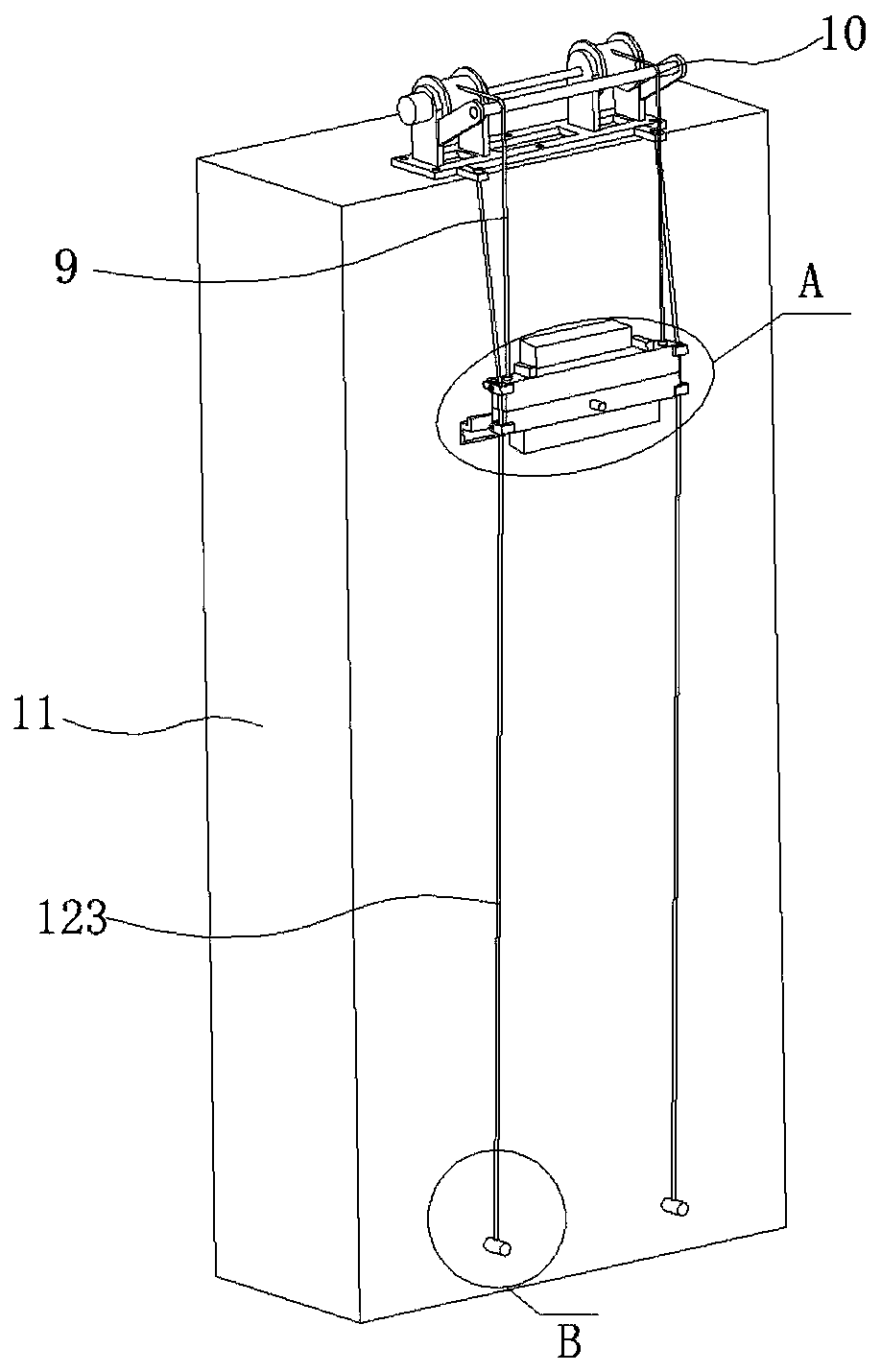

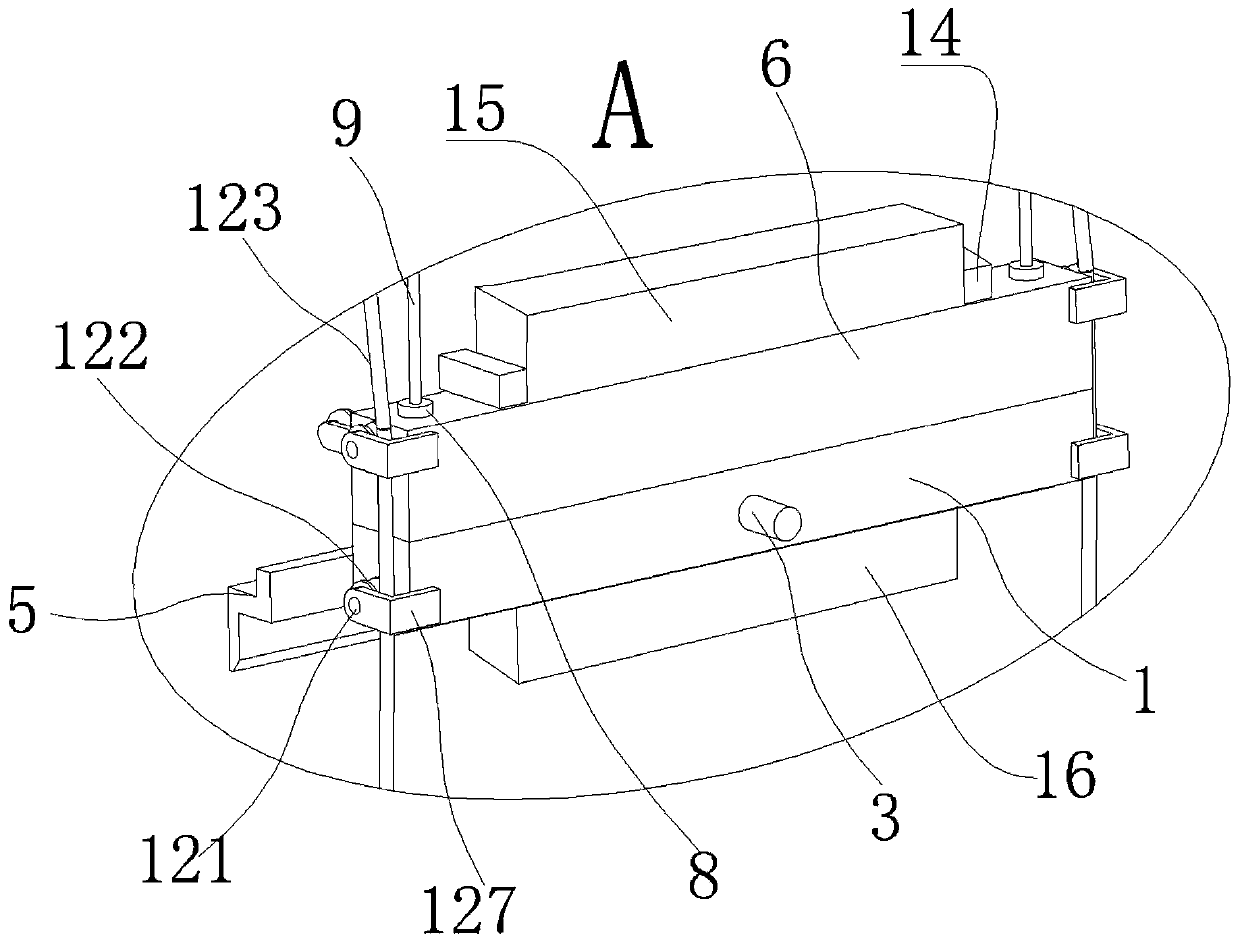

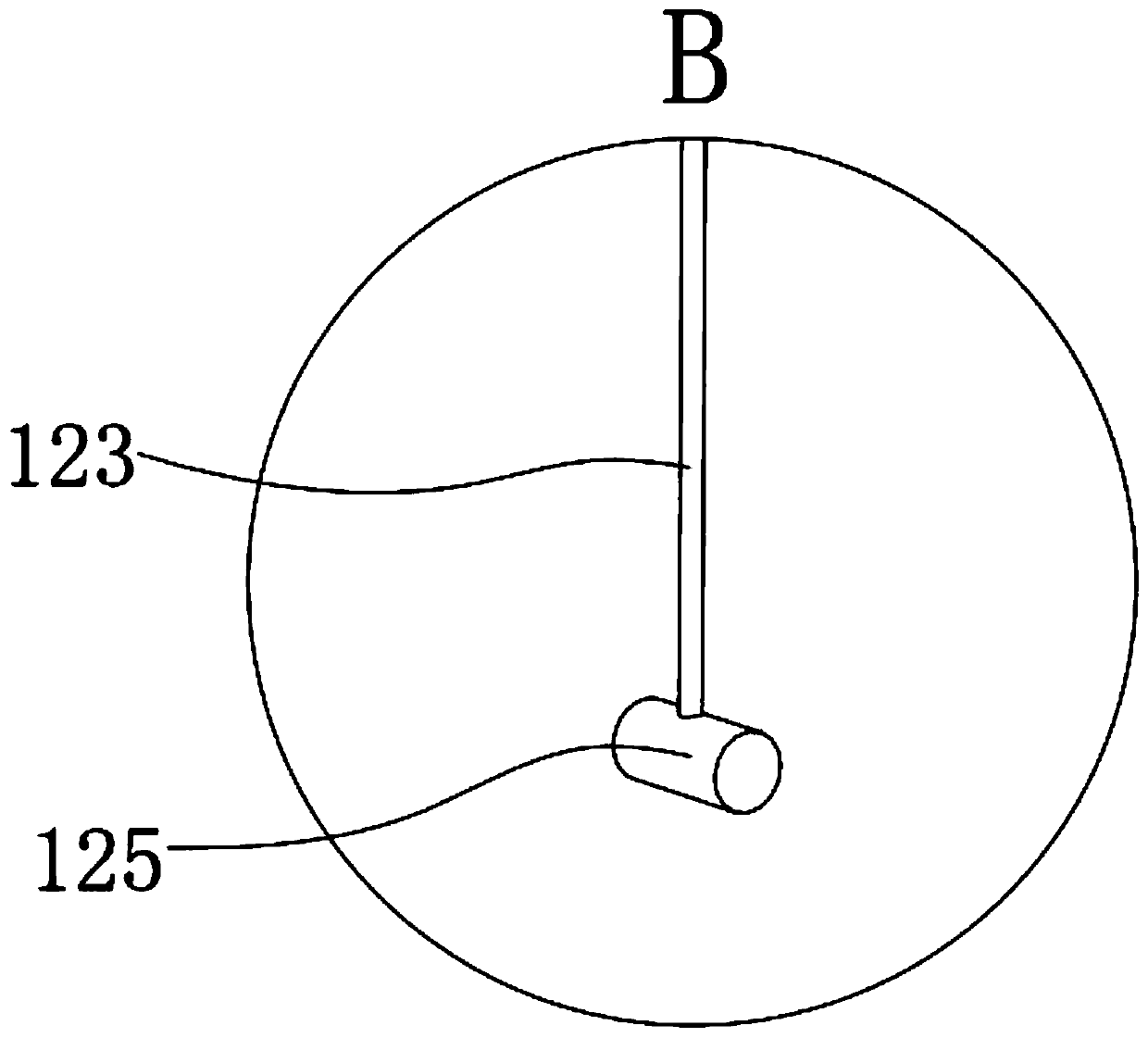

ActiveUS20180100481A1Easy to moveEasy scrapingEngine fuctionsMachines/enginesDrive wheelPower station

A wave power station for conversion and storage of energy from waves in an ocean or a sea includes a wave energy absorbing unit including a first floating body connected to a vertically hanging counterweight via a drive line and a drive wheel, a power generating unit including at least one power generation unit for conversion of wave energy, connected to a drive shaft, and a power accumulating unit including at least one power accumulator for storage of generated wave power. The power generating unit and the power accumulating unit are arranged in a second floating body firmly anchored under the first floating body to the ocean bed or sea bed. The drive line is connected to the at least one power generation unit via the drive wheel, and a coupling and transmission unit arranged on the drive shaft for driving of the at least one power generation unit via the up and down movements of the drive line in time with the wave movements.

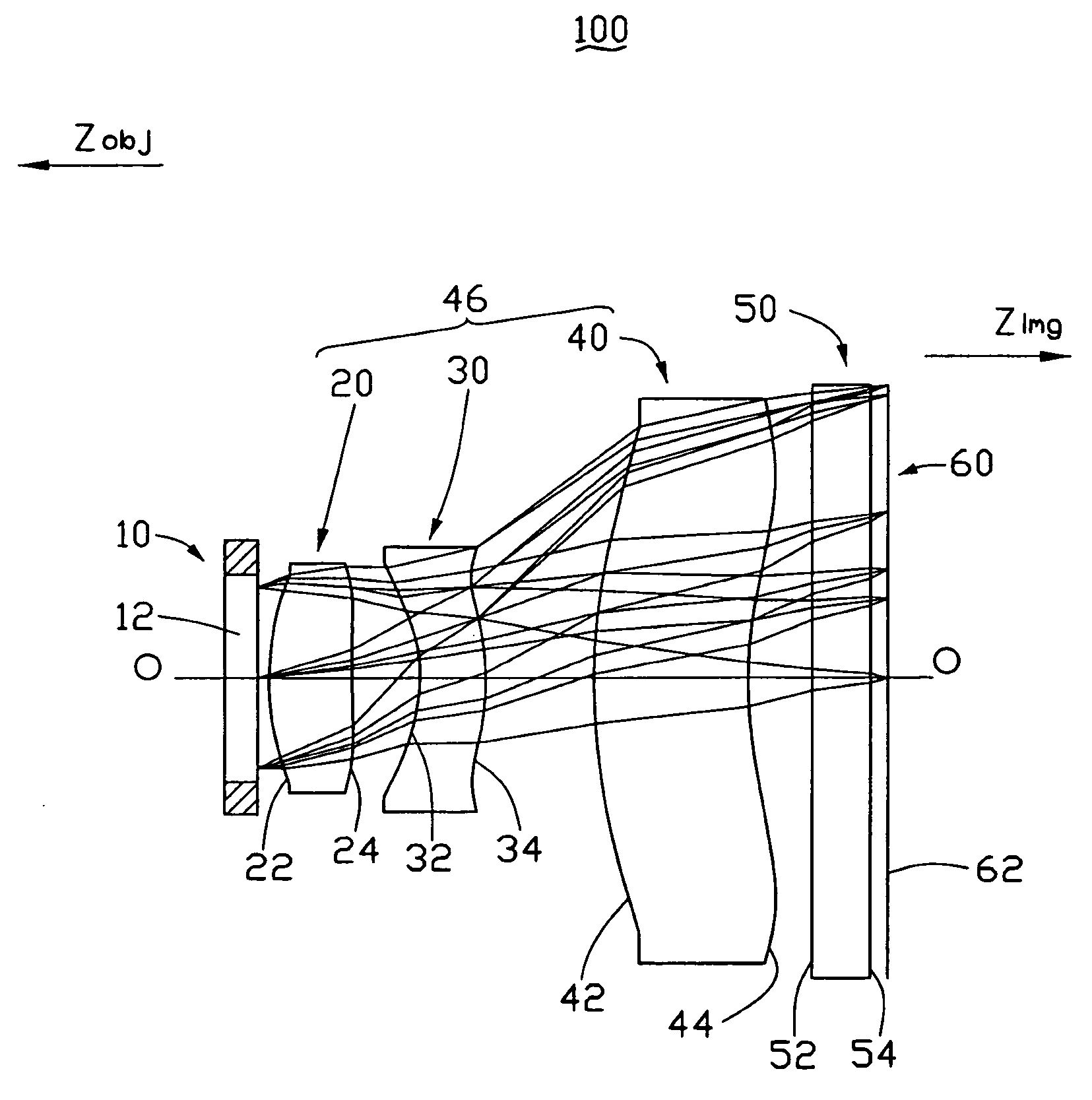

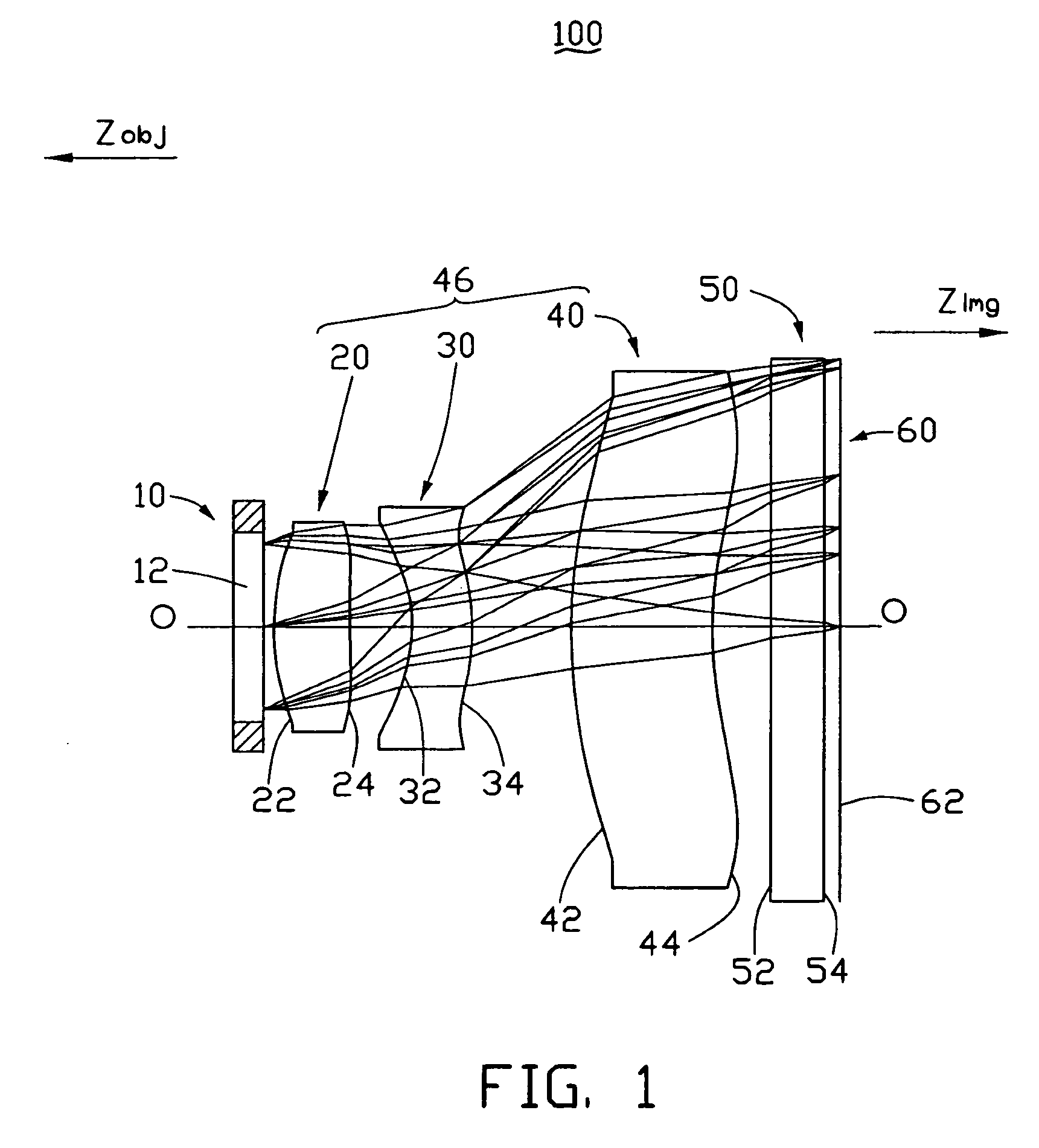

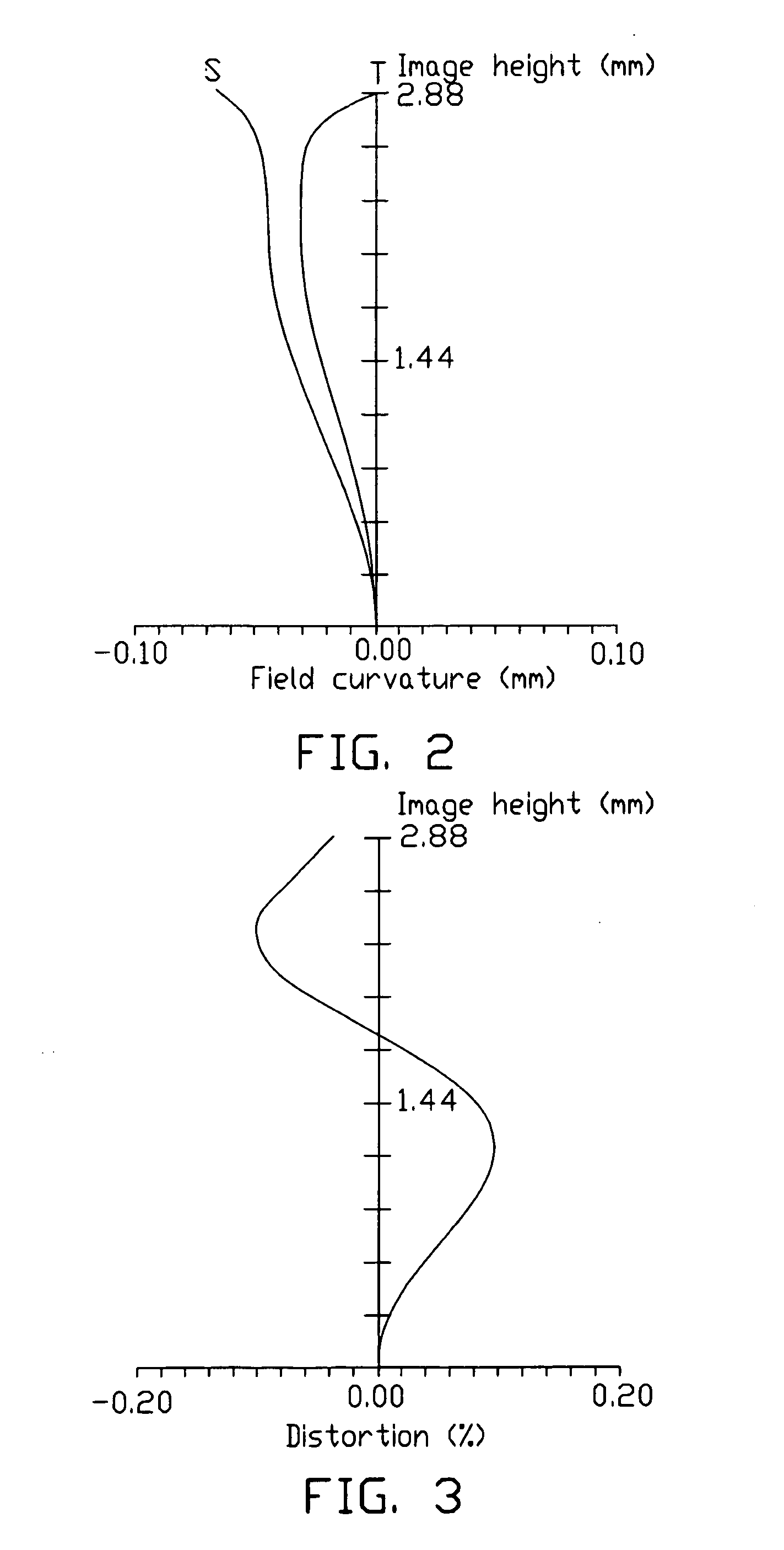

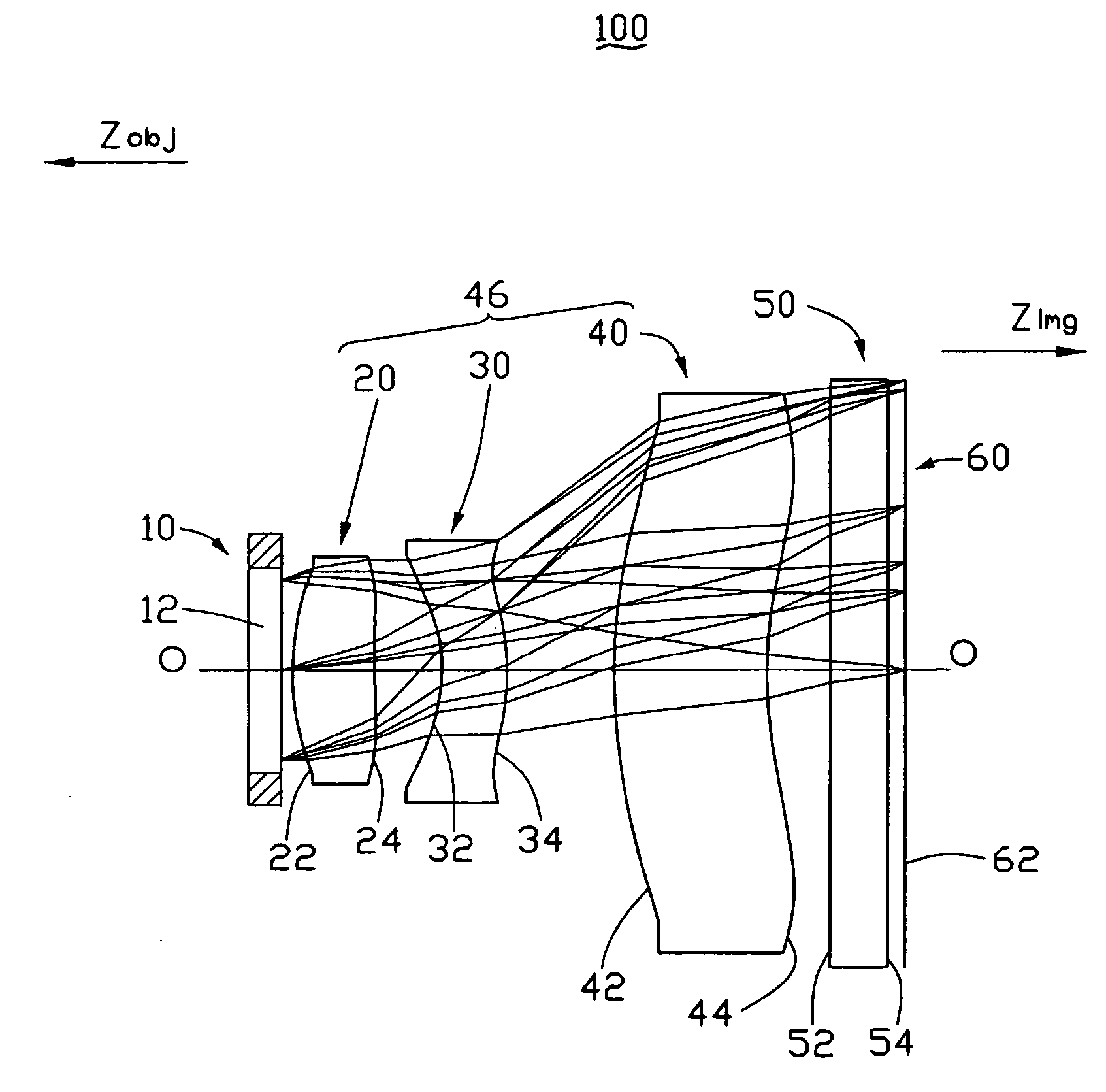

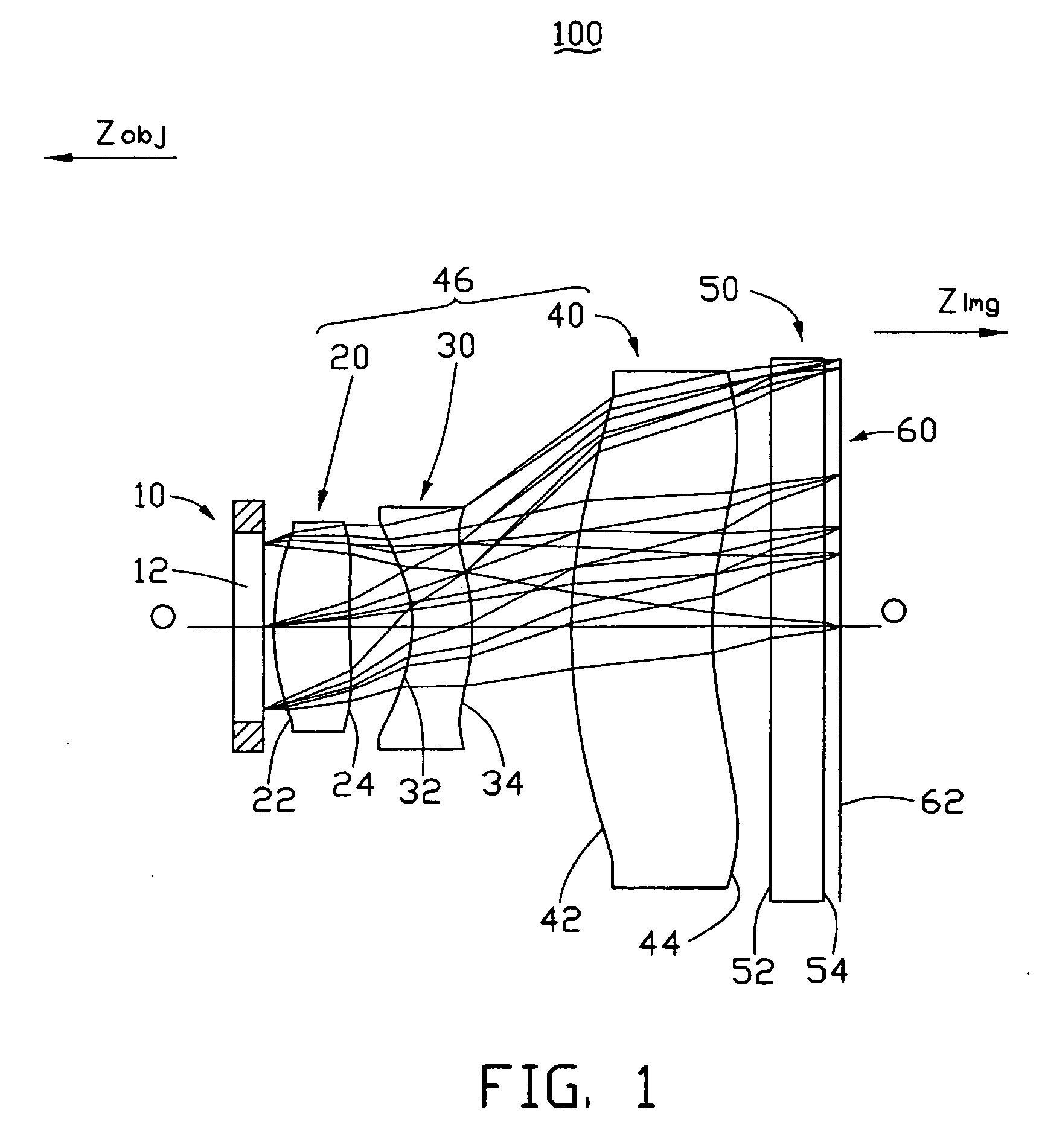

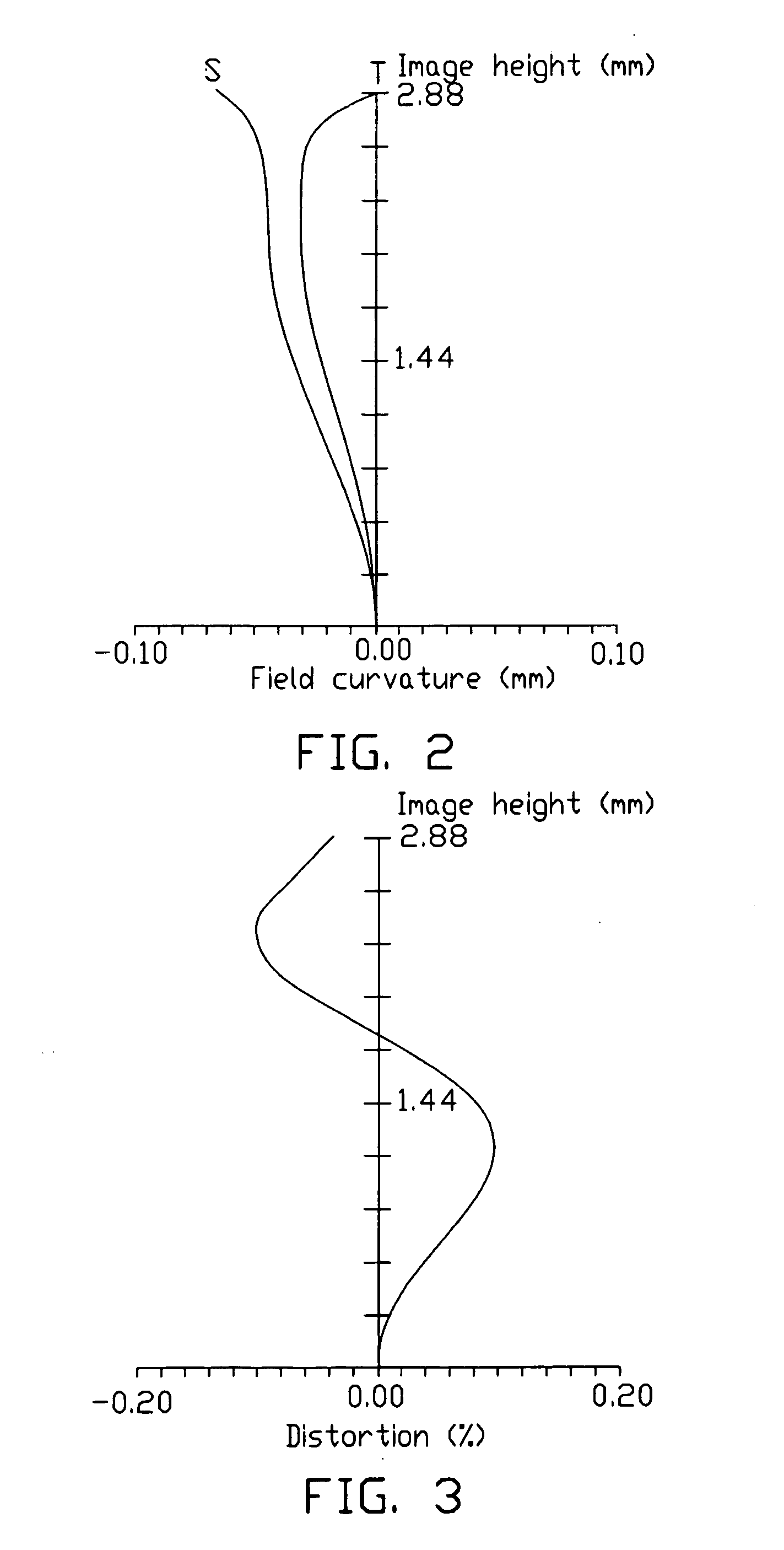

Lens system for digital camera

A lens system (46) for a digital camera consecutively includes a first lens element (20), a second lens element (30), and a third lens element (40). The first lens element is biconvex and has a first aspheric surface (22) and an opposite second aspheric surface (24). The second lens element is concavo-convex and includes a third aspheric surface (32) and an opposite fourth aspheric surface (34). The third lens element convexo-concave and has a fifth aspheric surface (42) and an opposite sixth aspheric surface (44). The first lens element is made of glass, and the second lens element and the third lens are made of optical plastic.

Owner:HON HAI PRECISION IND CO LTD

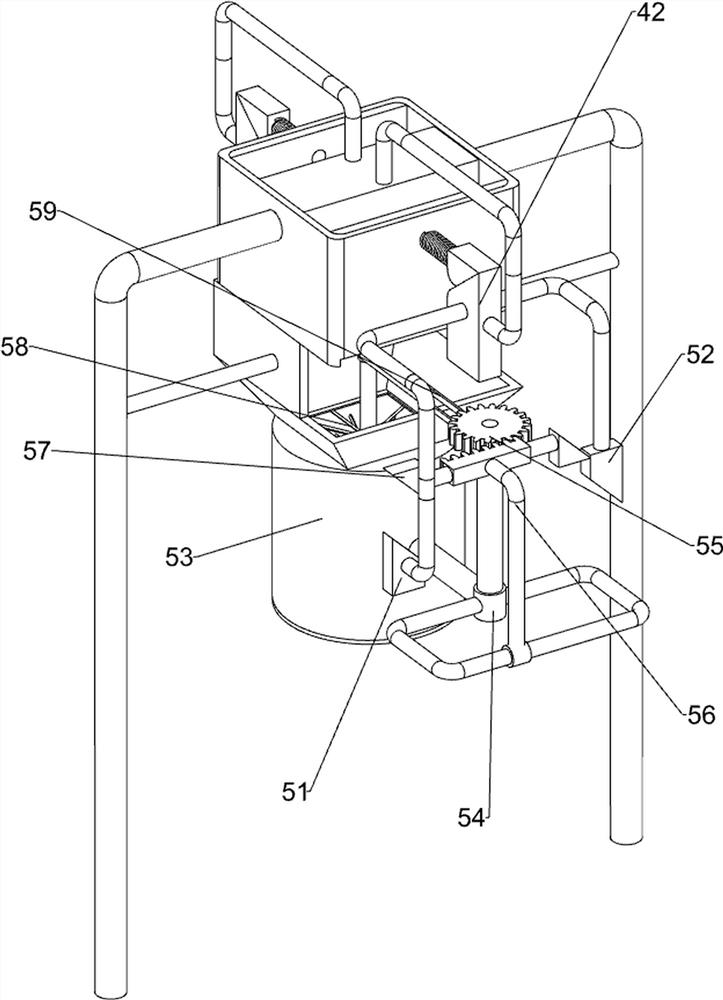

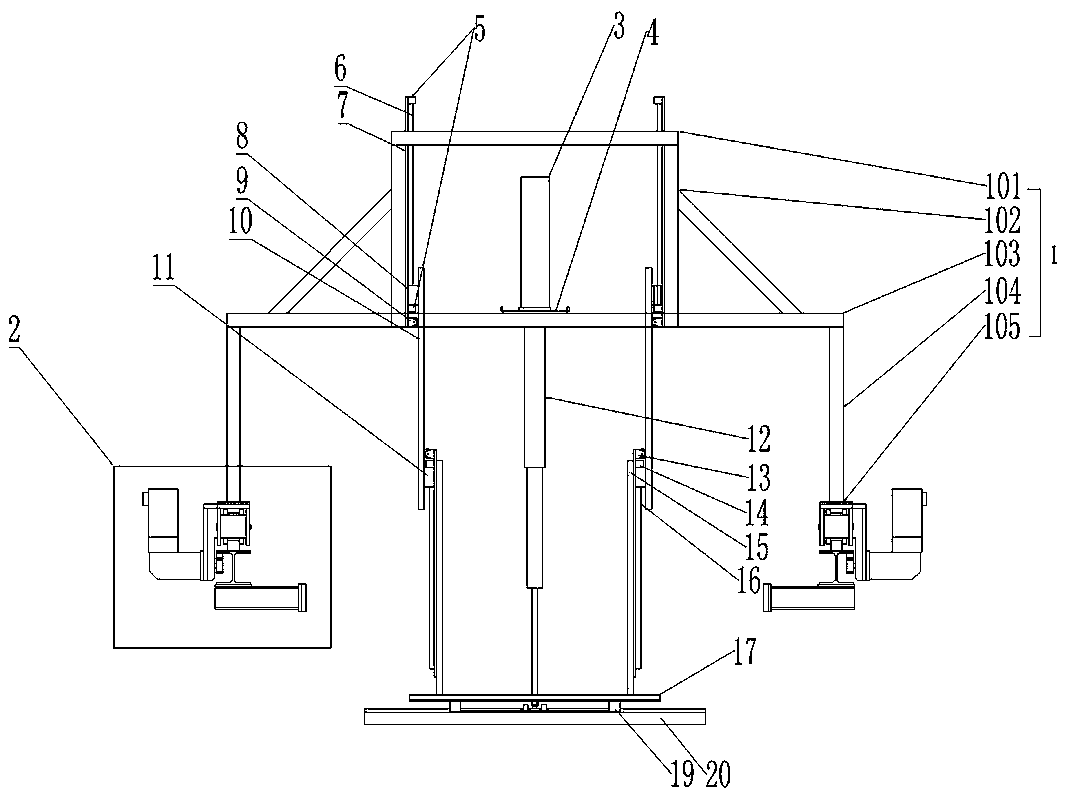

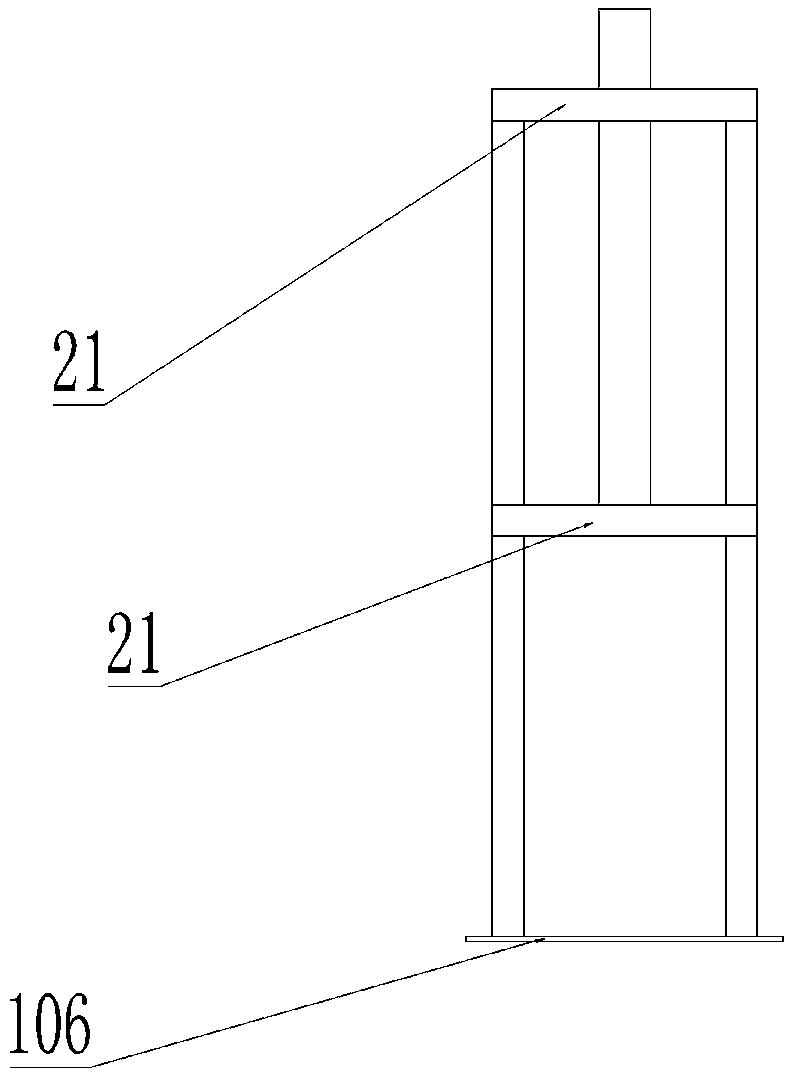

Automatic cleaning platform for insulating layer of external wall of building construction

The invention discloses an automatic cleaning platform for an insulating layer of an external wall of building construction. The automatic cleaning platform comprises a first installation box, a second installation box is fixed on the first installation box, a storage battery is fixed in the second installation box, the storage battery is electrically connected with an electric push rod, the electric push rod is fixed on the first installation box, a piston rod of the electric push rod is in threaded connection with a pushing block, a scraping knife is fixedly connected on the pushing block, the scraping knife is positioned on the outer portion of the front side of the first installation box, the front end of the scraping knife is in close contact with a wall, supporting mechanisms are arranged on two sides of the upper portion of the scraping knife, the supporting mechanisms are installed at the front end of the second installation box, connecting seats are welded on two sides of thetop end of the second installation box, lifting steel wire ropes are fixed on the connecting seats, a lifting mechanism is arranged at one end, far away from the corresponding connecting seat, of eachlifting steel wire rope, and platform limiting mechanisms are symmetrically arranged at the ends of the left end and the right end of the first installation box and the second installation box. The insulating layer on the wall can be automatically removed without labor, the safety is good, and the working efficiency is high.

Owner:左雪云

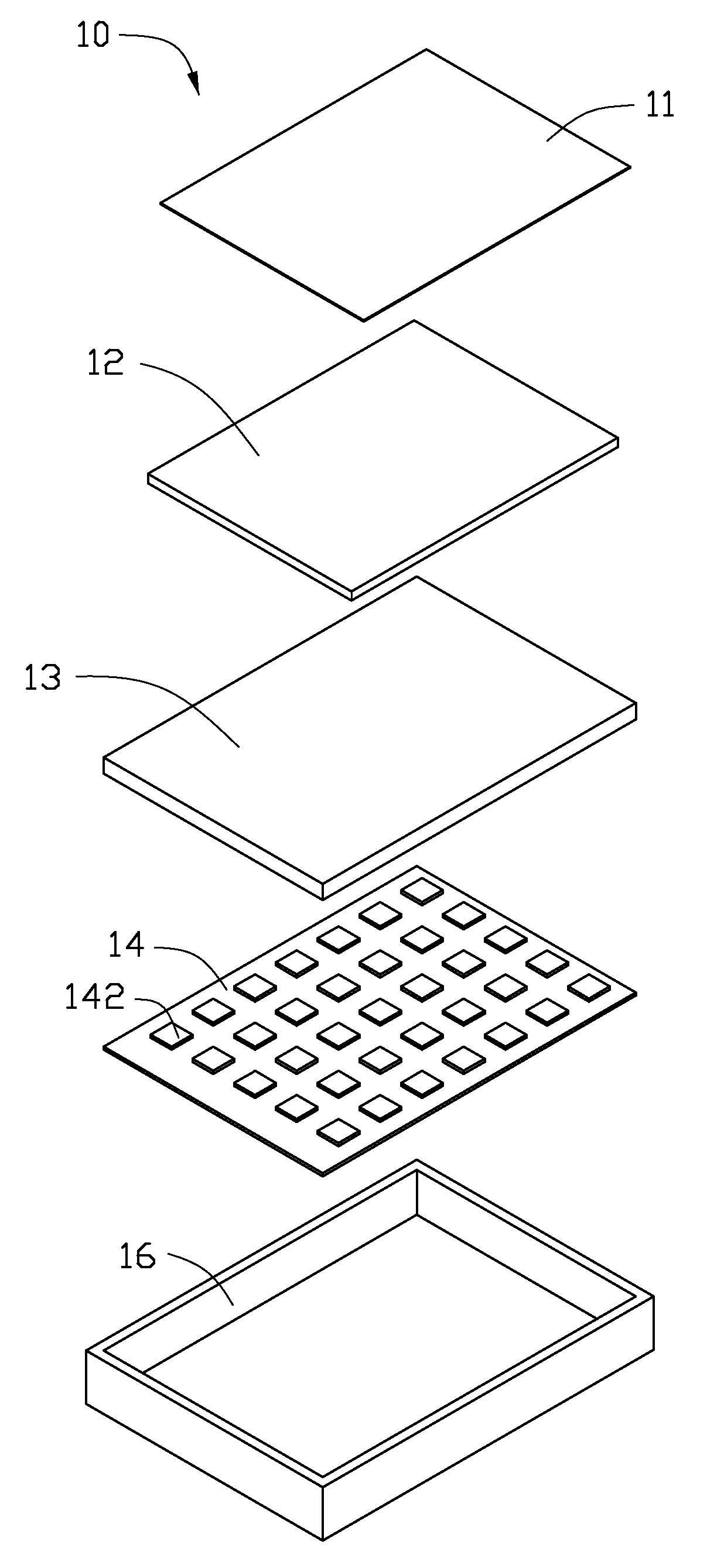

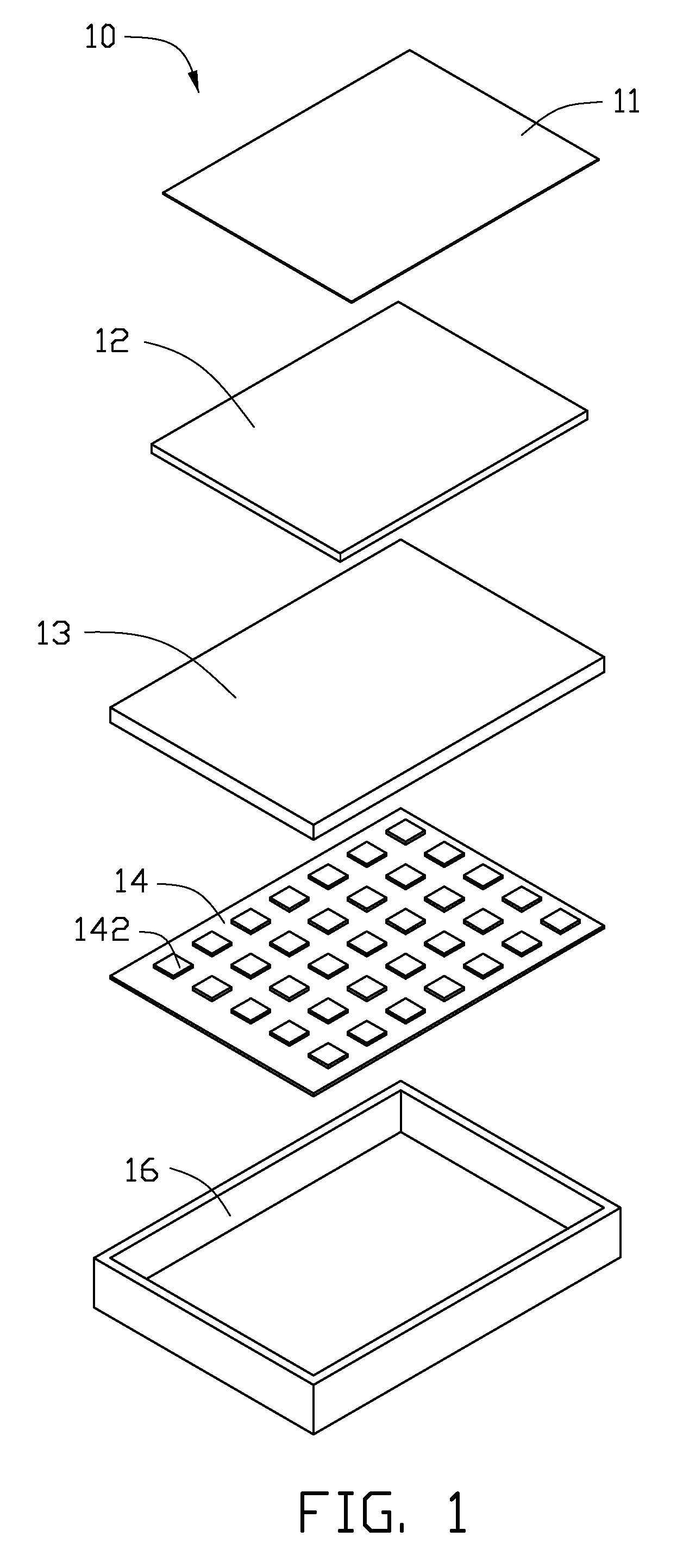

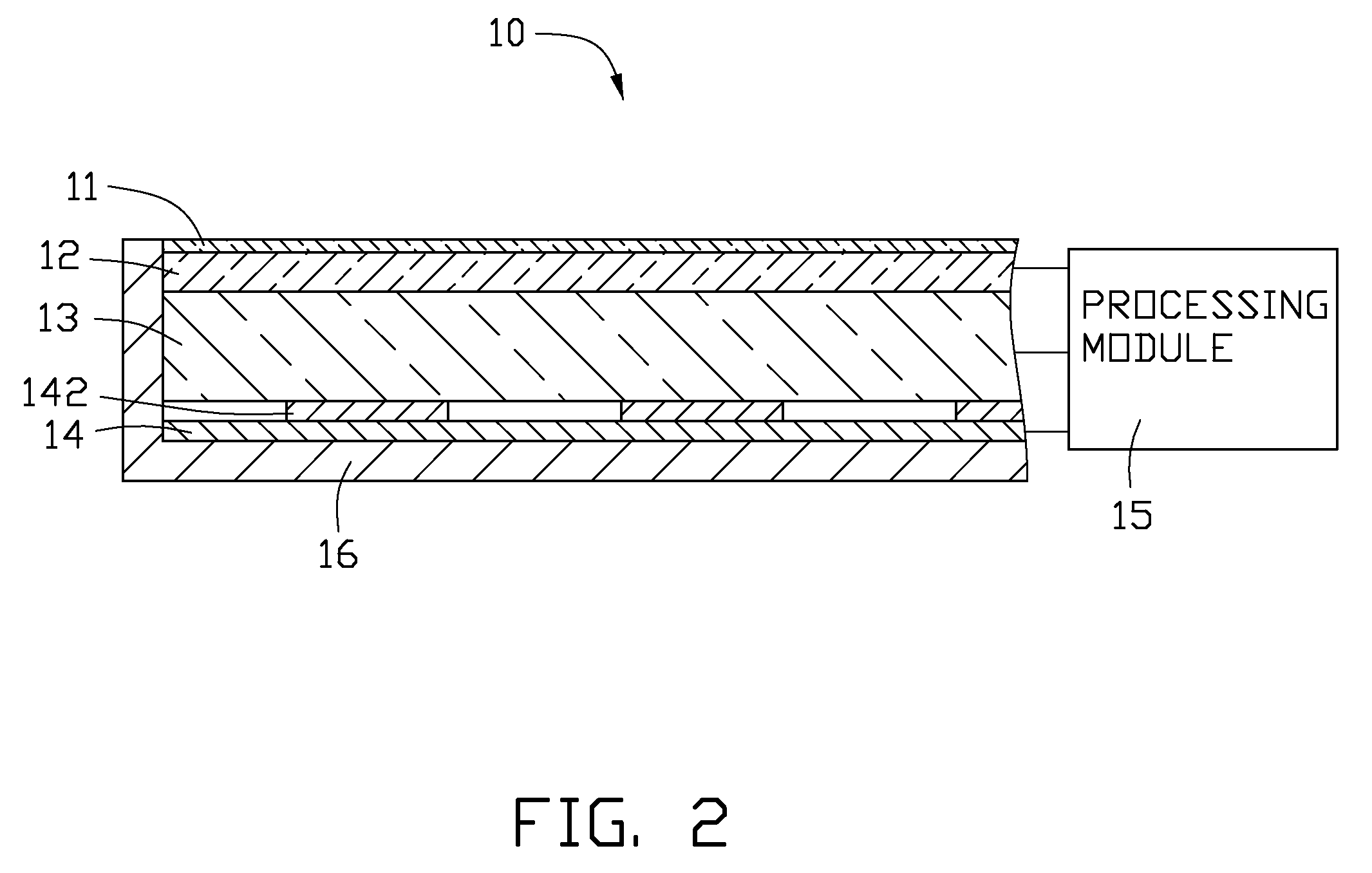

Display device with touch control function

InactiveUS20090289909A1Easy scrapingNon-linear opticsInput/output processes for data processingControl functionDisplay device

A display device (10) with touch control function includes a display panel (12), a backlight module (13), a circuit board (14), a processing module (15) and a frame (16). The backlight module supplies light to the display panel. The display panel, the backlight module, the circuit board and the processing module are contained in the frame. A plurality of magnetically sensitive elements (142) are mounted on the circuit board. The processing module electronically connects with the display panel, the backlight module and the circuit board. The processing module receives signals from the magnetically sensitive elements, and sends control data to the display panel and the backlight module.

Owner:CHI MEI COMM SYST INC

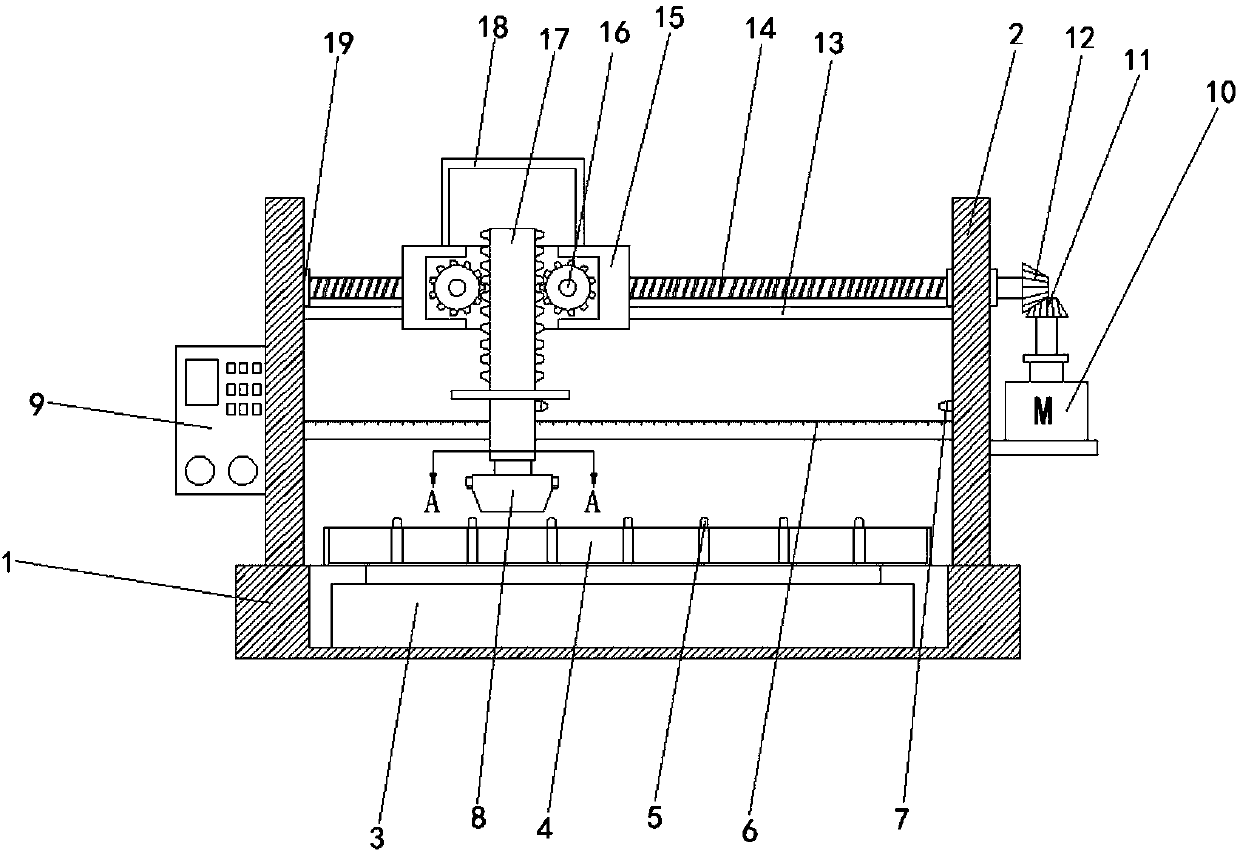

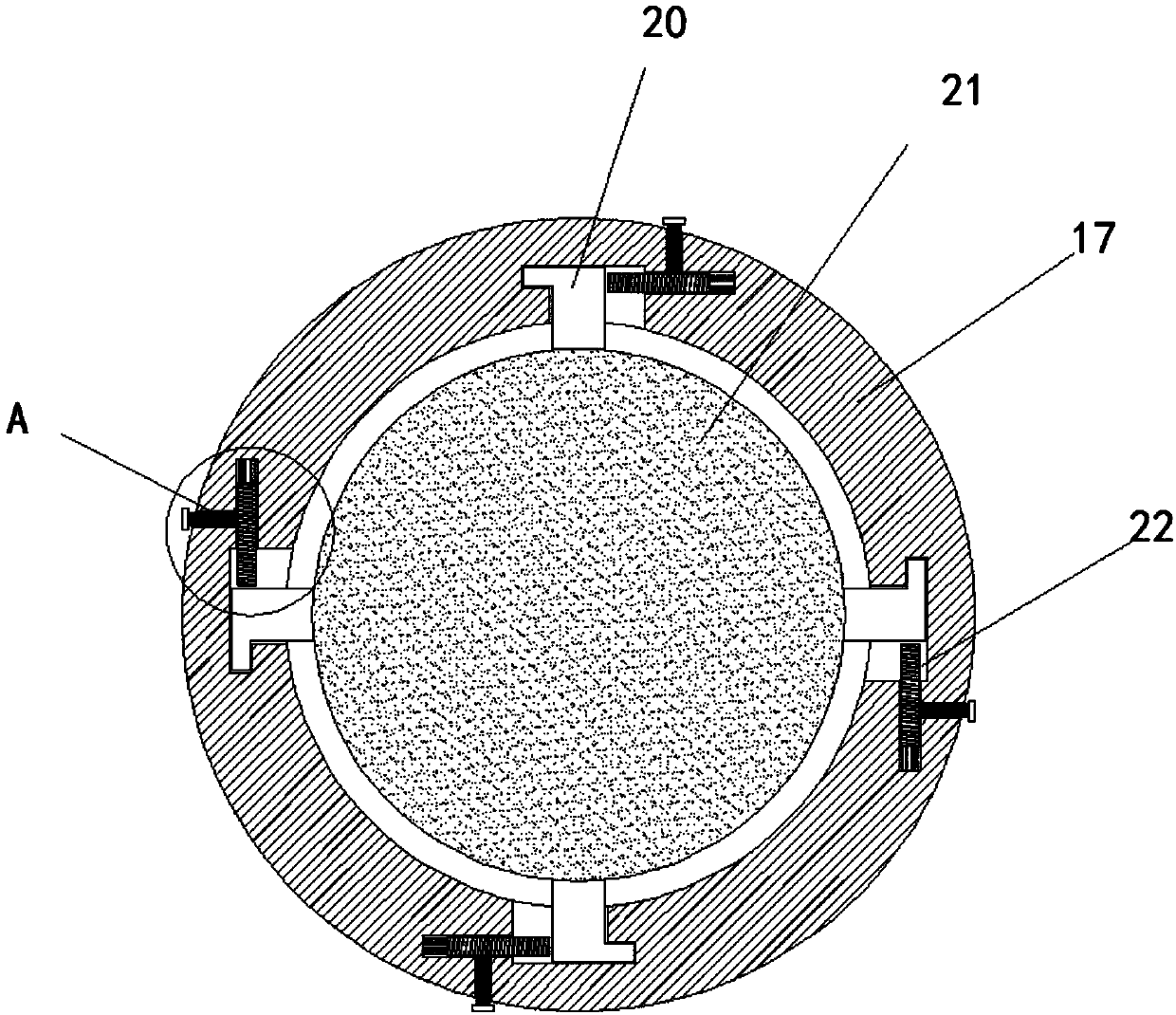

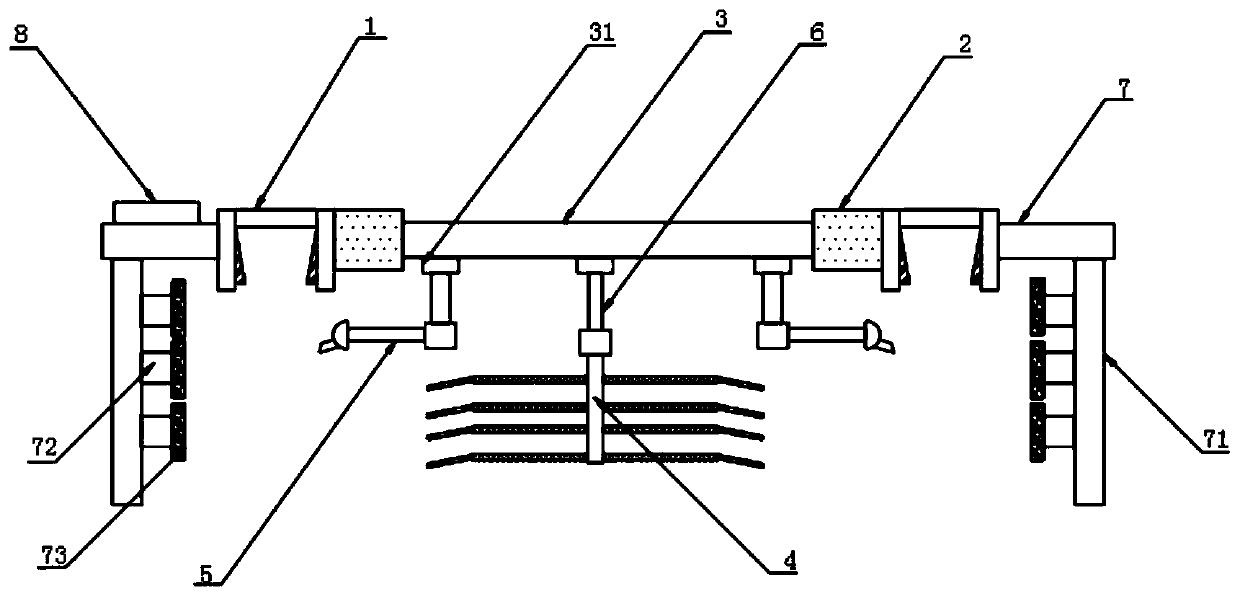

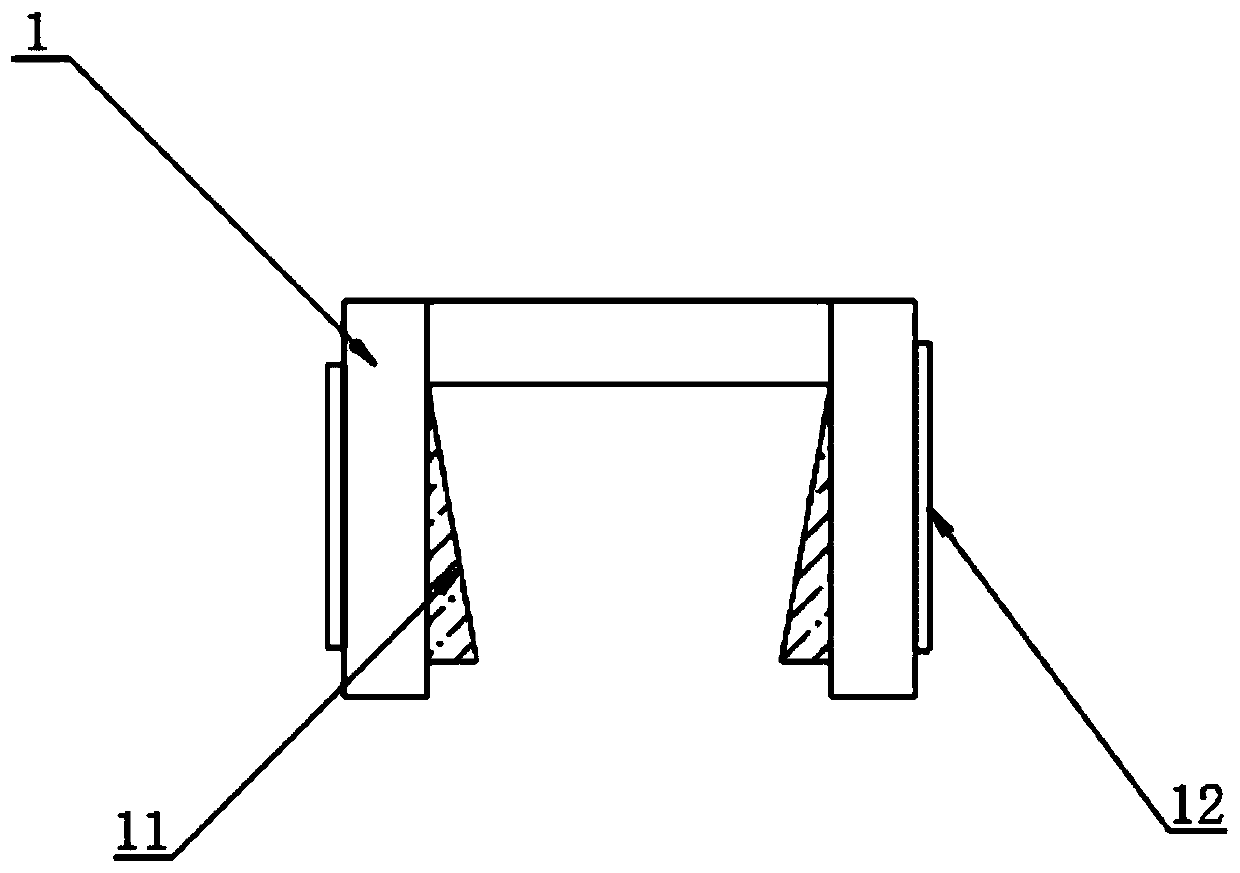

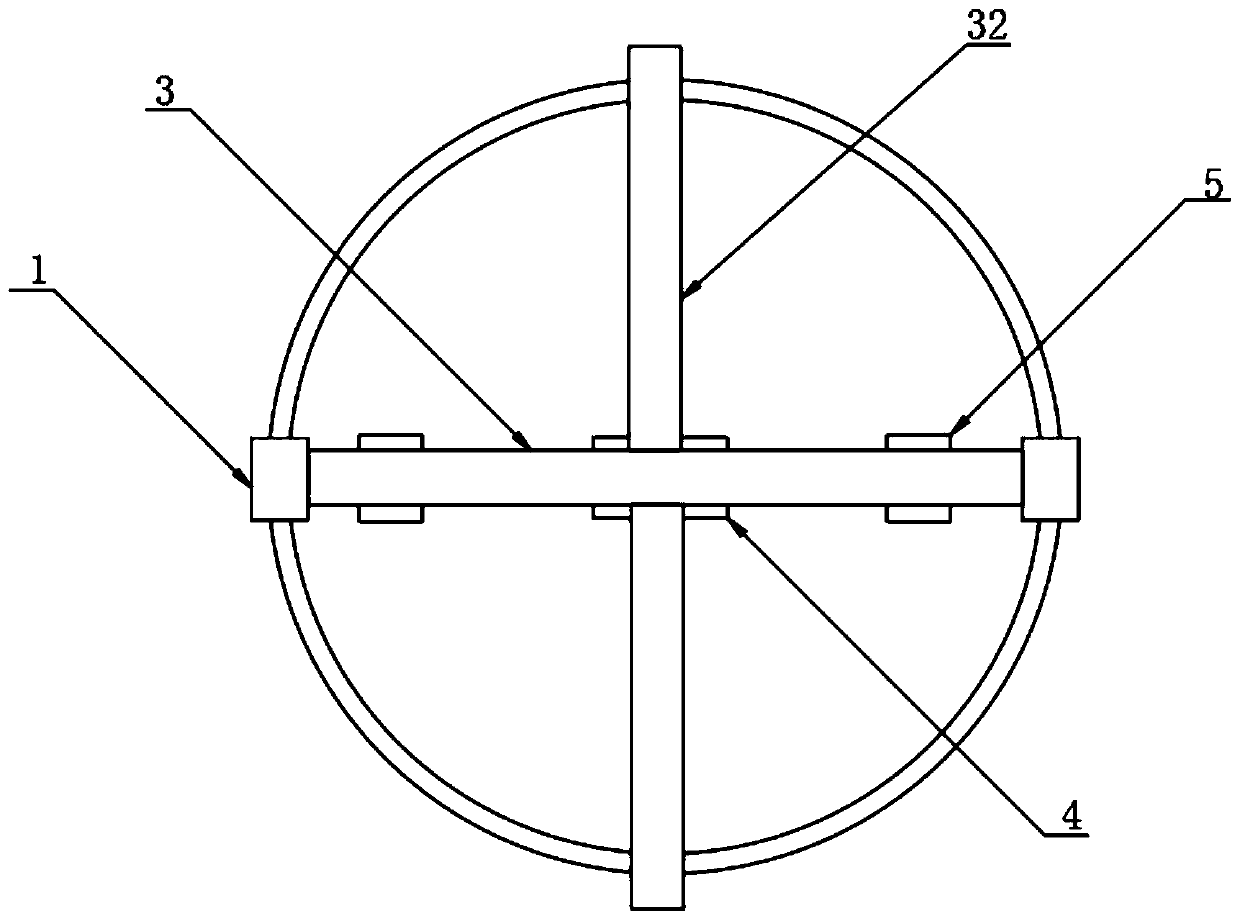

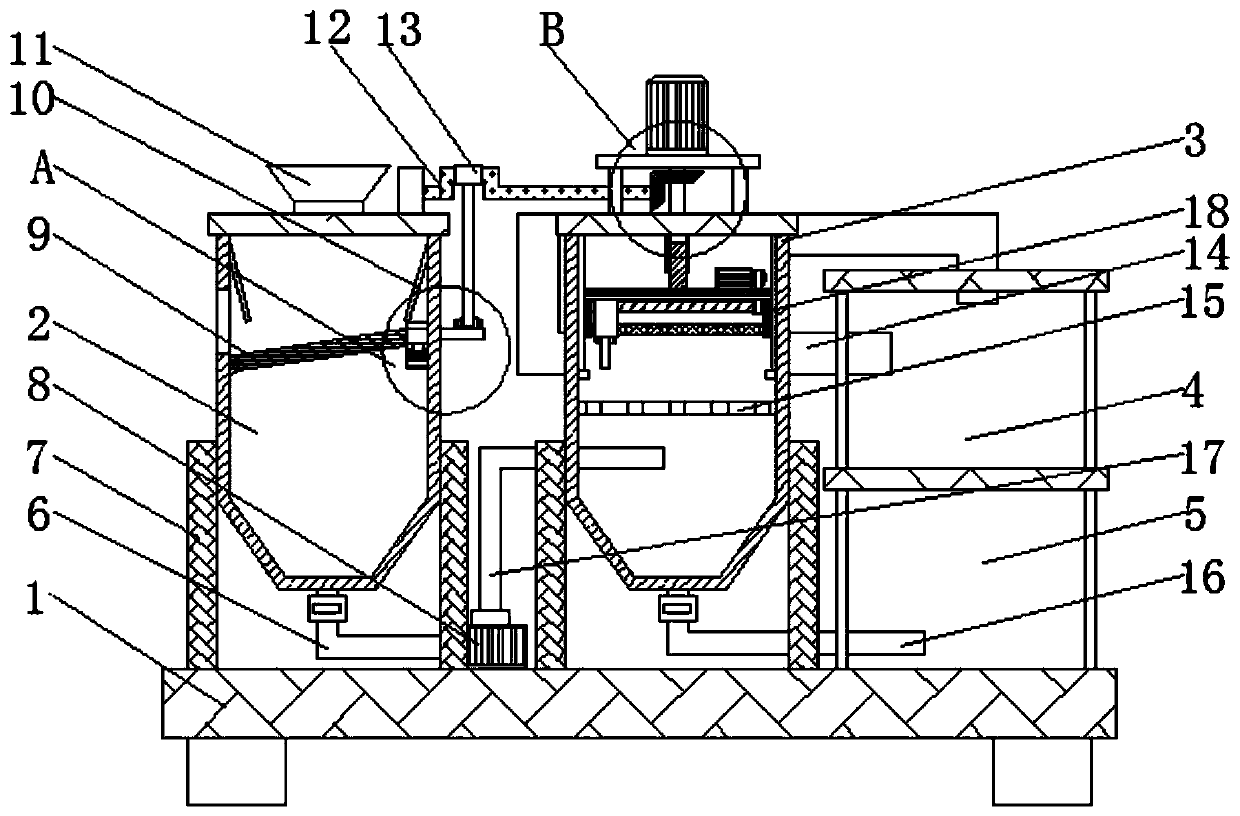

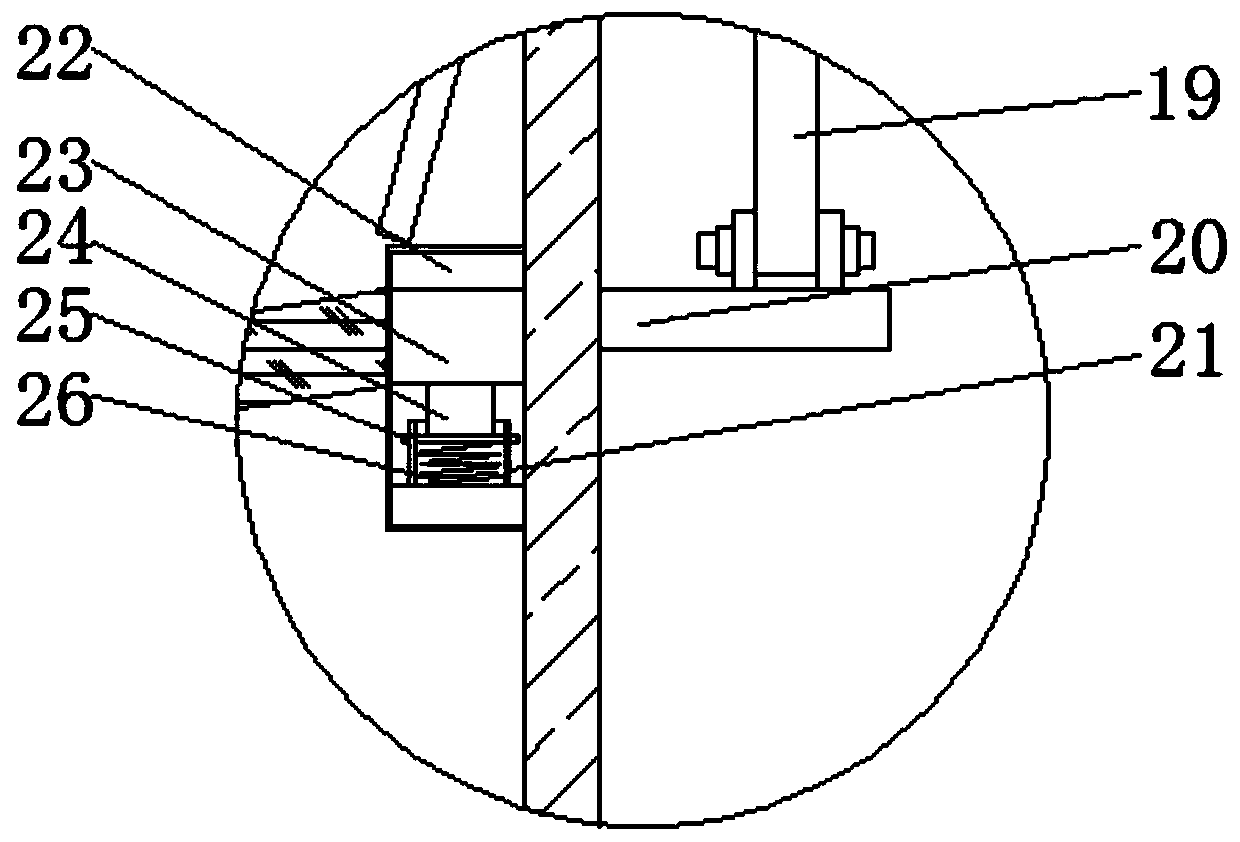

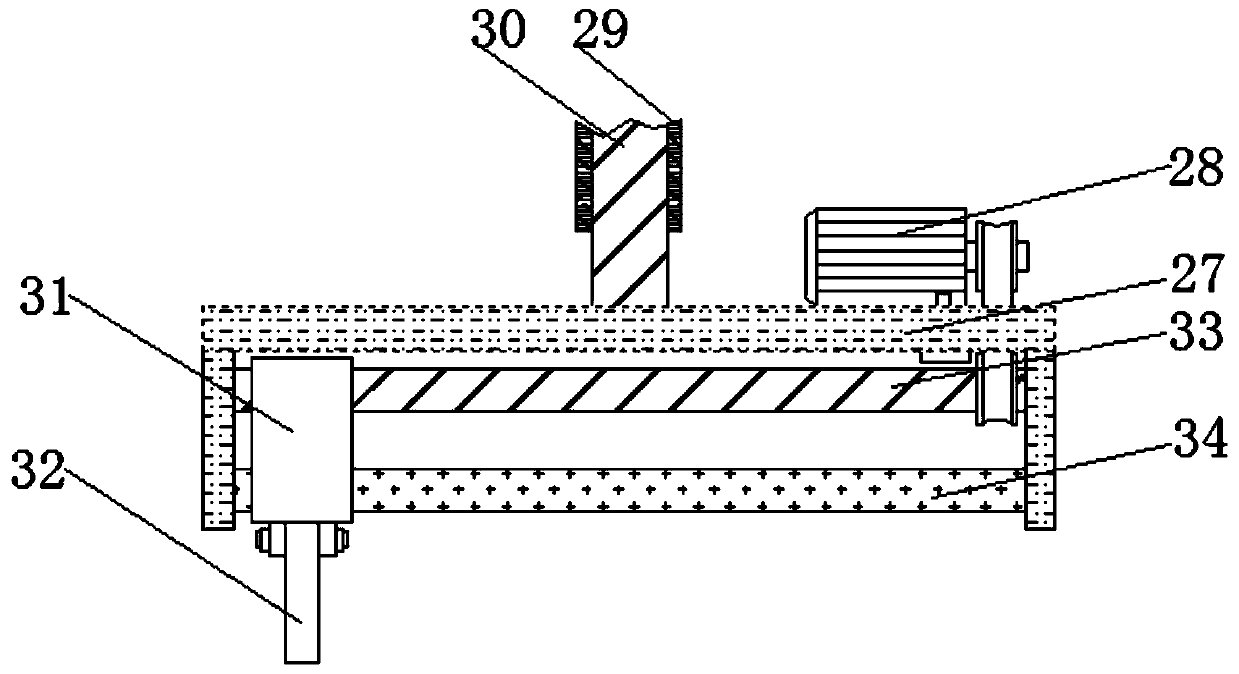

Grinding wheel production scraping device

InactiveCN107717766AAdjust horizontal displacementEasy scrapingGrinding devicesDrive motorAgricultural engineering

The invention discloses a grinding wheel production scraping device. The grinding wheel production scraping device comprises a base, a groove is formed in the upper end of the base, a first driving motor with an output shaft facing upwards is arranged at the inner bottom of the groove, and a grinding wheel forming mould is connected to the output end of the first driving motor; two support platesare further symmetrically arranged at the upper end of the base, two bearings are symmetrically arranged on the side walls of the opposite sides of the two support plates, a first threaded rod is arranged between the two bearings, one end of the first threaded rod penetrates through one support plate and is provided with a second bevel gear, a supporting plate and a second driving motor arranged on the supporting plate are arranged on the side wall of one support plate, and a rotating rod is connected to the driving end of the second driving motor through a connecting shaft. The grinding wheelproduction scraping device is convenient to operate; fast, effective and precise scraping can be conducted on grinding wheels, and the horizontal displacement and height adjustment can be conducted;besides, a scraping plate can be conveniently replaced, and the grinding wheel production scraping device has high practicability.

Owner:郭伟

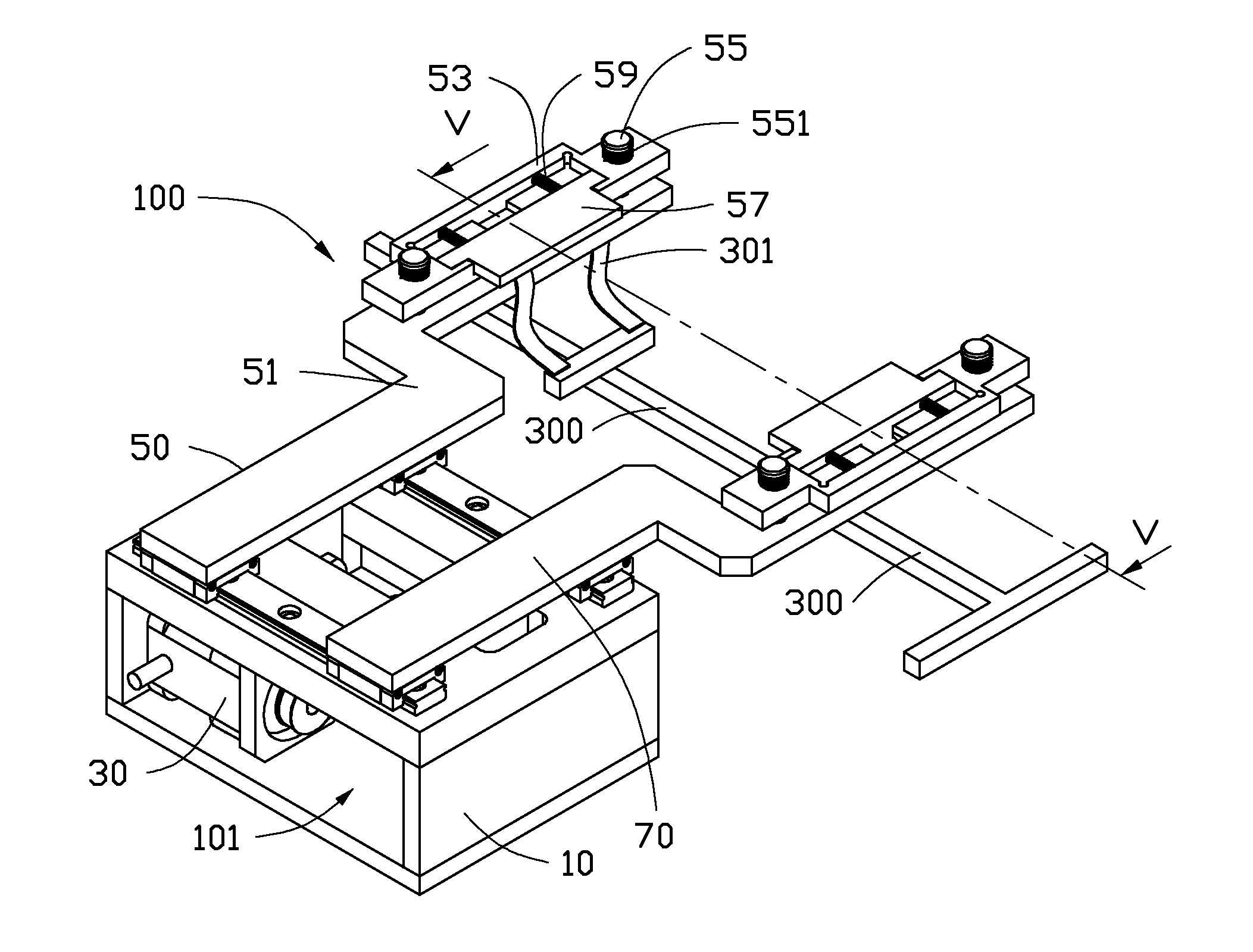

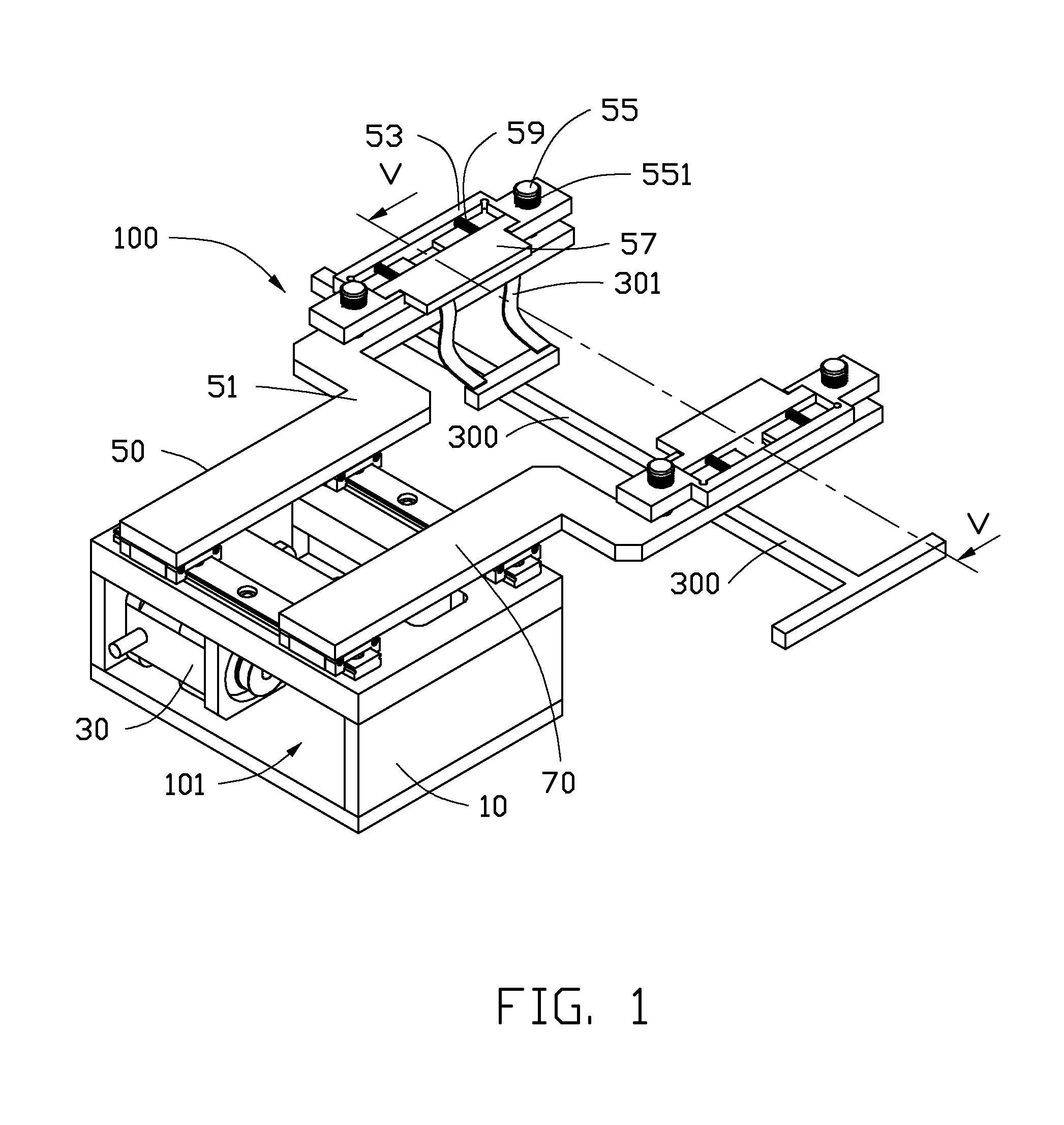

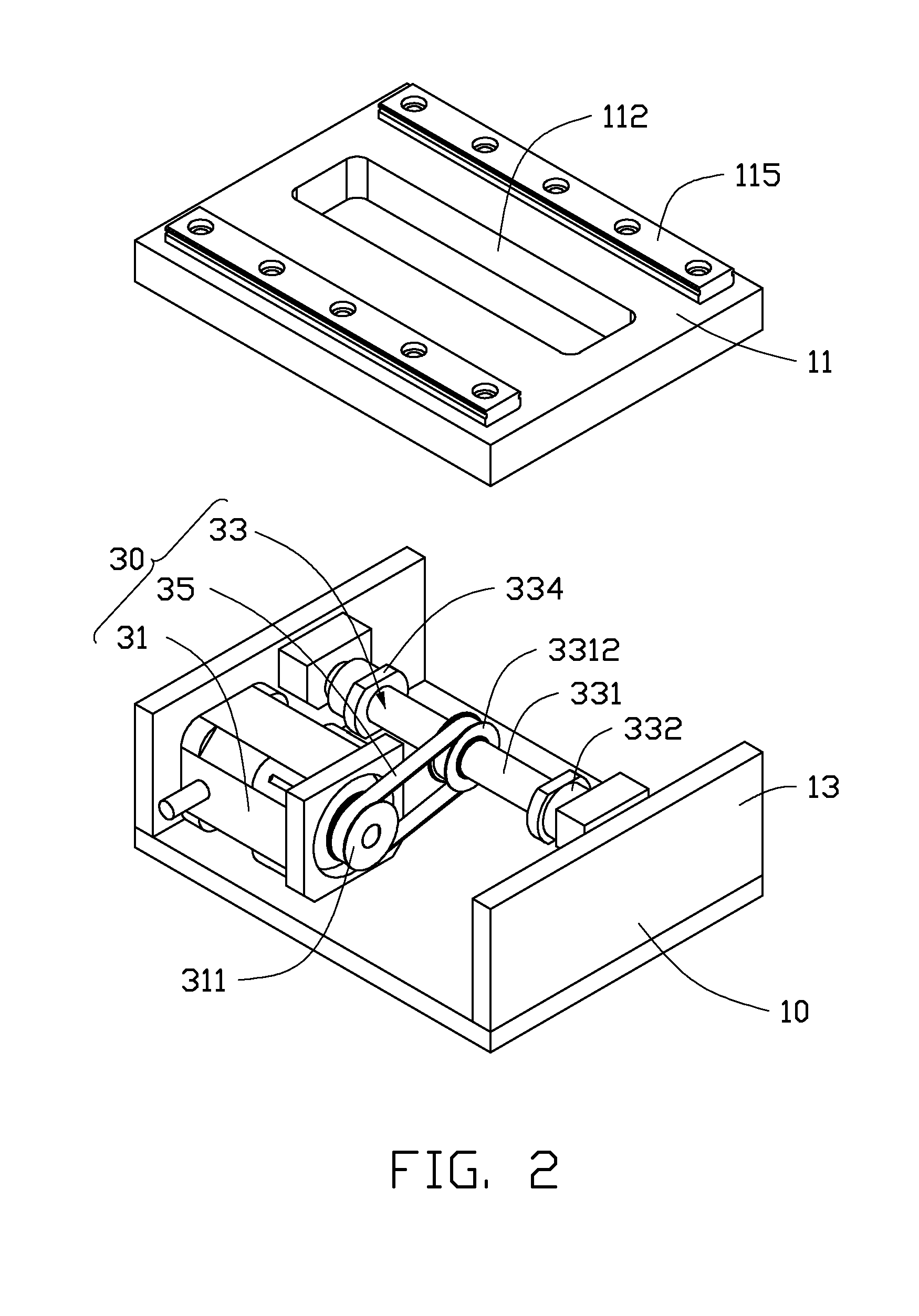

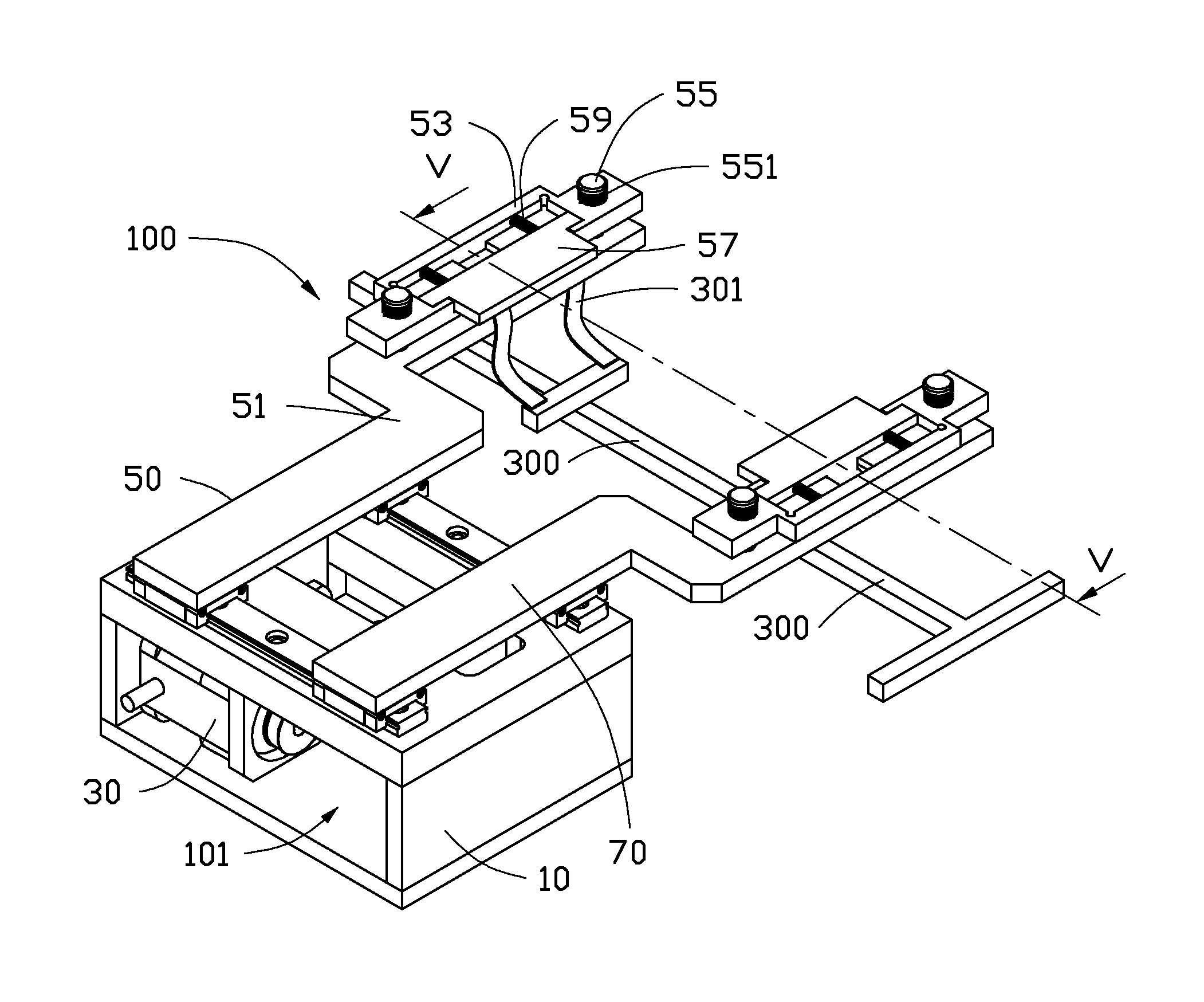

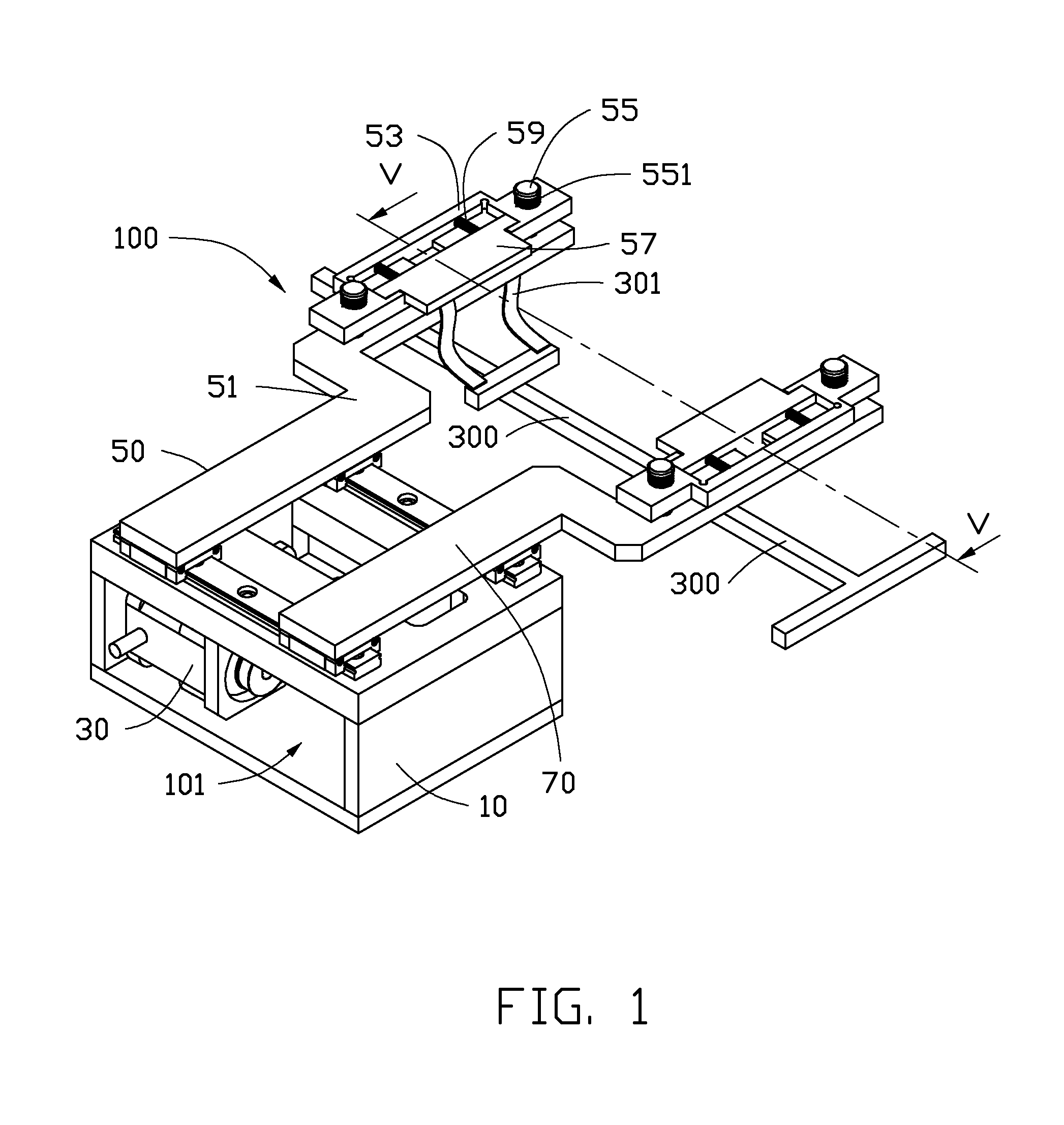

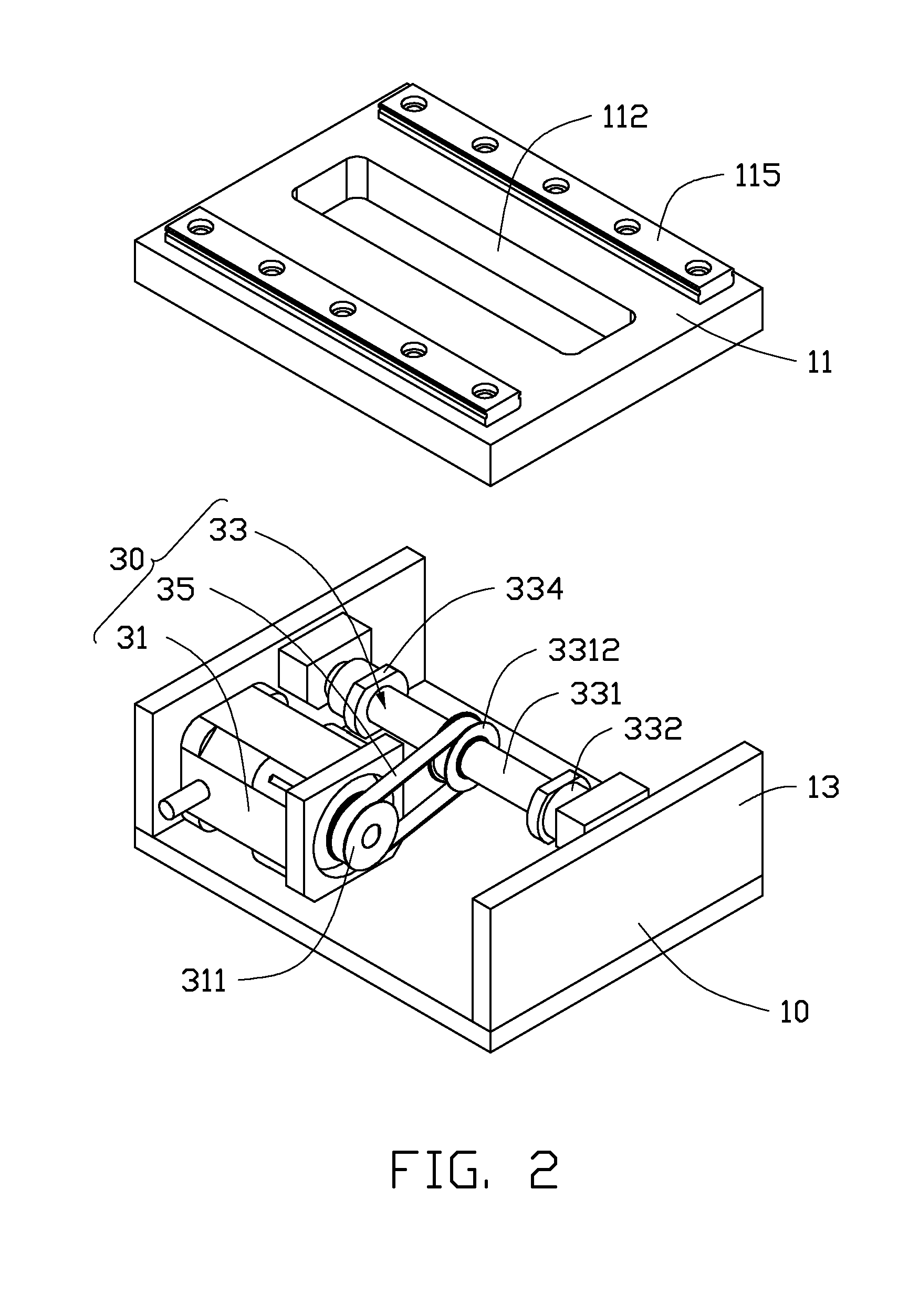

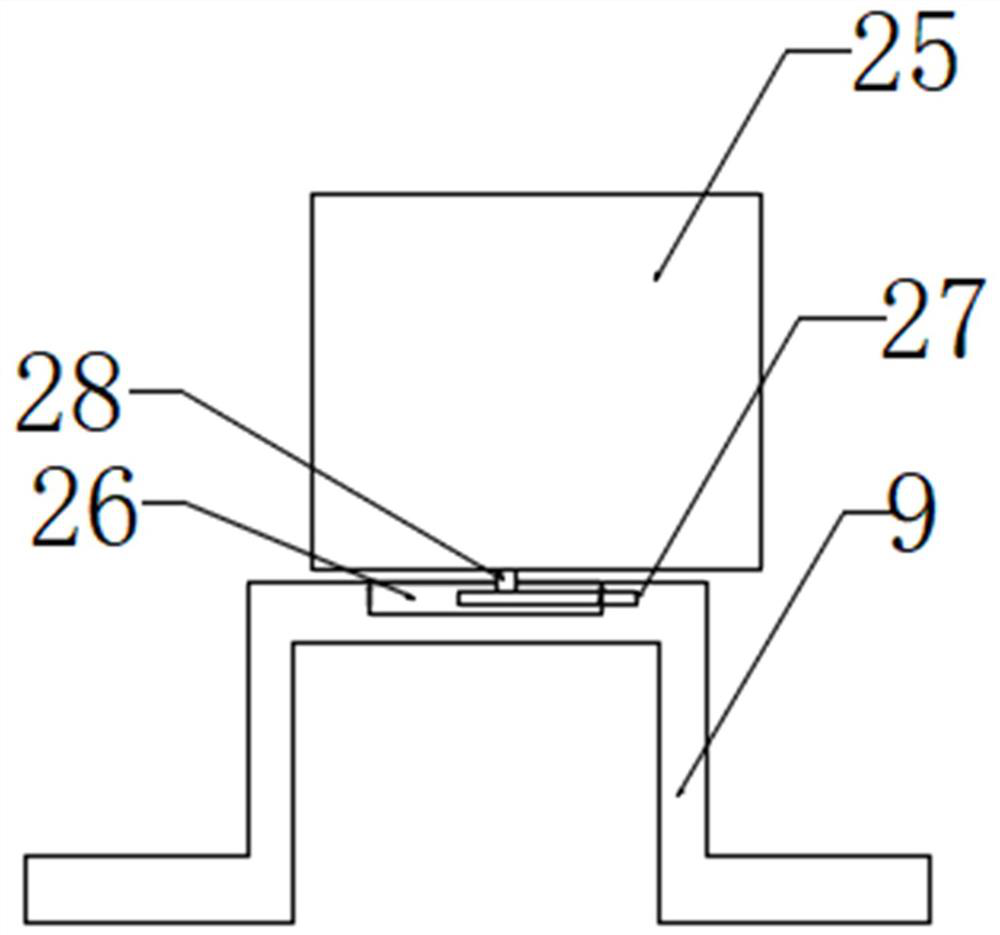

Clamping device

ActiveUS20140042761A1Easy scrapingElectrolysis componentsGripping headsMechanical engineeringPhysics

Owner:SHENZHENSHI YUZHAN PRECISION TECH CO LTD +1

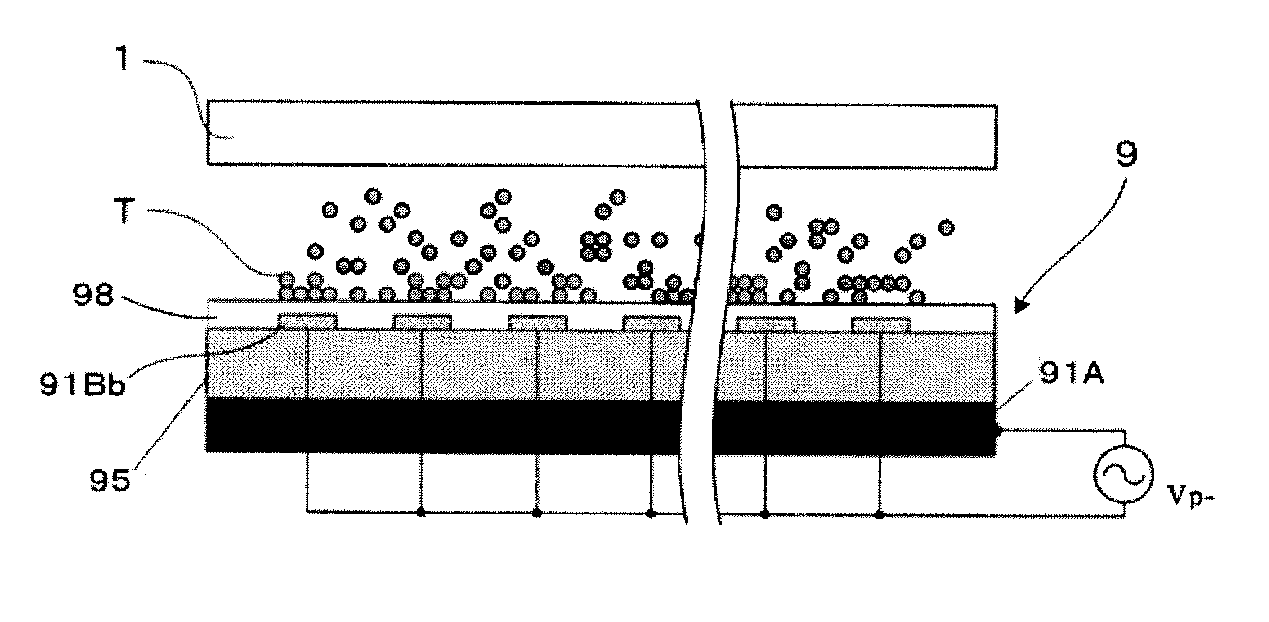

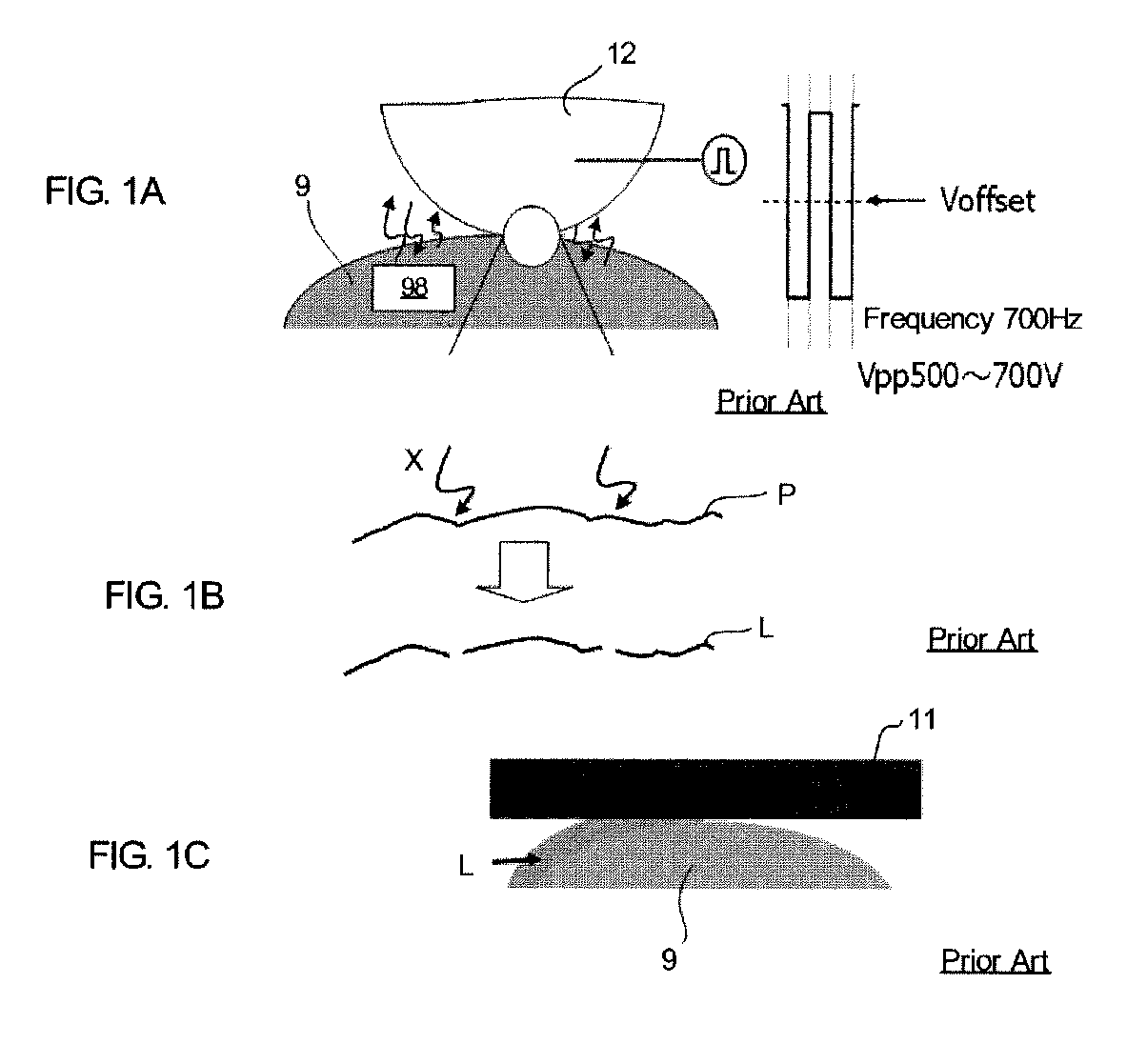

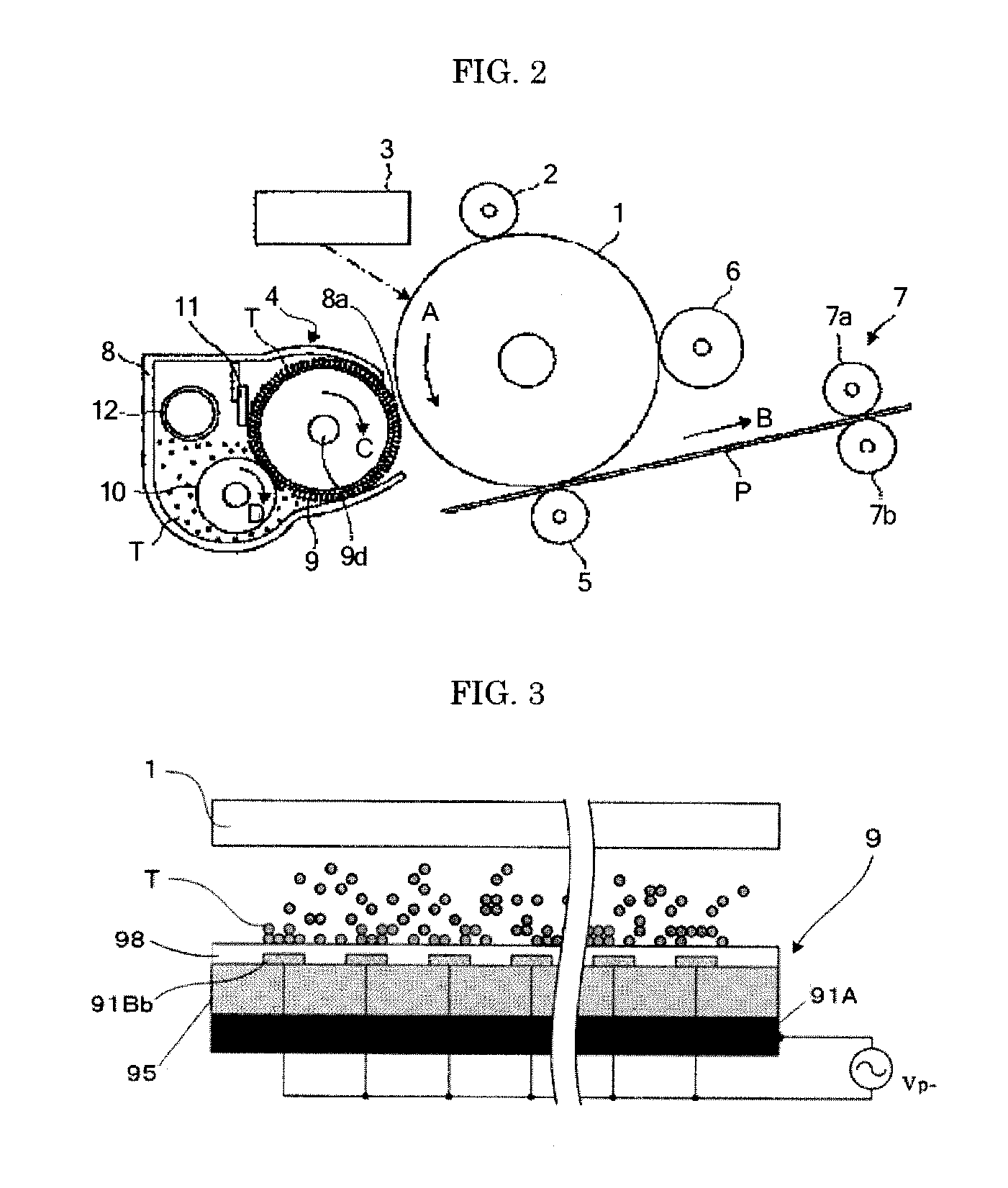

Toner bearing member, developing device, and image forming apparatus

InactiveUS20130064578A1Increased durabilityStable formElectrographic process apparatusSurface layerElectrical and Electronics engineering

To provide a toner bearing member, which contains: an electric conductive support; an insulating layer provided on the electric conductive support; a plurality of electrodes located on the insulating layer so that each electrode is separated from one another with a certain space; and a surface layer covering the insulating layer and the electrodes, wherein the surface layer contains a crosslink reaction product of a fluororesin, or a crosslink reaction product of a (meth)acrylate compound, or both thereof.

Owner:RICOH KK

Clamping device

ActiveUS8899649B2Easy scrapingElectrolysis componentsGripping headsEngineeringMechanical engineering

Owner:SHENZHENSHI YUZHAN PRECISION TECH CO LTD +1

Lens system for digital camera

A lens system (46) for a digital camera consecutively includes a first lens element (20), a second lens element (30), and a third lens element (40). The first lens element is biconvex and has a first aspheric surface (22) and an opposite second aspheric surface (24). The second lens element is concavo-convex and includes a third aspheric surface (32) and an opposite fourth aspheric surface (34). The third lens element convexo-concave and has a fifth aspheric surface (42) and an opposite sixth aspheric surface (44). The first lens element is made of glass, and the second lens element and the third lens are made of optical plastic.

Owner:HON HAI PRECISION IND CO LTD

Road crack sealing machine with self-cleaning function

InactiveCN110878511AScientific and reasonable structureEasy to useRoads maintainenceHelical bladeElectric machinery

The invention discloses a road crack pouring machine with a self-cleaning function. A cleaning assembly is mounted in the asphalt hot melting box. A second cleaning pipe is mounted in the first cleaning pipe in a sliding manner. A water inlet pipe sleeves the top end of the connecting pipe. A discharging assembly is mounted at one end of the asphalt pipe. An output shaft of the motor is connectedwith a polytetrafluoroethylene helical blade. A scraping assembly is mounted on one side of the limiting frame. A scraping plate is embedded in the middle of the scraping groove; after being used. After the machine is used, the first cleaning pipe and the second cleaning pipe are drawn out. The first cleaning pipe and the second cleaning pipe are close to the inner wall of the asphalt hot meltingbox, to scrape asphalt. The introduced cleaning liquid is sprayed out from the edges of the first cleaning pipe and the second cleaning pipe. The machine is convenient to clean. The first cleaning pipe and the second cleaning pipe are contained in the mounting pipe during work, normal use is not hindered, more asphalt is fed into gaps through extrusion of the rotating polytetrafluoroethylene spiral blades, the joint sealing effect is better, and the strength of the asphalt in the gaps is higher.

Owner:长兴展鹏五金有限公司

Novel paint scraping off device for paint production

PendingCN110076159AEasy to adjust controlEasy scrapingHollow article cleaningArchitectural engineeringPre treatment

Owner:ANHUI LINGYANG NEW MATERIAL CO LTD

Wave power station

A wave power station for conversion and storage of energy from waves in an ocean or a sea includes a wave energy absorbing unit including a first floating body connected to a vertically hanging counterweight via a drive line and a drive wheel, a power generating unit including at least one power generation unit for conversion of wave energy, connected to a drive shaft, and a power accumulating unit including at least one power accumulator for storage of generated wave power. The power generating unit and the power accumulating unit are arranged in a second floating body firmly anchored under the first floating body to the ocean bed or sea bed. The drive line is connected to the at least one power generation unit via the drive wheel, and a coupling and transmission unit arranged on the drive shaft for driving of the at least one power generation unit via the up and down movements of the drive line in time with the wave movements.

Owner:OLCON ENG

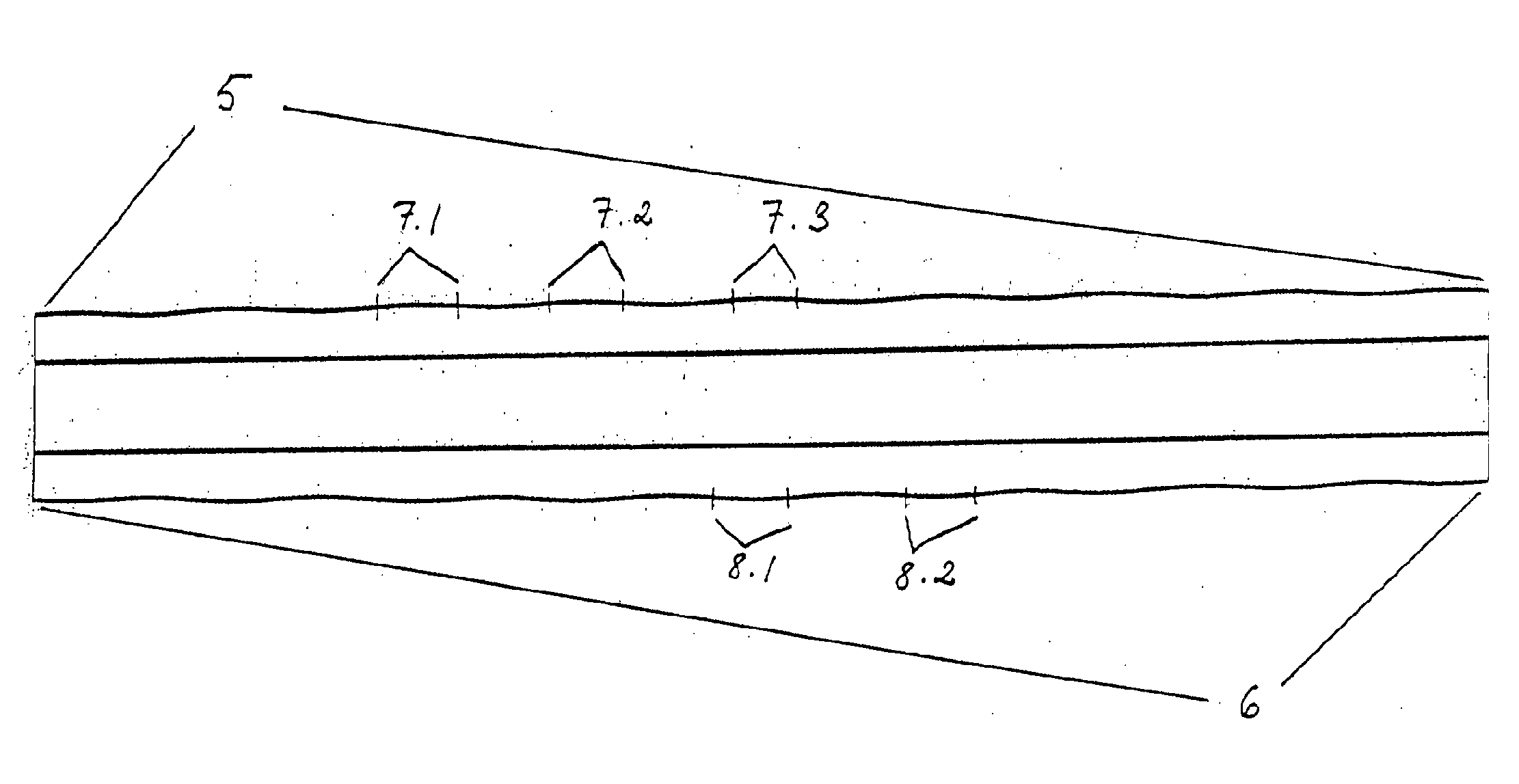

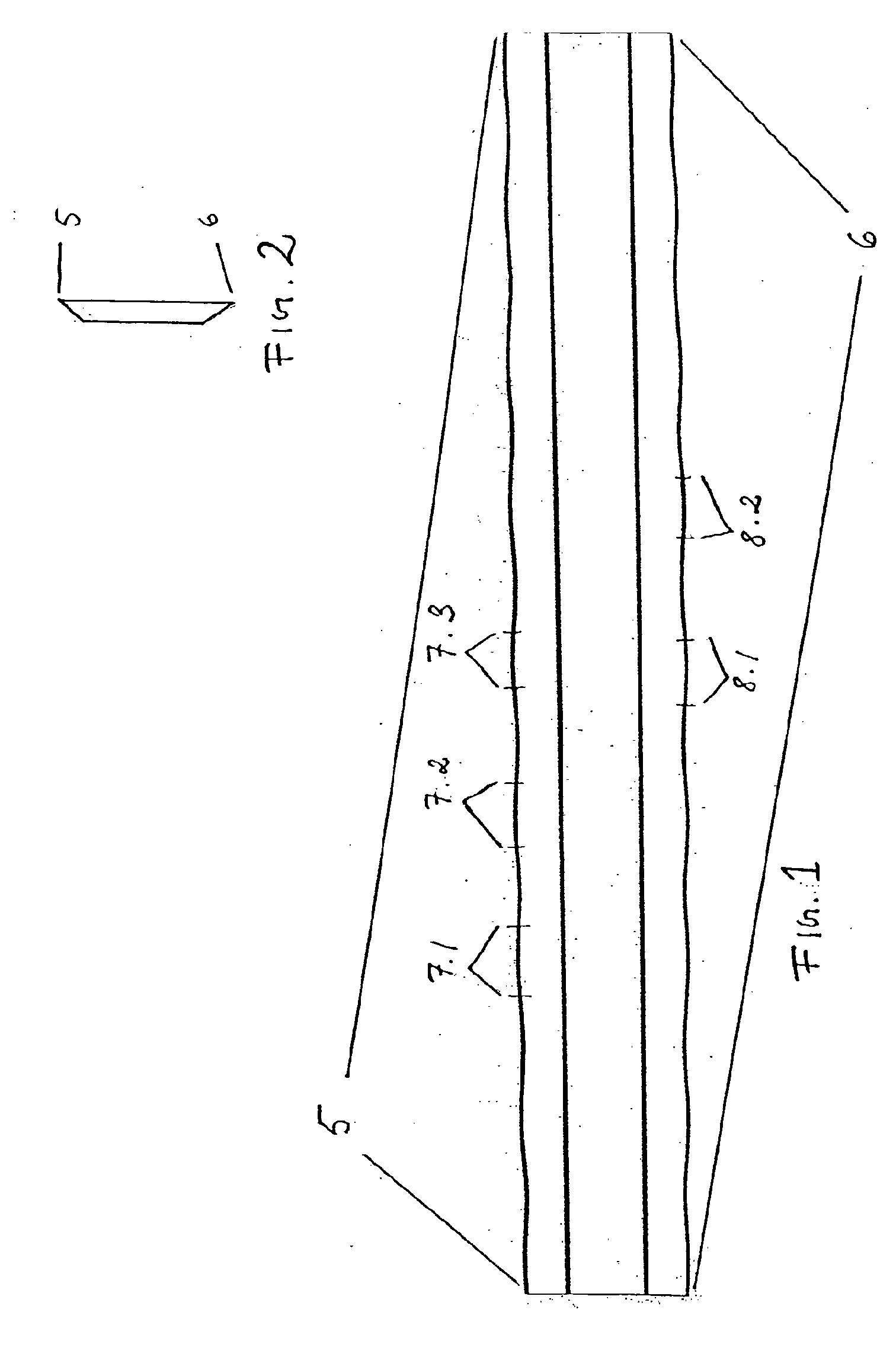

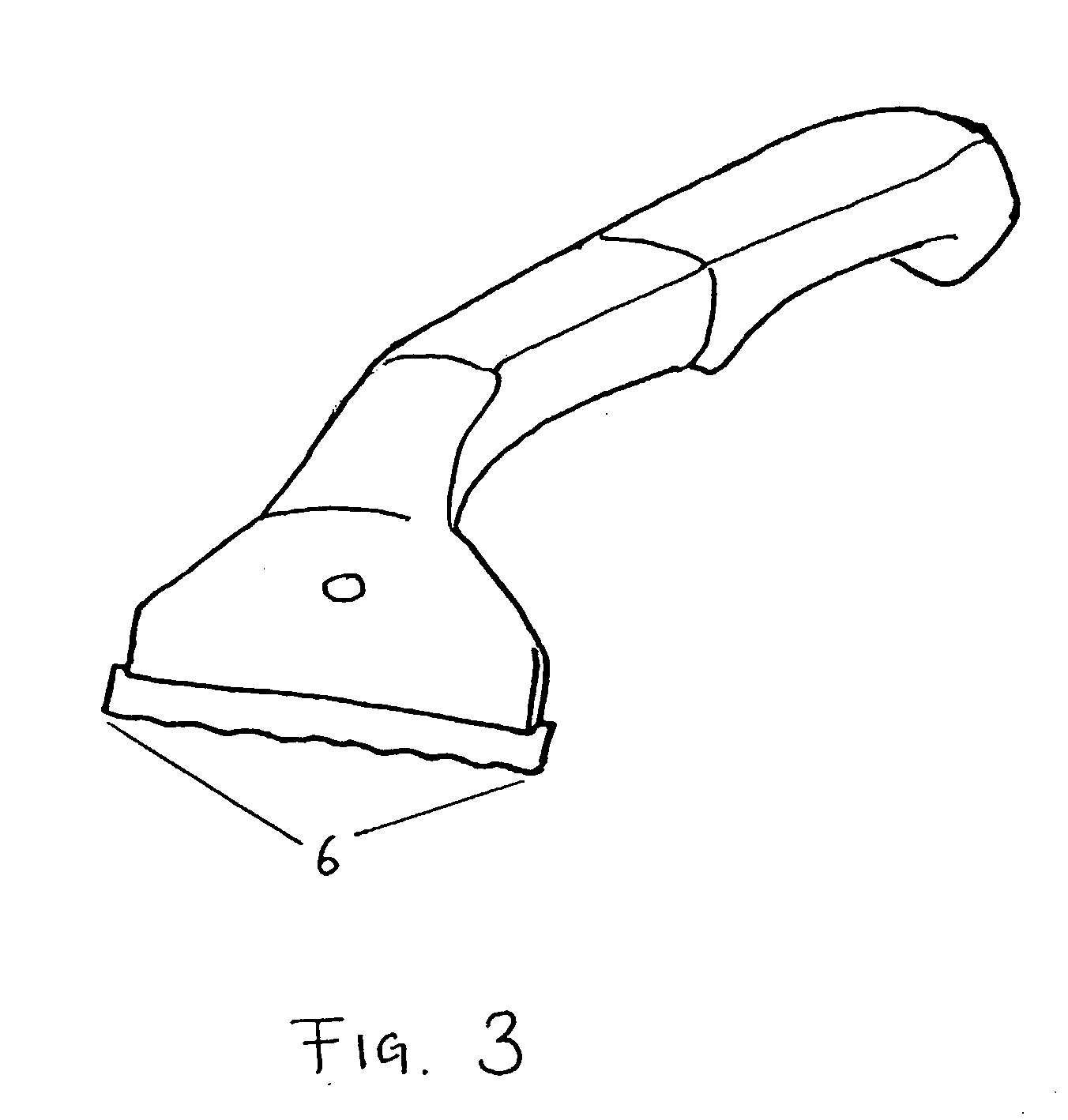

Scraping Blade For Paint Scraper Intended For Removing Paint

InactiveUS20070209136A1Less forceGood effectLiquid surface applicatorsCarpet cleanersScraping - actionEngineering

A scraper blade for a paint scraper intended for removing paint from a surface includes at least one scraping edge. The scraping edge is divided into at least two abutting portions extending along the scraping edge, which, upon abutting scraping action, extend transversely to the direction of scraping, each abutting portion being convex in the plane of the scraping edge, whereby an effective scraping effect is provided.

Owner:KAPMAN

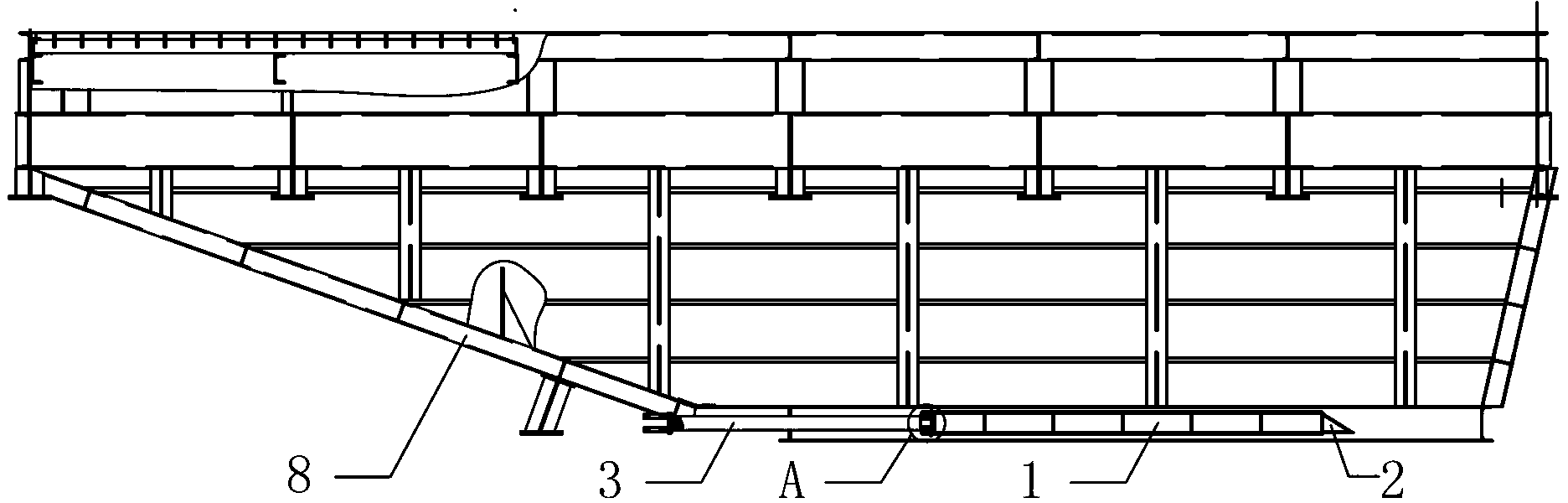

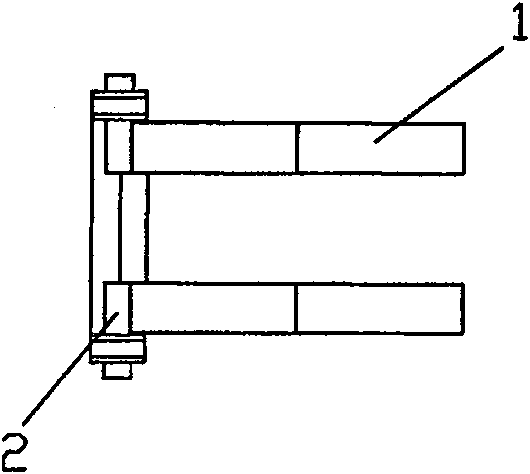

Hydraulic slide frame at bottom of sludge bin

InactiveCN103264852ASimple and durable structureEasy scrapingLarge containersHydraulic cylinderSludge

The invention provides a hydraulic slide frame at the bottom of a sludge bin. The hydraulic slide frame is mainly used for scraping sludge in the sludge bin during industrial processing for the sludge. The hydraulic slide frame comprises a frame. The frame is arranged at the bottom of the sludge bin, a wedge-shaped scraper is arranged at one end of the frame, and a connecting shaft is arranged at the other end of the frame and penetrates out of the sludge bin to be connected with a hydraulic cylinder. The hydraulic slide frame has the advantages that the hydraulic slide frame is simple and durable in structure and cannot be damaged easily, and the sludge can be scraped conveniently by the hydraulic slide frame.

Owner:ZHEJIANG ZOKSEN ENVIRO ENERGY EQUIP

Internet of Things oil-water separator

InactiveCN111068399AImprove filtering effectAvoid affecting the separation effectLiquid separationFiltration circuitsOil waterOil–water separator

The invention relates to the technical field of Internet of Things. The invention further discloses an Internet of Things oil-water separator comprising a fixed base; a water pump is fixedly mounted on one side of the upper end of the surface of the fixed base; wherein two supporting frames are fixedly mounted on one side of the upper end of the surface of the fixed base; a filtering tank and a separation tank are fixedly mounted at the middle positions of the two supporting frames; a discharging pipe is mounted in the middle of the lower end of the filtering tank; one end of the discharging pipe is fixedly connected with the water pump; the other end of the water pump is fixedly connected with the separation tank through a connecting pipe; a water collecting tank is fixedly mounted on oneside of the upper end of the surface of the fixed base; a water outlet pipe is fixedly installed on one side of the water collecting tank, one end of the water outlet pipe is fixedly connected with the lower end of the separation tank, an oil collecting tank is fixedly installed at the upper end of the water collecting tank, an oil outlet pipe is fixedly installed at one end of the oil collectingtank, and through arrangement of the filtering tank and the separation tank, the whole device has a very good oil-liquid separation effect.

Owner:徐州普瑞赛思物联网科技有限公司

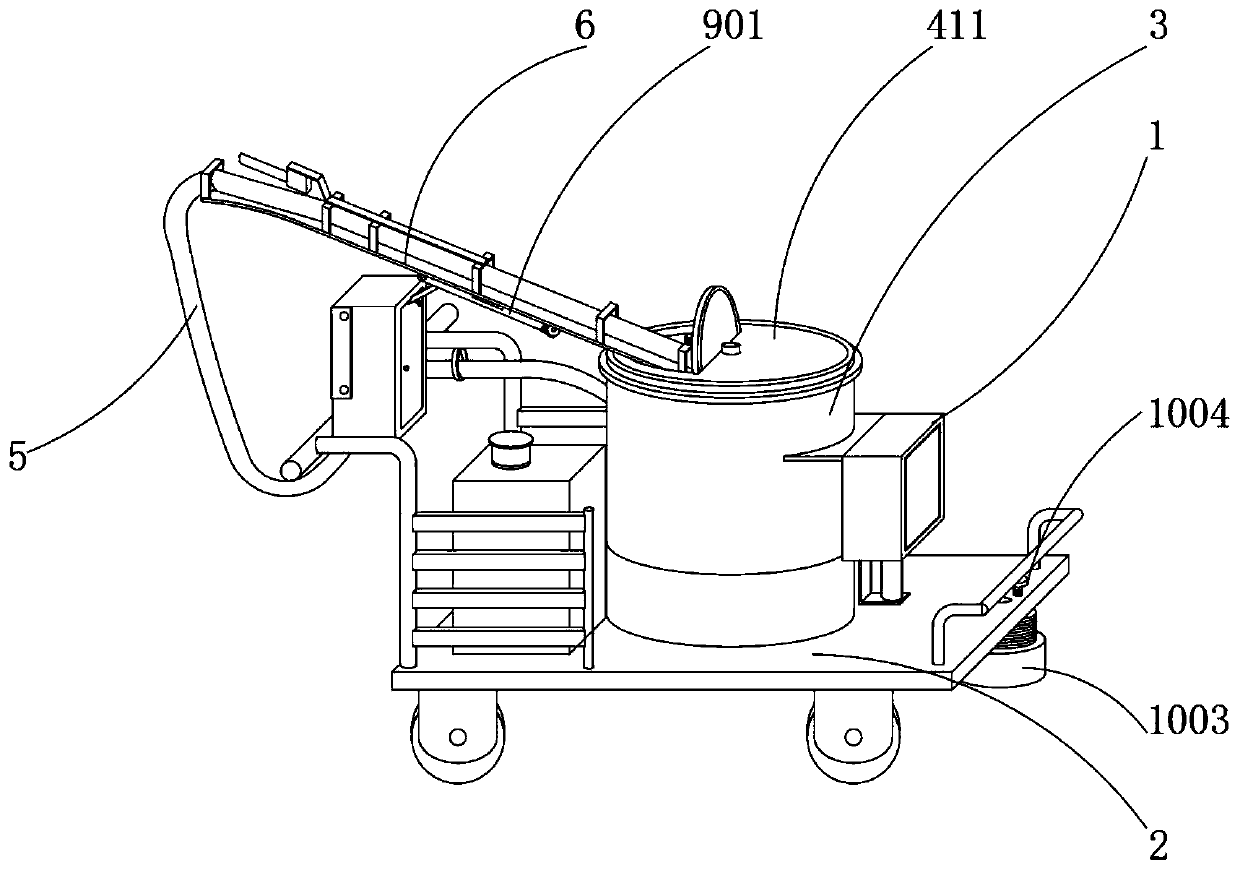

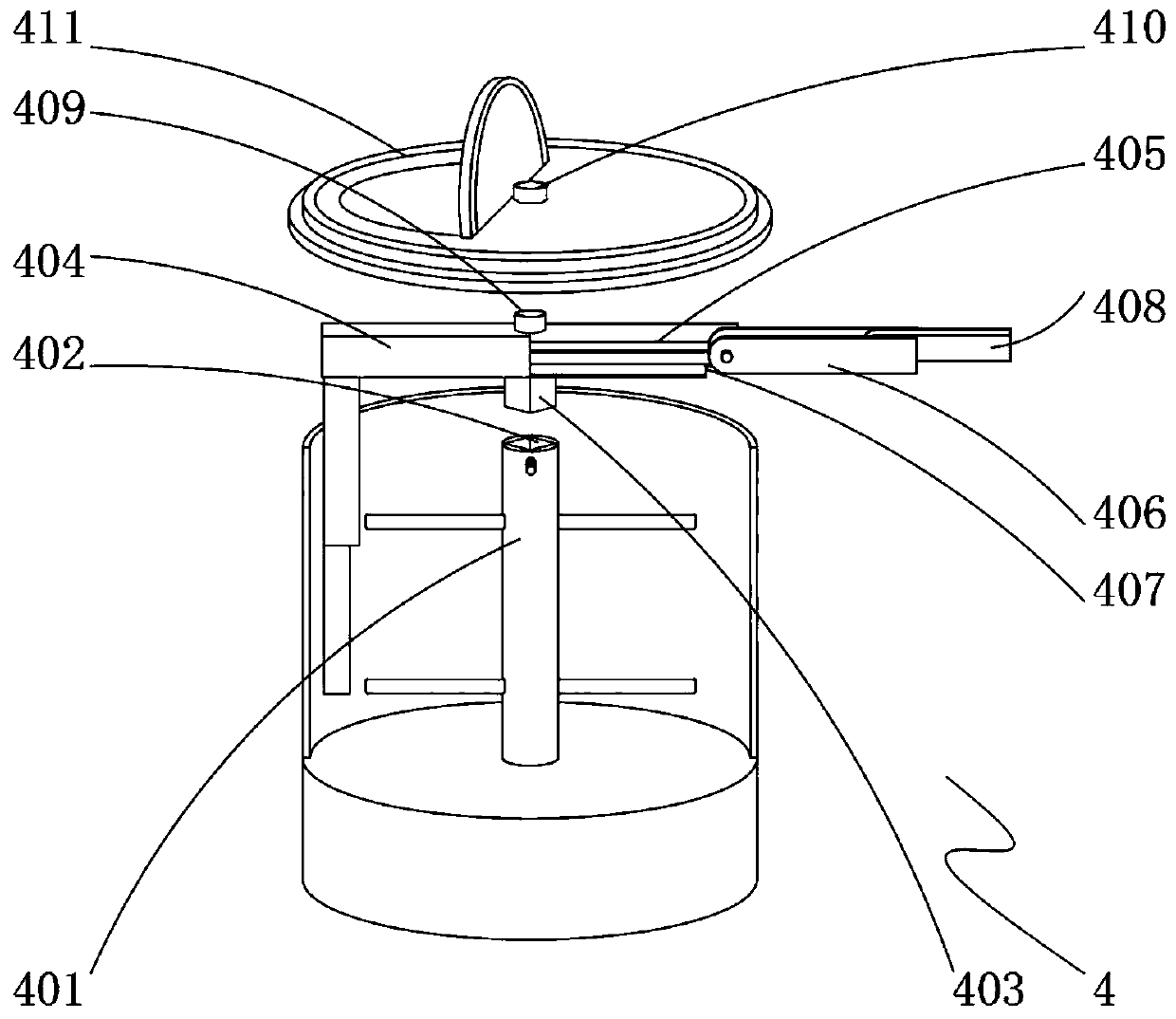

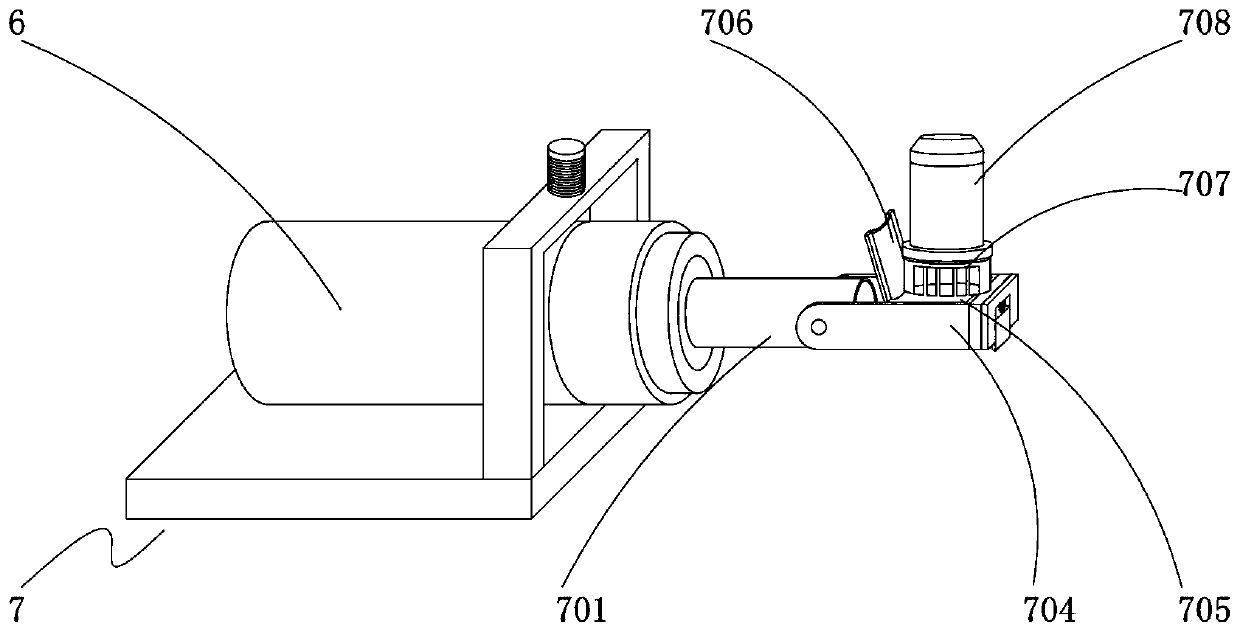

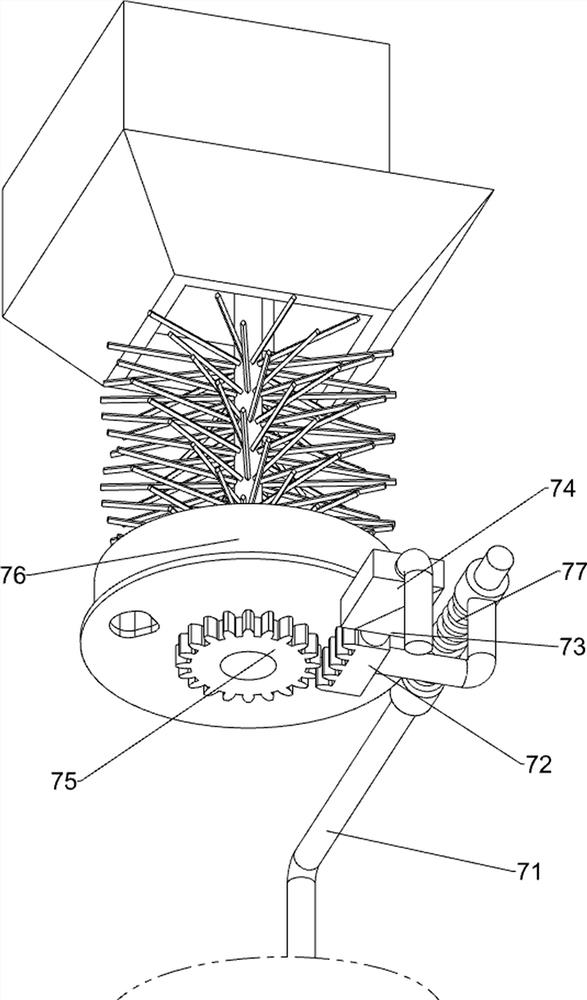

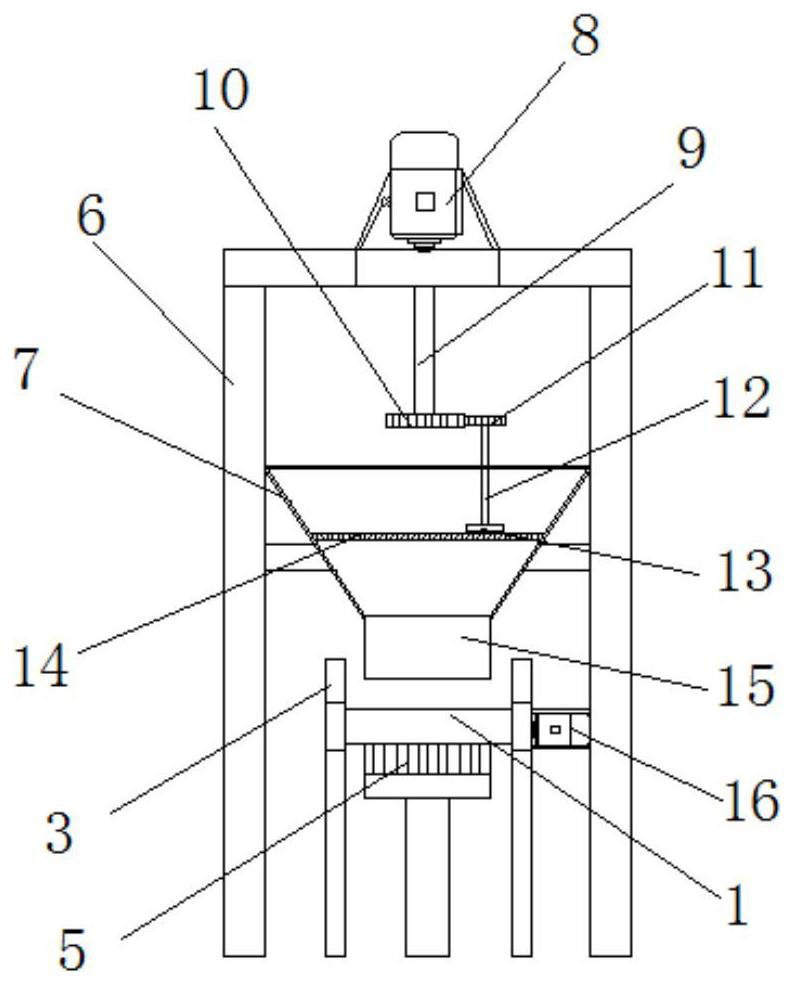

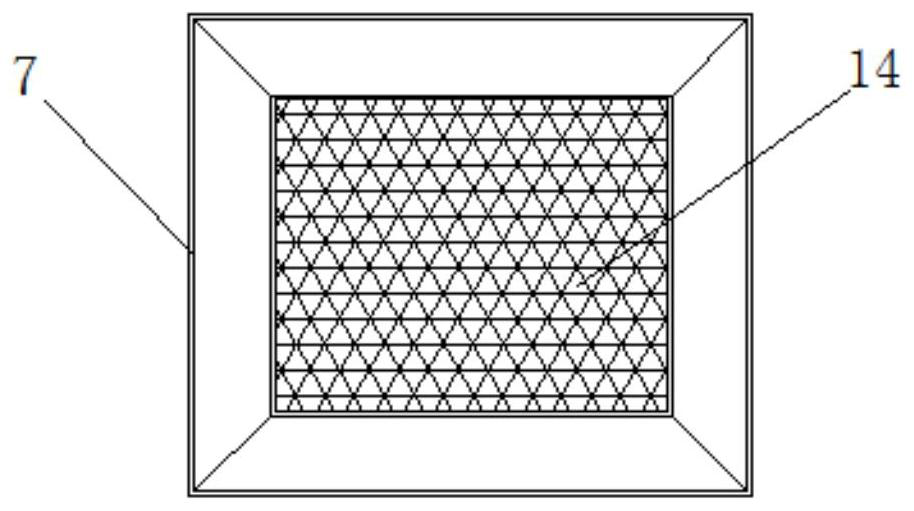

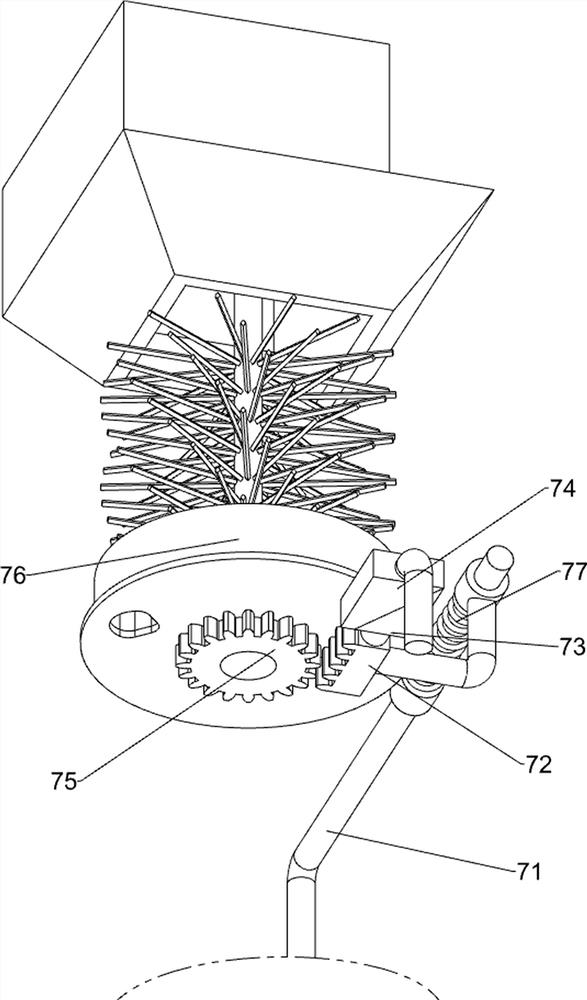

Quick meat pie soup making machine for food processing

ActiveCN112616894AEasy to operateRealize intermittent feedingMeat processing devicesProcess engineeringMincing

The invention relates to a meat pie soup making machine, in particular to a quick meat pie soup making machine for food processing. The quick meat pie soup making machine for food processing, which can be used for carrying out secondary mincing on meat and can realize indirect discharging is provided. The quick meat pie soup making machine for food processing comprises a base, a mincing mechanism and a scraping mechanism, wherein the mincing mechanism is arranged in the middle of the top of the base; and the scraping mechanism is arranged at the bottom of the mincing mechanism. According to the quick meat pie soup making machine for food processing, a worker starts an air cylinder to enable a mincing knife to continuously move up and down to fully mince meat, then a sliding bearing plate is pulled forwards to enable the meat in a bearing mechanism to fall off, and the operation is simple; when a stirring cutter continuously rotates clockwise and anticlockwise, the meat can be subjected to secondary mincing, so that the mincing effect is improved; and when a liftable horizontal moving and clamping plate moves outwards and moves upwards at the same time, bowls in a storage frame are loosened, the minced meat is contained, and intermittent discharging is achieved.

Owner:中芝堂药业(山东)有限公司

Beneficiation process of skarn type magnetite containing copper and gold

The invention discloses a beneficiation process of skarn type magnetite containing copper and gold. The beneficiation process of the skarn type magnetite containing copper and gold comprises the following steps that firstly, the dimension of ores is made to reach less than 12mm through three-stage closed-circuit crushing, sorting is conducted through a permanent magnet wet magnetic separator, magnetic separation concentrates directly enter a ball mill, and magnetic separation tailings enter a linear vibrating screen to be screened; secondly, bulk flotation is performed after ore grinding to obtain copper-sulfur bulk concentrates, and the copper-sulfur bulk concentrates are subjected to copper-sulfur separation to obtain qualified copper concentrates and sulfur concentrates; and thirdly, the bulk flotation tailings enter a one-roughing two-concentration one-scavenging magnetic separation process to obtain qualified iron ore concentrate products. According to the beneficiation process ofthe skarn type magnetite containing copper and gold, after the ores are crushed, special metal distribution with a low copper grade in non-magnetic ores in coarse fraction is fully utilized, a pre-selection process before grinding is added, discarded waste coarse particles can be sold as building materials to generate economic benefits, and meanwhile, the grinding and separation cost and the tailing treatment cost of the discarded waste coarse particles are reduced; and fine-fraction materials in the non-magnetic materials do not enter the ball mill any more.

Owner:安徽太平矿业有限公司

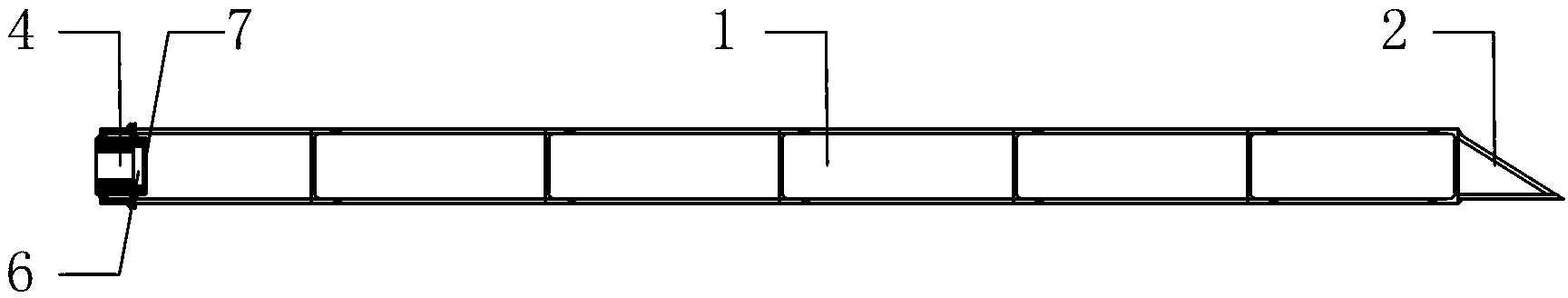

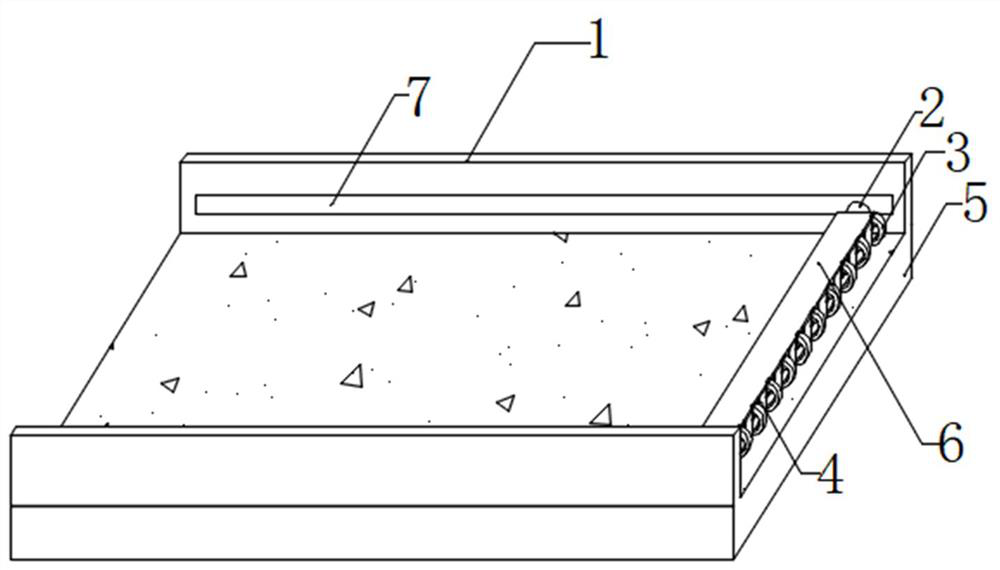

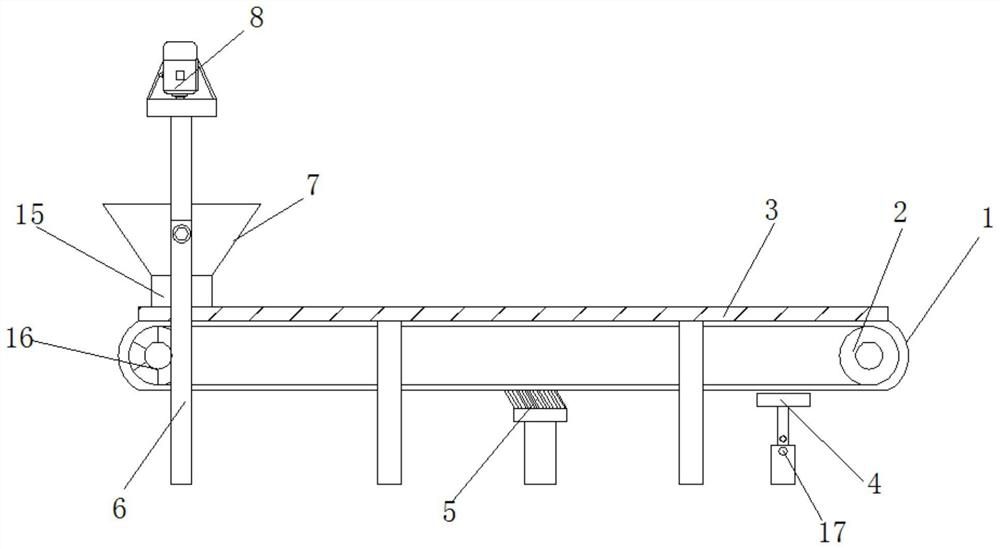

Rice flour conveying equipment for rice flour processing

The invention discloses rice flour conveying equipment for rice flour processing. The rice flour conveying equipment comprises a conveying belt body and a material baffle, wherein a transmission shaftis arranged in the conveying belt body, a conveying transmission motor is arranged at the left side of the transmission shaft, the material baffle is arranged above the conveying belt body, and a material scraping plate is arranged below the conveying belt body; and a telescopic adjusting supporting rod is arranged below the material scraping plate, a material removing brush is arranged at the left side of the material scraping plate, a driving gear is arranged below a rotating rod, a driven gear is arranged on the surface of the driving gear, a material mixing column is arranged below the driven gear, and an anti-blocking brush is arranged below the material mixing column. The rice flour conveying equipment for rice flour processing is provided with the material removing brush, attachments which are not scraped off on the surface of the conveying belt body can be cleaned again, so that the attachments on the conveying belt body can be thoroughly removed; and meanwhile, the material removing brush is arranged to be a brown brush, and a material is soft, so that scratches cannot be caused to the surface of the conveying belt body.

Owner:常德市源宏食品有限责任公司

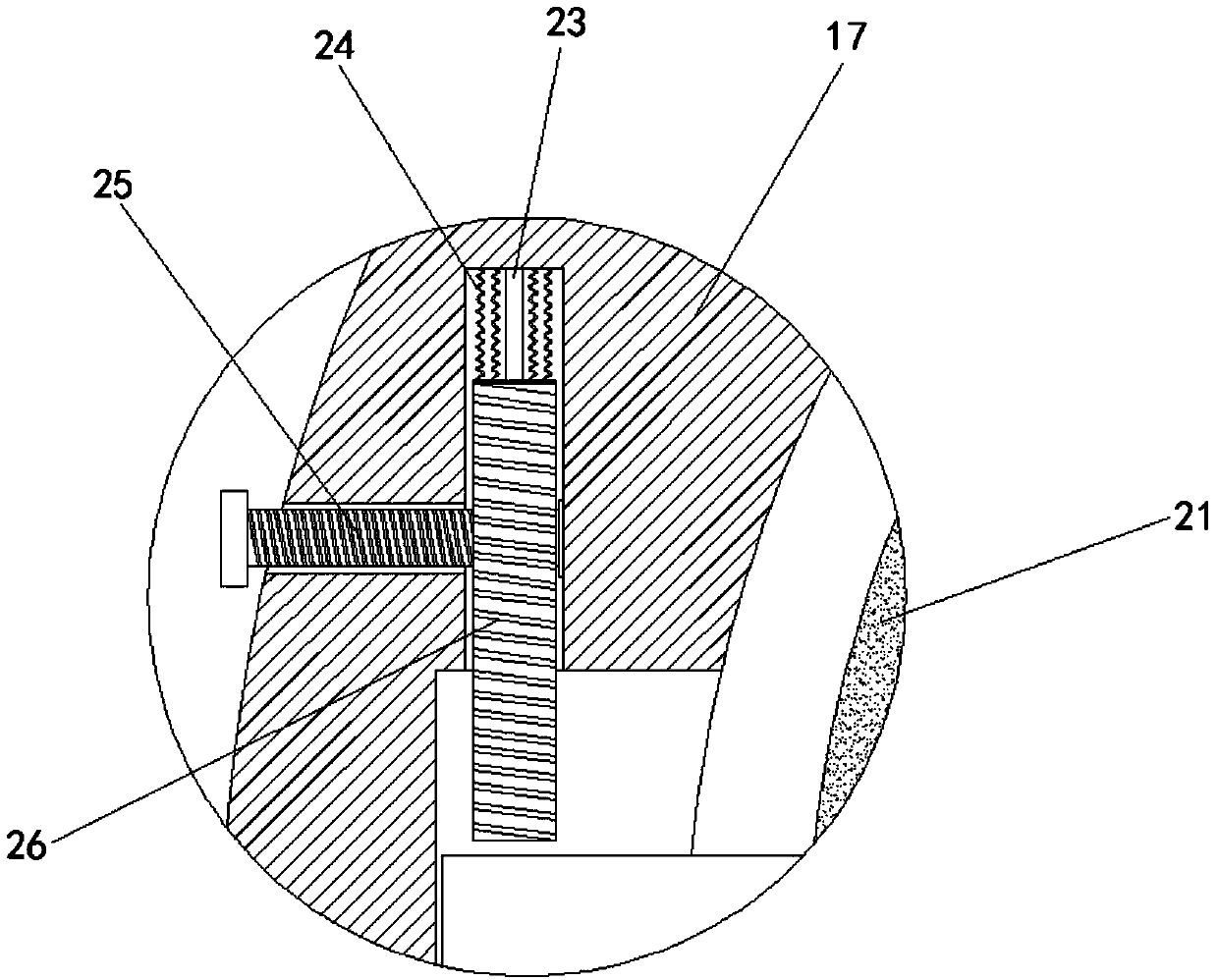

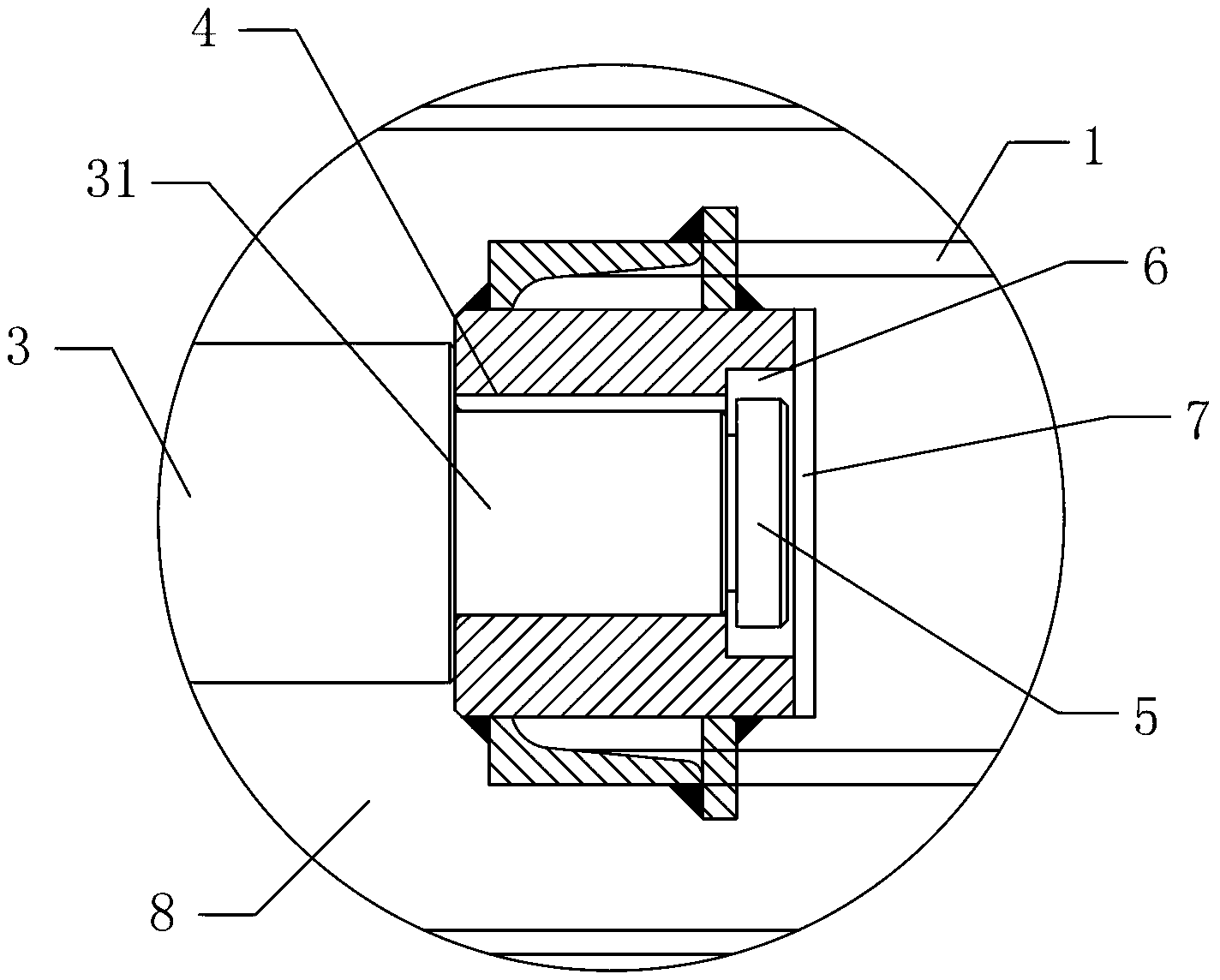

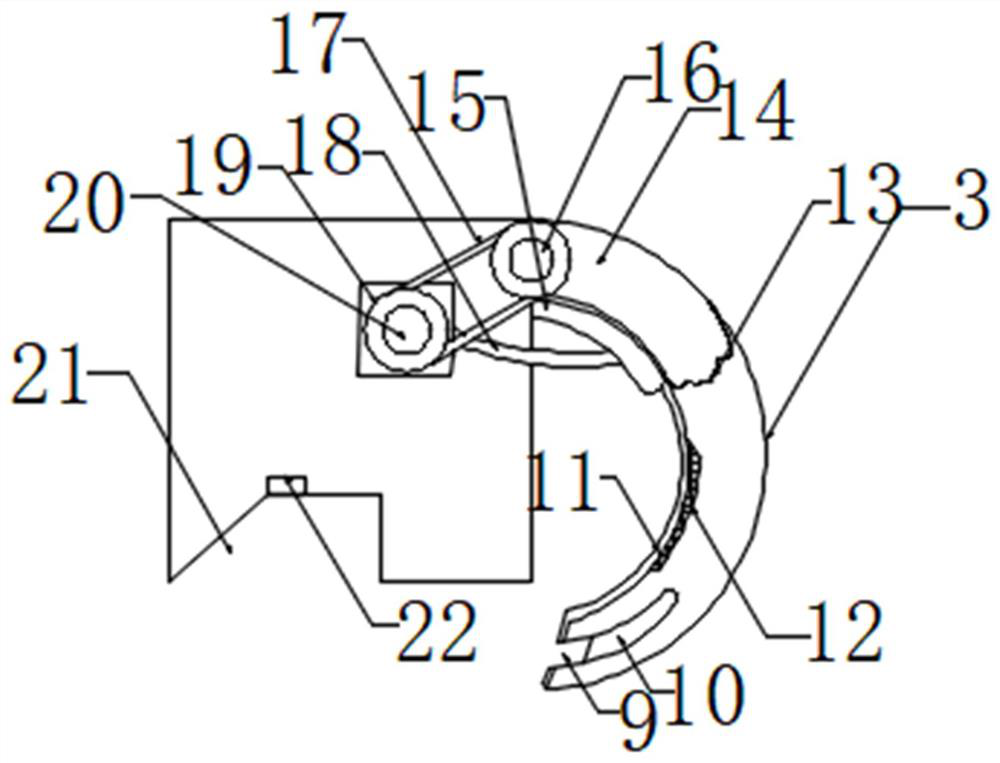

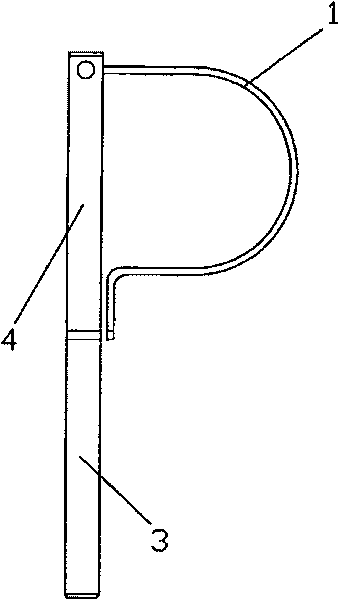

Polyethylene tube scale scraper

The invention relates to a peeling device for once eliminating an oxidizing layer on the outer surface of the end part of pipes, aiming to provide a peeler for qualitatively eliminating the polyethylene pipe oxidizing layer on the outer surface of pipes more convenient and efficient and faster. The peeler for eliminating the polyethylene pipe oxidizing layer comprises a knife tool, which is characterized in that the peeler also comprises an underframe and a fixed bracket; wherein, the fixed bracket comprises an arc slot, the fixed bracket is fixed and connected with the underframe in a detachable way, the underframe is provided with the knife tool and the blade direction of the knife tool parallels the axial direction of the arc slot. The peeler for eliminating the polyethylene pipe oxidizing layer has the advantages that the linear contact between the knife tool and the pipe surface can evenly and effectively eliminate the oxidizing layer on the surface of pipes; the peeling depth canbe adjusted by regulating the screwing depth of a tightening screw and the oxidizing layer can be easily eliminated by manually rotating a spanner; the quality of the pipe surface after being peeledcan be effectively controlled; the peeling device also has the advantages of simple structure, easy production and practicality.

Owner:ZHEJIANG UNIV

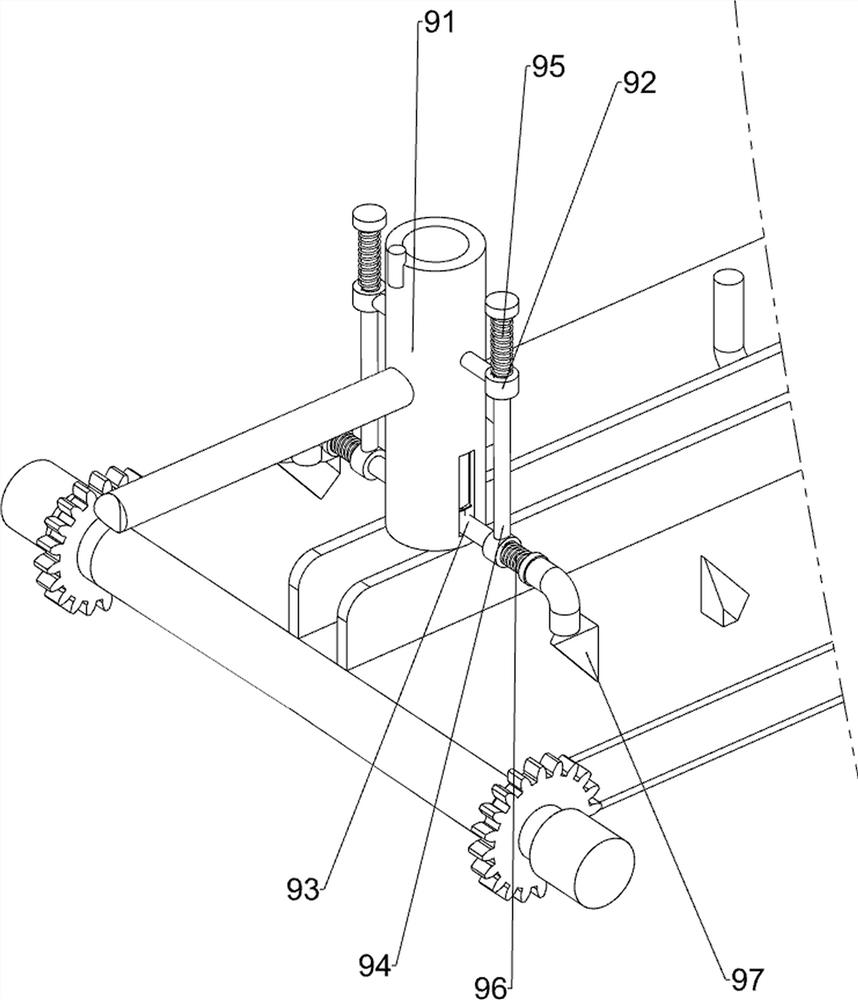

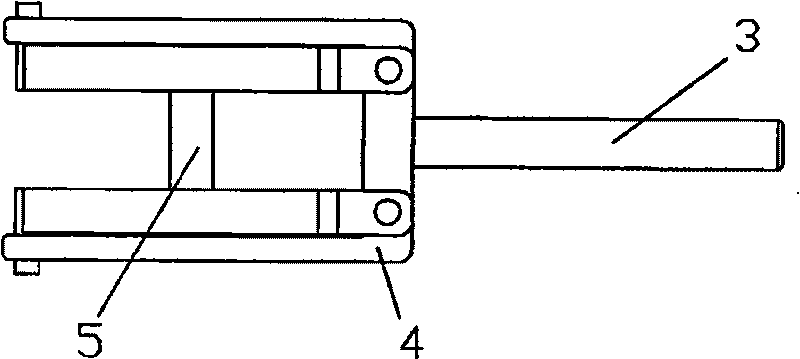

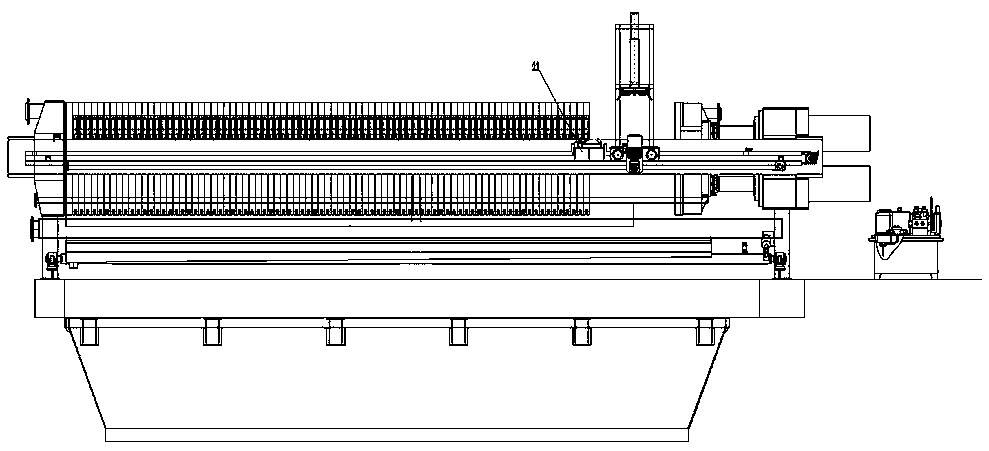

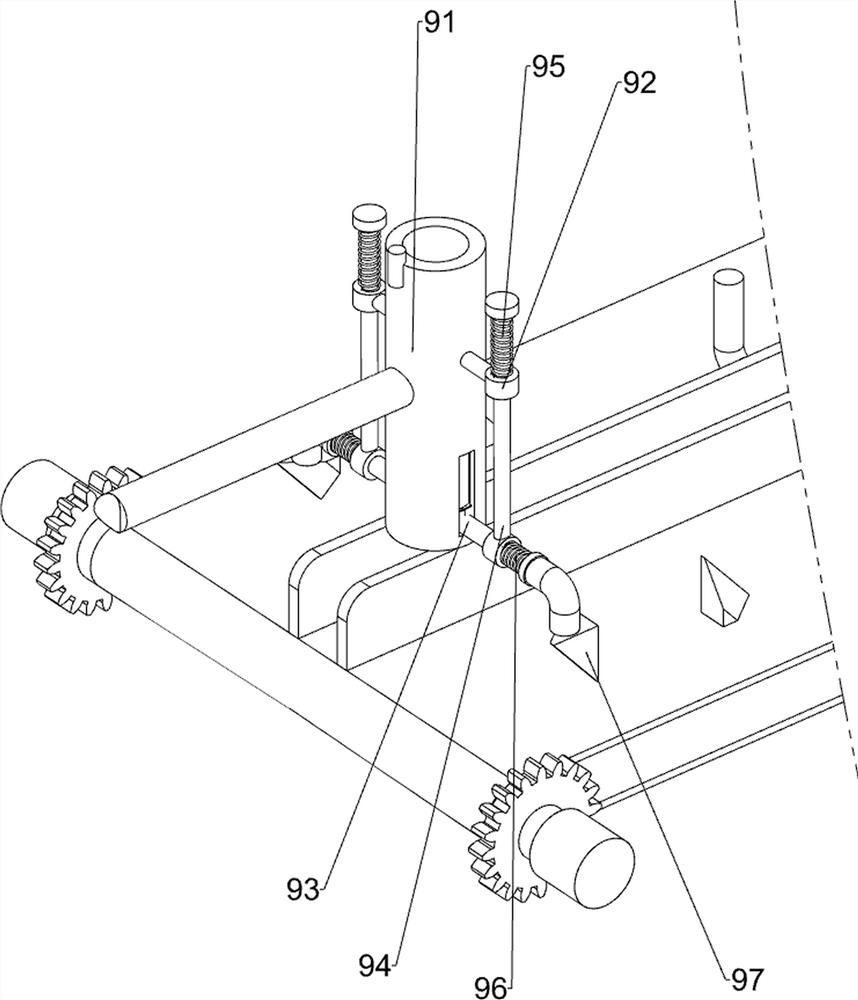

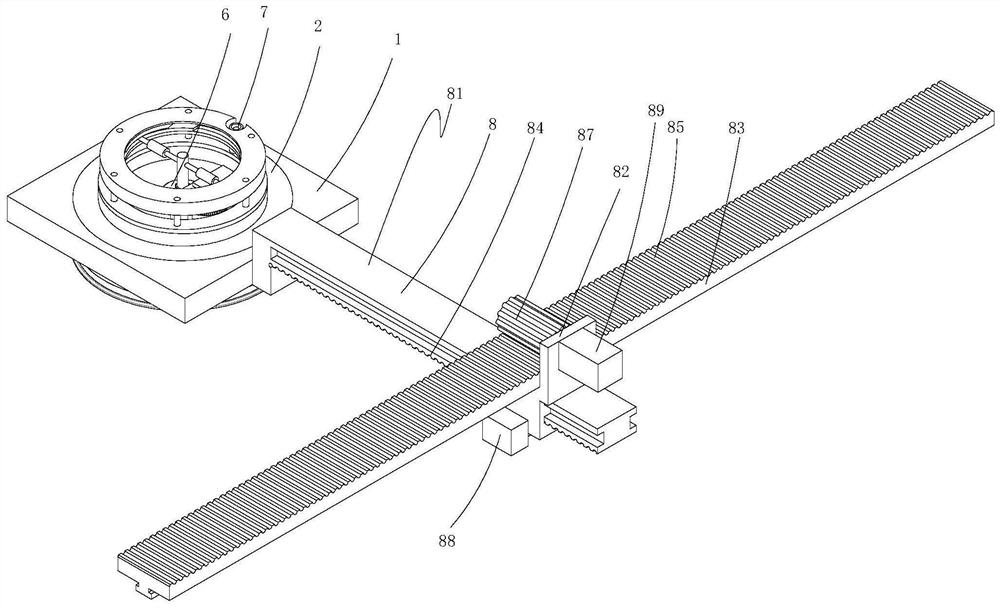

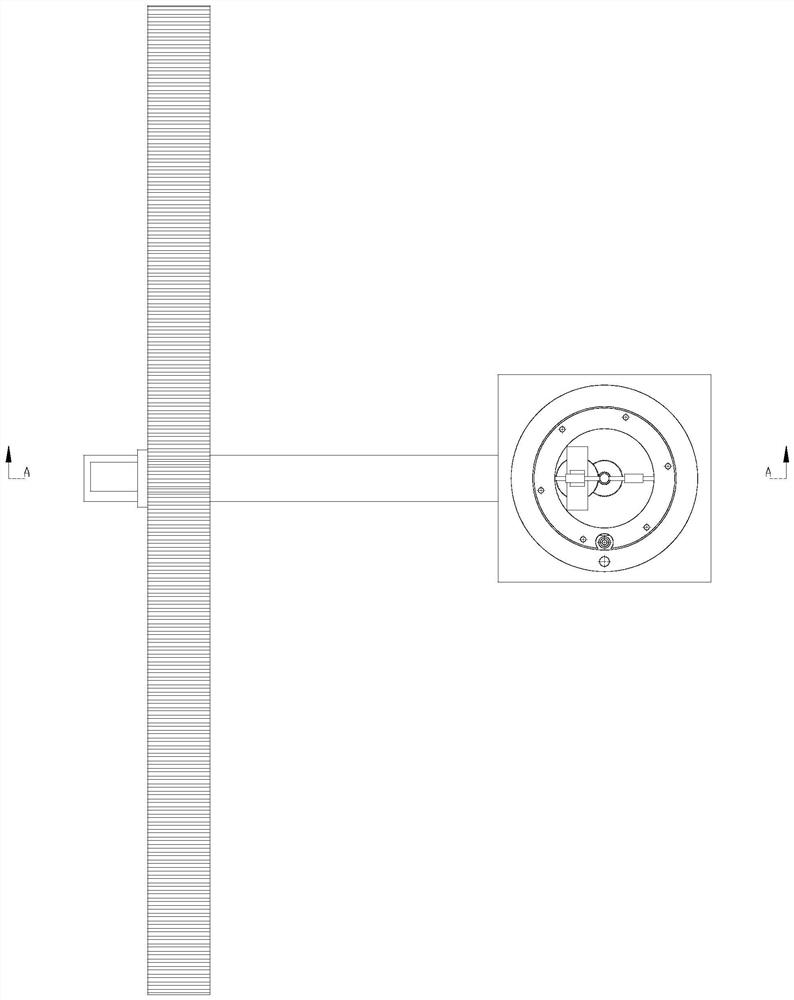

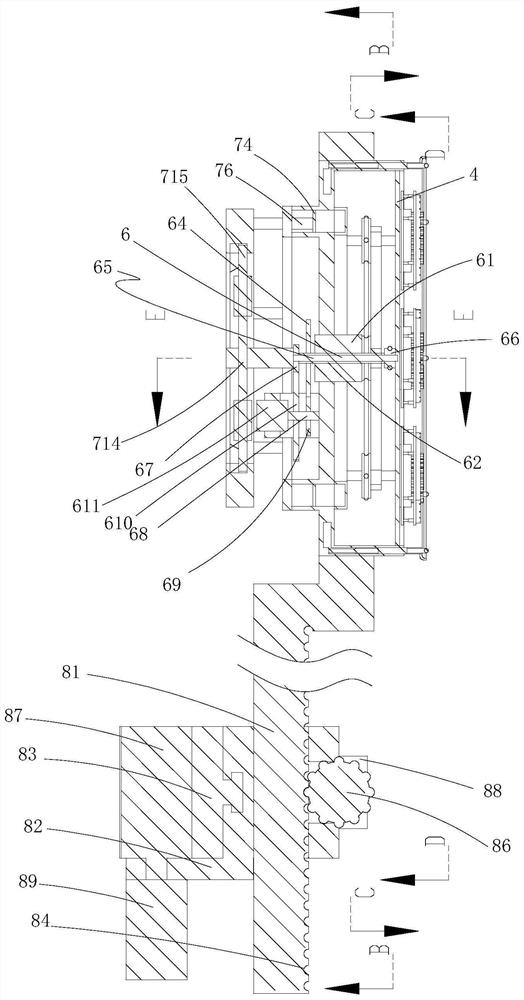

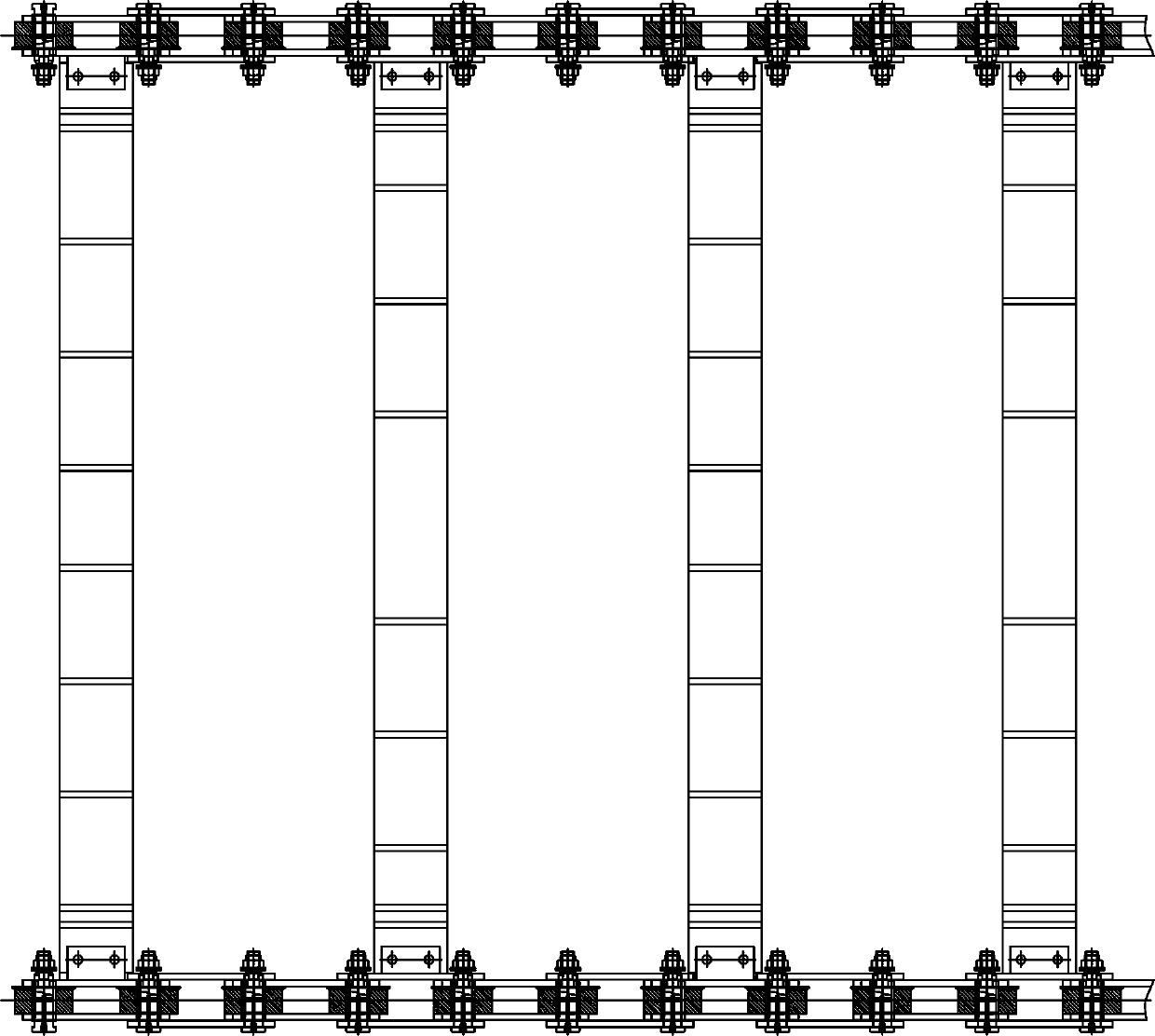

Scraping device for filter press

PendingCN111589202AScrape achievedImprove work efficiencyFiltration separationGear wheelElectric machinery

The invention provides a scraping device for a filter press. An upper cylinder is mounted on the frame; the bottom of the upper cylinder is connected with a bottom plate; a scraping plate is mounted on the bottom plate; a walking mechanism is connected to a frame connecting plate installed on the frame lower stand column; a bracket of the walking mechanism comprises an inverted U-shaped structureand a hanging plate; roller connecting shafts are connected to side plates at the two ends of the inverted U-shaped structure in a penetrating manner; a bearing and a walking roller are connected to the roller connecting shaft; a sliding rail making contact with a roller groove of the walking roller is installed on the lower portion of the walking roller and fixedly installed on the upper end faceof the upper portion of the I-shaped steel; the motor is connected with a speed reducer, the speed reducer is connected with a gear, and a speed reducer shell is fixedly connected with a hanging plate of the bracket; a toothed belt is mounted on one side, parallel to the moving direction of the walking rollers, of the I-shaped steel and engaged with the gears; connecting parts are mounted at thefront and rear ends of the I-shaped steel and fixedly connected with the filter press. The equipment is simple in structure, and the scraping equipment can be driven by the walking mechanism to walk on the track, so that continuous scraping production is realized.

Owner:江苏华诚自动化设备有限公司

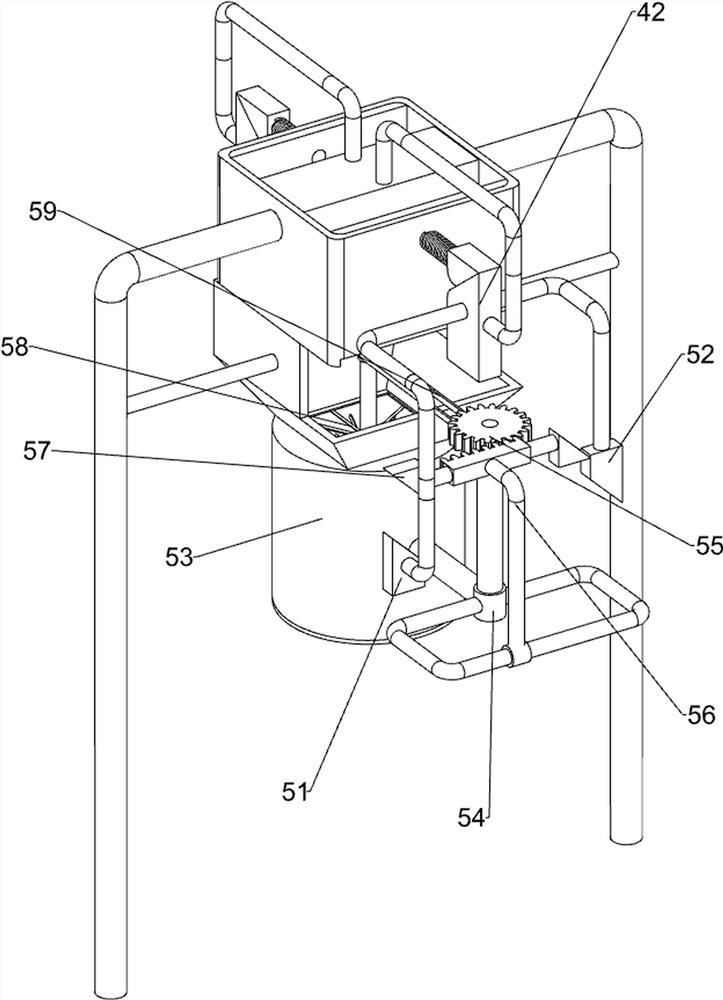

A kind of fast making machine of meatloaf soup for food processing

The invention relates to a machine for making meat pie soup, in particular to a machine for quickly making meat pie soup for food processing. The invention provides a meat pie soup rapid making machine for food processing, which can perform secondary chopping on meat and realize indirect feeding. The invention discloses a machine for quickly making meat pie soup for food processing, which comprises a base and a chopping mechanism, wherein a chopping mechanism is arranged in the middle of the top of the base; a material scraping mechanism is provided, and a scraping mechanism is arranged at the bottom of the chopping mechanism. In the present invention, the staff starts the air cylinder to make the chopping knife move up and down continuously to chop the meat fully, and then pulls the sliding bearing plate forward to make the meat in the bearing mechanism drop, and the operation is simple; when the stirring and cutting knife is continuously Turning clockwise and counterclockwise, the meat can be minced twice to improve the mincing effect; when the lifting and translation clamping plate moves outward and upward at the same time, the bowl in the storage frame is released and the mincing is held The meat can realize intermittent feeding.

Owner:中芝堂药业(山东)有限公司

A photovoltaic building exterior wall cleaning system

ActiveCN112523531BImprove cleaning efficiencyEasy to cleanCarpet cleanersFloor cleanersRolling chassisCivil engineering

Owner:浙江龙能电力科技股份有限公司

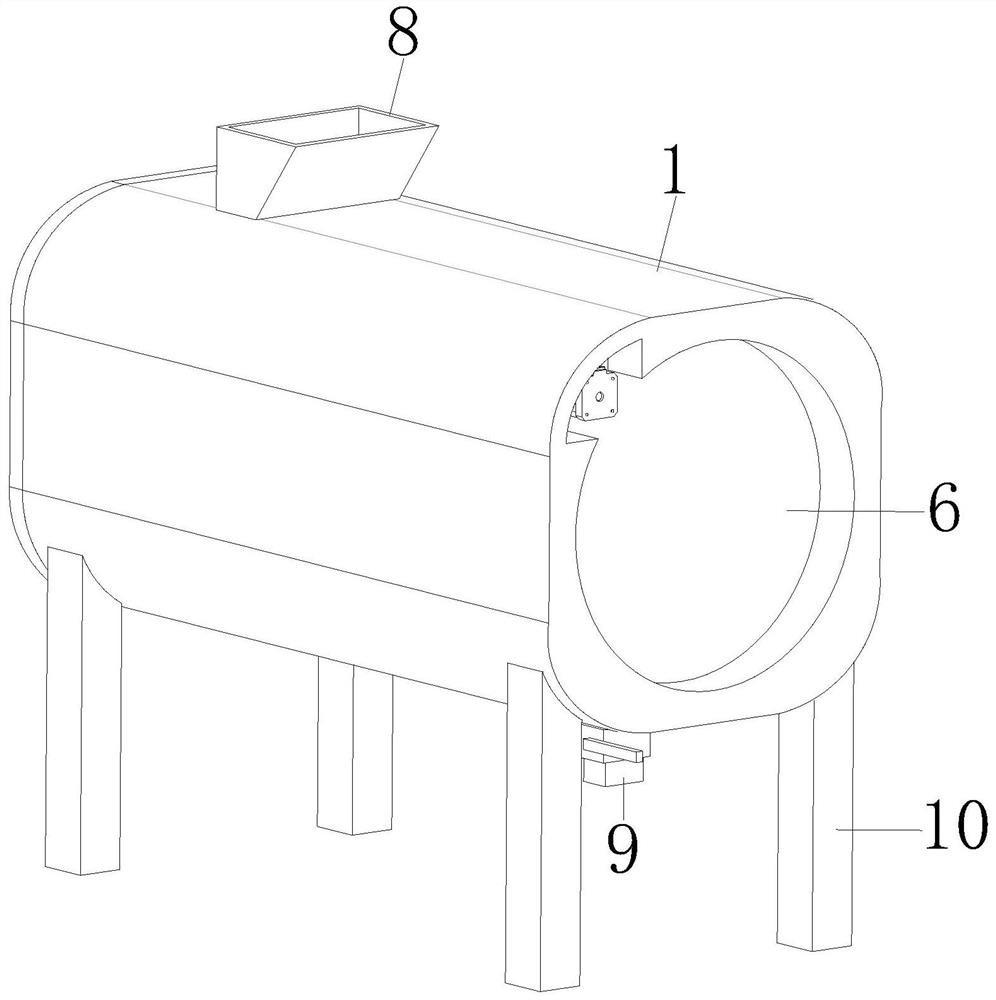

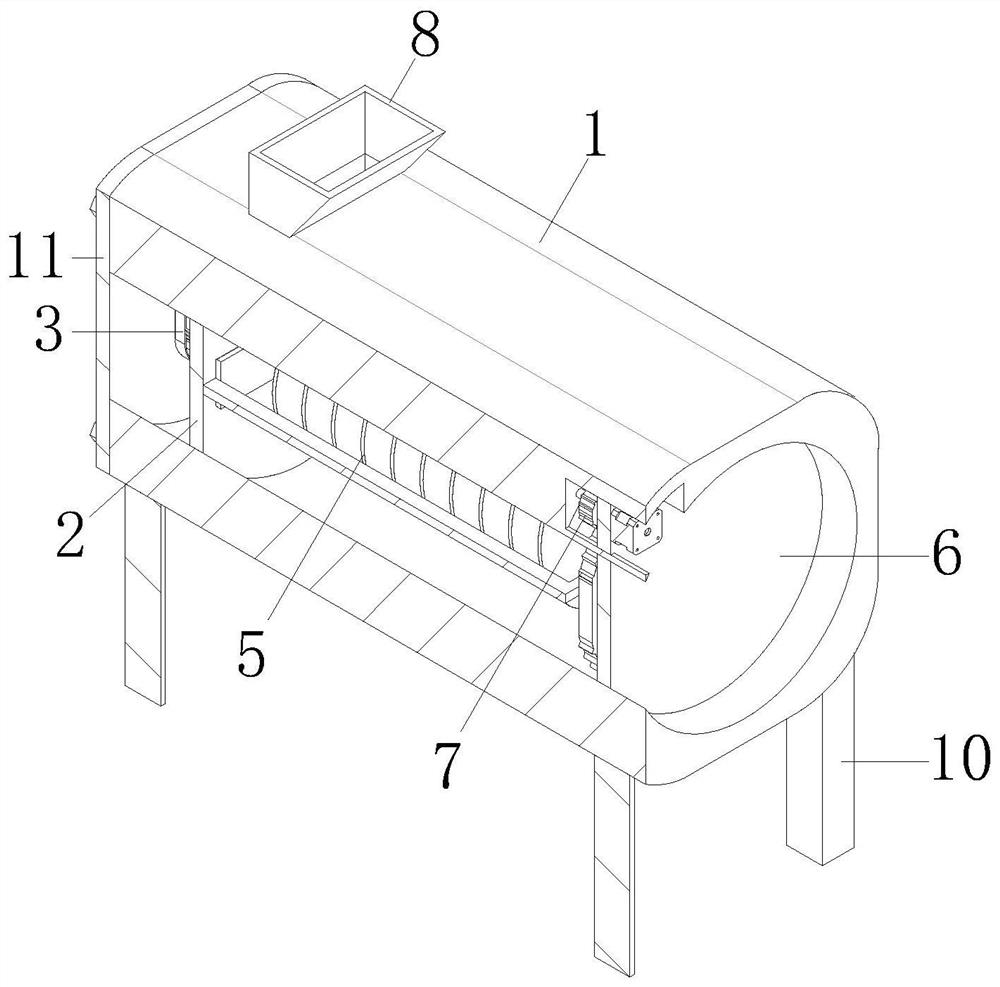

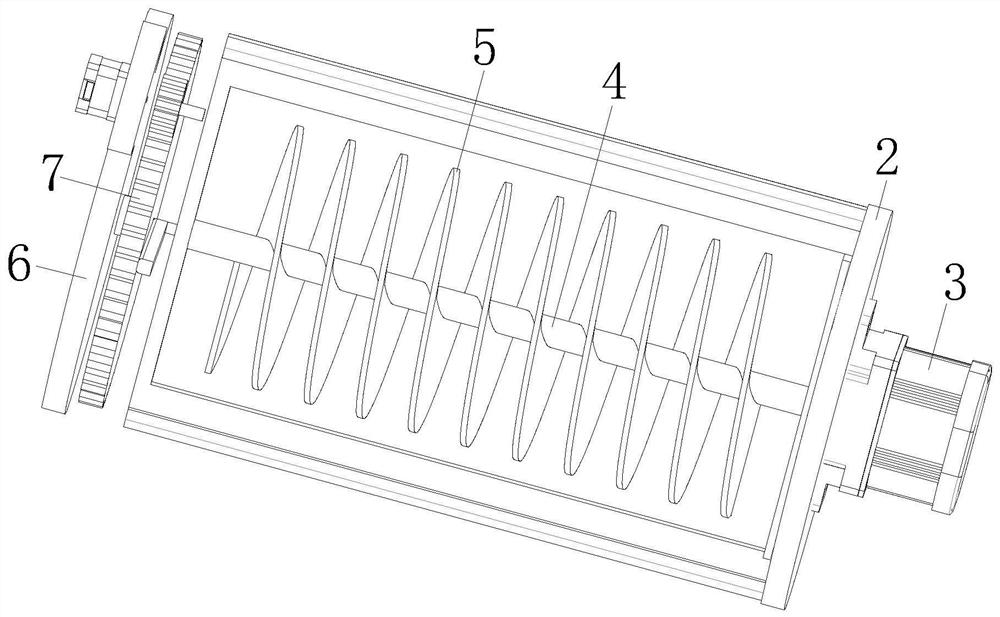

Horizontal esterification reaction kettle

ActiveCN112958028AEasy scrapingSmooth rotationHollow article cleaningChemical/physical/physico-chemical stationary reactorsGear driveElectric machine

The invention relates to the technical field of reaction kettles, and discloses a horizontal esterification reaction kettle. The kettle comprises a kettle body, a partition plate is fixedly connected to the inner wall of the kettle body, a stirring motor is fixedly connected to one side of the partition plate, and the output end of the stirring motor penetrates through the side, away from the stirring motor, of the partition plate and is fixedly connected with a rotating shaft. The surface of the rotating shaft is fixedly connected with stirring paddles, and the inner wall of the kettle body is fixedly connected with a mounting plate. According to the horizontal esterification reaction kettle, the rotating shaft is driven to rotate through operation of the stirring motor, then the stirring paddles are driven to rotate for stirring, a driven gear is driven to rotate through operation of a cleaning motor, then a driving gear is driven to rotate, the driving gear drives a rotating frame to rotate through a connecting rod, and a first cleaning piece and a second cleaning piece rotate, so the horizontal esterification reaction kettle solves the problems of non-uniform stirring and waste caused by incomplete discharging due to adsorption of high-grade ester produced by esterification reaction to the inner wall.

Owner:浙江华大树脂有限公司

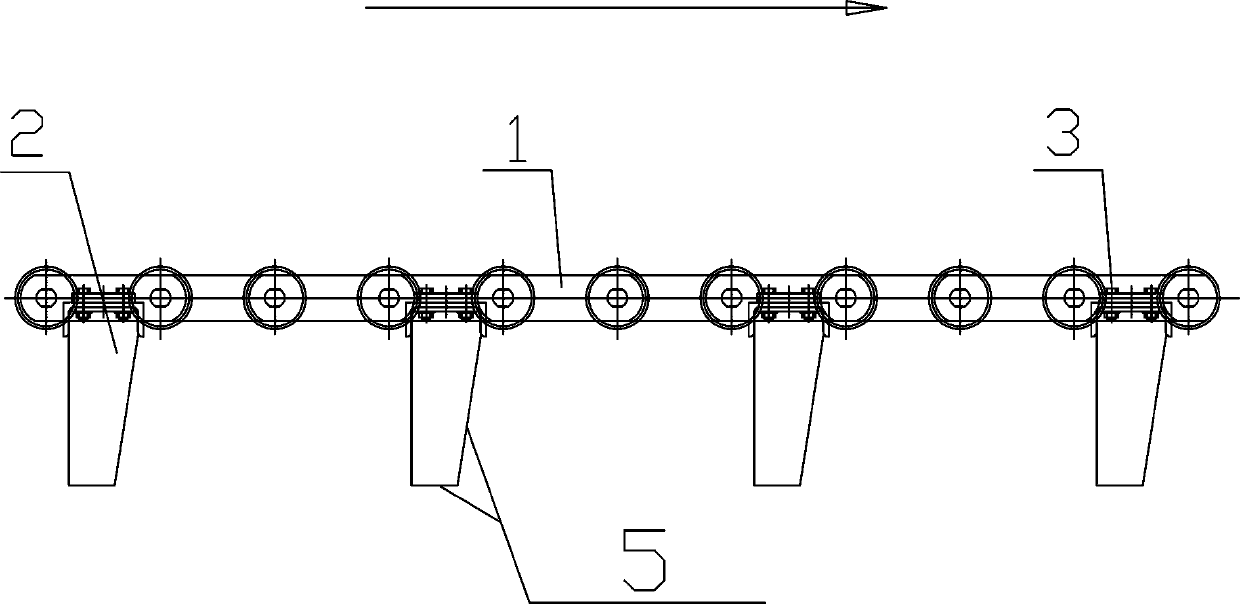

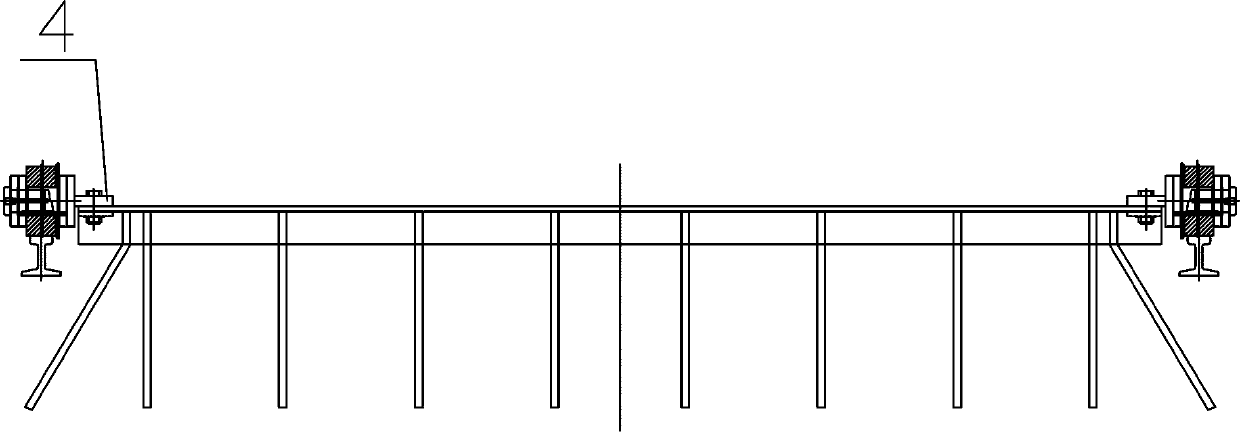

Super-wide hanging movable type harrow knife machine scraper chain

A super-wide hanging movable type harrow knife machine scraper chain comprises conveying chains and a harrow knife. The conveying chains are used in a pair. The harrow knife is connected between the two conveying chains. Each conveying chain comprises an inner chain plate, an outer chain plate, a rolling wheel, a sleeve and a hinge pin, wherein the inner chain plate, the outer chain plate, the rolling wheel, the sleeve and the hinge pin form the chain. The harrow knife comprises a fixed beam. Sweeping harrow knife blades are arranged on the two sides of the fixed beam. A row of scraping harrow knife blades are distributed in the middle in an array mode. Through the super-wide hanging movable type harrow knife machine scraper chain provided by the invention, conveying work of bagasse can be completed.

Owner:HUBEI YIDU ZHONGJI ENVIRONMENTAL ENG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com