Photovoltaic panel cleaning tool assembly

A photovoltaic panel and tooling technology, applied in the field of surface cleaning, can solve the problems of prolonged drying time, easy inflow of cleaning liquid, and general erasing effect, so as to save the operation of manual cleaning, improve the scraping efficiency, and ensure the cleanliness. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0064] Embodiments of the technical solutions of the present invention will be described in detail below in conjunction with the accompanying drawings. The following examples are only used to illustrate the technical solutions of the present invention more clearly, and therefore are only examples, rather than limiting the protection scope of the present invention.

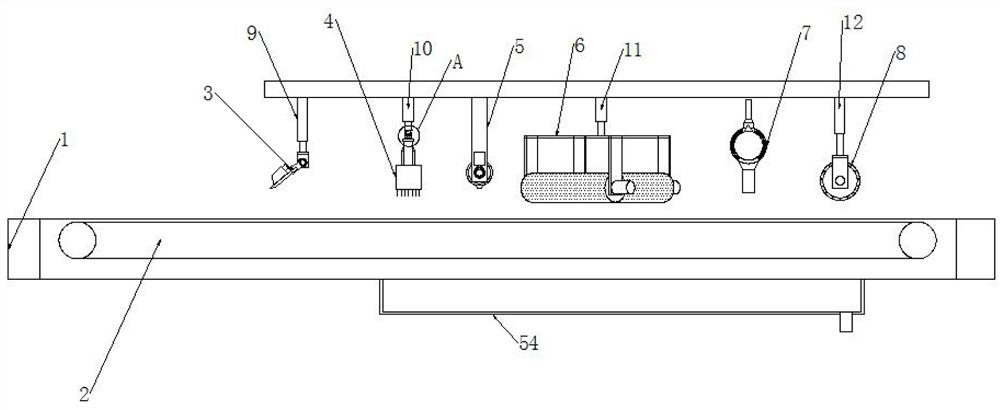

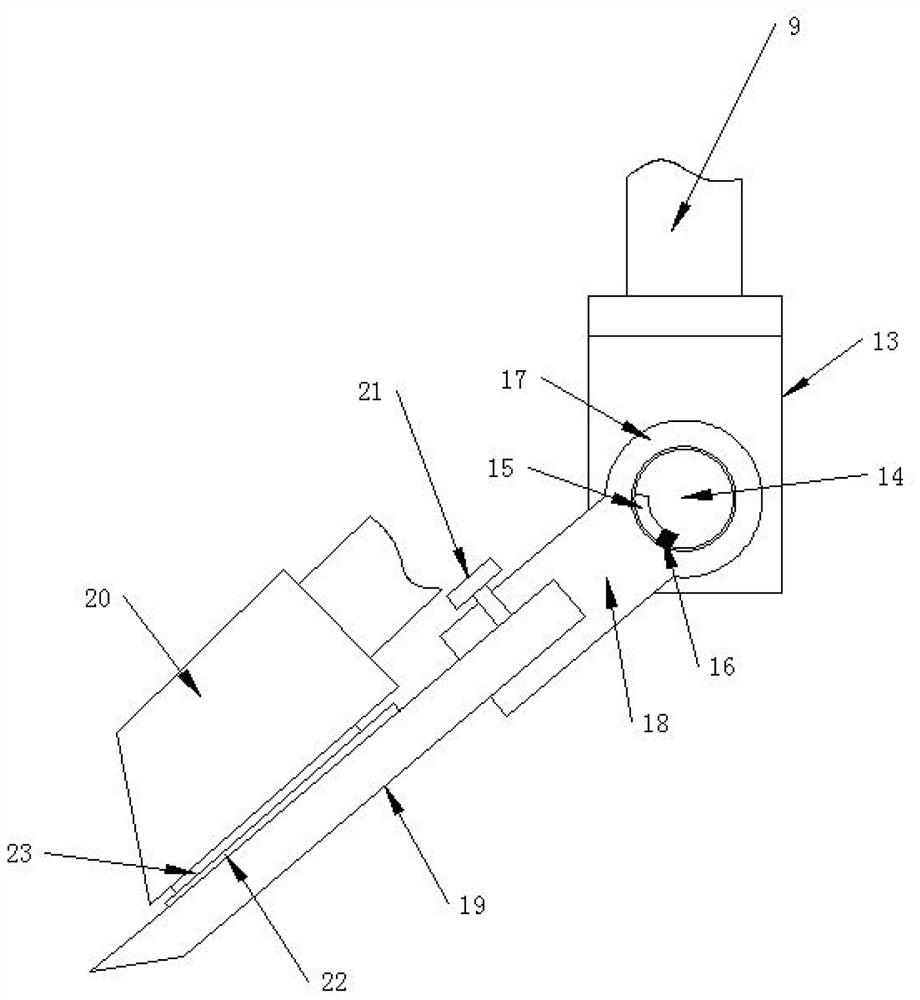

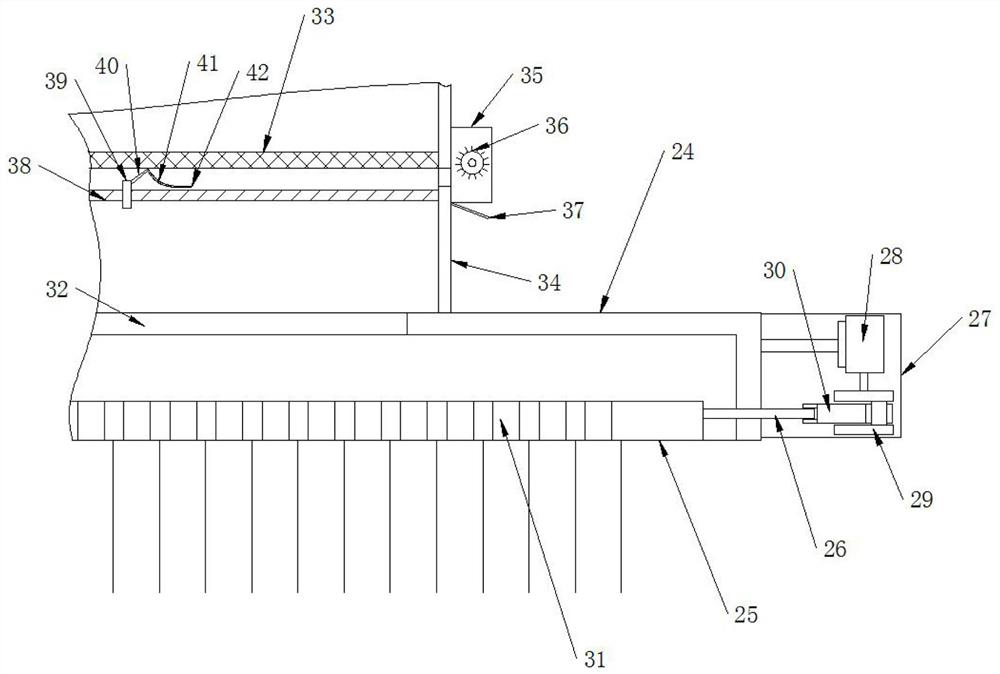

[0065] Such as Figure 1 to Figure 9 As shown, the photovoltaic panel cleaning tool assembly includes a working platform 1, on which a conveyor belt 2 is rotated, and along the feeding direction of the conveyor belt, the working platform 1 is sequentially provided with a scraping device 3, a cleaning device 4, Water spray device 5, water guiding device 6, drying device 7 and erasing device 8; scraper 19 is swingably arranged on scraper device 3, and a suction device for discharging scraper is also arranged on scraper device 3 Components, reciprocating sliding on the cleaning device 4 is provided with a blackboard ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com