Polyethylene tube scale scraper

A technology of polyethylene pipe and oxide skin, applied in the field of scrapers, can solve the problems of wasting time and manpower, fragile blades, high cost, etc., and achieve the effects of reducing labor intensity, easy manufacturing, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] With reference to accompanying drawing, the utility model will be described in detail below.

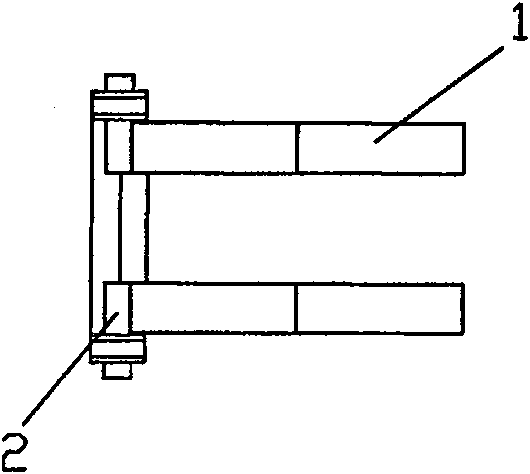

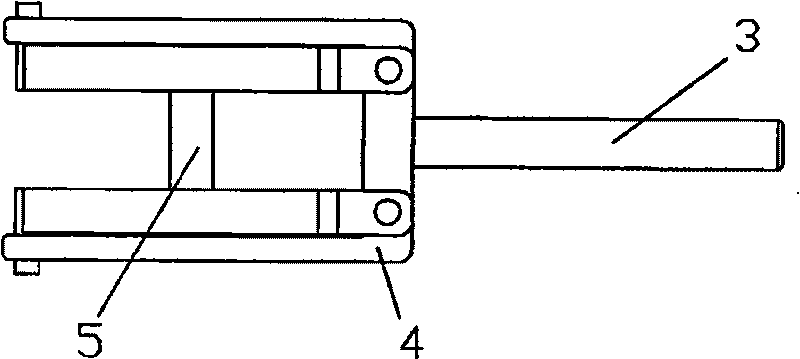

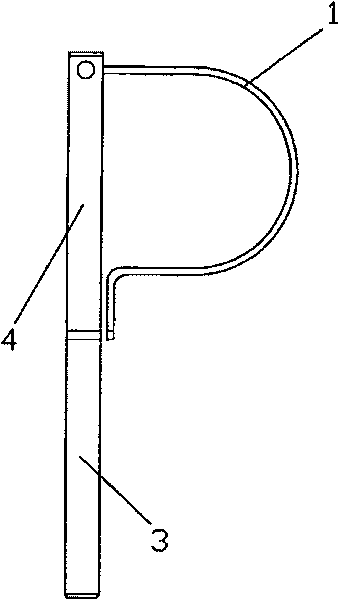

[0024] A polyethylene pipe oxide skin scraper, including a cutter 5; also includes a bottom frame 4, a fixed frame 1; A cutter 5 is arranged on the frame 4, and the blade direction of the cutter 5 is parallel to the axial direction of the arc groove.

[0025] One end of the fixed frame 1 is connected to the underframe 4 through a straight plate; the other end is connected to the underframe 4 through a short shaft 2; the underframe 4 includes two parallel beams, and the cutter 5 is arranged between the beams; one end of the underframe 4 A wrench 3 is provided; a through hole is provided at the end of the straight plate, and the straight plate is threadedly connected with the bottom frame 4; the short shaft 2 and the fixed frame 1 are integrally structured, and the outer end is a threaded structure, and the through hole on the bottom frame 4 is installed through a nut; Offer th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com