Beneficiation process of skarn type magnetite containing copper and gold

A technology of skarn and magnetite, which is applied in the field of skarn-type copper-bearing gold-magnetite mineral processing technology, can solve the problems affecting the efficiency of ore unloading, the force of unloading plates is different, and the efficiency of ore unloading is low. Achieve the effects of improving efficiency, improving monomer dissociation degree, and ensuring the quality of concentrate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

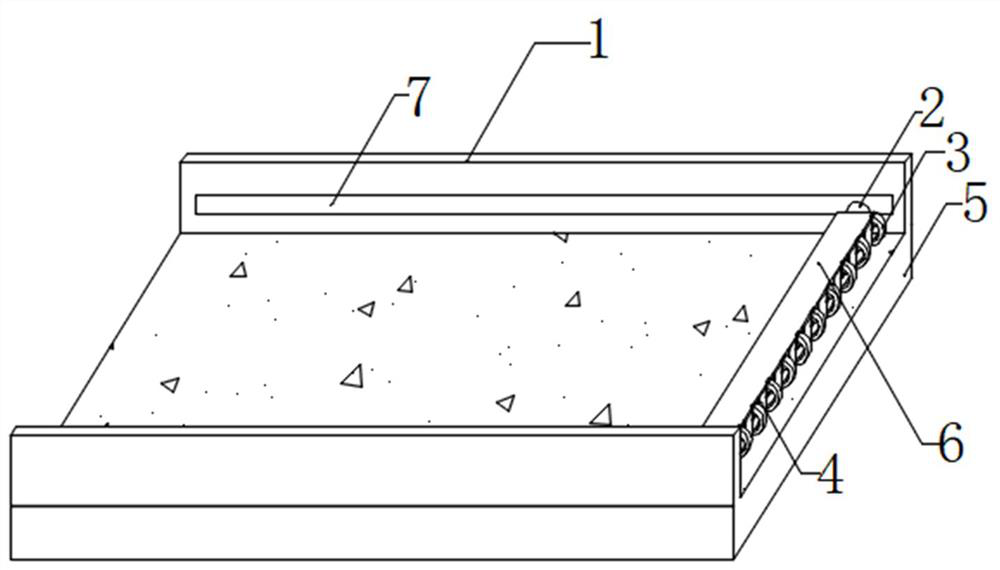

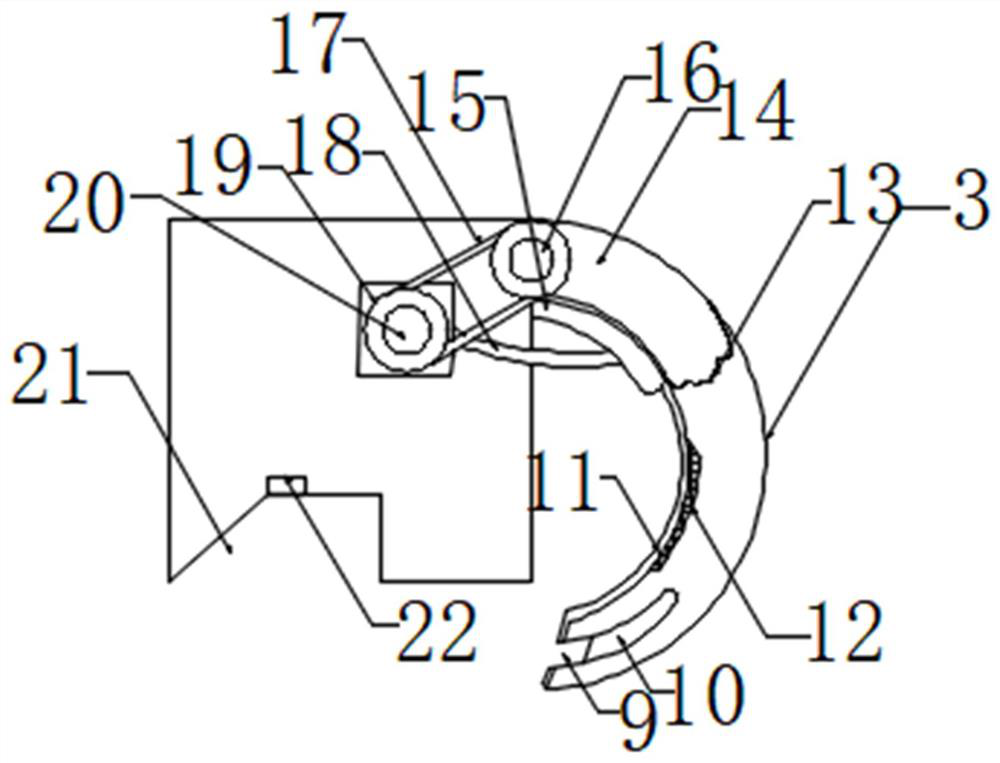

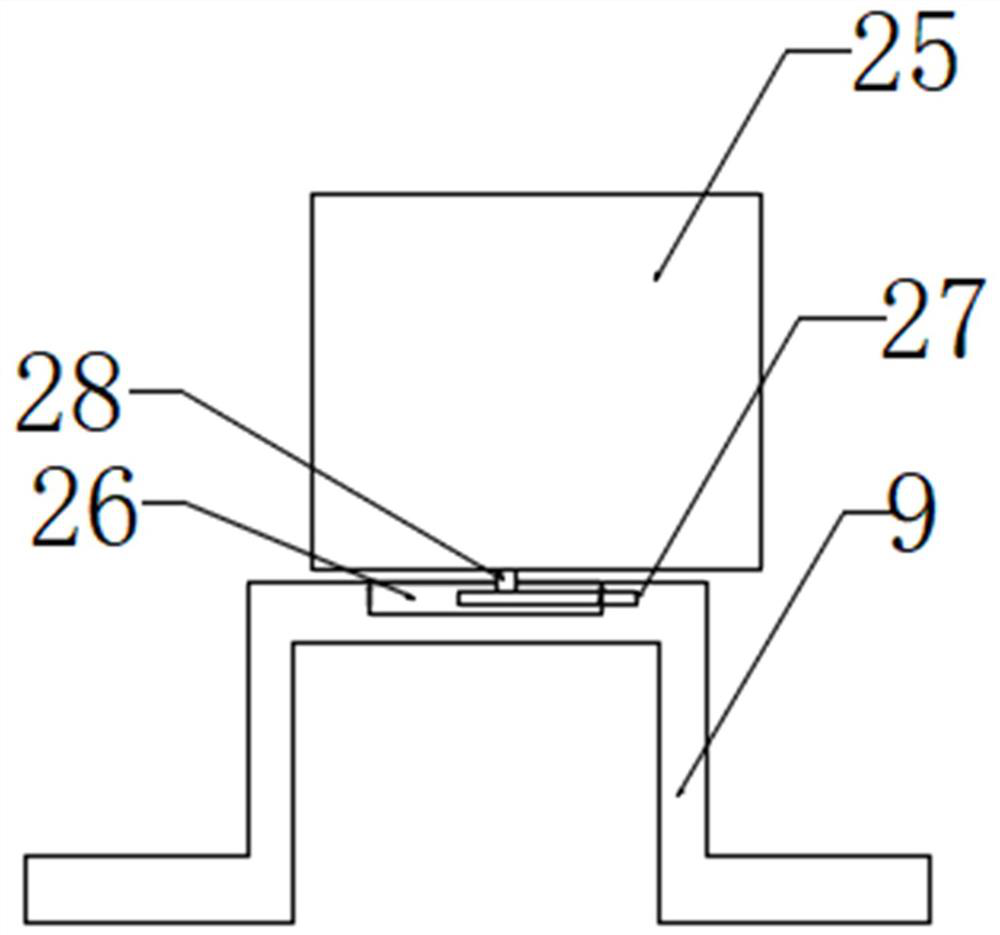

[0040] like Figure 1-10 Shown, a kind of skarn type copper-bearing gold magnetite ore dressing process comprises the following process steps:

[0041] Step 1: The ore is crushed to less than 12mm by three-stage closed circuit, and then separated by permanent magnet wet magnetic separator. The product is used as a building material. The under-screen product is classified by the cyclone behind the ball mill. The copper grade in the over-screen material is lower than the mixed flotation tailings grade, and the iron grade is lower than the iron grade in the magnetic separation tailings. The copper content in the magnetic material is high and must be recycled, and this part will not enter the ball mill to reduce the secondary mud caused by over-grinding;

[0042] Step 2: After grinding, enter mixed flotation to obtain copper-sulfur mixed concentrate, copper-sulfur mixed concentrate is separated from copper and sulfur to obtain qualified copper concentrate and sulfur concentrate, ...

Embodiment 2

[0059] like Figure 1-10 Shown, a kind of skarn type copper-bearing gold magnetite ore dressing process comprises the following process steps:

[0060] Step 1: The ore is crushed to less than 12mm by three-stage closed circuit, and then separated by permanent magnet wet magnetic separator. The product is used as a building material. The under-screen product is classified by the cyclone behind the ball mill. The copper grade in the over-screen material is lower than the mixed flotation tailings grade, and the iron grade is lower than the iron grade in the magnetic separation tailings. The copper content in the magnetic material is high and must be recycled, and this part will not enter the ball mill to reduce the secondary mud caused by over-grinding;

[0061] Step 2: After grinding, enter mixed flotation to obtain copper-sulfur mixed concentrate, copper-sulfur mixed concentrate is separated from copper and sulfur to obtain qualified copper concentrate and sulfur concentrate, ...

Embodiment 3

[0072] like Figure 1-10 Shown, a kind of skarn type copper-bearing gold magnetite ore dressing process comprises the following process steps:

[0073] Step 1: The ore is crushed to less than 12mm by three-stage closed circuit, and then separated by permanent magnet wet magnetic separator. The product is used as a building material. The under-screen product is classified by the cyclone behind the ball mill. The copper grade in the over-screen material is lower than the mixed flotation tailings grade, and the iron grade is lower than the iron grade in the magnetic separation tailings. The copper content in the magnetic material is high and must be recycled, and this part will not enter the ball mill to reduce the secondary mud caused by over-grinding;

[0074] Step 2: After grinding, enter mixed flotation to obtain copper-sulfur mixed concentrate, copper-sulfur mixed concentrate is separated from copper and sulfur to obtain qualified copper concentrate and sulfur concentrate, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com