Scraping Blade For Paint Scraper Intended For Removing Paint

a scraper and paint technology, applied in the field of scraper blade for scraper, can solve the problems of poor scraping effect of paint scrapers with pointed scraping teeth, scratching and damage to the underlying surface of edges, etc., and achieve the effect of less force removal and effective scraping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

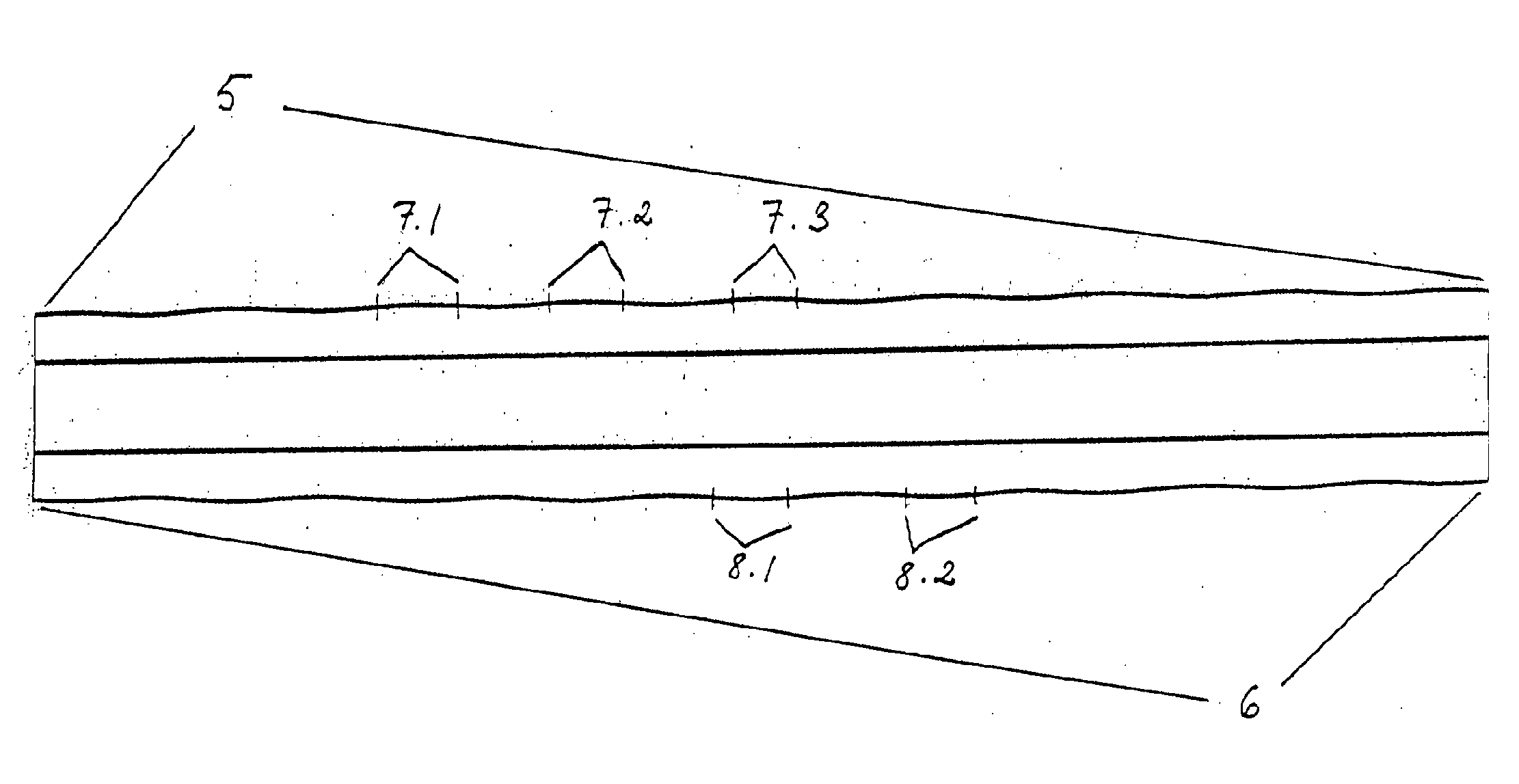

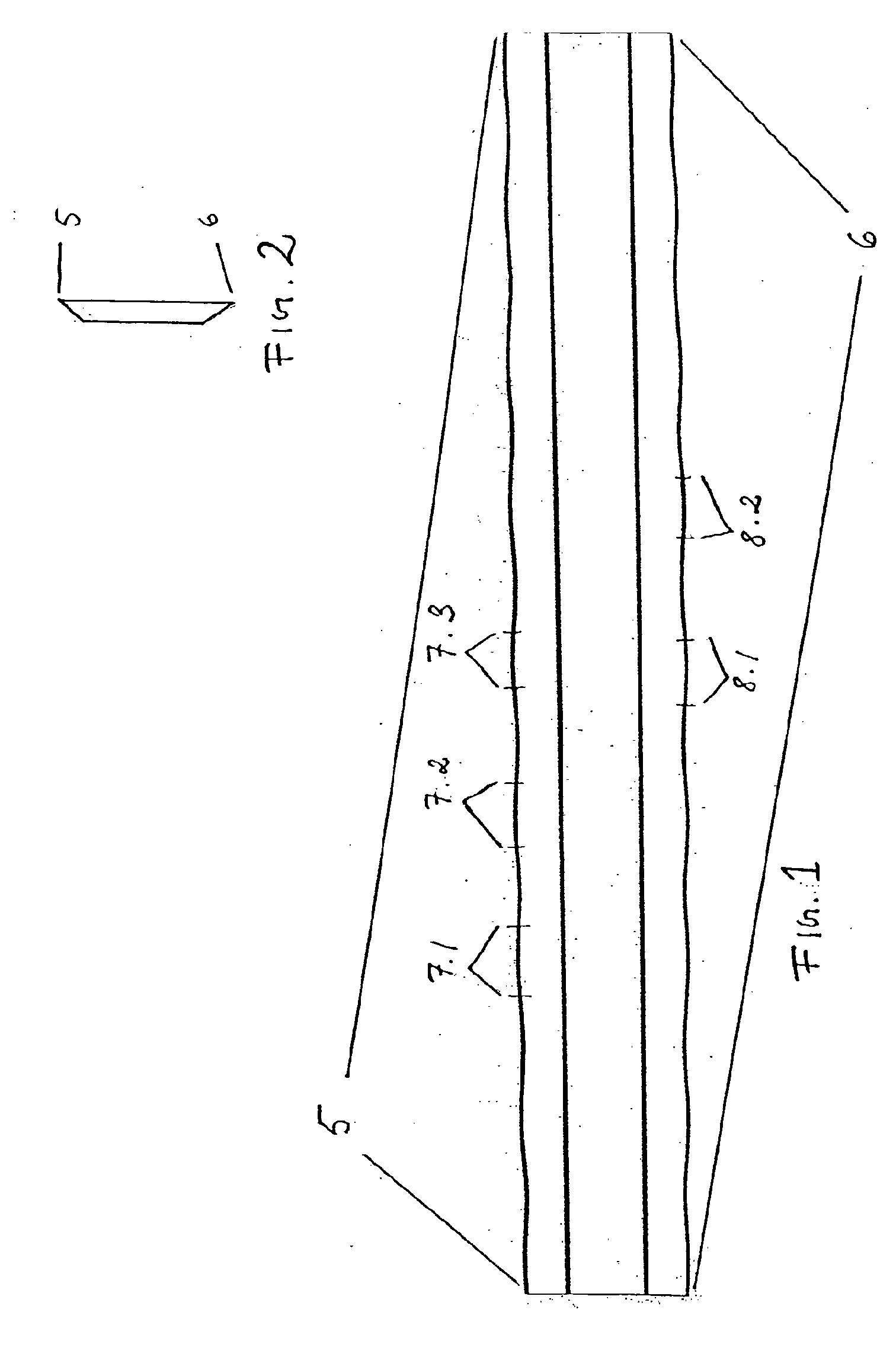

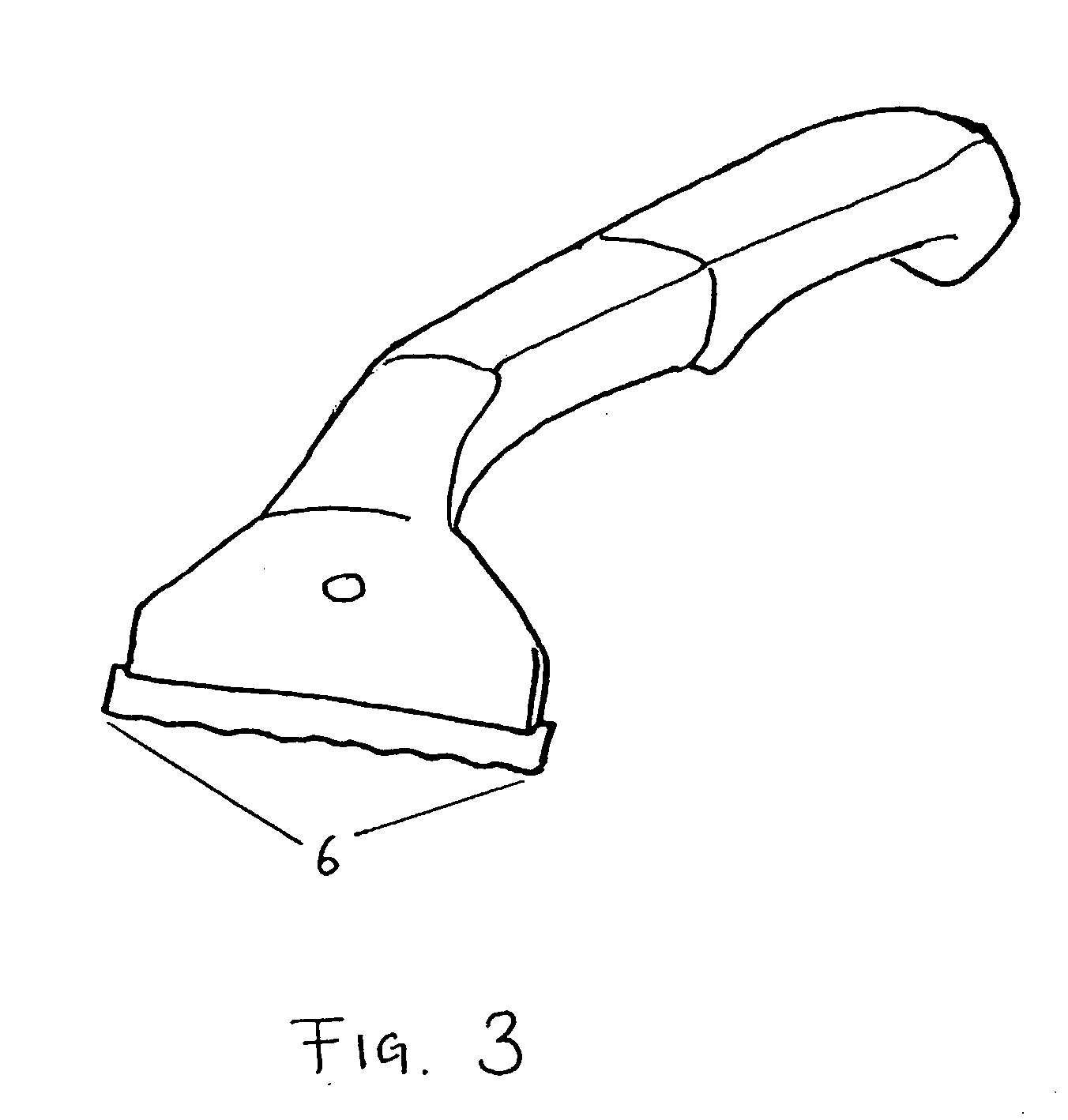

[0024]FIG. 1 shows an embodiment of the scraper blade according to the present invention, the both longitudinal margins of which are transversally chamfered (see FIG. 2), which substantially provides two longitudinal scraping edges, a first scraping edge 5 at the upper longitudinal margin of the scraper blade, and a second scraping edge 6, opposite the first scraping edge 5, at the lower longitudinal margin of the scraper blade. The first and second scraping edges 5, 6, of the embodiment are divided into several abutting portions 7.1, 7.2, 7.3, 8.1, 8.2, which, upon abutting scraping action, extend transversely to the direction of scraping, and additionally are continuous in the plane of each scraping edge 5, 6. Each scraping edge 5, 6 is wave shaped in its scraping edge plane, and each abutting portion 7.1, 7.2, 7.3, 8.1, 8.2 is convex in the plane of the scraping edge 5, 6 and forms a part of a crest of the wave shape. The longitudinal extensions of the abutting portions 7.1, 7.2,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com