Quick meat pie soup making machine for food processing

A technology for food processing and meat patties, which is applied in the direction of processing meat, meat processing equipment, applications, etc., can solve the problems of not being able to chop twice, and cannot realize indirect cutting, and achieve the effect of simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0080] A kind of fast making machine of meatloaf soup for food processing, such as Figure 1-3 As shown, a base 1, a chopping mechanism 2 and a scraping mechanism 3 are included, the chopping mechanism 2 is provided in the middle of the top of the base 1, and the scraping mechanism 3 is provided at the bottom of the chopping mechanism 2.

[0081] When it is necessary to make meatloaf soup, the staff will place an appropriate amount of meat in the chopping mechanism 2, and then start the chopping mechanism 2, so that the chopping mechanism 2 will chop the meat, and when the meat is chopped, the staff will turn off the chopping Mechanism 2, and then pull the scraping mechanism 3 forward to make the chopped meat fall from the chopping mechanism 2. At this time, the staff catches the fallen meat in the chopping mechanism 2 under the scraping mechanism 3. After all the meat in the chopping mechanism 2 falls, the staff releases the scraping mechanism 3, resets the scraping mechanism...

Embodiment 2

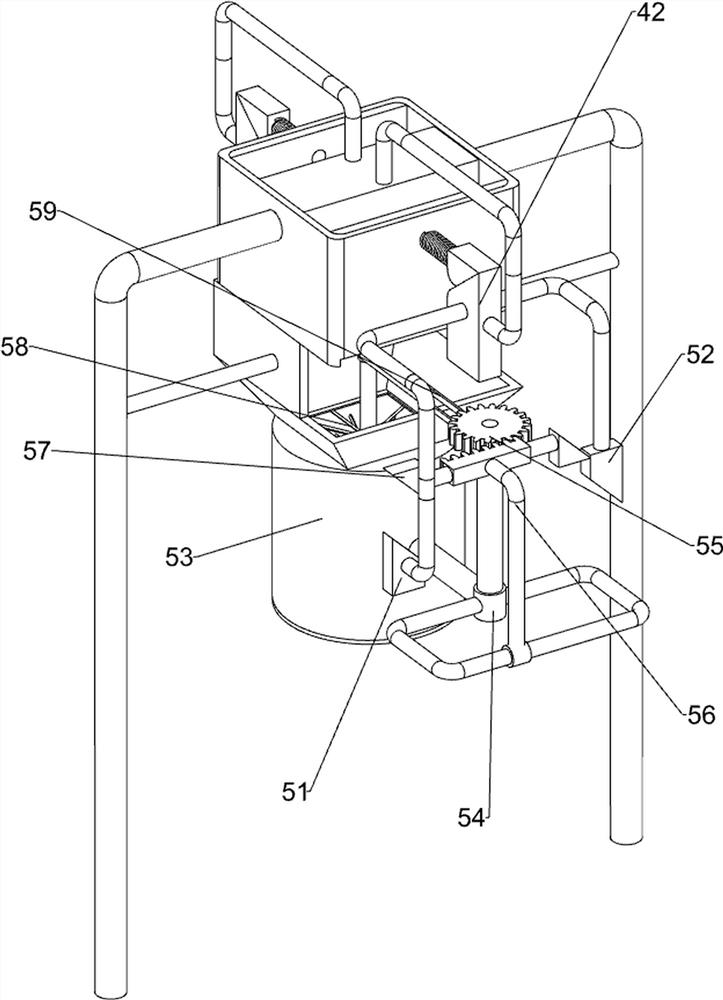

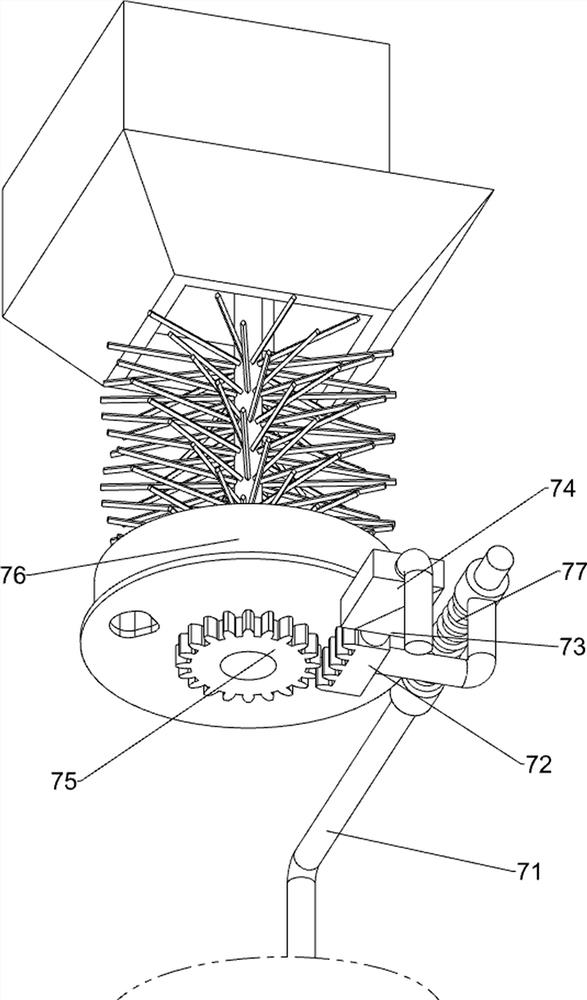

[0083] On the basis of Example 1, such as Figure 2-3 As shown, the chopping mechanism 2 also includes a cylinder 21, a carrying mechanism 22 and a chopping knife 23. The upper part of the rear side of the base 1 is provided with a cylinder 21, and the middle part of the rear side of the base 1 is provided with a carrying mechanism 22. There is chopping knife 23, and chopping knife 23 is connected with cylinder 21.

[0084] When it is necessary to make meatloaf soup, the staff puts the meat into the carrying mechanism 22, and then starts the cylinder 21. When the cylinder 21 shrinks, it drives the chopping knife 23 to move upward. When the cylinder 21 extends, it drives the chopping knife 23 Moving down, the meat is chopped, and the cylinder 21 is continuously extended and contracted, so that the chopping knife 23 is continuously moved up and down, and the meat is fully chopped. When the meat is chopped, the staff closes the cylinder 21, and the staff will The meat in the car...

Embodiment 3

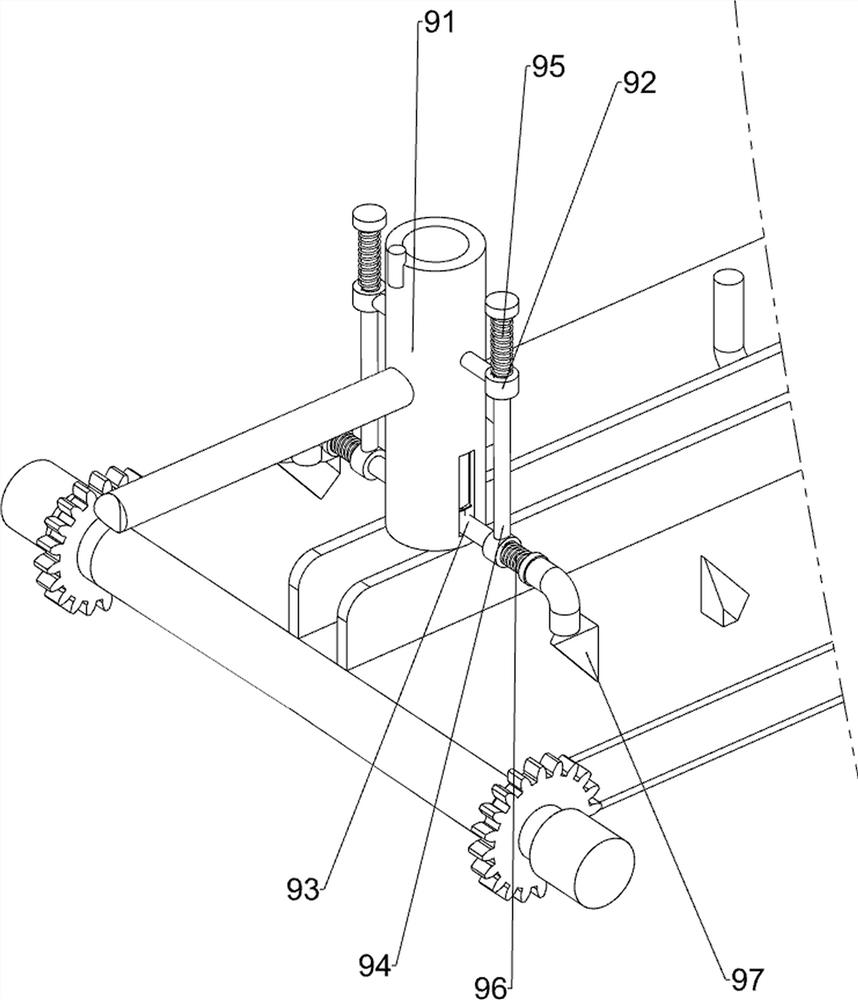

[0088] On the basis of Example 2, such as Figure 4-10 Shown, also include pushing mechanism 4, and pushing mechanism 4 comprises first inclined-plane driving block 41, second inclined-plane driving block 42, extruding pushing plate 43 and second spring 44, chopping knife 23 top front sides Be provided with the second inclined-plane driving block 42, the first inclined-plane driving block 41 is provided on the rear side of the top of the chopping knife 23, and the front and rear sides of the carrying mechanism 22 are slidingly provided with extruding pusher plates 43, extruding the pusher plates 43 Through the bearing mechanism 22, the extruding pusher plates 43 on the front and rear sides are respectively in contact with the second inclined-plane driving block 42 and the first inclined-plane driving block 41, and the extruding pusher plate 43 is provided with a second spring 44, and the second spring The two ends of 44 are respectively connected with the extruding pushing pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com