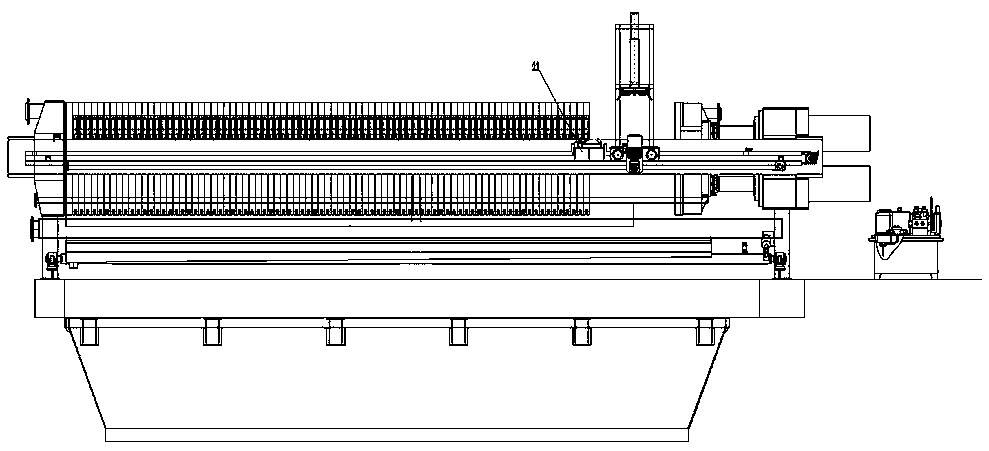

Scraping device for filter press

A filter press and equipment technology, applied in the field of scraping equipment for filter presses, can solve the problems of low work efficiency and low moisture content of filter cakes, and achieve the effects of improved work efficiency, reduced wear, and convenient scraping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] It should be noted that one element of the present invention is "connected" to another element, and one element can be directly connected to another element, or there can be an indirect connection of a central part. The direction of "front, back, up, and down" in the present invention The name is only for the convenience of explaining the drawings or distinguishing the components, and does not limit the protection scope of the present invention. The description of "first and second" is only for distinguishing the names of the components, and does not make any reference to the protection scope or installation sequence. limit.

[0045] The specific manner of "fixed connection" herein can be realized through existing technologies, such as welding or threaded connection, etc., which will not be repeated here.

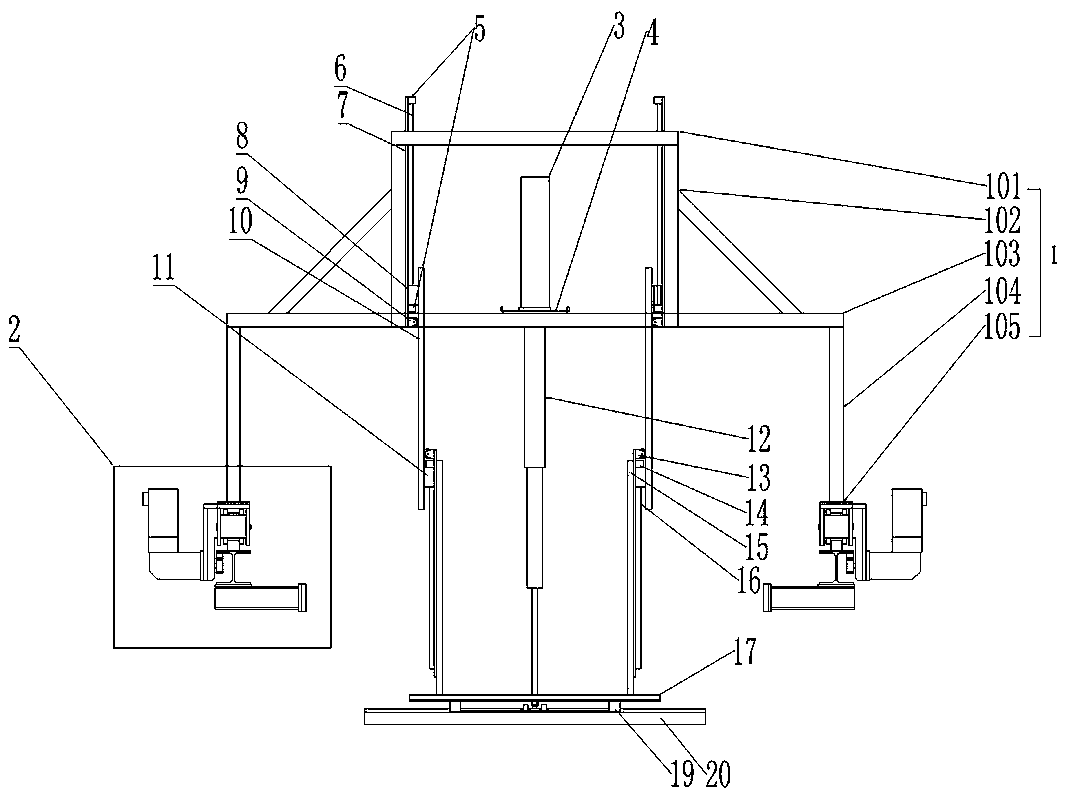

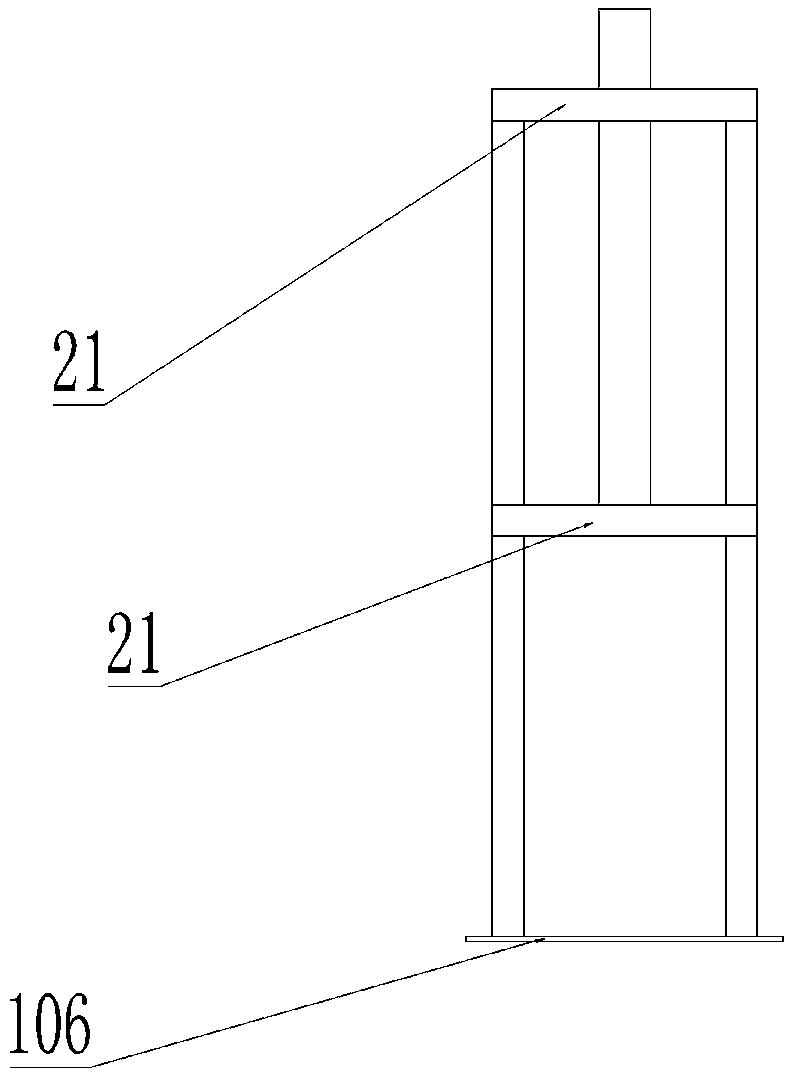

[0046] Describe in detail below in conjunction with accompanying drawing:

[0047] Depend on figure 1 As shown, a scraping device for a filter press includes a fra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com