Landscaping maintenance equipment

A landscaping and equipment technology, applied in the field of landscaping maintenance equipment, can solve the problems of inconvenient film application, difficult bark removal, jumping knife, etc., and achieve the effect of improving scraping efficiency, convenient cleaning and maintenance, and guaranteeing service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

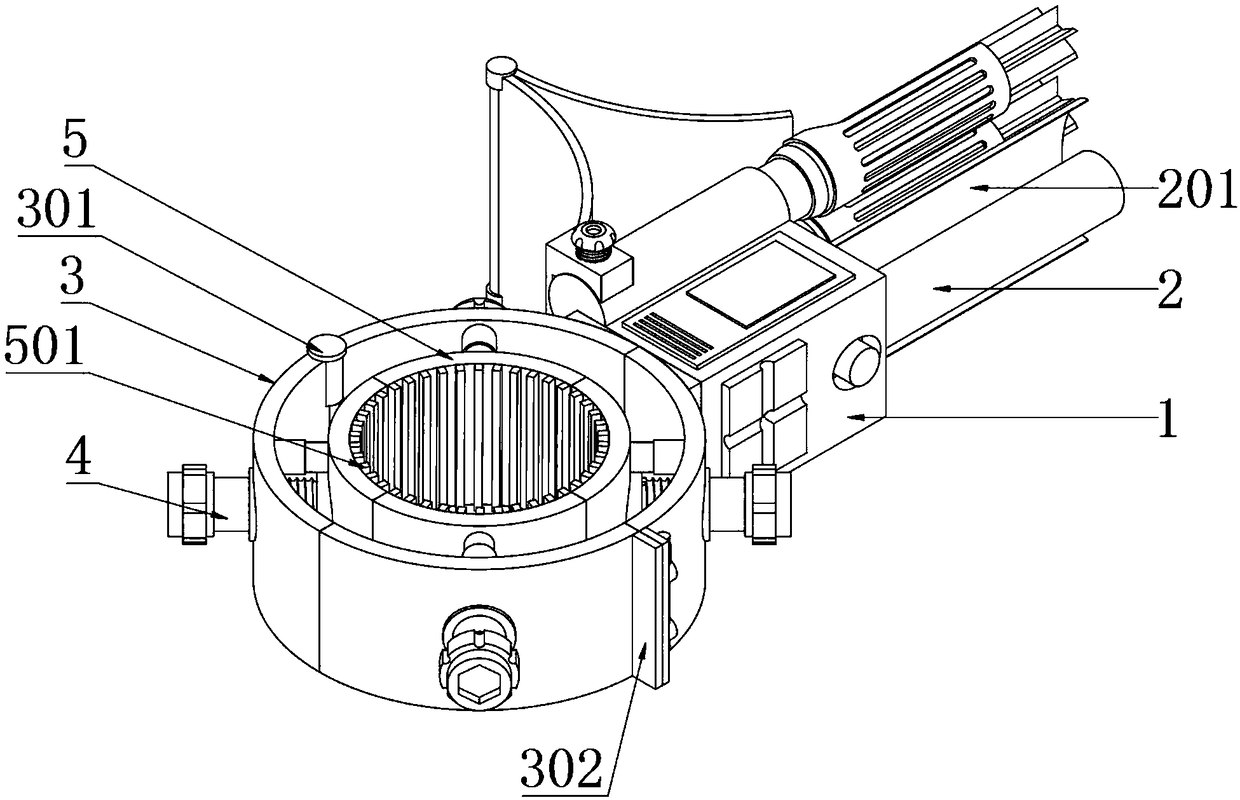

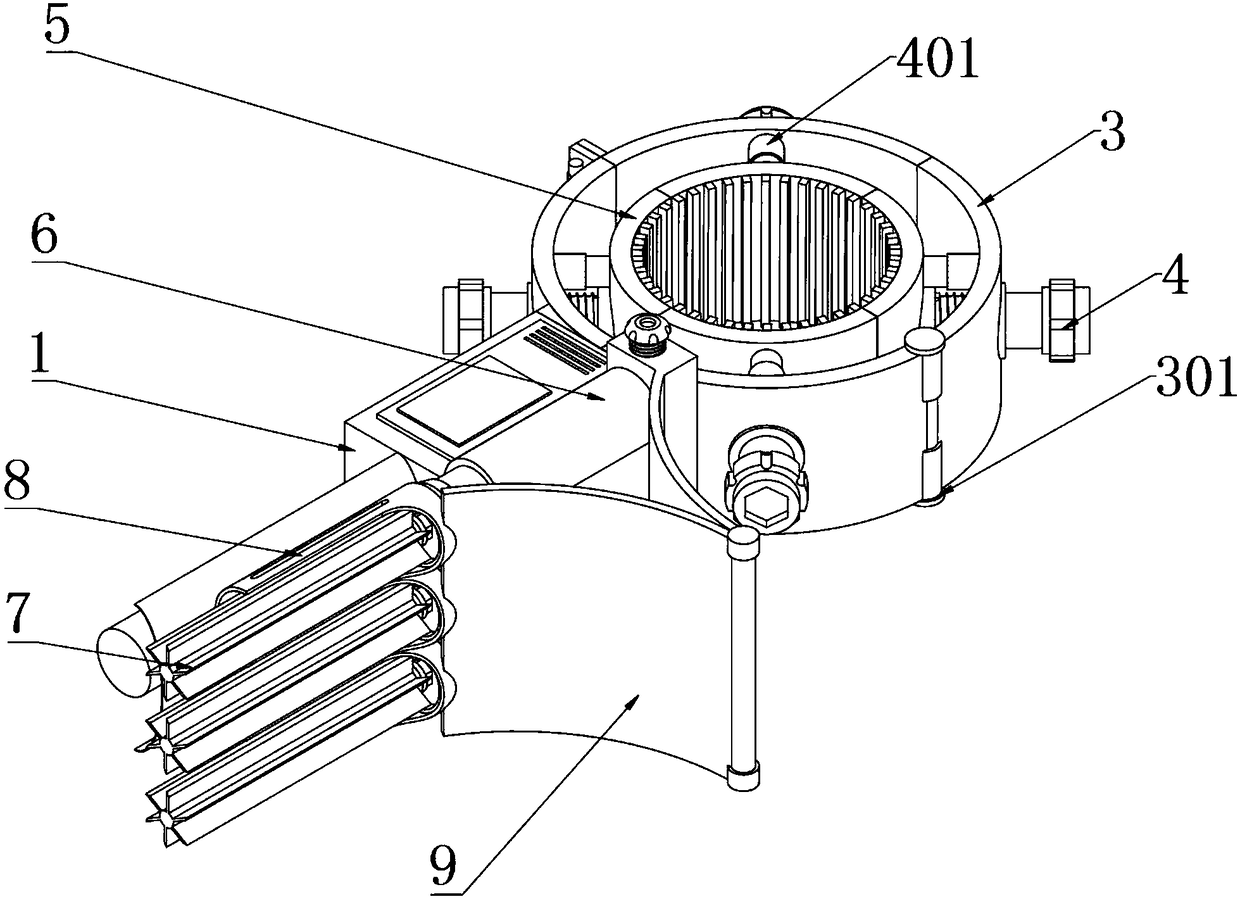

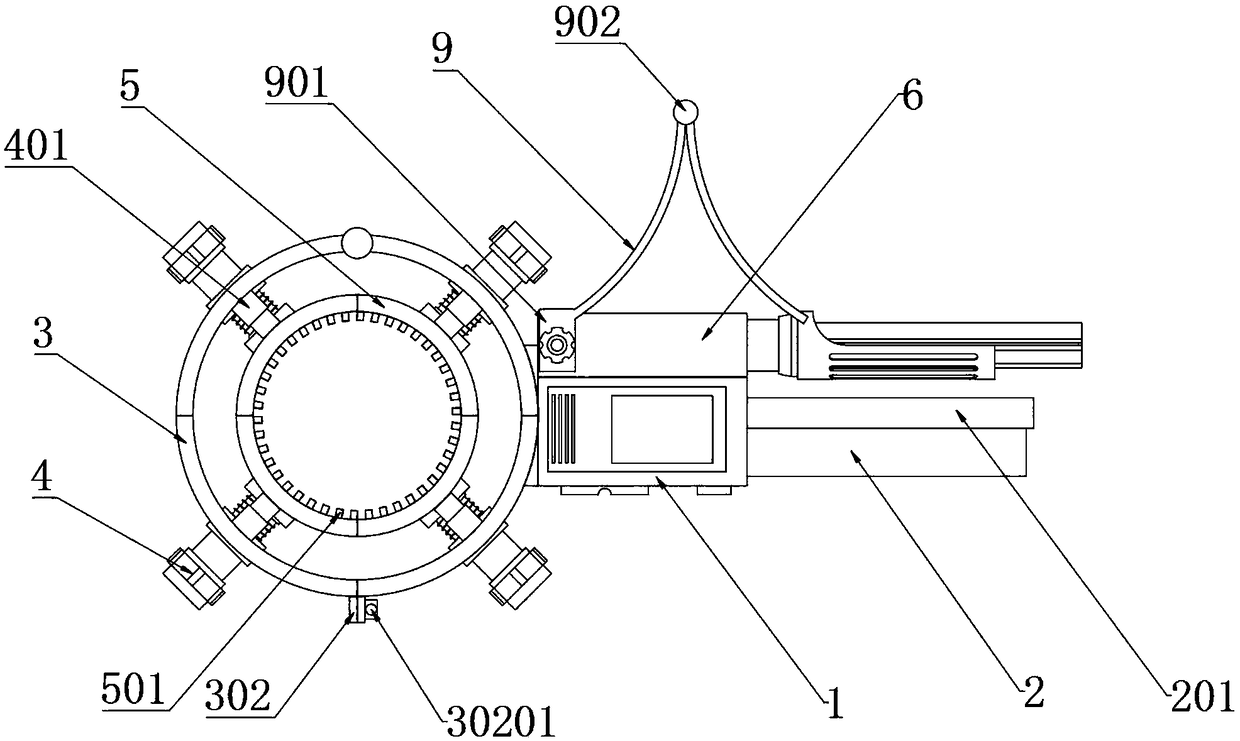

[0036] as attached figure 1 to attach Figure 8 Shown:

[0037]The invention provides a landscaping maintenance equipment, comprising a control device 1, a handle 2, a sleeve 3, a diameter adjusting bolt 4, an inner scraper 5, a motor 6, a scraper 7, a stopper 8, a guide 9, a shield 201, The first rotating shaft 301, the lug 302, the automatic telescopic column 401, the inner scraping strip 501, the sleeve block 901, the second rotating shaft 902, the locking column 30201, the protruding column 30202, the fixing bolt 90101 and the chute 90102, the control device 1 A cylindrical handle 2 is vertically arranged on the right side wall of the casing, and an arc-shaped shield 201 is fixedly arranged on the control device 1 inside the handle 2; Three motors 6 are sequentially arranged on the wall from top to bottom, and the motors 6 are fixedly embedded on the control device 1 and are electrically connected with the control device 1; the right end of the motor 6 is connected with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com