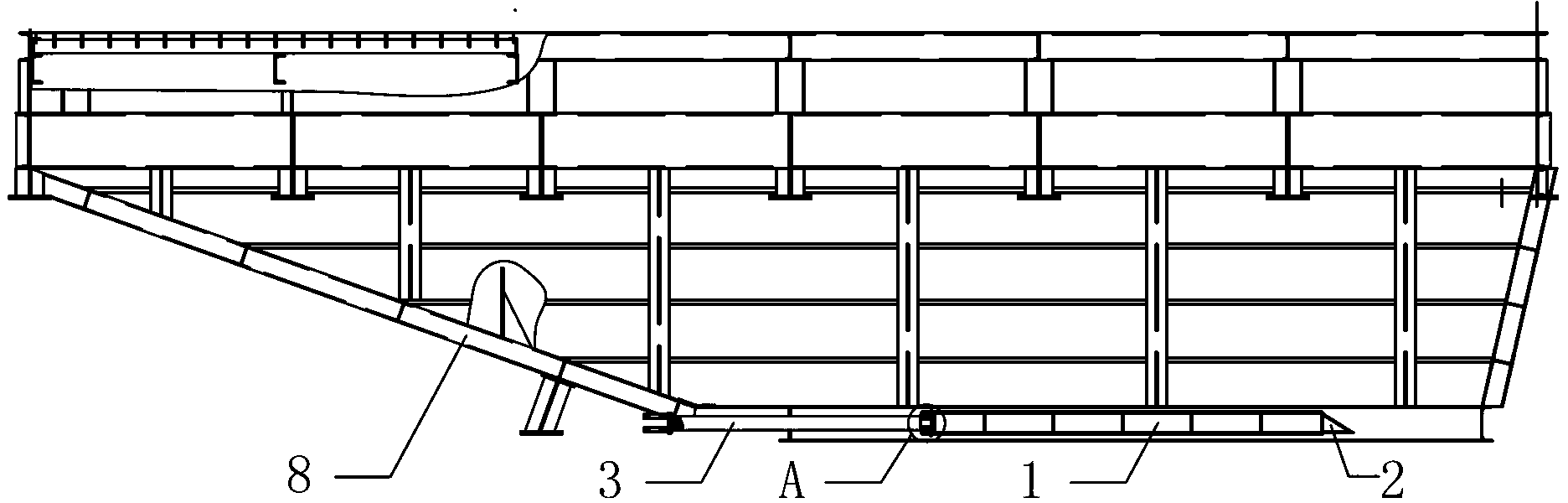

Hydraulic slide frame at bottom of sludge bin

A silo and sludge technology, applied in the field of hydraulic slides at the bottom of the sludge silo, can solve the problems of easy damage, inconvenient scraping, and poor fluidity of sludge in the sludge silo, achieving convenient scraping and simple structure Durable, unbreakable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

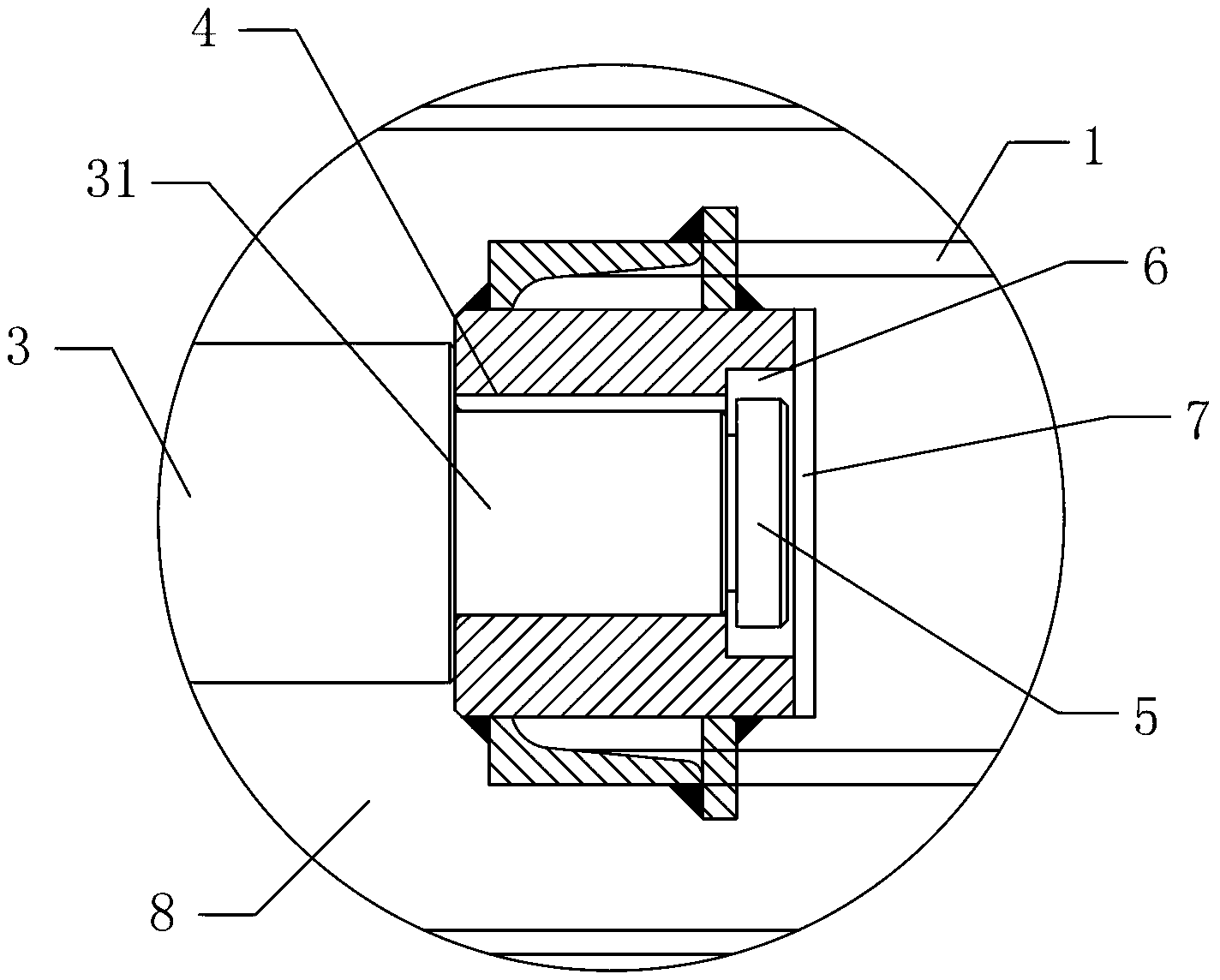

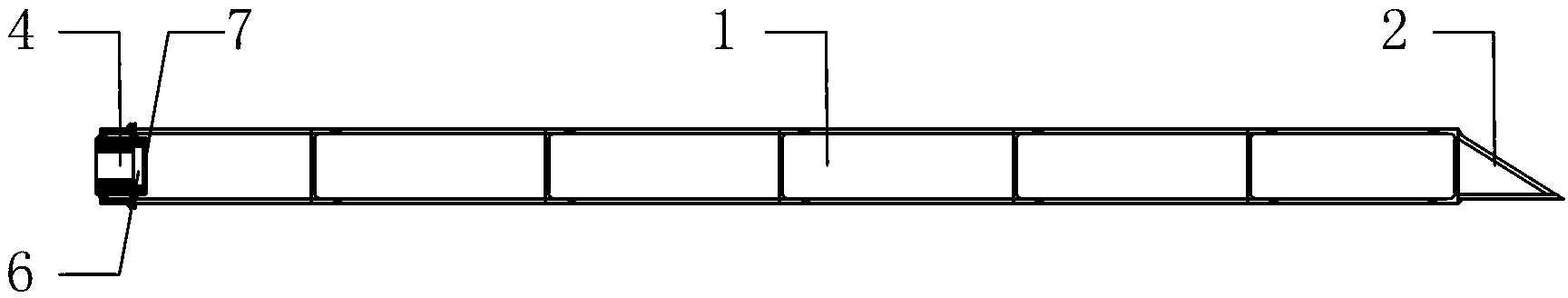

[0017] Such as Figures 1 to 4 As shown, the hydraulic carriage at the bottom of the sludge silo includes a frame 1 arranged at the bottom of the sludge silo 8, one end of the frame 1 is provided with a wedge-shaped scraper 2, and the other end is provided with a connecting shaft 3. The connecting shaft 3 passes through the sludge silo and is connected with the hydraulic oil cylinder. The end connecting the connecting shaft 3 to the frame 1 is matched with the bolt 5, the end connecting the frame 1 to the connecting shaft 3 is provided with a hole 4, and the threaded end of the bolt 5 extends from the end of the hole 4 away from the connecting shaft 3 Cooperate with the connecting shaft 3 in the hole 4 or pass through the hole 4 to cooperate with the connecting shaft 3 , and the head of the bolt 5 is stuck in the end of the hole 4 away from the connecting shaft 3 . The frame 1 is provided with a slot 6 on the inside of one end of the connecting shaft, the hole 4 is located at...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com