Patents

Literature

35results about How to "Avoid affecting the separation effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

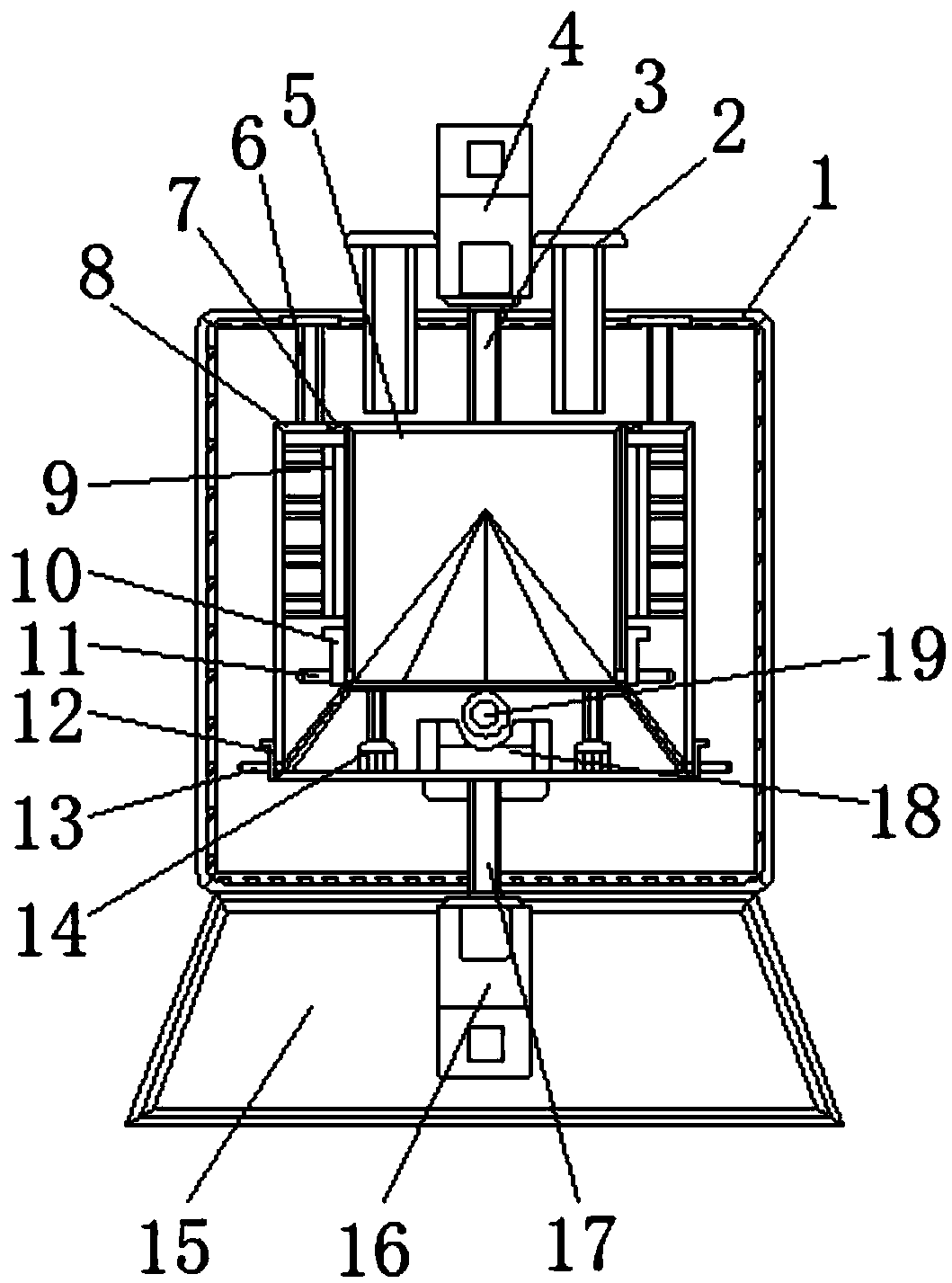

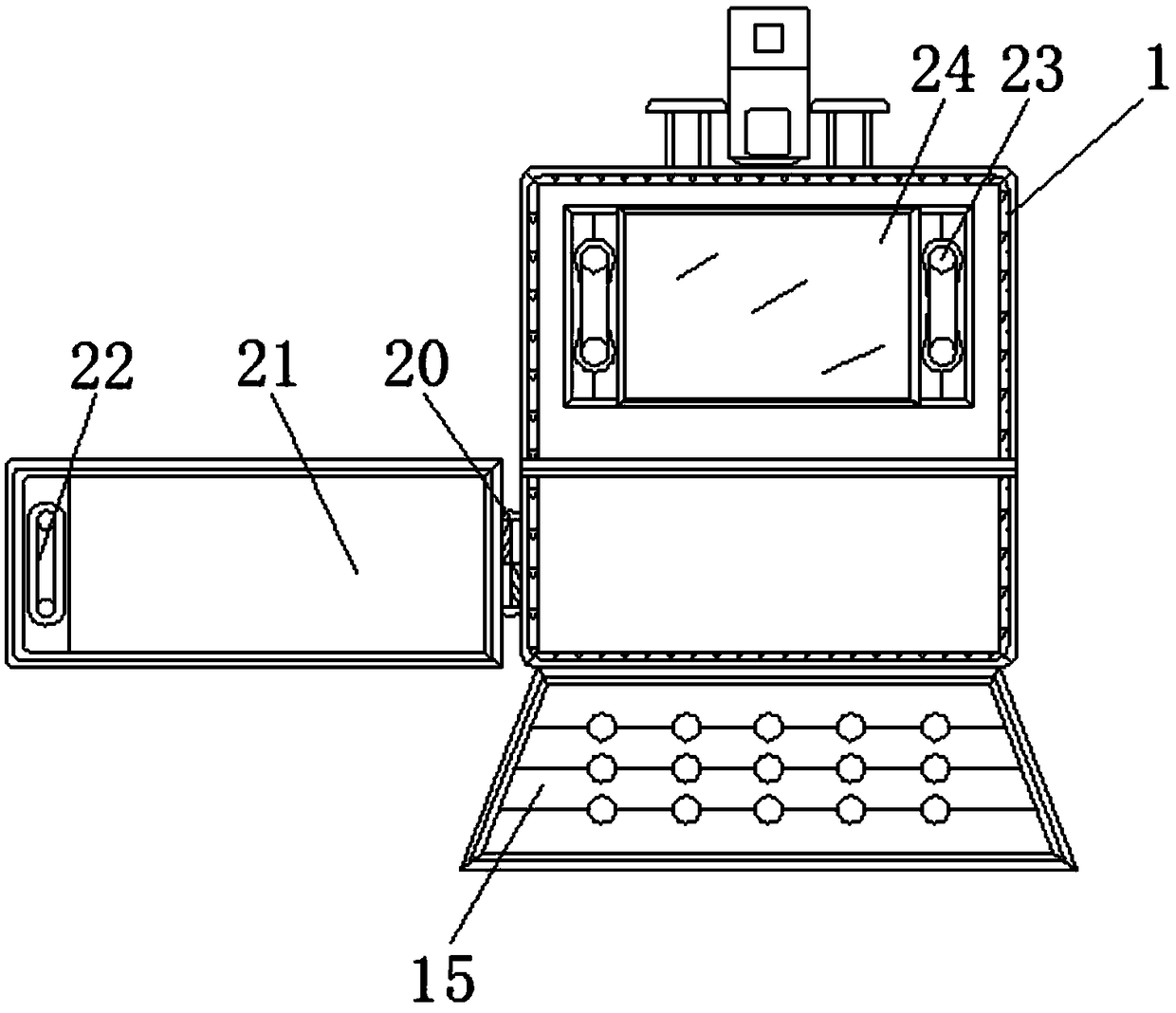

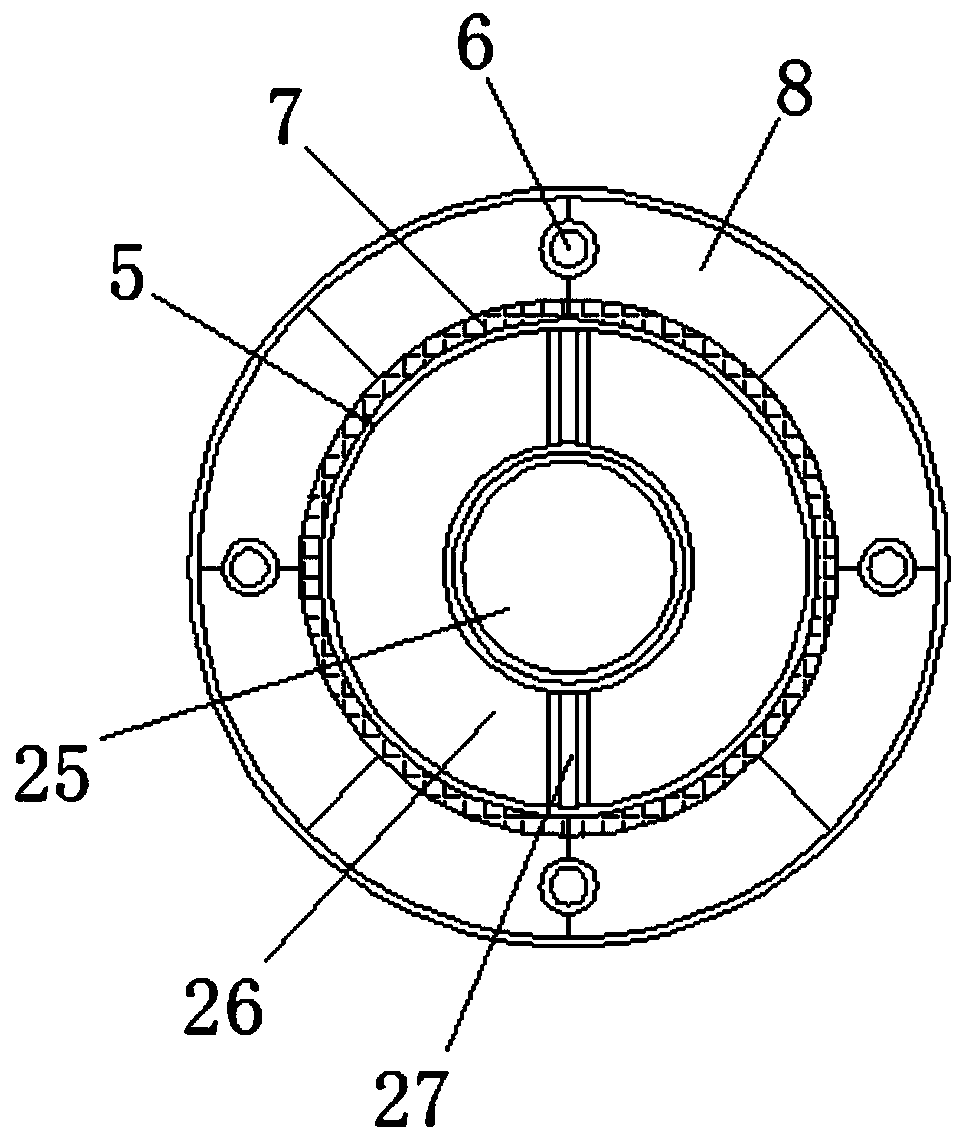

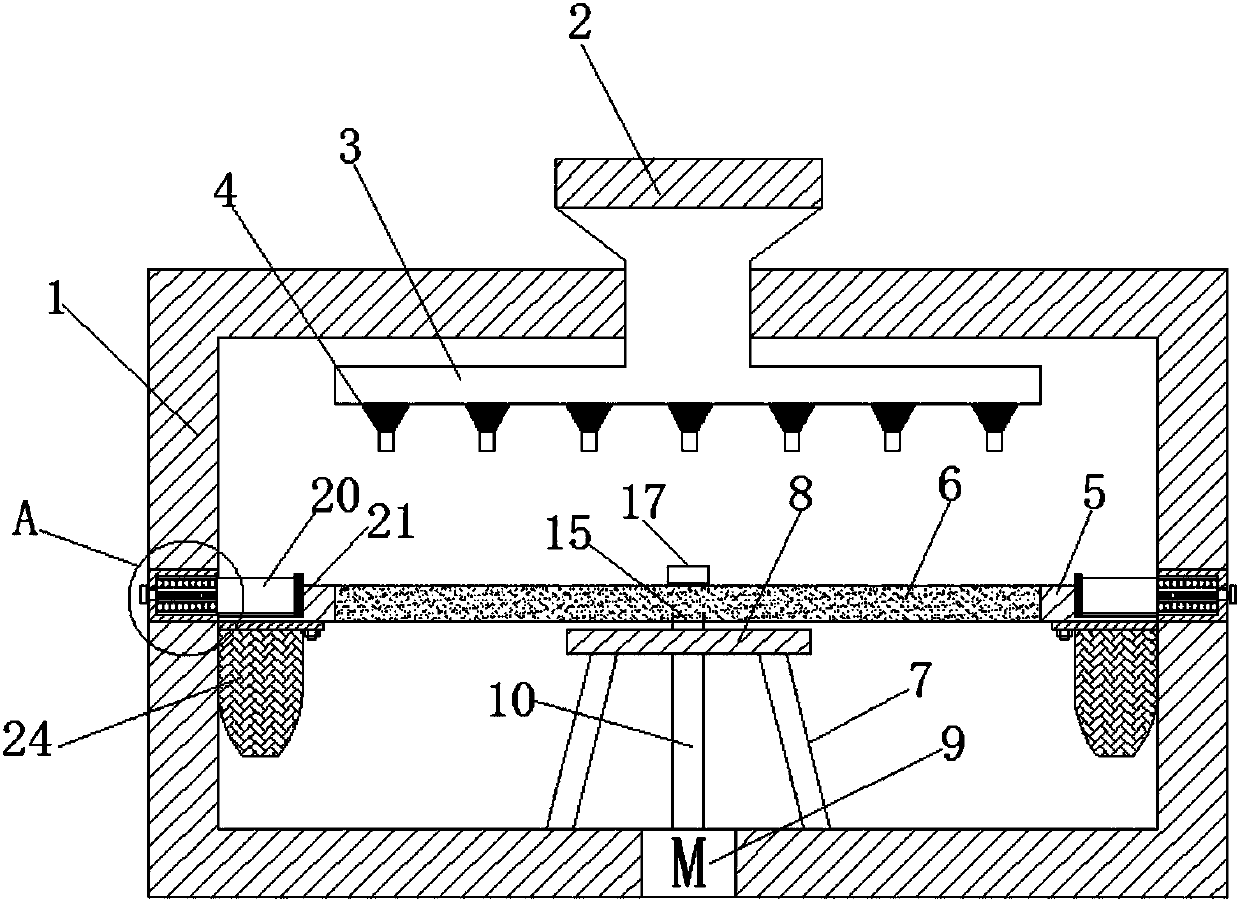

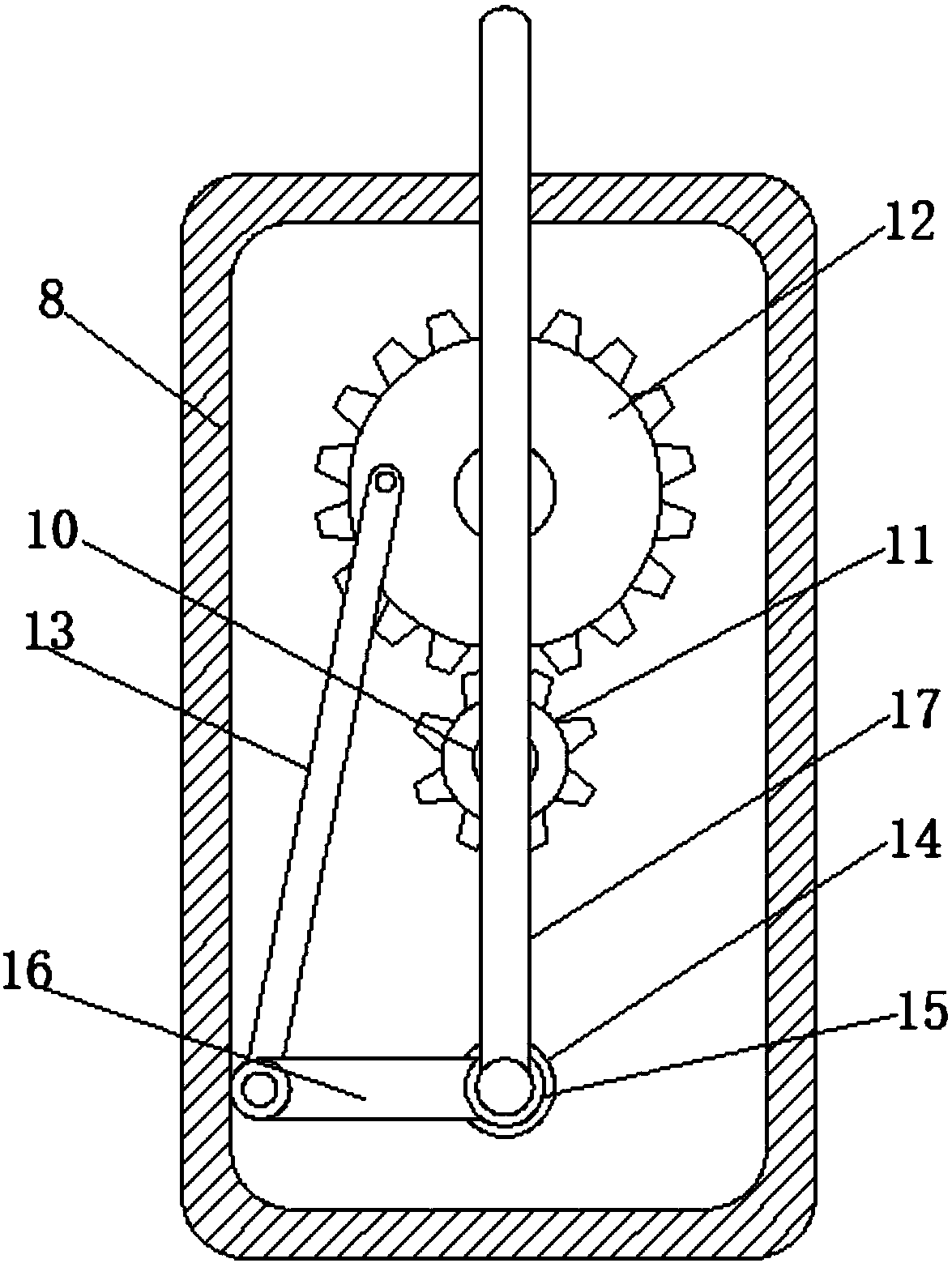

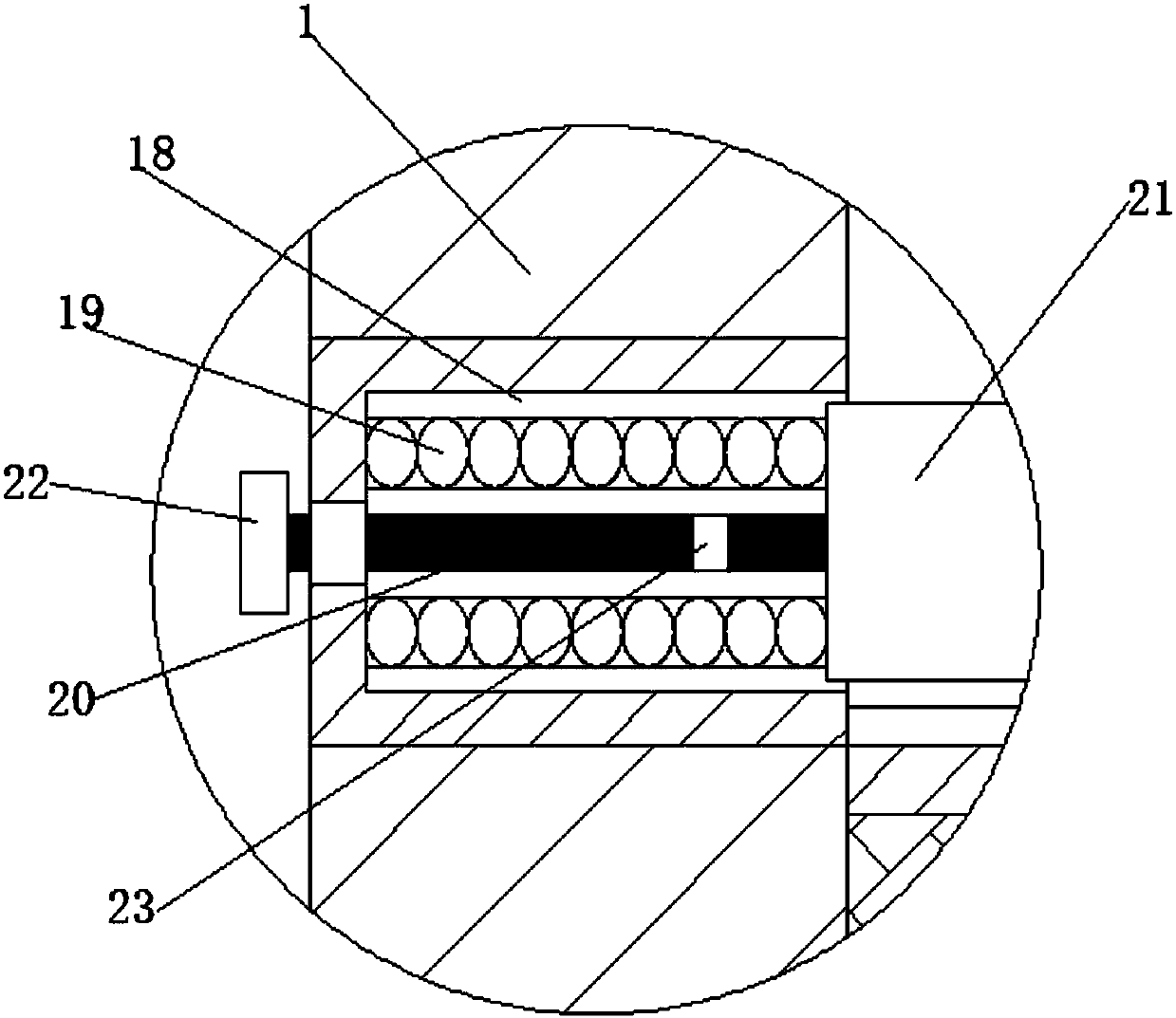

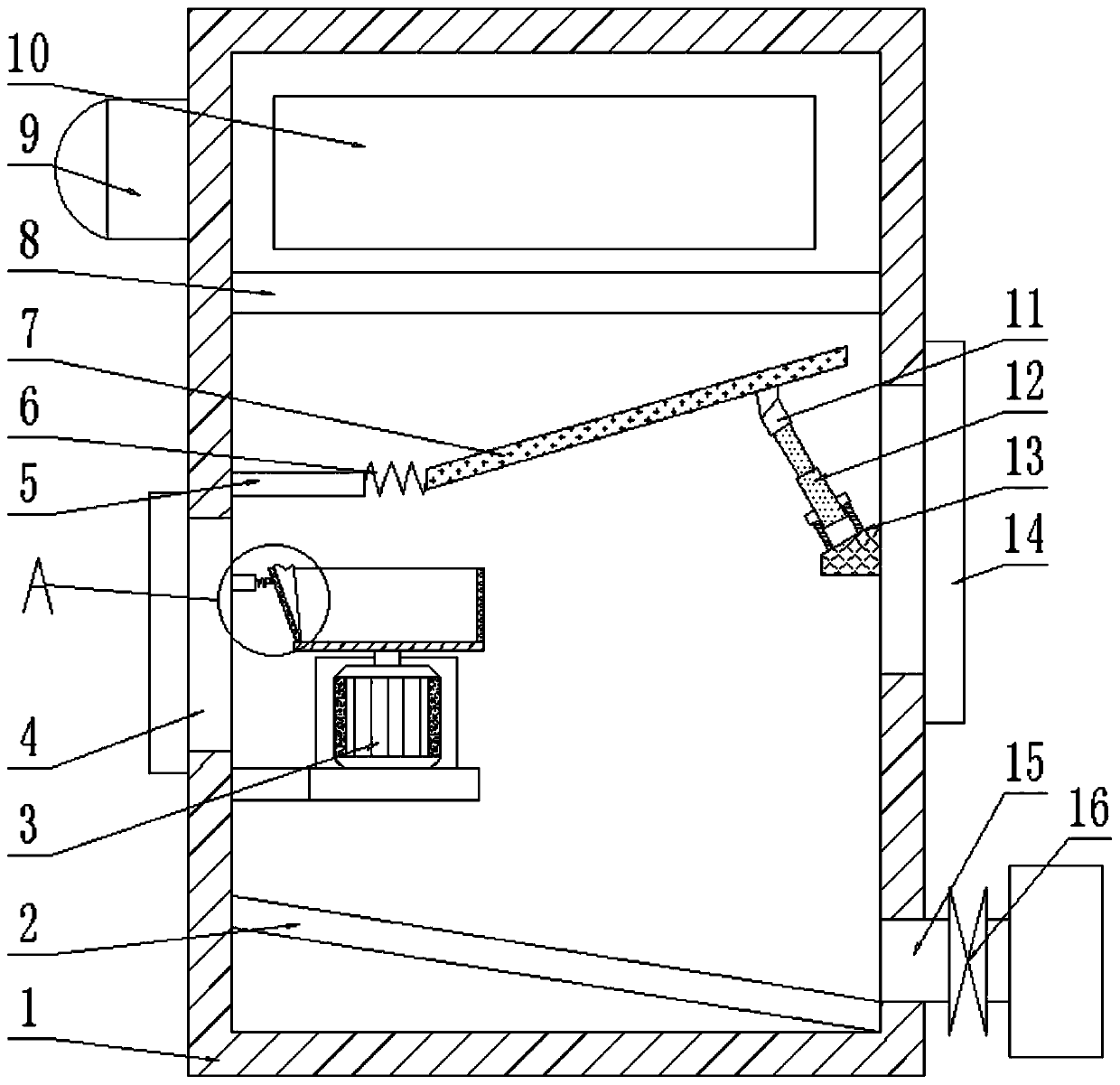

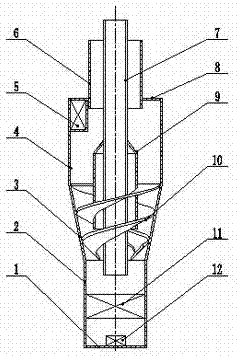

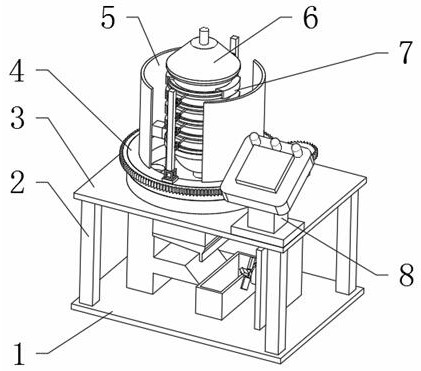

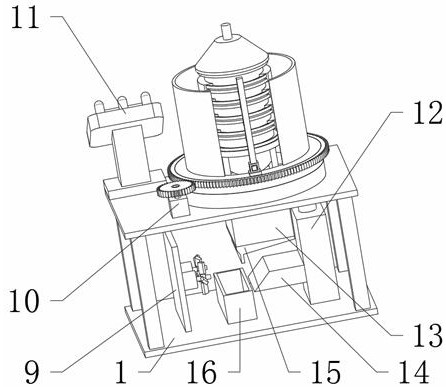

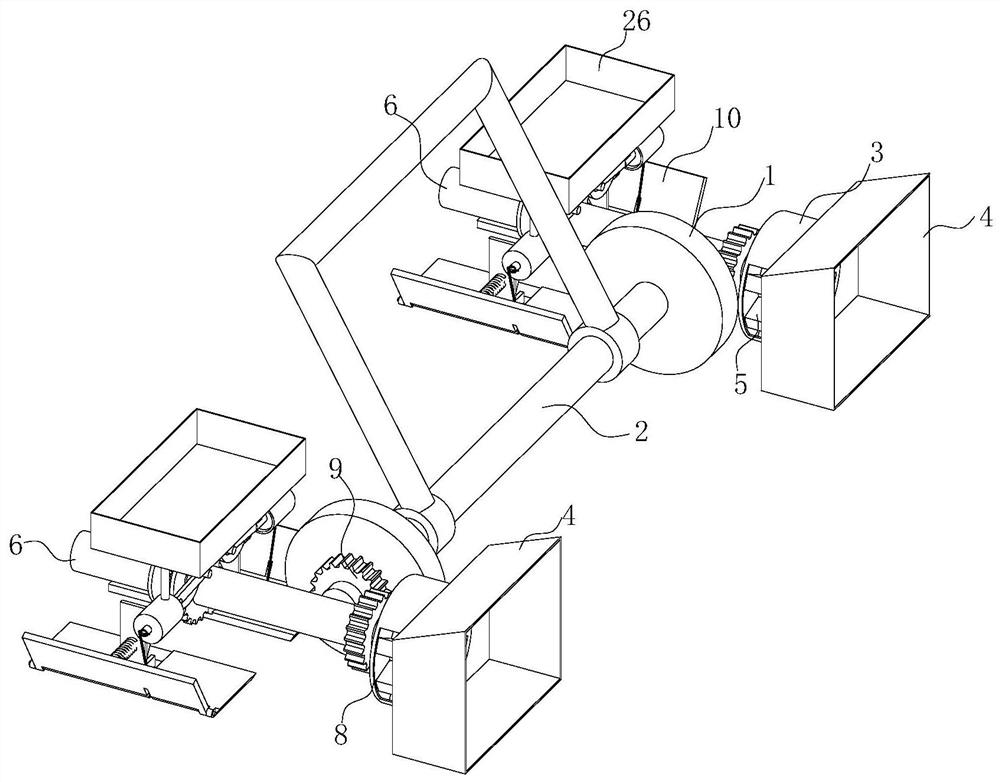

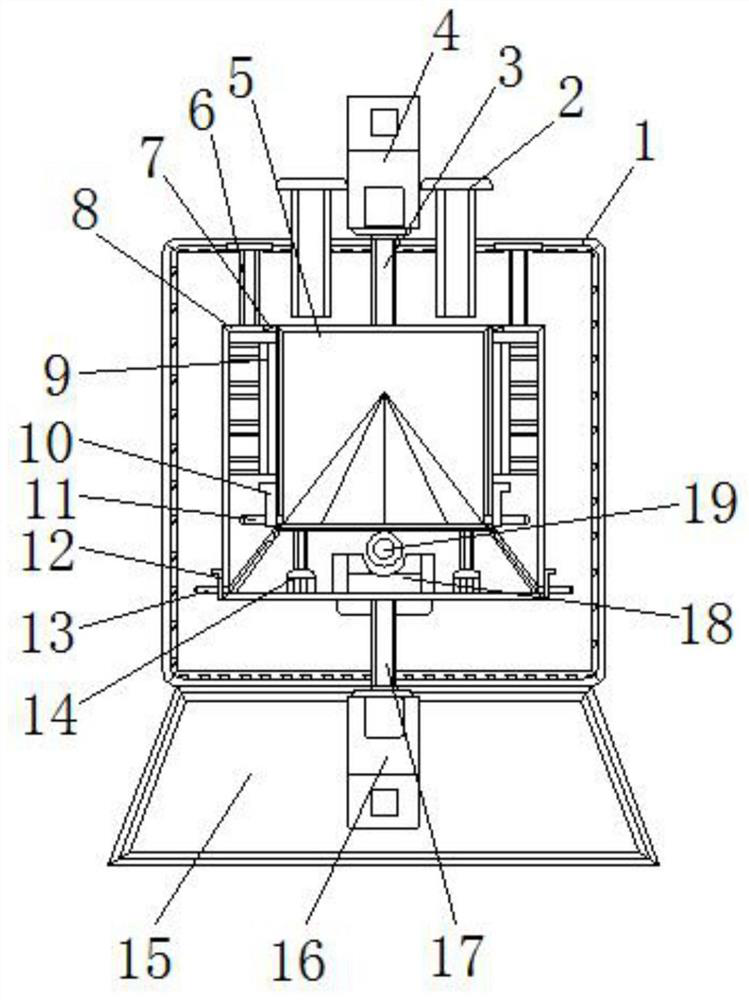

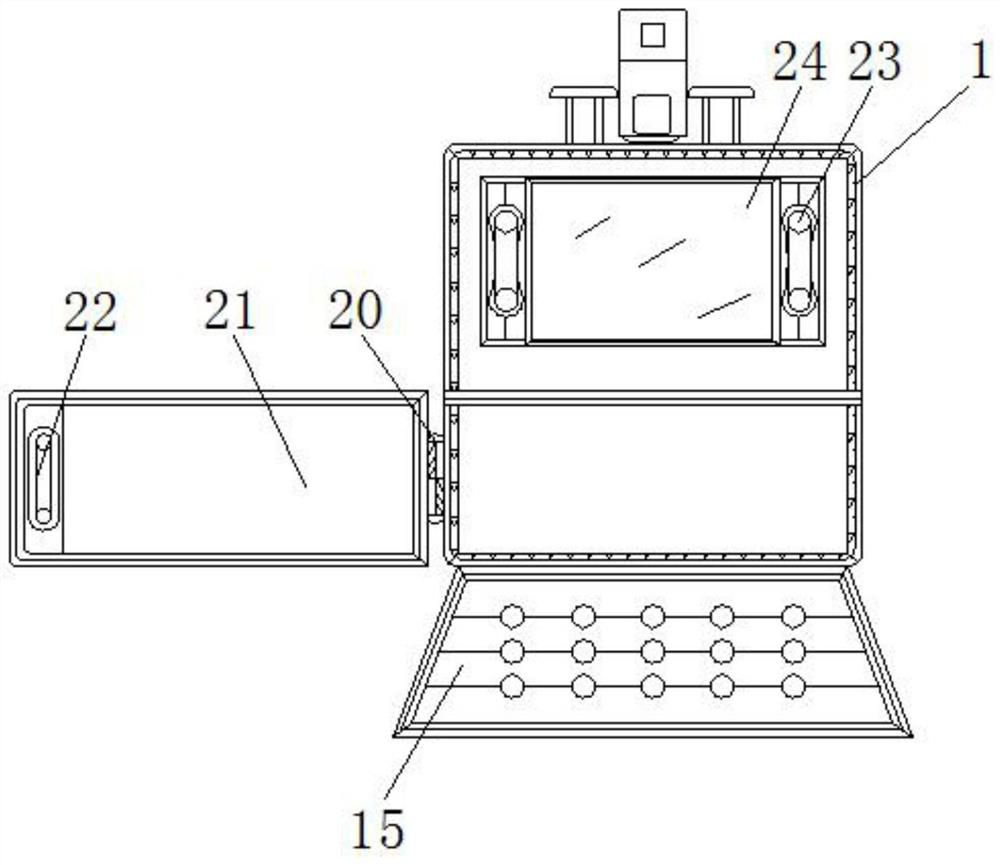

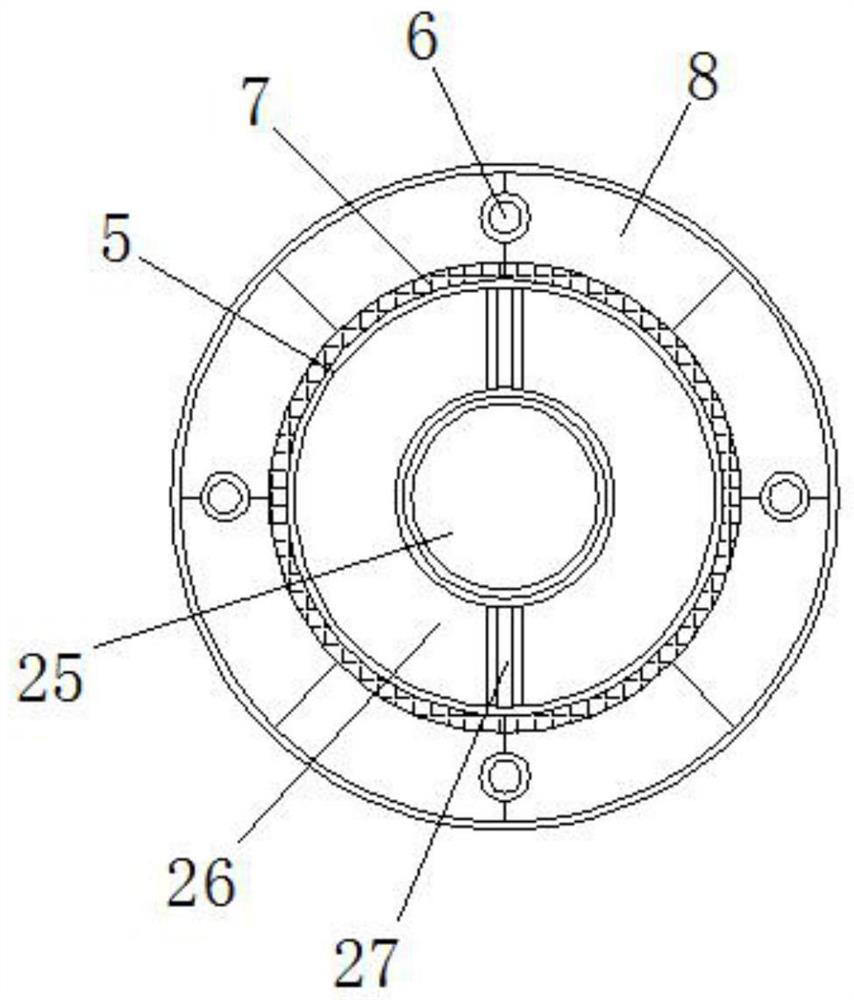

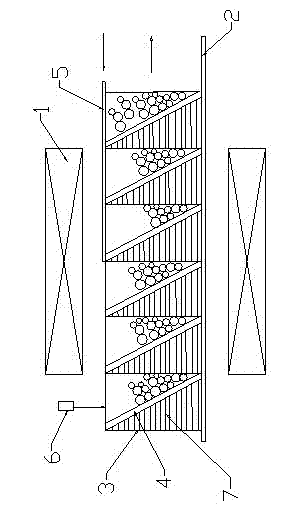

Smashing and separating device for recoverable iron scraps in building garbage

InactiveCN107252717AImprove adsorption capacityImprove separation efficiencyMagnetic separationGrain treatmentsHelical bladeEngineering

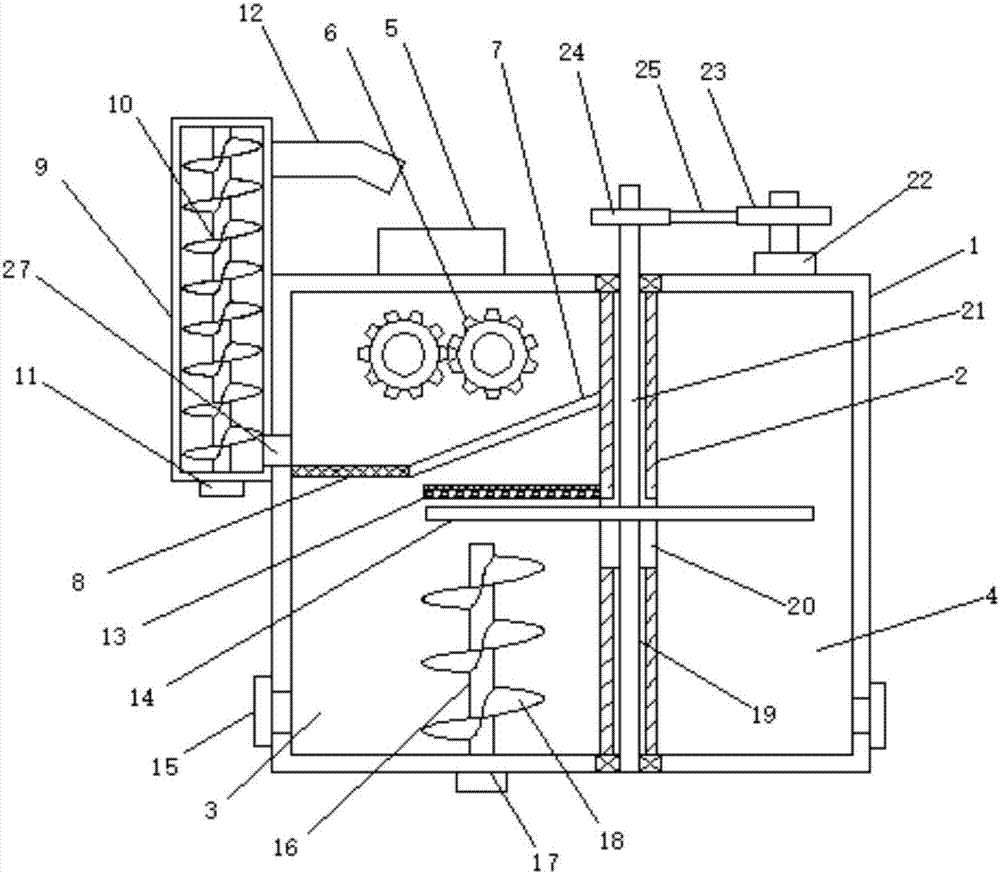

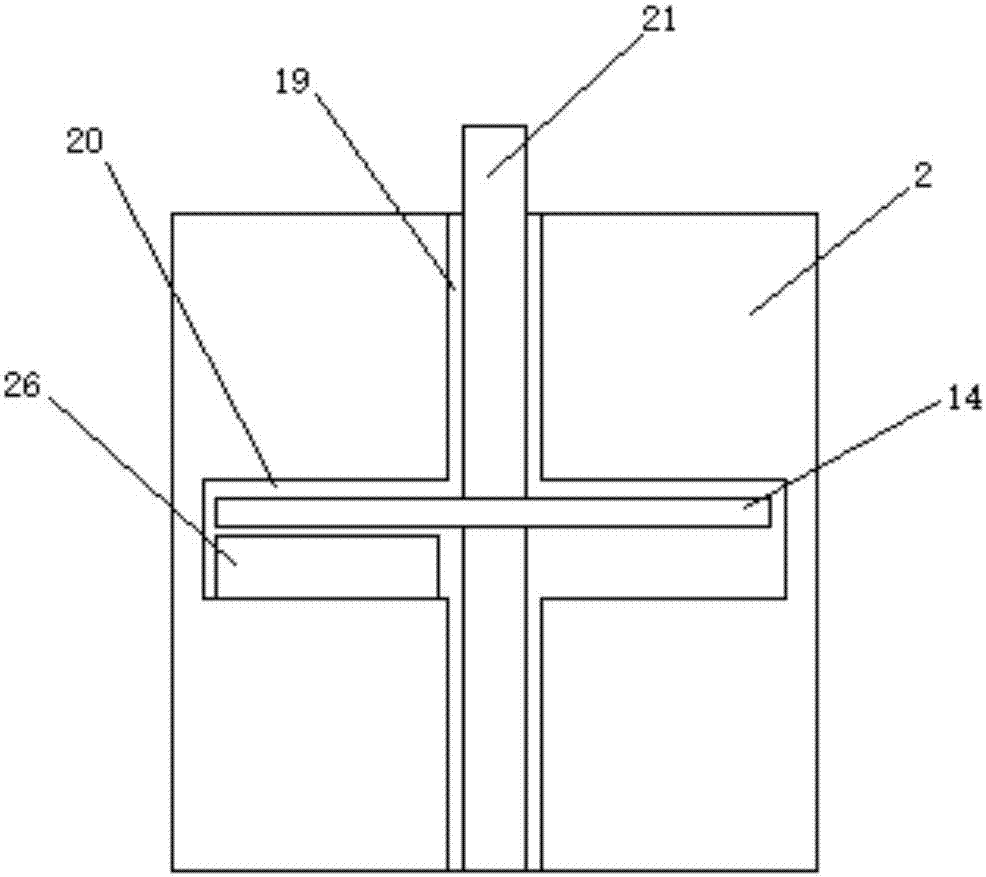

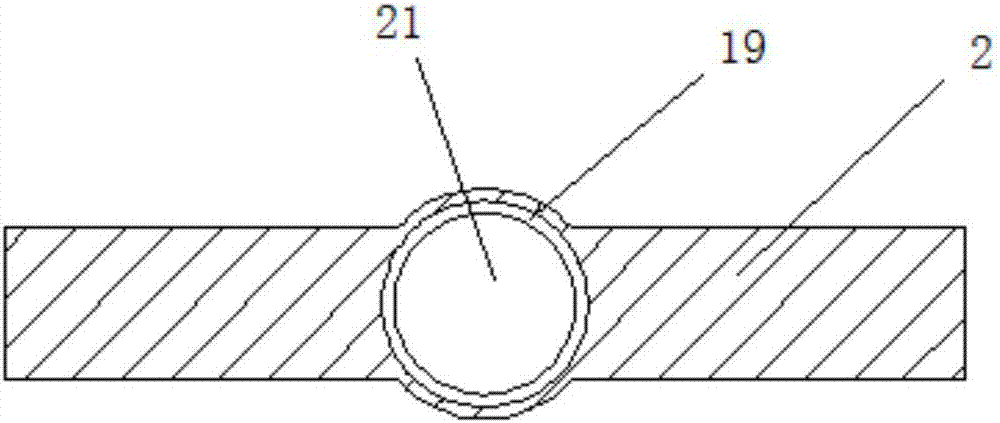

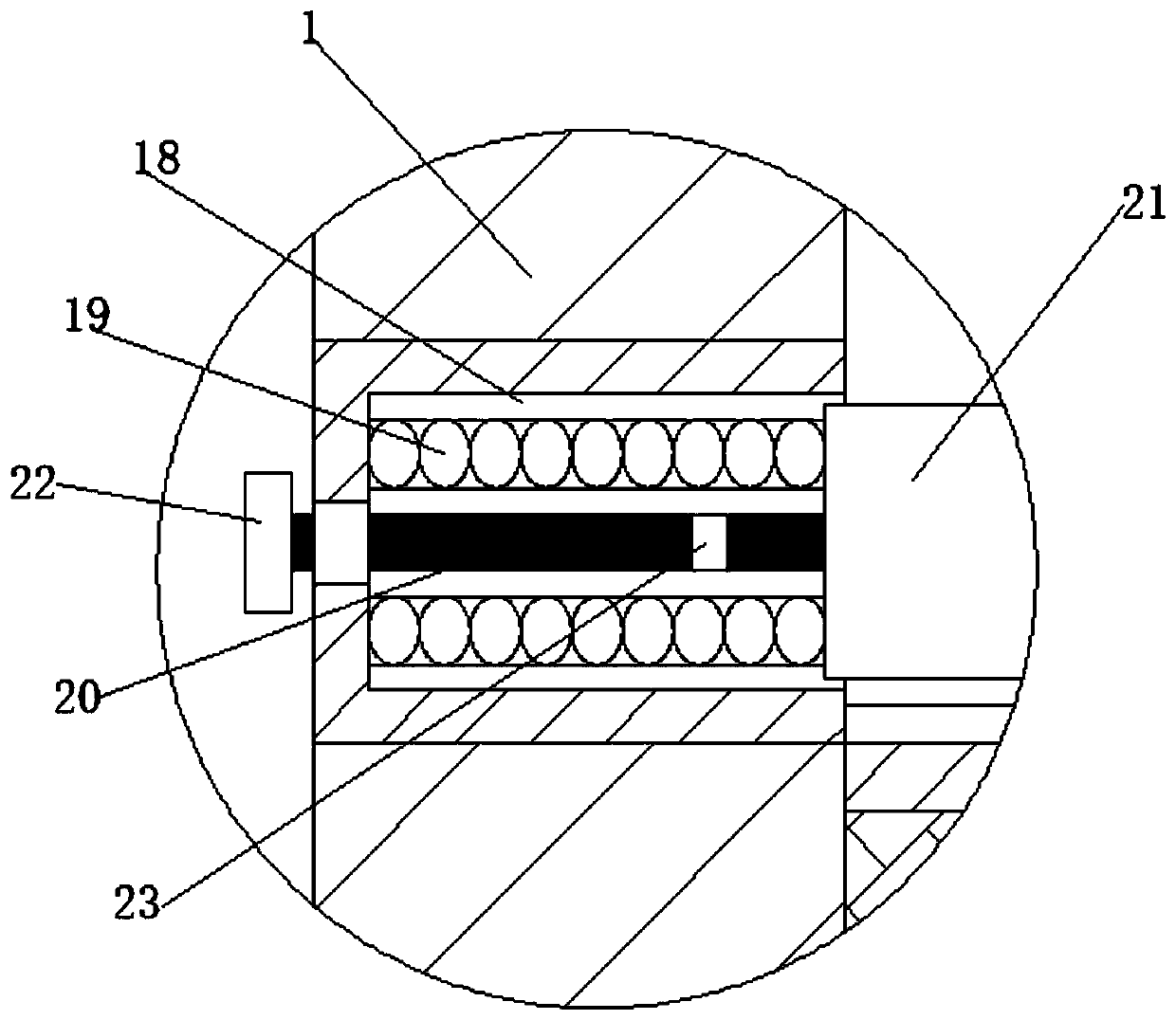

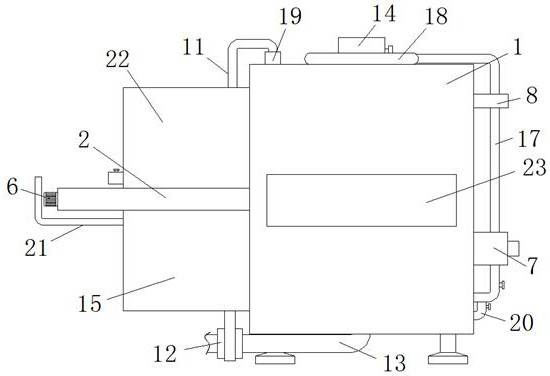

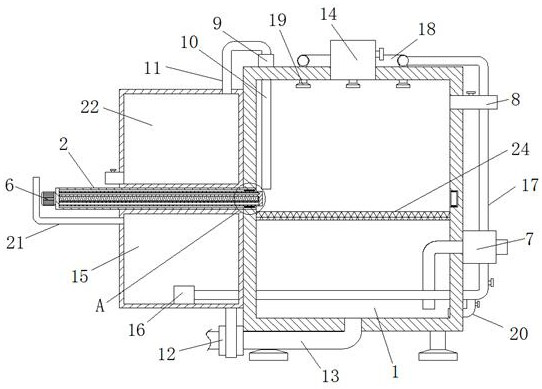

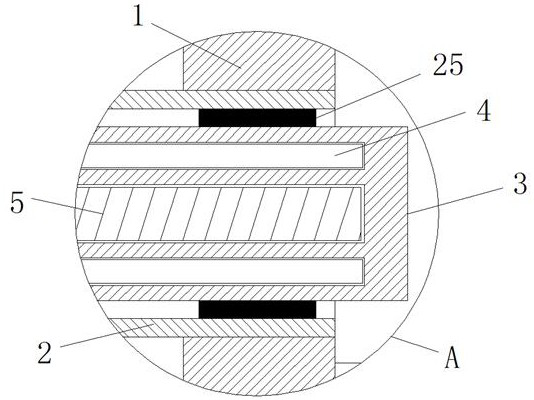

The invention discloses a smashing and separating device for recoverable iron scraps in building garbage. The smashing and separating device for the recoverable iron scraps in the building garbage comprises a treatment box. The treatment box is internally provided with a partition plate. Two abreast smashing rollers are arranged in a treatment room. The side, close to the treatment room, of the partition plate is provided with a half-round permanent magnet disk. The middle of the partition plate is provided with a vertical rotating shaft penetrating hole. The rotating shaft penetrating hole is internally provided with a rotating shaft. The rotating shaft is provided with a material suction disk. The permanent magnet disk is located on the upper portion of the material suction disk. The rotating shaft is provided with screw blades. The lower end of the rotating shaft is connected with a second motor arranged at the bottom of the treatment box. The lower end of a drainage oblique plate is provided with a sieving plate. A circular material opening is formed in the side wall, where the sieving plate is located, of the treatment box. A screw conveyer is arranged in an elevating pipeline. According to the smashing separating device for the recoverable iron scraps in the building garbage, the structure is simple, the iron scraps can be smashed and separated simultaneously, the separation efficiency is high, the separation effect of the iron scraps is good, manual operation is not needed, and the practicability is high.

Owner:杜鑫

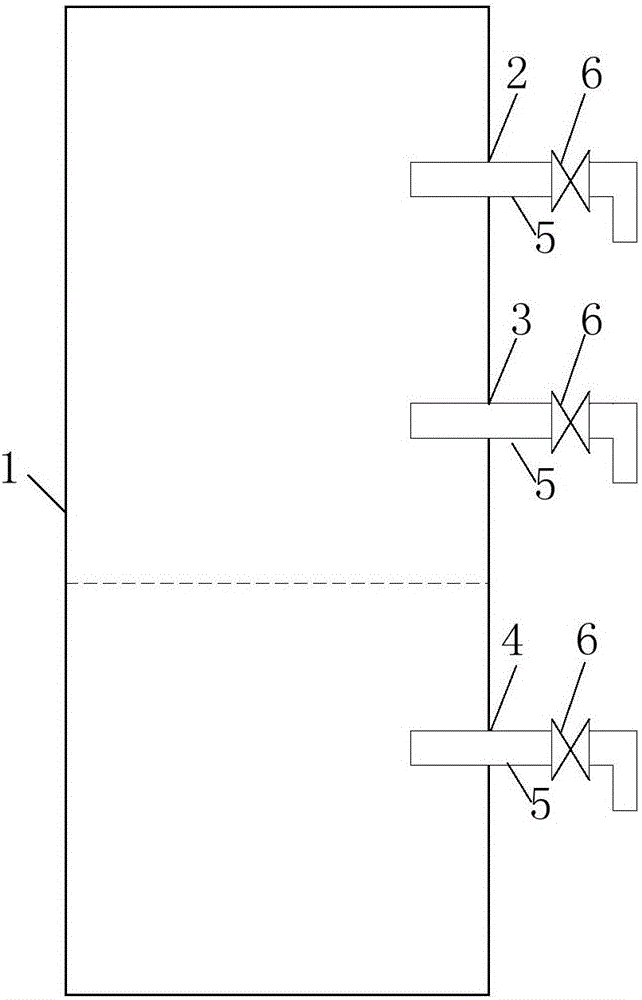

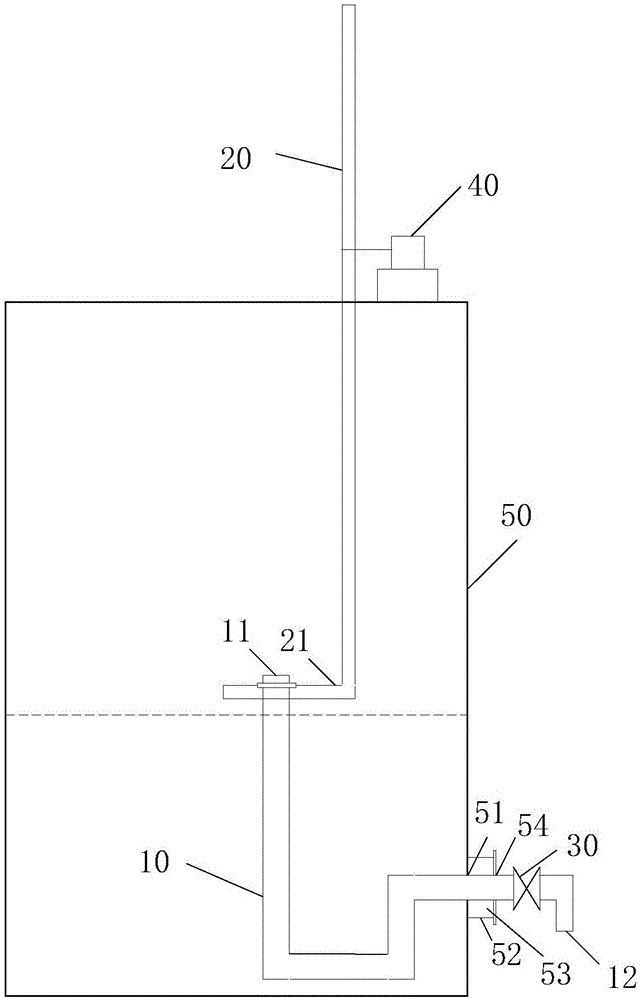

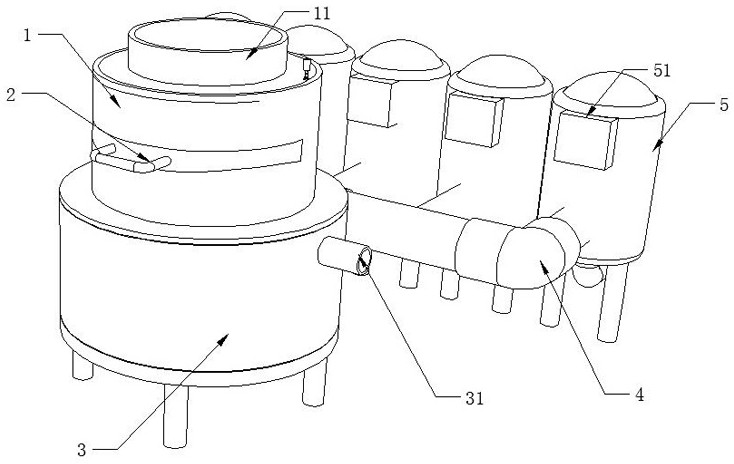

Floating-type oil absorption device of oil-water separator

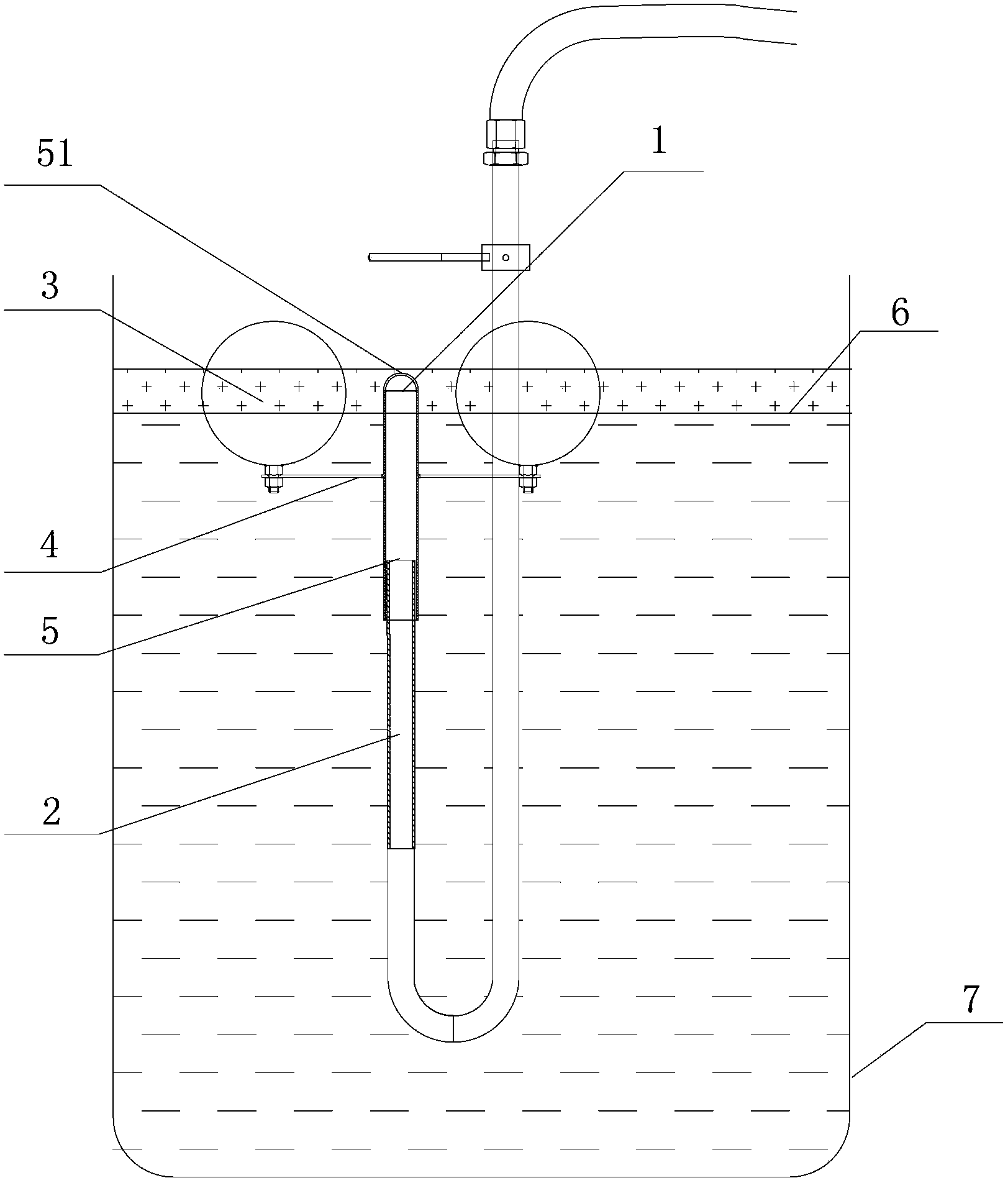

The invention relates to an oil absorption device, in particular to a floating-type oil absorption device of an oil-water separator. The oil absorption device comprises an oil absorption hole, an oil absorption pipe, two stainless steel floating balls, a connecting rod which is arranged on the lower ends of the two stainless steel floating balls and fixedly connected with the two stainless steel floating balls, and an oil absorption sleeve, wherein the oil absorption hole is arranged on the top end of the oil absorption sleeve, the oil absorption sleeve is connected with the oil absorption pipe in a sliding manner and fixedly connected with the middle part of the connecting rod, and the other end of the oil absorption pipe is connected with an oil absorption starting device. The oil absorption sleeve is connected with the oil absorption pipe in a sliding manner, and can move up and down along the floating balls, so that an oil-water interface can be automatically and precisely tracked, the horizontal height of an oil-water inlet can be consistent with the oil-water interface, the substance entering the pipeline is basically oil, air and impurities can be prevented from entering, the separation effect is good, the automation degree is high, and simplicity and convenience in operation can be realized.

Owner:HEPHAES HEAT TREATMENT SYST JIANGSU

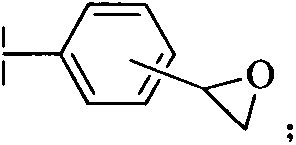

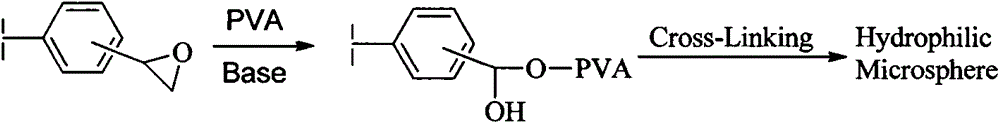

Hydrophilic modification method for PS-DVB (polystyrene-divinyl benzene) crosslinked microspheres grafted and bonded with PVA (polyvinyl alcohol)

InactiveCN106478974AAvoid affecting the separation effectEliminate hydrophobicityDouble bondChemistry

The invention relates to a hydrophilic modification method for PS-DVB (polystyrene-divinyl benzene) crosslinked microspheres grafted and bonded with PVA (polyvinyl alcohol). The method comprises steps as follows: epoxy groups with high reaction activity are introduced into surfaces of PS-DVB crosslinked microspheres and subjected to a reaction with hydroxyl in PVA, bonded PVA is subjected to a post-crosslinking reaction with a cross-linking agent, compact hydrophilic PS-DVB crosslinked microspheres wrapped with PVA are obtained, and hydrophobicity caused by benzene ring residues and pendent double bonds on the surfaces of the PS-DVB crosslinked microspheres is eliminated; furthermore, PVA is subjected to the post-crosslinking reaction, so that the phase collapse phenomenon of PVA long chains on the surfaces of the PS-DVB crosslinked microspheres in the field of bioseparation under the high-salt condition is avoided, further derivatization of a large amount of hydroxyl in PVA can be facilitated, chromatography separation media meeting different requirements can be prepared, and the method belongs to the field of modification of functional polymer microspheres.

Owner:扬州倍赛德生物科技有限公司

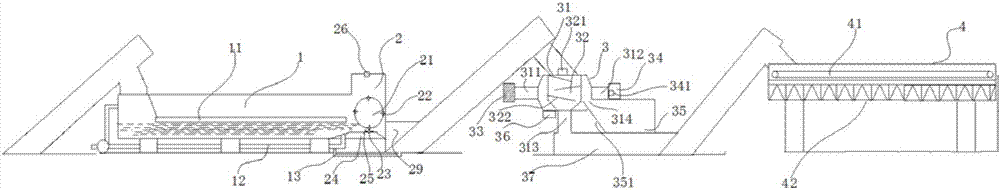

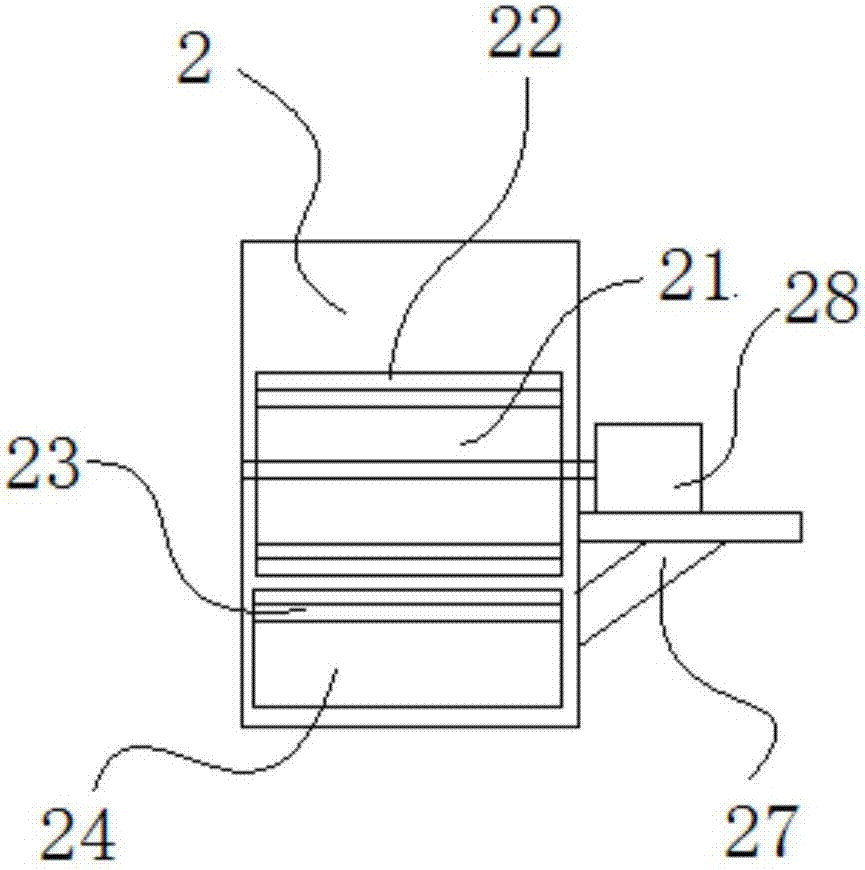

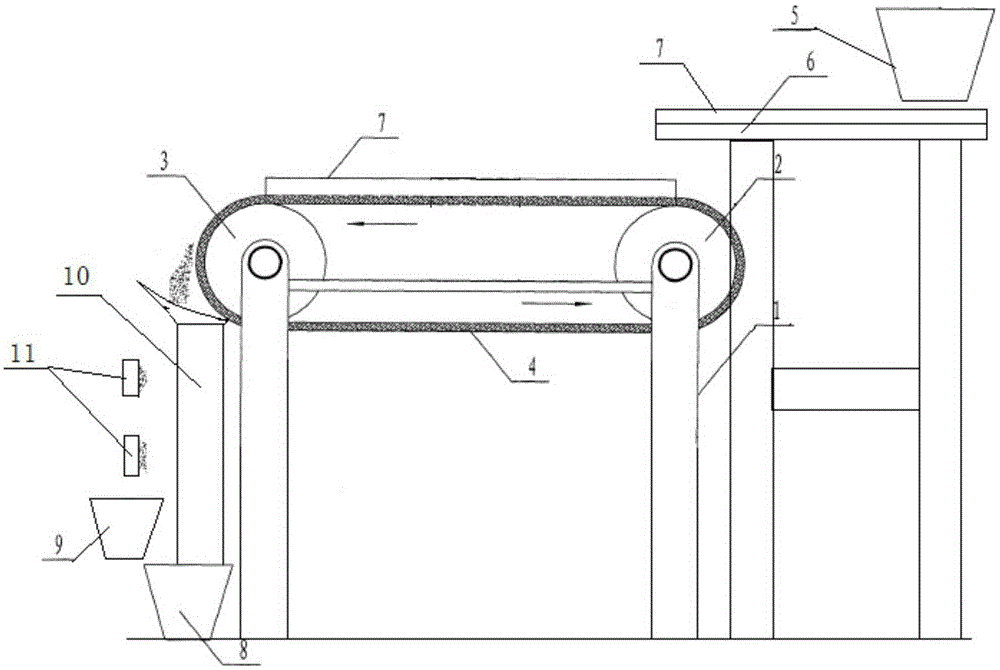

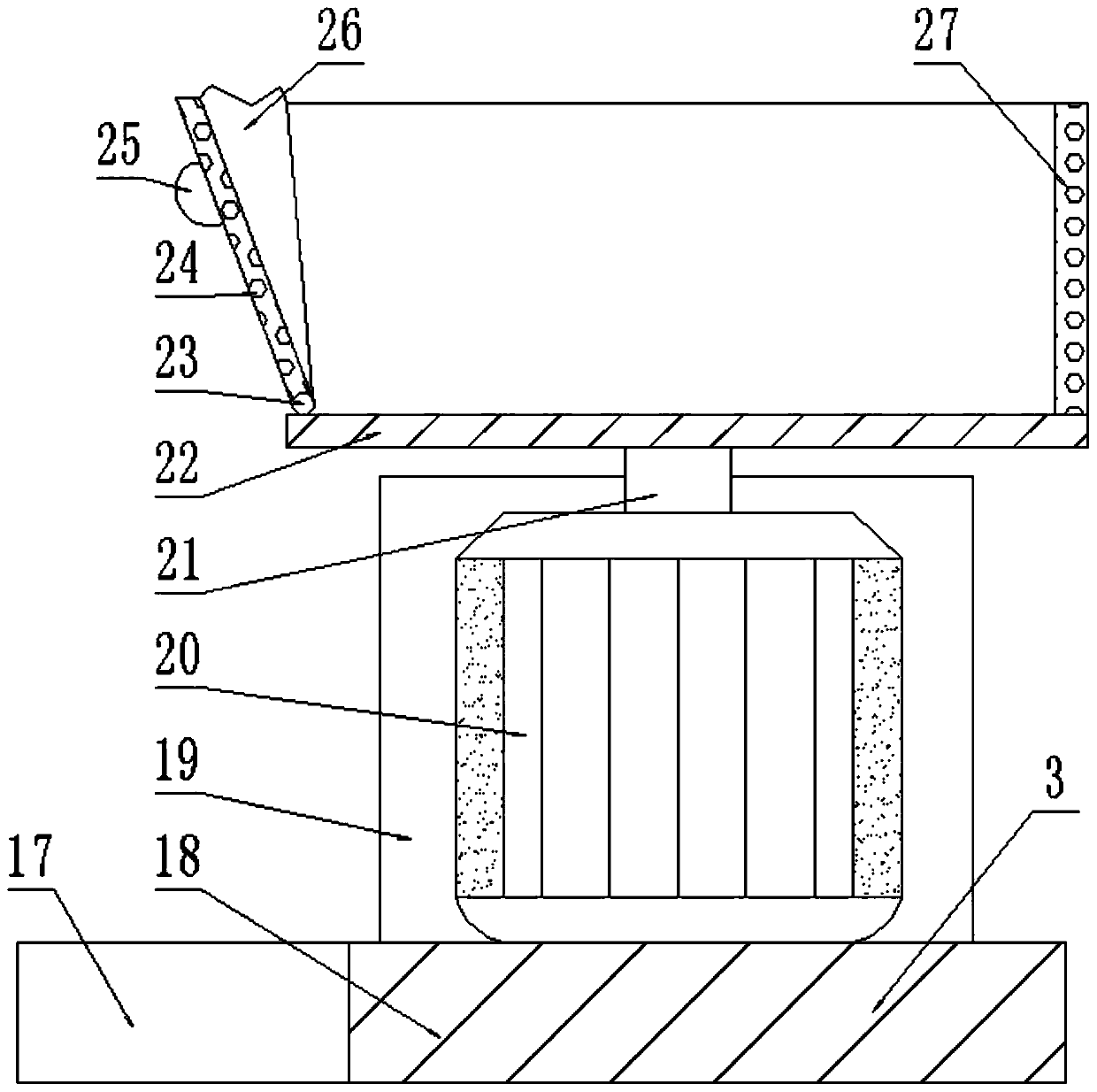

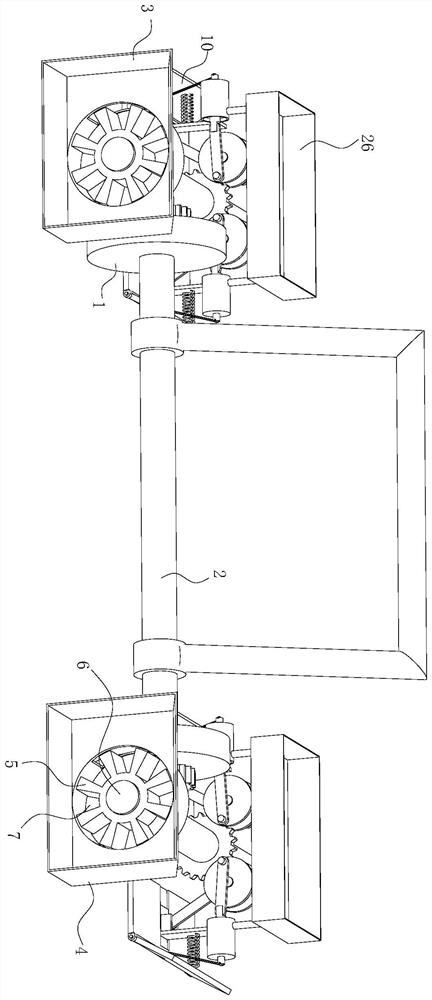

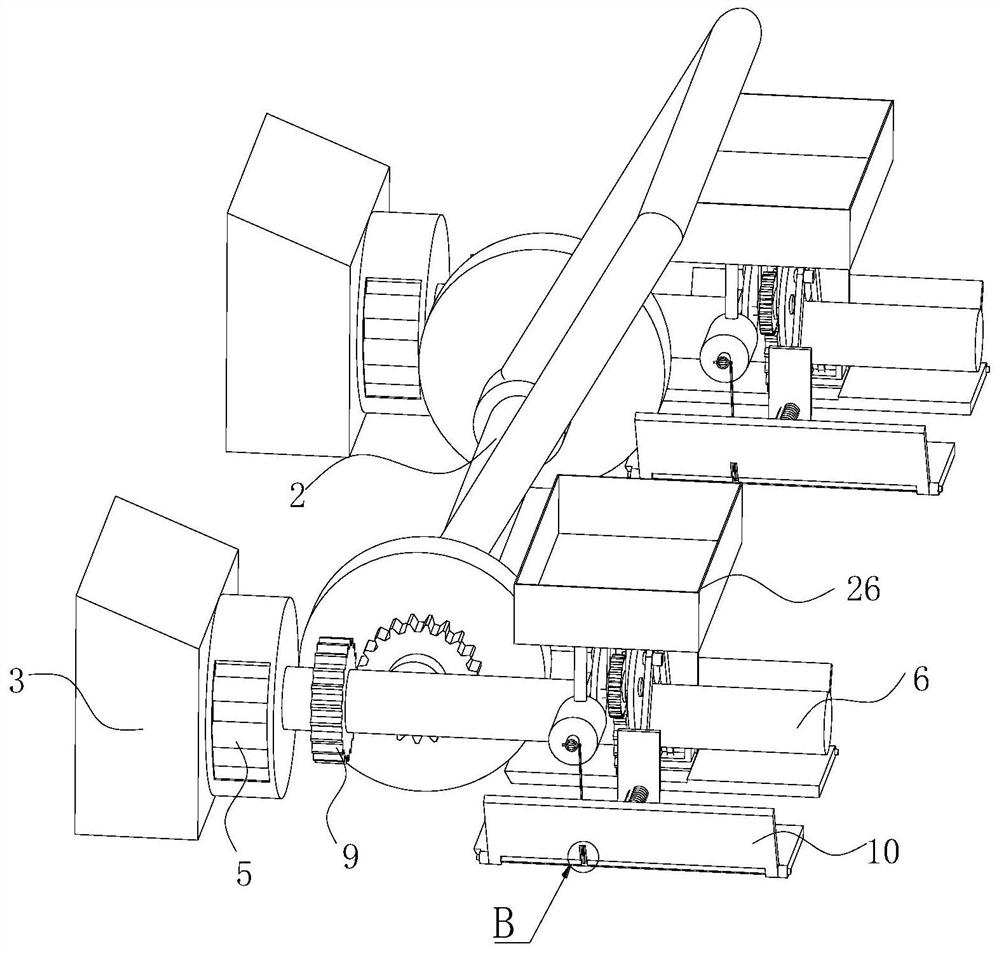

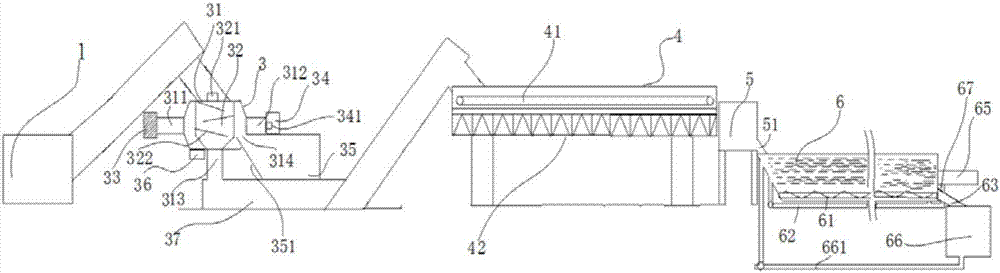

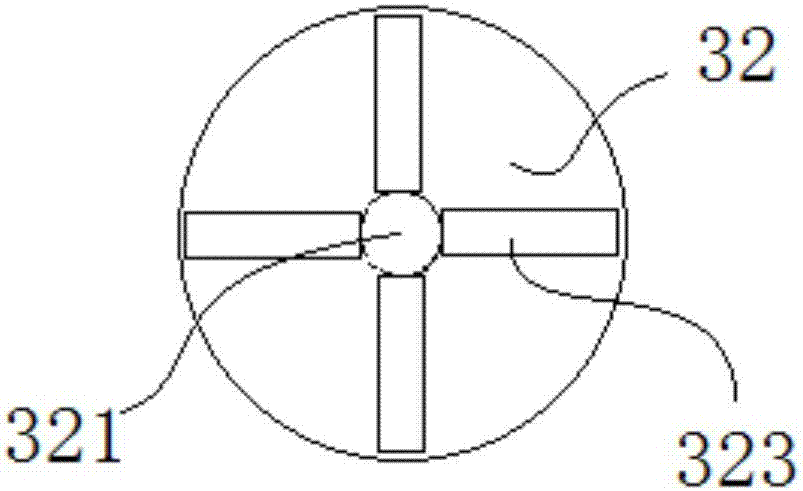

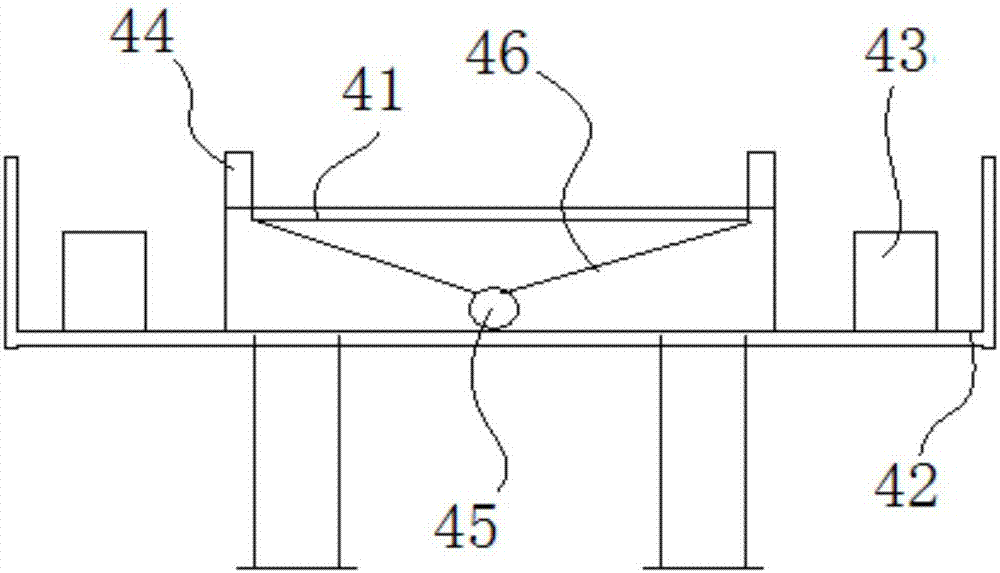

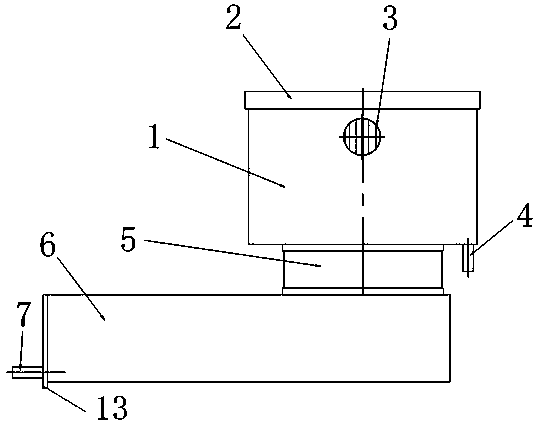

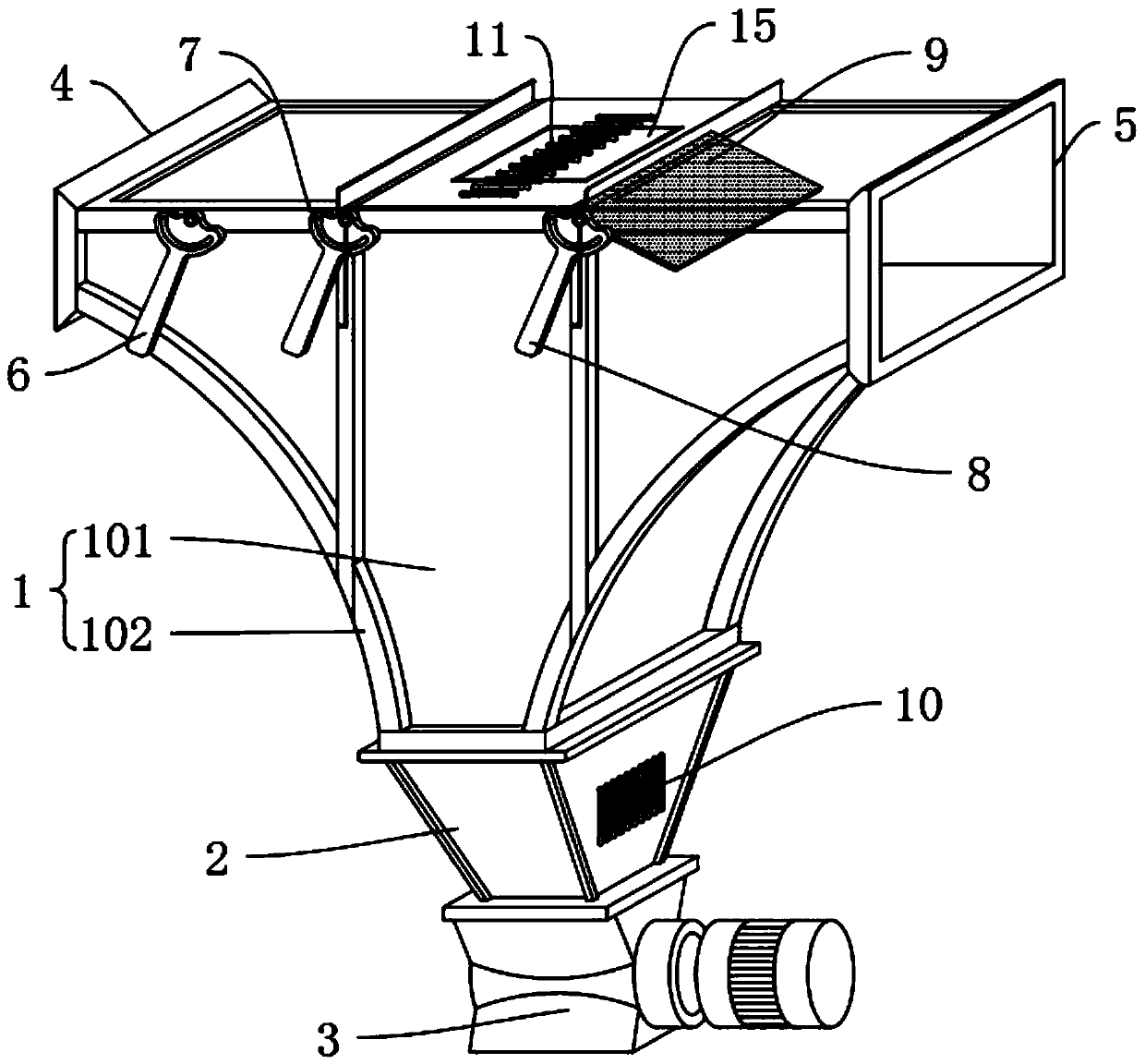

Waste plastic bottle label separation system and application thereof

InactiveCN106964618ASolve technical problems with low purityTo achieve the goal of complete strippingHollow article cleaningPlastic recyclingState of artAfter treatment

The invention discloses a waste plastic bottle label separation system and application thereof, and belongs to the technical field of waste plastic bottle recycling. The waste plastic bottle label separation system comprises a soaking pond, a stripping mechanism, a winnowing mechanism and a picking platform which are sequentially arrayed according to the working procedures. The soaking pond communicates with the stripping mechanism. The stripping mechanism, the winnowing mechanism and the picking platform sequentially communicate with one another through a feeding auger. A bottle body label of a waste plastic bottle is softened by means of soaking, then the stripping mechanism is used for stripping the label, and afterwards, hand picking is performed after the winnowing mechanism is used for blowing off the label, so that the purpose of thoroughly separating the waste plastic bottle label is achieved, and recycling of the waste plastic bottle after treatment can be facilitated. By means of the waste plastic bottle label separation system and the application thereof, the problems that the bottle body label of the waste plastic bottle is tight in bonding and cannot be separated easily in the prior art, and secondary pollution is likely to be caused when a chemical method is adopted for treatment are solved.

Owner:MAANSHAN ZHICHENG SCI & TECH

Yao-folk medicine head treatment powder for expelling wind and promoting restoration of consciousness and preparation method of Yao-folk medicine head treatment powder

InactiveCN111514261AImprove separation efficiencyGuaranteed qualityPowder deliverySievingPittosporum illicioidesBlumea

The invention discloses Yao-folk medicine head treatment powder for expelling wind and promoting the restoration of consciousness. The Yao-folk medicine head treatment powder comprises the raw materials in parts by weight of 2-4 parts of pittosporum illicioides Makino, 4-8 parts of baec juov nqungh, 4-8 parts of maerng juon nqungh, 2-4 parts of dornh hongh nzunx, 2-4 parts of feix bung nzunx, 1-2parts of alpinia chinensis Rosc. roots, 1-2 parts of laciniate blumea herbs, 2-4 parts of to angle wind, 1-2 parts of rhizoma gastrodiae, 3-6 parts of rhizoma polygonati, 1-2 parts of radix angelica sinensis and 2-4 parts of cortex albiziae. The invention discloses a preparation method of the Yao-folk medicine head treatment powder for expelling wind and promoting the restoration of consciousness.The preparation method comprises the following steps of mixing the pittosporum illicioides Makino with the baec juov nqungh, the maerng juon nqungh, the dornh hongh nzunx, the feix bung nzunx, the alpinia chinensis Rosc. roots, the laciniate blumea herbs, the to angle wind, the rhizoma gastrodiae, the rhizoma polygonati and the radix angelica sinensis, performing grinding, performing screening and performing separating to obtain the Yao-folk medicine head treatment powder for expelling wind and promoting the restoration of consciousness.

Owner:罗捷

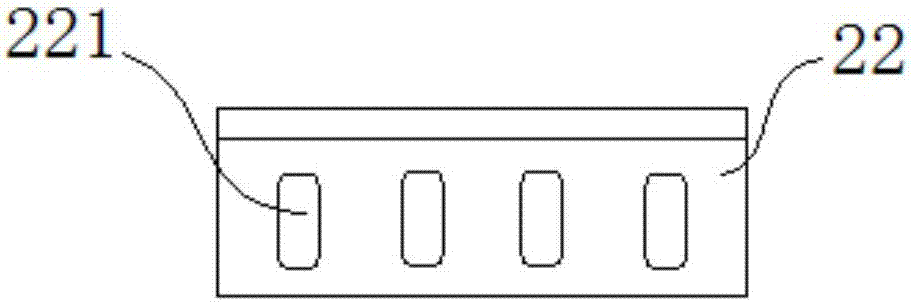

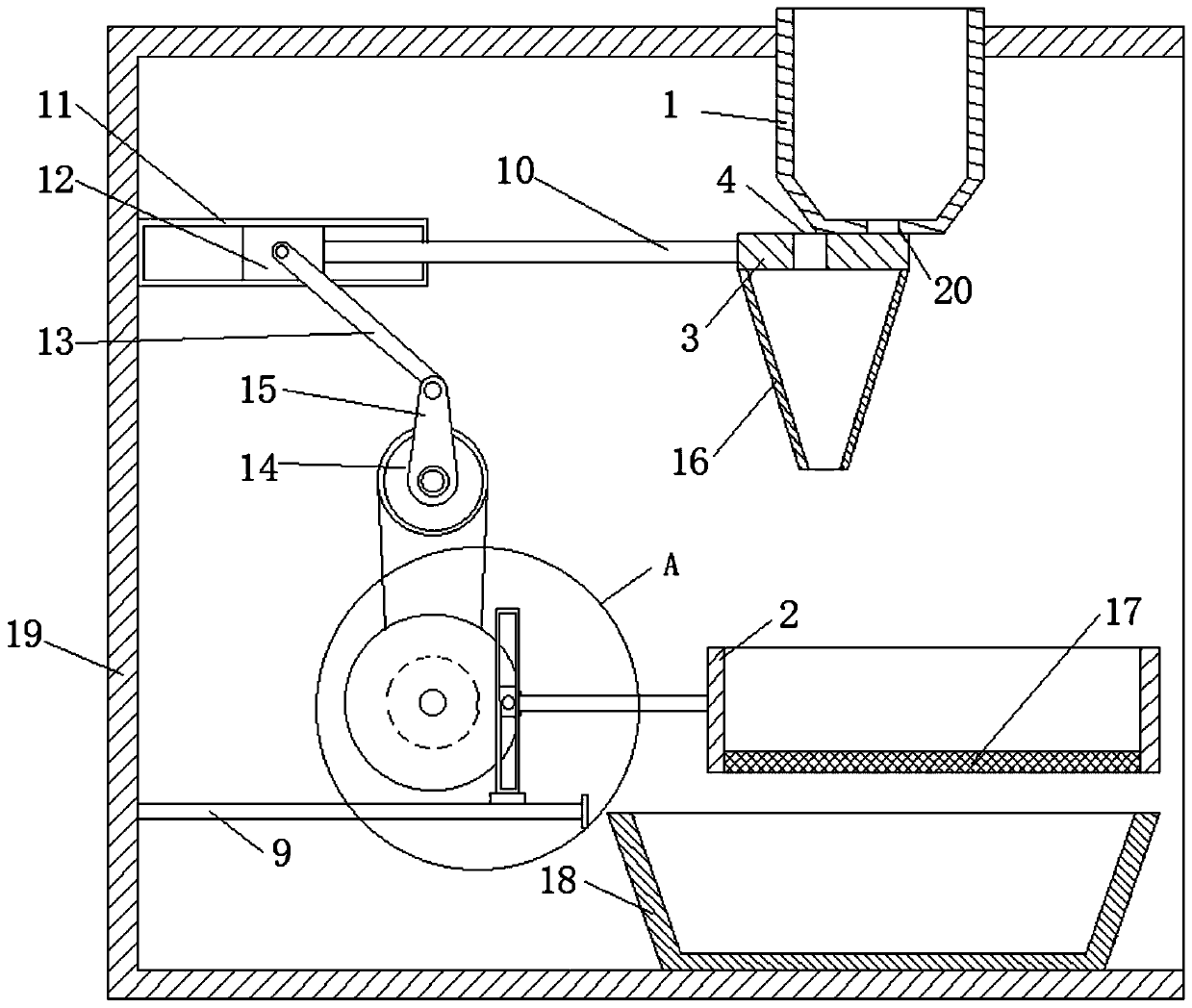

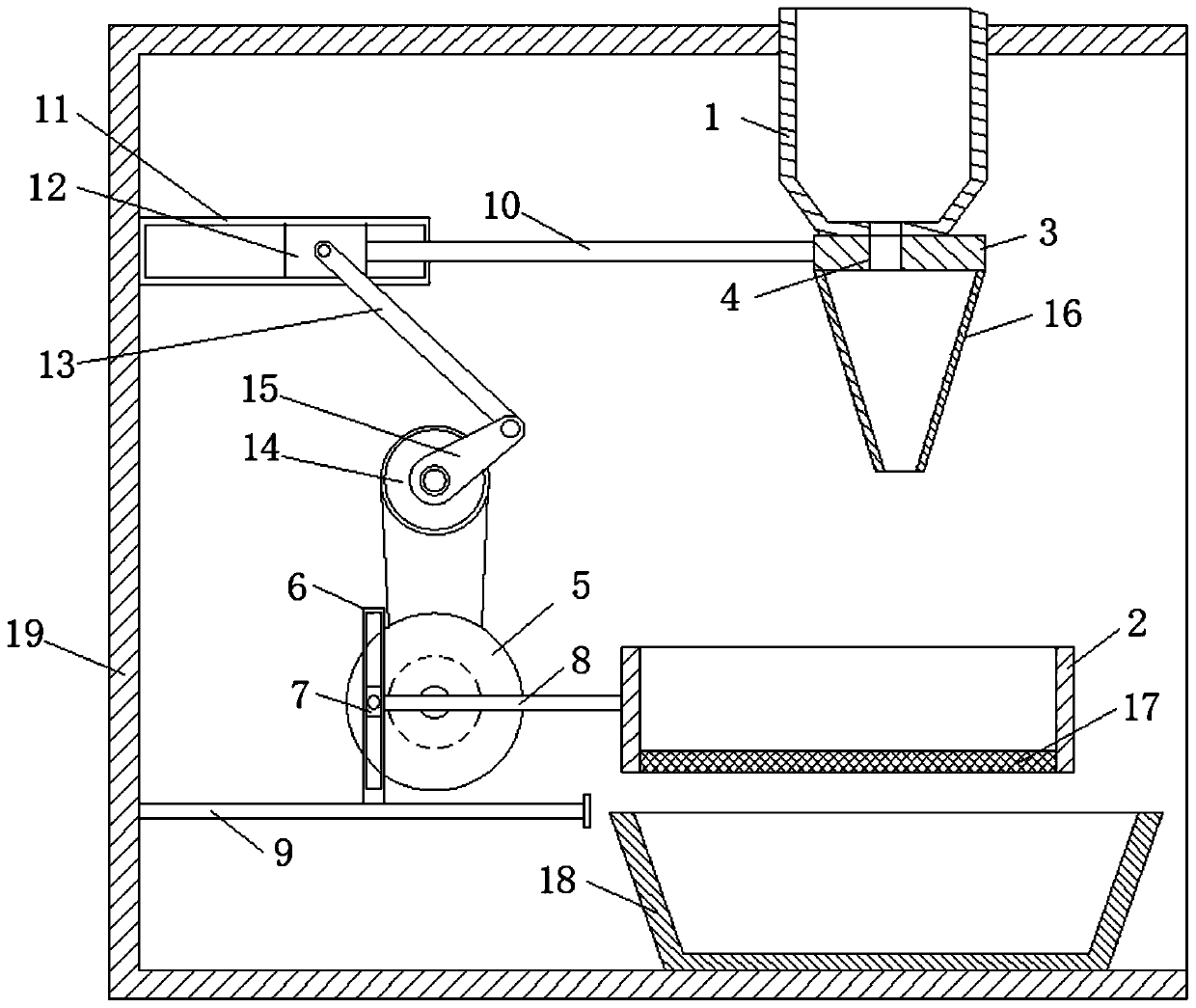

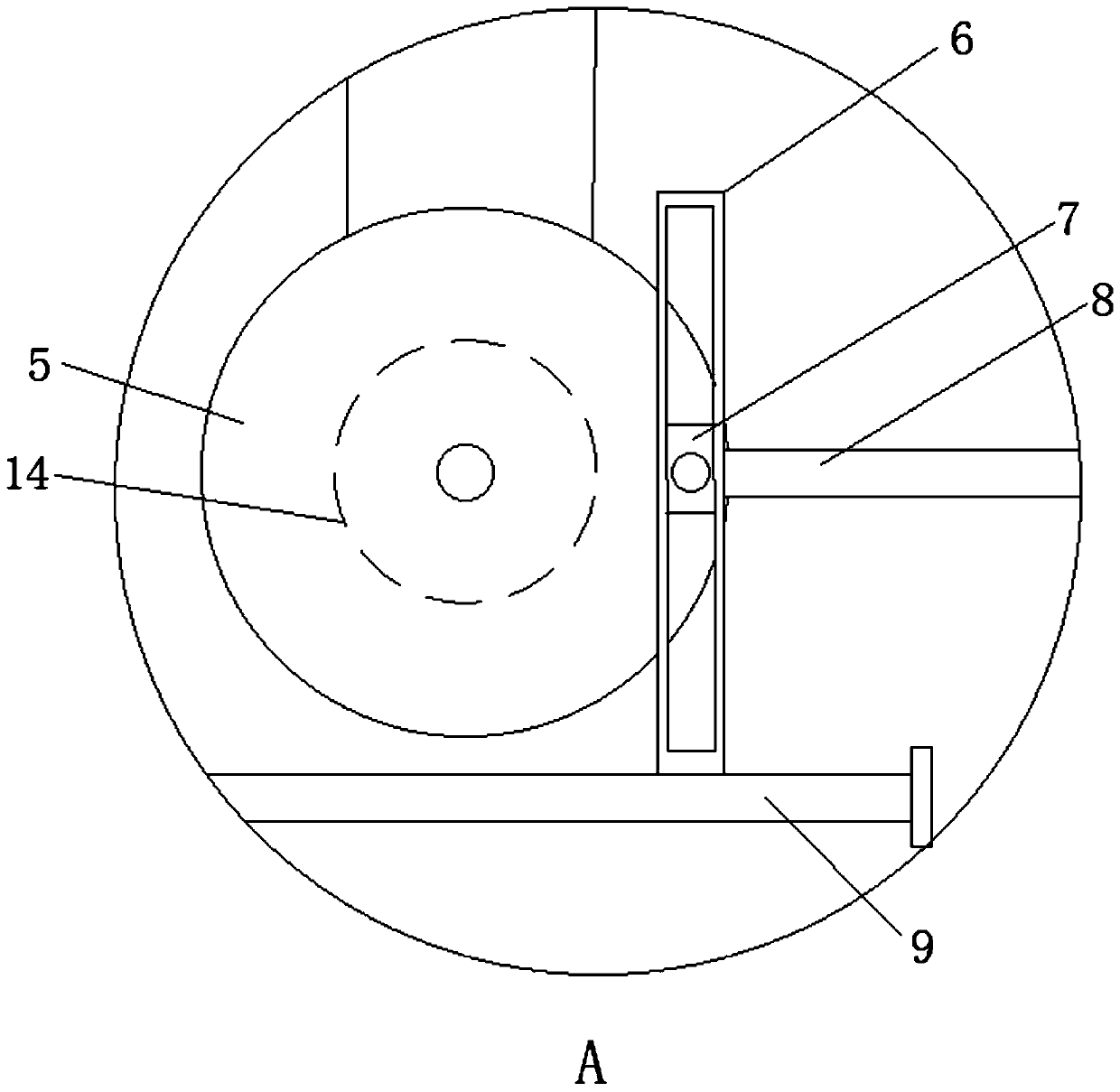

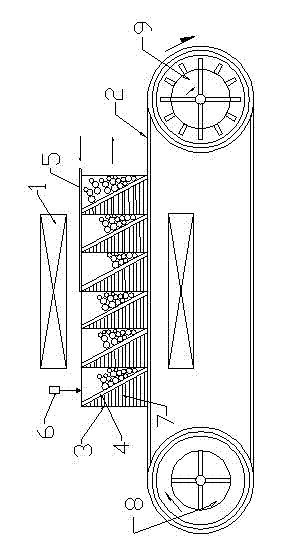

Device for separating impurities from spice for pastry

The invention discloses a device for separating iron impurities from a spice for pastry. The device comprises a rack, wherein a driving belt roller and a driven belt roller are arranged at two ends of the rack respectively; a transmission belt winds around the driving belt roller and the driven belt roller; the upper part of the driving belt roller corresponds to the discharging end of a vibration screen; the feeding end of the vibration screen corresponds to the outlet of a feeding box; the driving belt roller is driven by a power mechanism; a flat-container-shaped receiving device is correspondingly arranged below the driven belt roller; at least two horizontal holes are formed in at least one side surface of the receiving device from top to bottom; electromagnets are arranged outside the receiving device and correspond to the horizontal holes. Through adoption of the device, the spice from the feeding box is uniformly spread and conveyed onto the transmission belt under the action of the vibration screen; when the iron impurities enter the flat-container-shaped receiving device and pass through the horizontal holes, the energized electromagnets generate strong magnetic force, so that the iron impurities are attracted onto the electromagnets, and the spice drops to a collecting box at the lower part of the device after turning around from the driven belt roller and passing through the receiving device. After the electromagnets are powered off, the magnetic force disappears, and thus the iron impurities drop to an impurity box.

Owner:UNIV OF JINAN

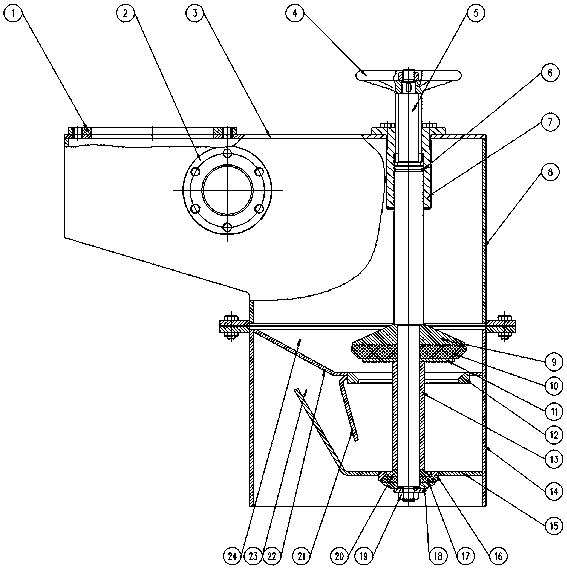

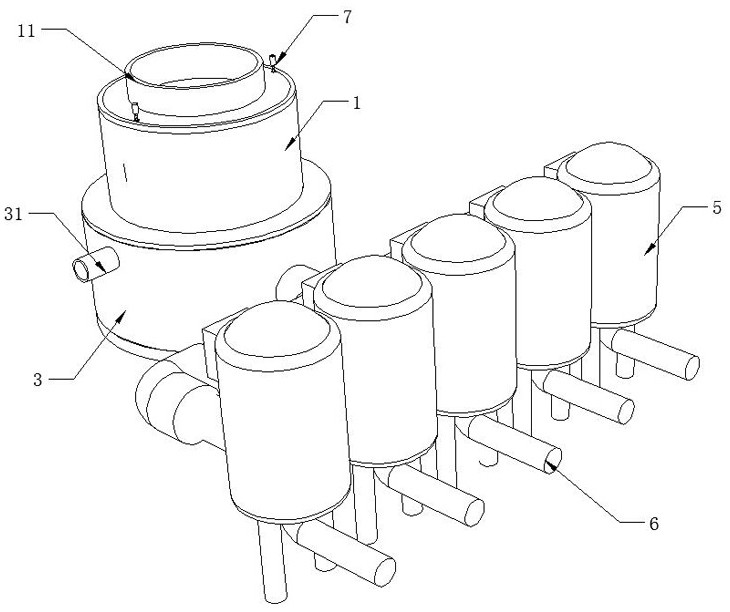

Novel negative pressure gas-liquid separator

InactiveCN108579218AAvoid affecting the separation effectSmall footprintDispersed particle separationVapor–liquid separatorEngineering

The invention relates to a novel negative pressure gas-liquid separator, which is mainly composed of: a gas outlet flange, a gas-liquid mixture inlet flange, a top cover, a hand wheel, an upper box body, a tapered ring, an upper rubber valve core, a lining board, an upper valve base, a lower box body, a lower valve base board, a lower valve base, a lower valve core, a lower conical ring, an upperconical ring, a baffle, an upper valve base board, and a liquid outlet, etc. The upper box body is in bolt connection with the lower box body. The gas outlet flange is connected to an external exhaustfan or a vacuum pump. An overflow device composed of the baffle and valve bases are arranged in the lower box body. By means of the manual valve and the overflow device, liquid seal is achieved at aliquid outlet essentially, so that technical problems that air enters the separator from the liquid outlet and installation position of the separator is limited since there is no throttling or forcedliquid discharge apparatus at the liquid outlet in the prior art can be solved, thereby increasing gas-liquid separation efficiency.

Owner:SOUTHWEST PETROLEUM UNIV

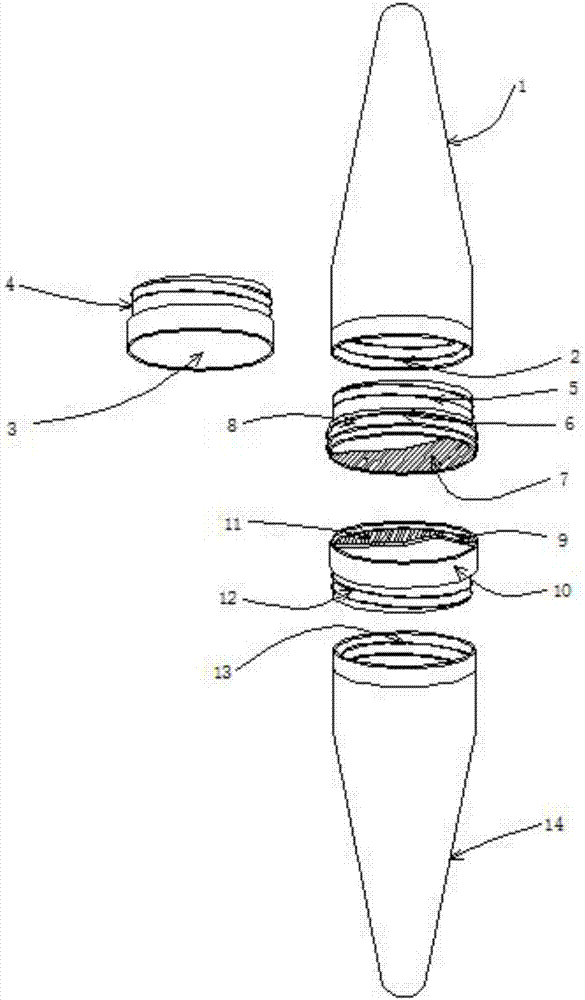

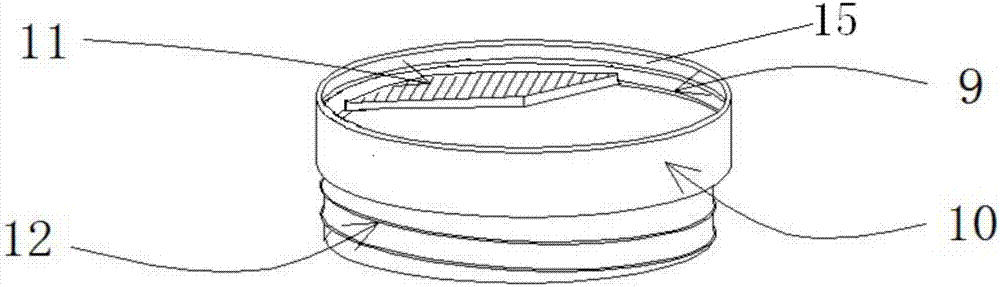

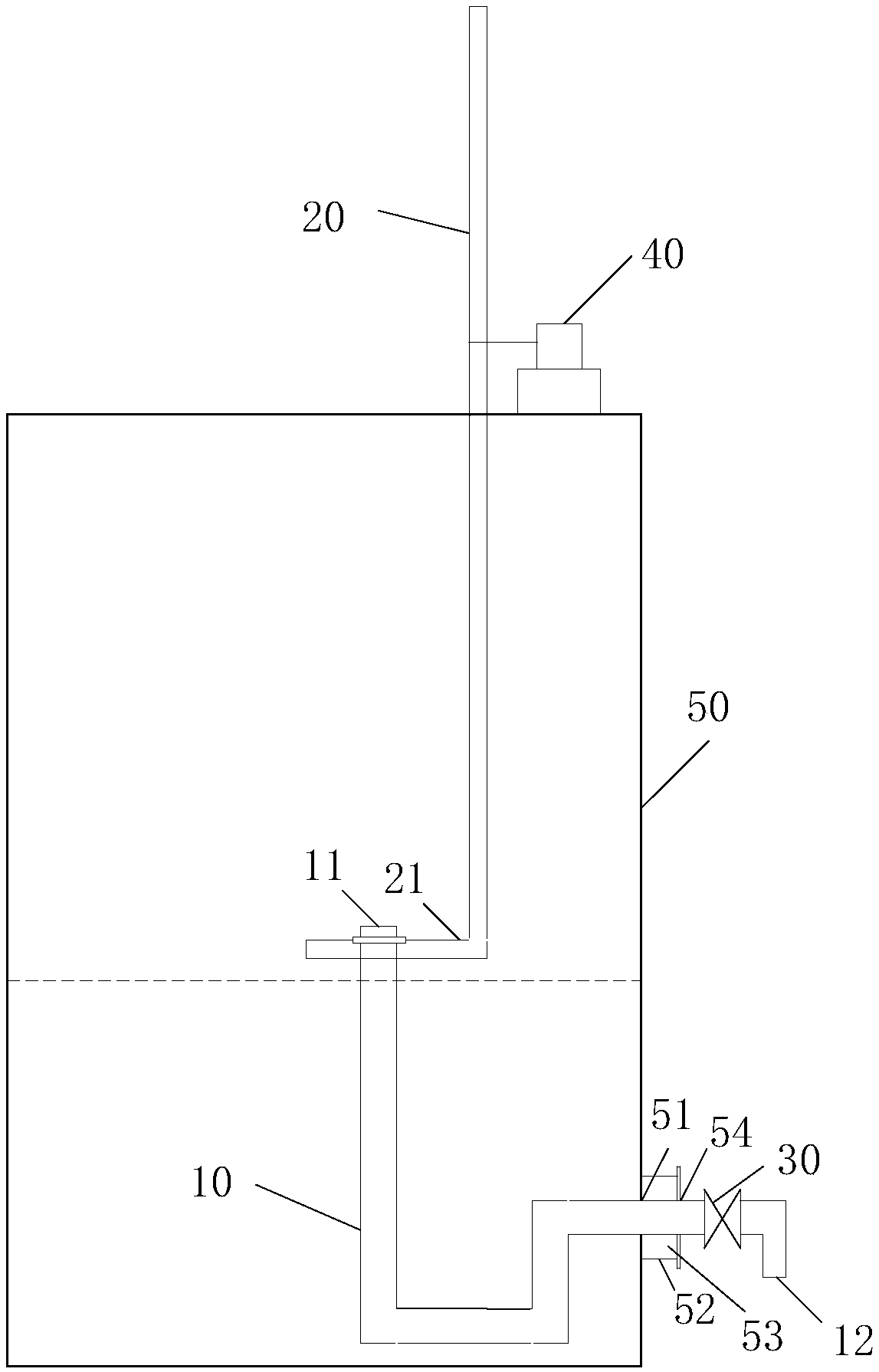

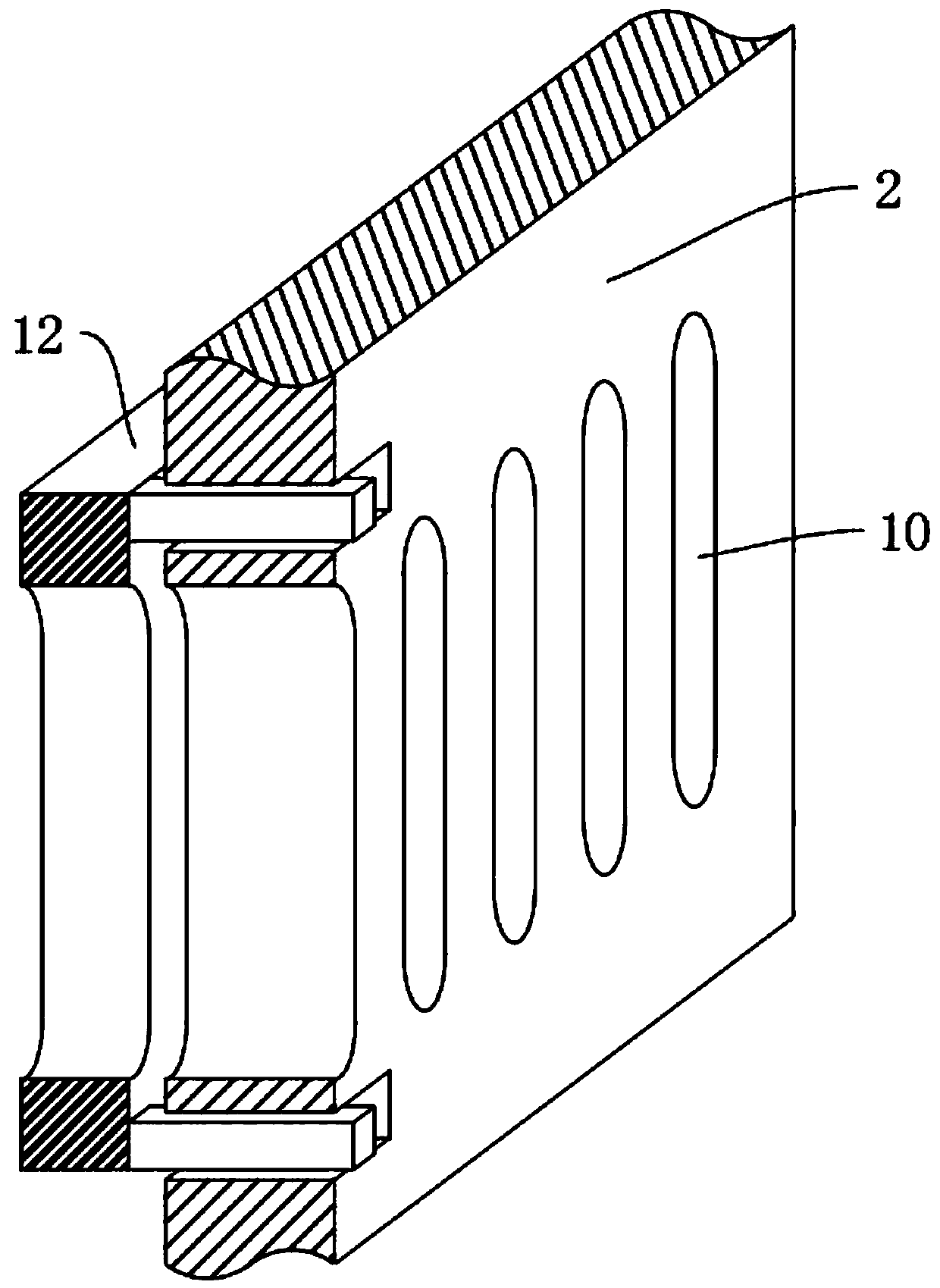

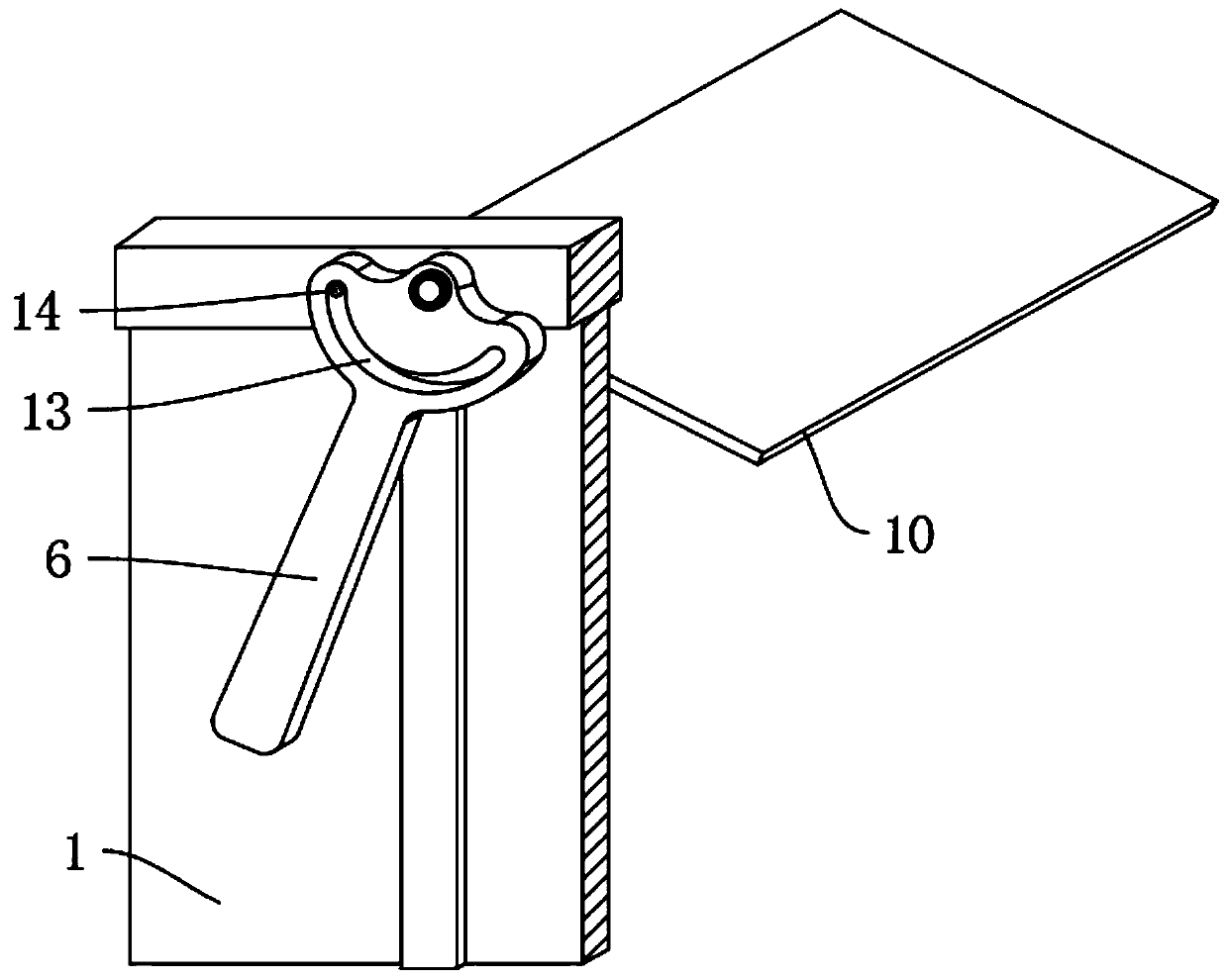

Sperm ascending device for sperm optimization

PendingCN107460116AAvoid affecting the separation effectReduce pollutionBioreactor/fermenter combinationsBiological substance pretreatmentsEngineeringStructural engineering

The invention discloses a sperm ascending device for sperm optimization. The device is characterized by comprising an ascending pipe, an upper connecting pipe, a lower connecting pipe and a sperm pipe which are detachably connected sequentially from top to bottom, wherein the upper end of the ascending pipe is sealed; the lower end of the ascending pipe is communicated with the upper connecting pipe; the lower end of the sperm pipe is sealed; the upper end of the sperm pipe is communicated with the lower connecting pipe; a first sector plate is fixedly arranged at an inner wall of the upper connecting pipe; a second sector plate complementary to the first sector plate is fixedly arranged at an inner wall of the lower connecting pipe; when the first sector plate and the second sector plate are at least overlapped partially, the upper connecting pipe is communicated with the lower connecting pipe; when the first sector plate and the second sector plate are complementary on the same horizontal plane so as to be connected into a circular shape, a closed passage is formed between the upper connecting pipe and the lower connecting pipe. The sperm ascending device for sperm optimization has the advantages of simple structure, good separating effect and high repeatability.

Owner:SUZHOU RES INST OF TONGJI UNIV

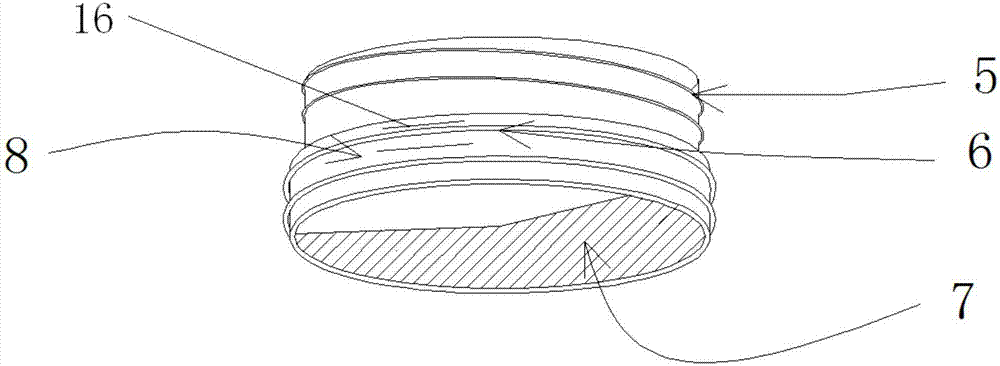

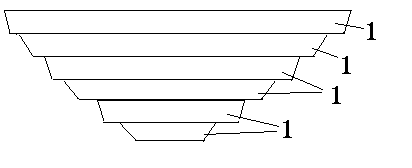

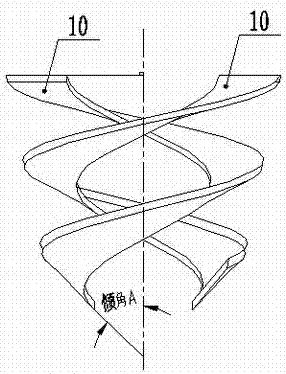

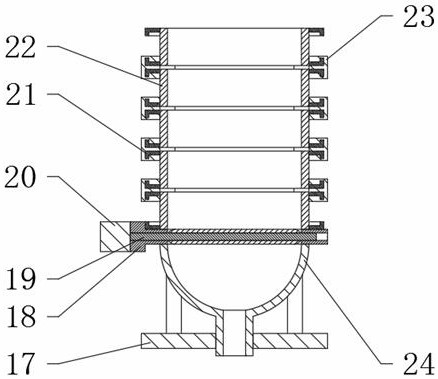

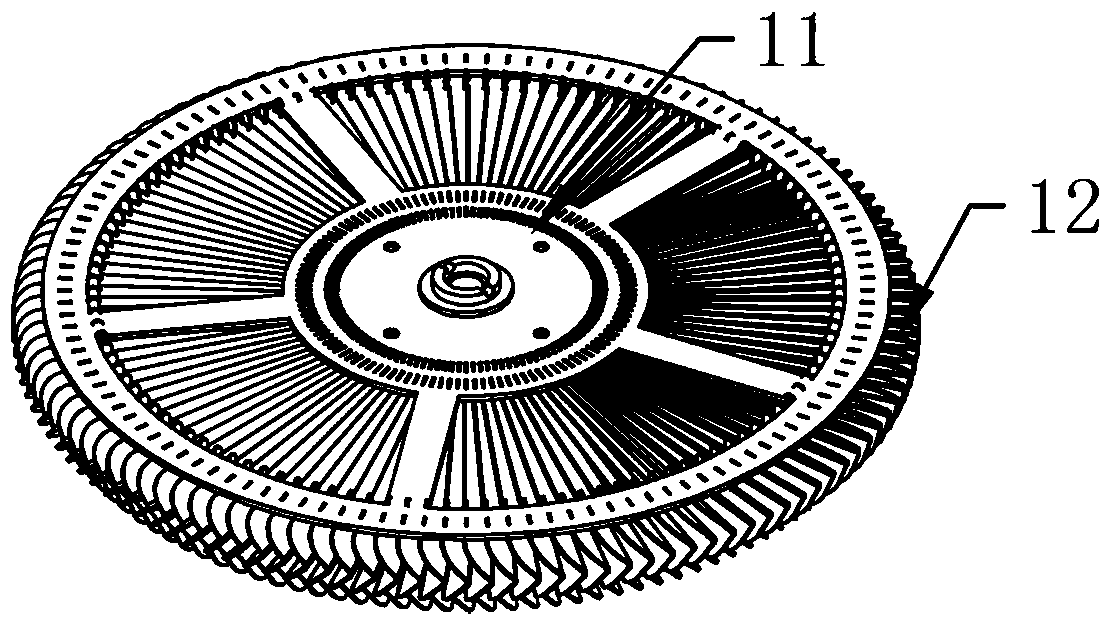

Revolving drum of conical basket type centrifuge

InactiveCN104014437AGuaranteed to move outwardPrecise control of discharge speedCentrifugesEngineeringSolid particle

The invention discloses a revolving drum of a conical basket type centrifuge. The revolving drum comprises a plurality of rotary frames which are sequentially overlaid from top to bottom, wherein each rotary frame is shaped like an inverted truncated cone. The center axes of all the rotary frames are located on the same straight line. According to every two adjacent rotary frames, the area of a bottom circular surface of the upper rotary frame is larger than the area of a top circular surface of the lower rotary frame; the inclination angles of side edges of every two adjacent rotary frames are different; a filter screen matched with each rotary frame is fixed to the corresponding rotary frame. On the basis of a terrace type revolving drum, each rotary frame is shaped like the inverted truncated cone according to the design, the side edges of the rotary frames have certain angles when the centrifuge operates, as a result, it is guaranteed that the filter screens are filled with solid particles while outward movement of the solid particles can be guaranteed, and the filter screens can be protected without being blocked.

Owner:SUZHOU JINXIANG TITANIUM EQUIP

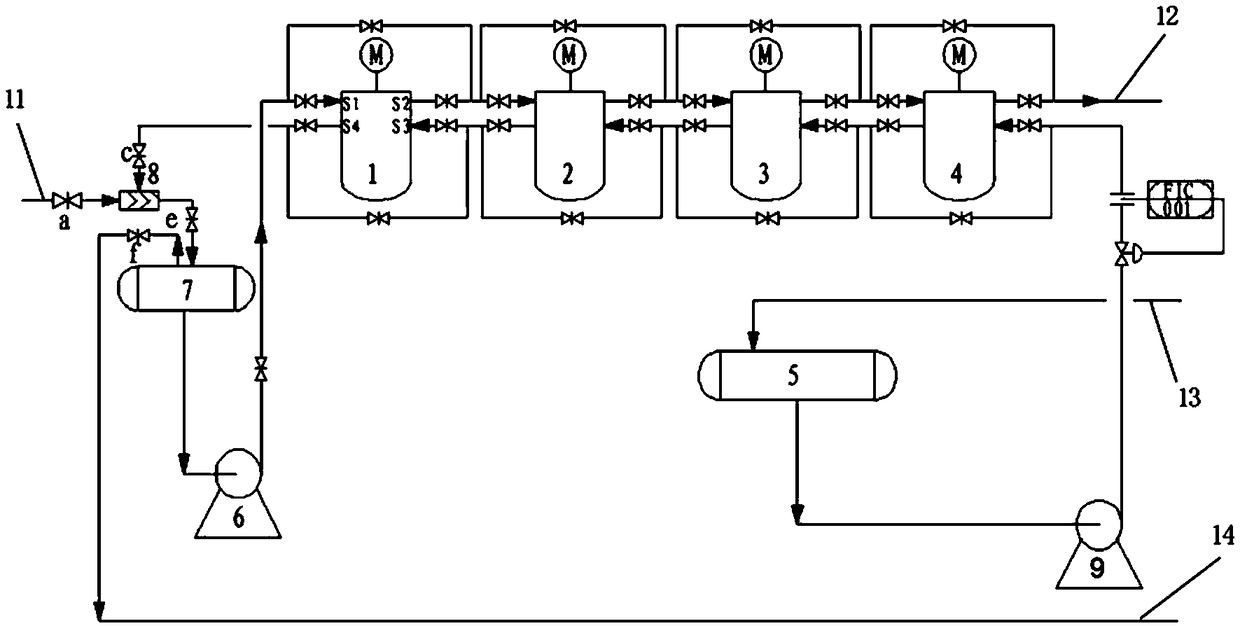

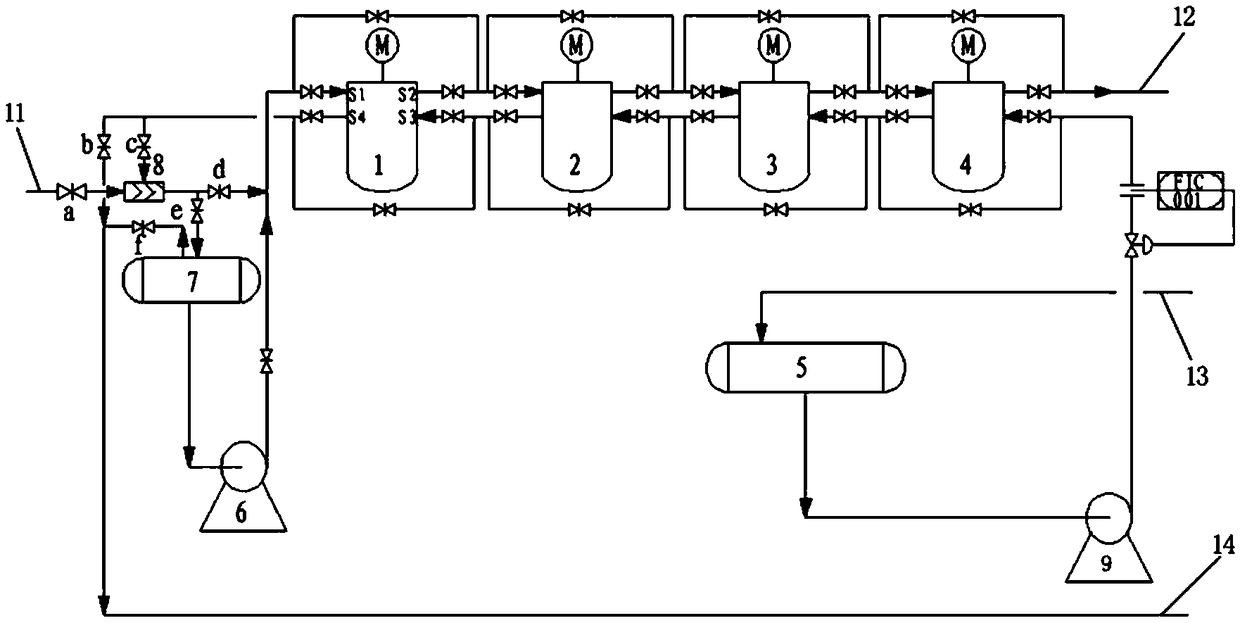

Extraction dephenolization device and extraction dephenolization method for coal chemical industry wastewater treatment

PendingCN109293030AImprove cleanlinessReduced extraction efficiencyWater/sewage treatment by centrifugal separationWater contaminantsInlet valveWastewater

The invention provides an extraction dephenolization device for coal chemical industry wastewater treatment. The device includes a static mixer, a mixing clarification extraction tank and a pluralityof centrifugal extractors. Specifically, the inlet of the mixing clarification extraction tank is communicated with the outlet of the static mixer; the feed liquid inlet of a first-stage centrifugal extractor is communicated with the raffinate outlet of the mixing clarification extraction tank; the extracted liquid outlet of the first-stage centrifugal extractor is communicated with the extractantinlet of the static mixer through a pipeline; all the centrifugal extractors are in countercurrent connection; at least one of the centrifugal extractors is equipped with a first feed liquid inlet valve and a first raffinate outlet valve, and a first by-pass communicated with the valves are disposed outside; at least one of the centrifugal extractors is equipped with a second extractant inlet valve and a second extracted liquid outlet valve, and a second by-pass communicated with the valves are disposed outside; and the first by-pass and the second by-pass are equipped with valves. The invention also provides an extraction dephenolization method for coal chemical industry wastewater treatment.

Owner:辽宁大唐国际阜新煤制天然气有限责任公司

Metallurgy centrifugal separator capable of achieving classifying recycling

InactiveCN109351489APrevent affecting work performanceFirmly connectedRotary centrifugesElectric motorCentrifugal separator

The invention relates to a metallurgy centrifugal separator capable of achieving classifying recycling. A body, a first motor and a second filter barrel are included. A feeding port is formed in the top of the body, and a first rotation shaft penetrates through the top end of the body. The first motor is arranged on the top of the first rotation shaft, the bottom end of the first rotation shaft isconnected with a first filter barrel, a first discharging port is formed in the outer wall of the first filter barrel, and a brush is arranged on the outer side of the first filter barrel. The metallurgy centrifugal separator has the beneficial effects that through the arrangement of the first filter barrel, the second filter barrel, the first rotation shaft, the first motor, a second rotation shaft and a second motor, the top extension line of the first filter barrel and the top end extension line of the second filter barrel are collinear, the first motor and the second motor are started, under the action of the first rotation shaft and the action of the second rotation shaft, the first filter barrel and the second filter barrel conduct the rotation centrifugal movement, and it is ensured that the device can conduct classifying separation work on metal different in diameter.

Owner:李丹丹

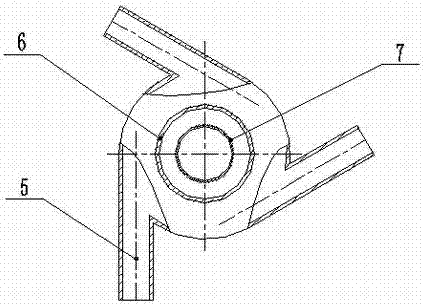

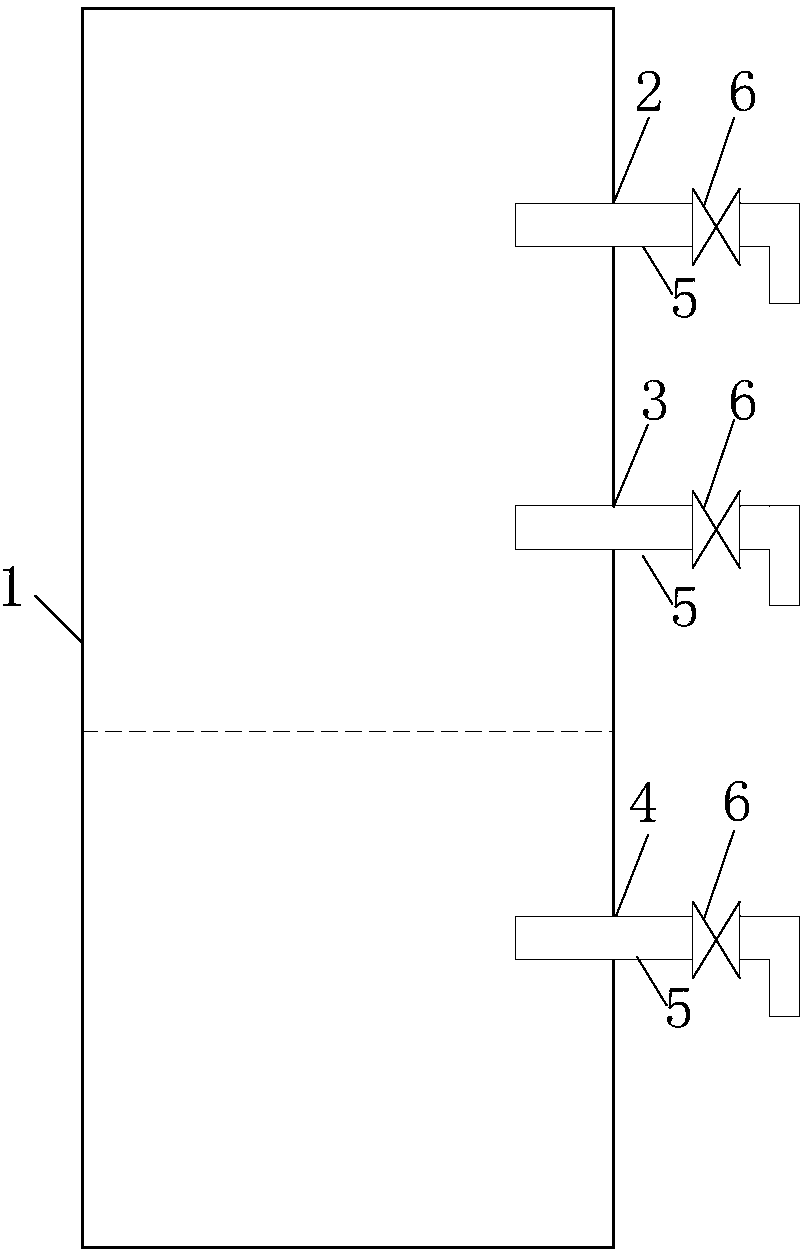

Flow guiding component of continuous type fluid separating device and continuous type fluid separating device

The invention discloses a flow guiding component of a continuous type fluid separating device and the continuous type fluid separating device. The flow guiding component comprises a flow guiding pipe and a flow guiding rod, wherein the flow guiding pipe comprises an inlet section and an outlet section; the inlet section is used for guiding fluid into the flow guiding pipe; the outlet section is used for guiding out the fluid in the flow guiding pipe; the inlet section of the flow guiding rod is fixed on the flow guiding rod; the flow guiding rod can drive the inlet section to move along with the upper fluid level of the fluid. The flow guiding component and the continuous type fluid separating device disclosed by the invention have the advantages that the problems that the separating effect is influenced due to the blind end of the existing flow guiding component and separating device in gravity separation and the like are solved.

Owner:CHNA ENERGY INVESTMENT CORP LTD +1

Separation device for atomized copper powder

The invention discloses a separation device for atomized copper powder. The separation device comprises a shell. The shell is of a hollow structure. A feeding inlet is formed in the side wall of the upper side of the shell, penetrates through the side wall of the shell and is connected with a transversely-arranged water pipe. A plurality of through ports are formed in the side walls of one side ofthe water pipe sequentially at equal intervals from left to right. A filter plate is arranged in the shell transversely, and a filter screen is arranged on the side wall of the filter plate. Strip-shaped openings are symmetrically formed in the side walls of the two sides of the filter plate. Two supporting rods are symmetrically arranged at the bottom of the shell, and a fixed plate is transversely arranged at the ends, away from the bottom of the shell, of the supporting rods. A driving motor is arranged on the side wall of the bottom of the shell, and an output shaft of the driving motor penetrates through the side wall of the fixed plate and is connected with a rotating shaft. According to the separation device for the atomized copper powder, the situation that the separated copper power is piled on the filter screen, and accordingly the subsequent separation effect is affected can be avoided.

Owner:铜陵市业永兴工贸有限责任公司

Back squeezing device for oil-dreg separation of oil press in research of agricultural science

PendingCN109777610AConvenience to workEasy to separateFatty-oils/fats refiningEngineeringCentrifugal force

The invention discloses a back squeezing device for oil-dreg separation of an oil press in a research of agricultural science. The device comprises an oil press shell. An oil outlet pipe is welded tothe bottom position of the outer wall of one side of the oil press shell, a valve is arranged on the oil outlet pipe, an oil guide plate which is obliquely arranged is welded to the inner wall of thebottom of the oil press shell, one end of the oil guide plate is connected to the oil outlet pipe, the side, close to the oil outlet pipe, of the oil guide plate is lower than the side, far away fromthe oil outlet pipe, of the oil guide plate, a side door is opened in the outer wall of one side of the oil press shell, and a separating device is arranged in the position, close to the side door, ofthe inner wall of one side of the oil press shell. The device can drive a vibrating plate to vibrate quickly so as to drive dreg and oil to flow into a collecting mesh enclosure smoothly and the device can be driven by a rotating motor to rotate to separate dreg from oil under the action of a centrifugal force, so that the oil-dreg separating effect of the device is improved, staff can be reminded to clean excessive dreg immediately, and the intelligence of the device is improved.

Owner:湖南全望信息科技有限公司

Two-stage multi-inlet dynamic pressure degasser

ActiveCN107362589AIncreased separation capacity and efficiencyGreat operating flexibilityLiquid degasificationEngineeringMulti phase

A two-stage multi-inlet dynamic pressure degasser belongs to the technical field of multi-phase flow separation and is characterized in that a plurality of evenly distributed rectangular tangent inlets are used to ensure uniformity of peripheral flow, a circular passage between an outer wall and an umbrella-shaped rectifying plate is used to carry out pre-degassing, precise separation guide blades are used to arrive at forced vortex, a separation factor is increased via a conical barrel, and precision gas removal is achieved for a bottom flow port. The two-stage multi-inlet dynamic pressure degasser comprises an external mechanism and an internal body; the external mechanism is composed of an upper cover, a coarse separation vortex inlet, a barrel body, a conical barrel, a straight round barrel, and a bottom cover; and the internal body is composed of a coarse separation exhaust pipe, a precise separation exhaust pipe, an umbrella-shaped rectifying plate, and precise separation guide blades. The two-stage multi-inlet dynamic pressure degasser is of two-stage separation structure, can generate a strong vortex field in cooperation with the precise separation guide blades, can provide significantly increased precise removal rate for gas with high gas-liquid ratio, is high in applicability and operational elasticity, is simple in structure and easy to maintain, and is widely applicable to various gas-liquid separation cases.

Owner:DALIAN UNIV OF TECH +1

Organic soybean processing device with shelling function

InactiveCN112690479AGuaranteed connection statusEasy accessCuttersFood treatmentStructural engineeringMechanical engineering

The invention discloses an organic soybean processing device with a shelling function, and relates to the field of soybean processing. The invention is to solve the problem of low production efficiency of a beating mode of an existing device. The device specifically comprises a bottom plate; the outer wall of the top of the bottom plate is fixedly connected with an upright column; the outer wall of the top end of the upright column is fixedly connected with a supporting plate; the outer wall of the top of the supporting plate is fixedly connected with a surrounding assembly and a charging barrel assembly; the charging barrel assembly comprises a seat plate and a lapping plate; and the outer wall of the bottom of the seat plate is fixedly connected to the outer wall of the top of the supporting plate. According to the invention, by arranging the charging barrel assembly, soybean raw materials are injected into the charging barrel assembly, then the charging barrel assembly is covered with a top cover, then the surrounding assembly is started, each blade is inserted into a gap between two adjacent ring sleeves, then the soybean raw materials are cut off and scattered, and then the surrounding assembly can continue to move to drive related assemblies to rotate and push a plug sleeve to slide between two adjacent clamping sleeves, so that the charging barrel assembly can be always kept in a connected state.

Owner:六安市叶集区辉耀农业发展有限公司

Flow guide assembly of continuous fluid separation device and continuous fluid separation device

The invention discloses a flow guiding component of a continuous type fluid separating device and the continuous type fluid separating device. The flow guiding component comprises a flow guiding pipe and a flow guiding rod, wherein the flow guiding pipe comprises an inlet section and an outlet section; the inlet section is used for guiding fluid into the flow guiding pipe; the outlet section is used for guiding out the fluid in the flow guiding pipe; the inlet section of the flow guiding rod is fixed on the flow guiding rod; the flow guiding rod can drive the inlet section to move along with the upper fluid level of the fluid. The flow guiding component and the continuous type fluid separating device disclosed by the invention have the advantages that the problems that the separating effect is influenced due to the blind end of the existing flow guiding component and separating device in gravity separation and the like are solved.

Owner:CHNA ENERGY INVESTMENT CORP LTD +1

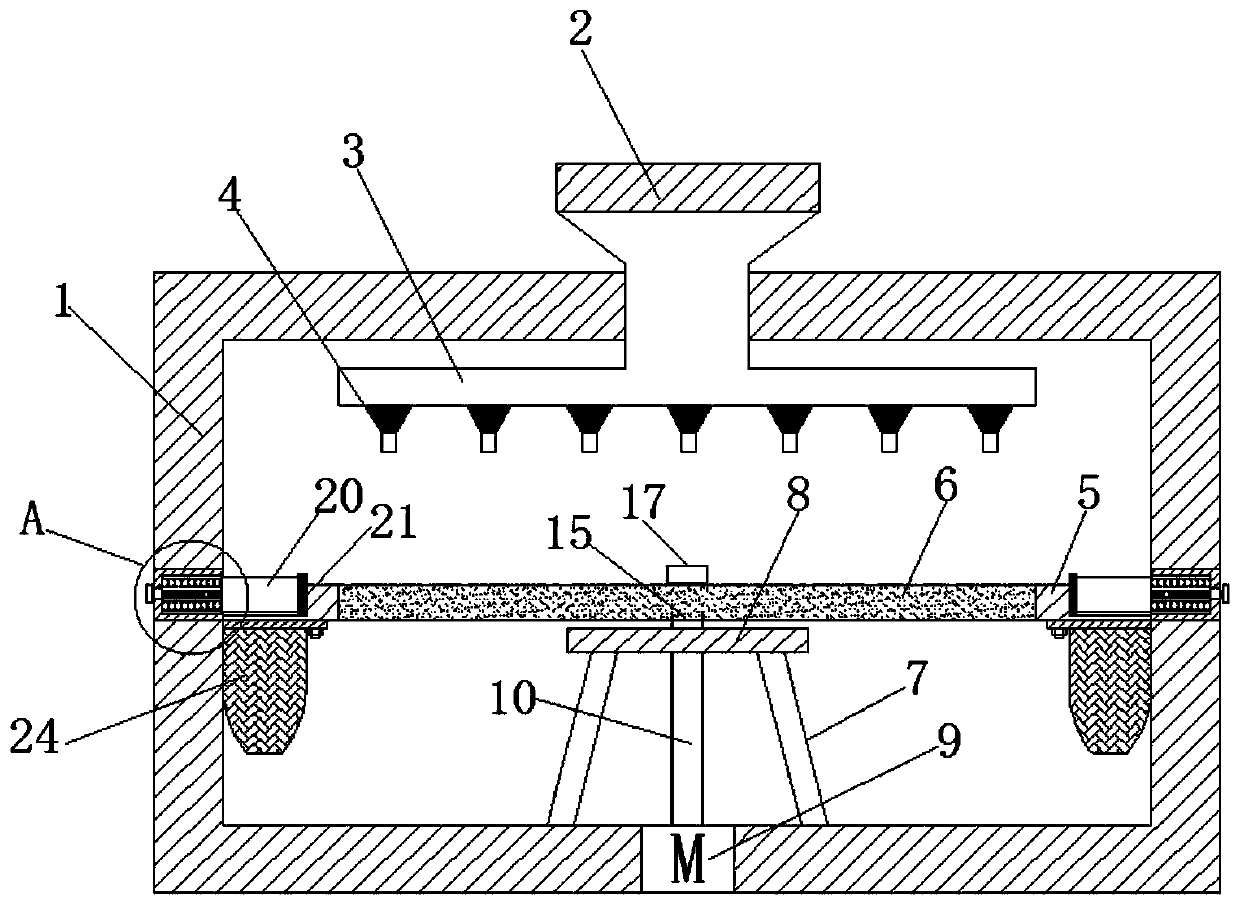

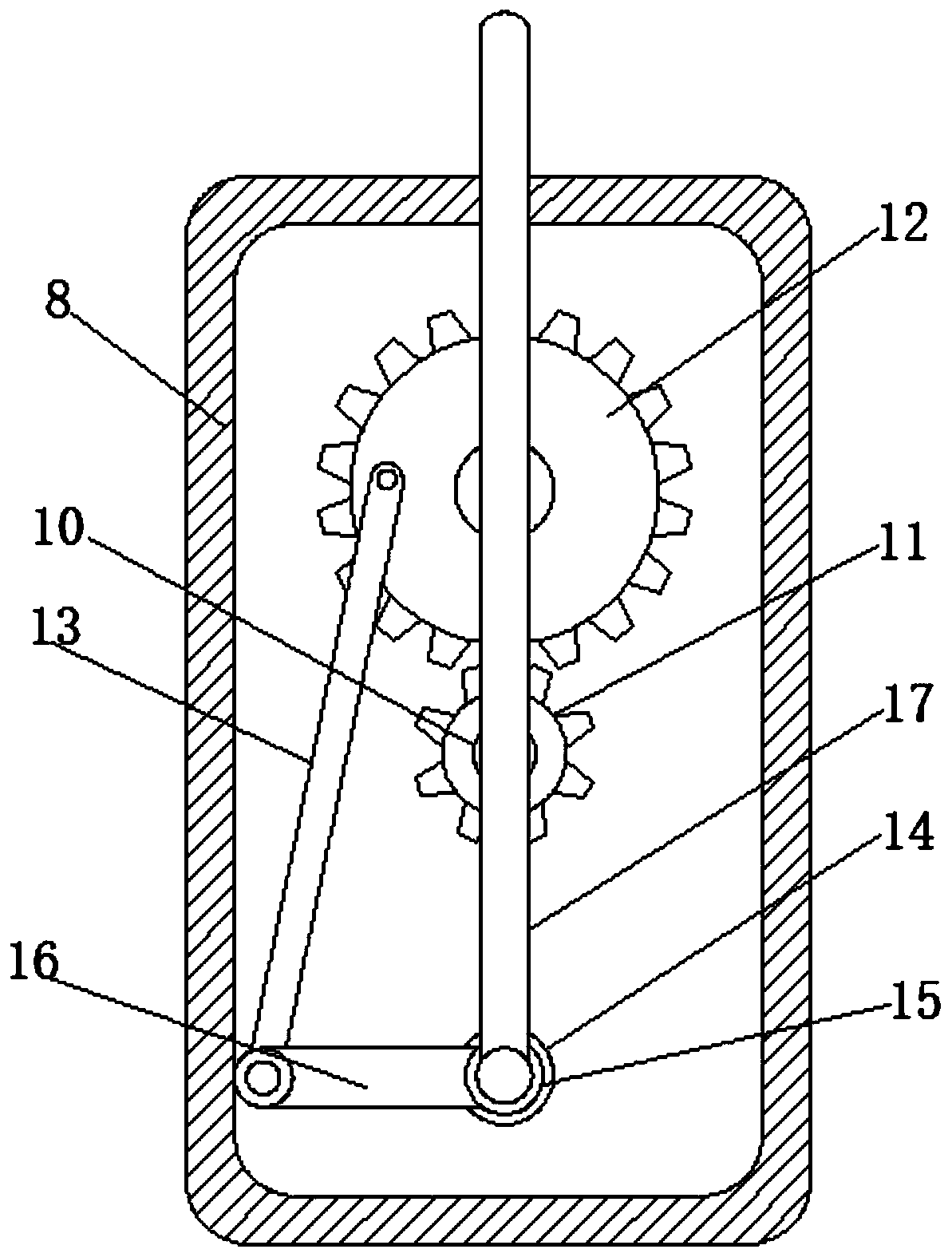

Equal-distance field reclamation and separation method for agricultural planting

InactiveCN114303488AGuaranteed levelAvoid affecting the separation effectSpadesWatering devicesAgricultural scienceAgricultural engineering

The invention discloses an equal-distance field reclamation and separation method for agricultural planting in the field of agricultural production. The equal-distance field reclamation and separation method applying a separation device comprises the steps that S1, the separation device is moved to a field to be subjected to reclamation and separation; s2, water is injected into the cutting device, and meanwhile, a soil shifting mechanism is aligned to the direction needing to be separated; s3, driving a motor to enable a cutting mechanism forward wheel to rotate, and enabling a separating device to start working; and S4, after separation is completed, the motor is turned off, the advancing wheels stop advancing, the separation device stops working, and separation is completed. The soil shifting mechanism is arranged in front of the forward wheel, so that the field passed by the forward wheel is soil shoveled by the dozer blade in advance when the forward wheel moves. In this way, the field is roughly flat, the separation device can be kept horizontal when the advancing wheels advance, and therefore equal-distance separation can be guaranteed by fixing the distance between the soil shifting devices on the two sides.

Owner:刘琦瑞 +2

A separation device for atomized copper powder

The invention discloses a separation device for atomized copper powder. The separation device comprises a shell. The shell is of a hollow structure. A feeding inlet is formed in the side wall of the upper side of the shell, penetrates through the side wall of the shell and is connected with a transversely-arranged water pipe. A plurality of through ports are formed in the side walls of one side ofthe water pipe sequentially at equal intervals from left to right. A filter plate is arranged in the shell transversely, and a filter screen is arranged on the side wall of the filter plate. Strip-shaped openings are symmetrically formed in the side walls of the two sides of the filter plate. Two supporting rods are symmetrically arranged at the bottom of the shell, and a fixed plate is transversely arranged at the ends, away from the bottom of the shell, of the supporting rods. A driving motor is arranged on the side wall of the bottom of the shell, and an output shaft of the driving motor penetrates through the side wall of the fixed plate and is connected with a rotating shaft. According to the separation device for the atomized copper powder, the situation that the separated copper power is piled on the filter screen, and accordingly the subsequent separation effect is affected can be avoided.

Owner:铜陵市业永兴工贸有限责任公司

Oil-water separation device for chemical machinery

InactiveCN112357993AImprove convenienceAvoid affecting the separation effectFatty/oily/floating substances removal devicesSpecific water treatment objectivesStructural engineeringSewage treatment

The invention relates to the technical field of chemical sewage treatment, and discloses an oil-water separation device for chemical machinery. The device comprises a separation box, a supporting plate is fixedly connected to the left side wall of the separation box, a storage groove is formed in the right side wall of the supporting plate, a flashboard is slidably connected into the storage groove, and sliding rods are fixedly connected to the upper end and the lower end of the groove bottom of the storage groove. Sliding grooves matched with the sliding rods are formed in the upper end and the lower end of the left side wall of the gate plate correspondingly, and a threaded rod is rotatably connected to the position, located between the two sliding rods, of the groove bottom of the storage groove through a bearing. According to the oil-water separation device, the oil-water layering position can be sealed and separated, the situation that the separation effect is affected due to re-mixing of part of oil and water caused by suction force during pumping is avoided, meanwhile, people can wash the interior of the separation box conveniently, cleaning inconvenience caused by attachment and condensation of part of oil drops is avoided, people can adjust the oil-water layering position conveniently, and use is convenient.

Owner:西安汇龙中鼎机械设备有限公司

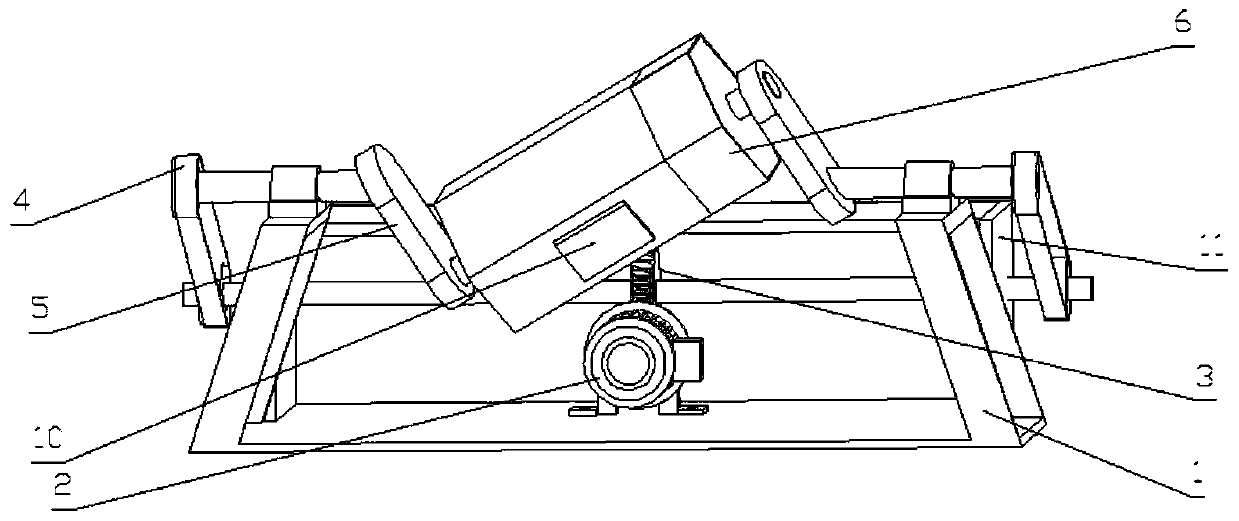

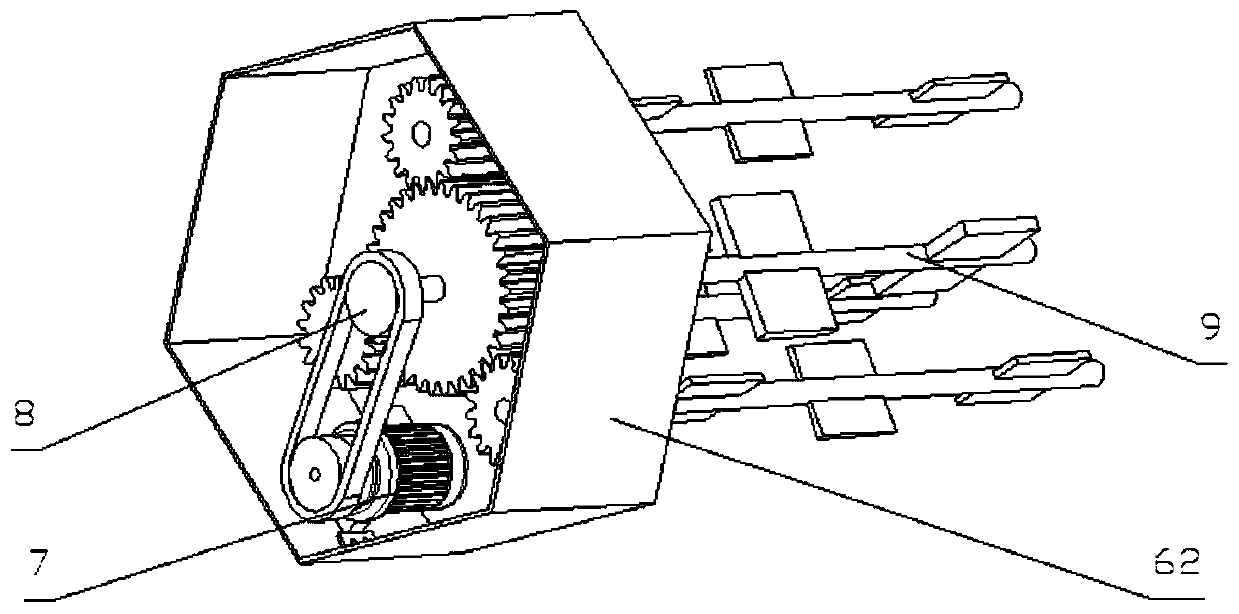

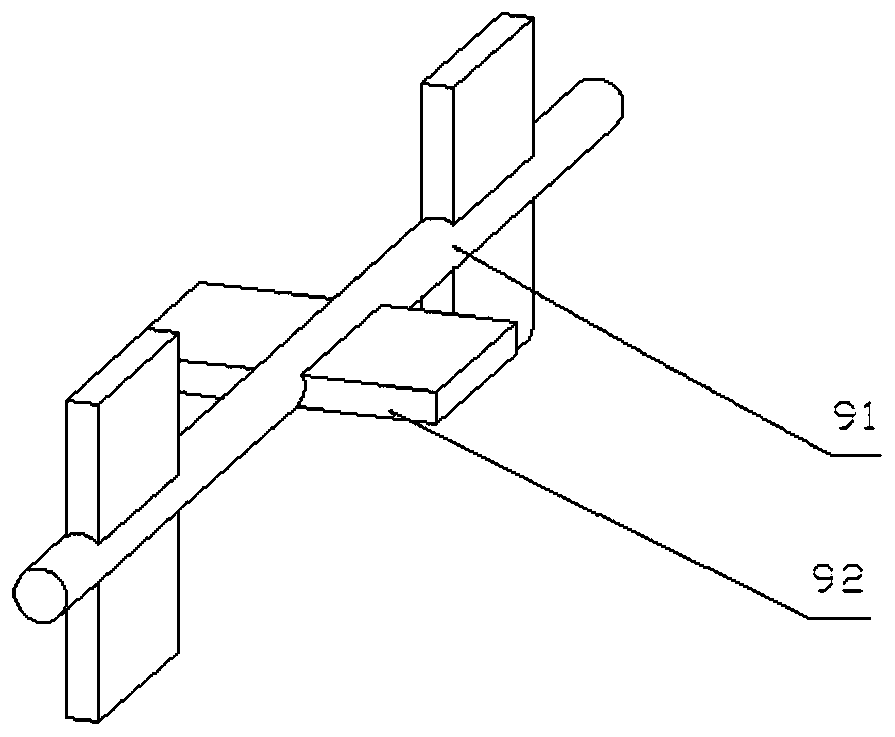

Equipment for separating frozen chicken legs

PendingCN110521755ASolve the problem of freezing together and not being easy to separateIngenious structurePoultry processingEngineeringBroiler

The invention discloses equipment for separating frozen chicken legs, and belongs to the technical field of broiler production and processing equipment. The technical scheme lies in that the equipmentcomprises a bracket, wherein a first driving mechanism is arranged on the side surface of the bottom of the bracket; a speed reducing mechanism is arranged at the output end of the first driving mechanism; a first transmission mechanism is arranged at the output end of the speed reducing mechanism; a rotating mechanism is arranged at the output end of the first transmission mechanism, penetratesthrough a shaft seat arranged on the bracket and is connected with a separating cylinder; a charging and discharging opening is formed in the separating cylinder; a second driving mechanism is arranged in the separating cylinder; a second transmission mechanism is arranged at the output end of the second driving mechanism; and a stirring mechanism is arranged at the output end of the second transmission mechanism. The equipment disclosed by the invention has the beneficial effects of being ingenious in structure, novel in design, good in separating effects and high in working efficiency, the problem that after freezing, single chicken legs are frozen together and are not liable to separate is successfully solved, and time and cost for manual treatment are reduced; and besides, the whole equipment is simple in manufacturing and low in cost, so that largest return can be obtained through smallest investment.

Owner:QINGDAO TIANRUN FOOD CO LTD +1

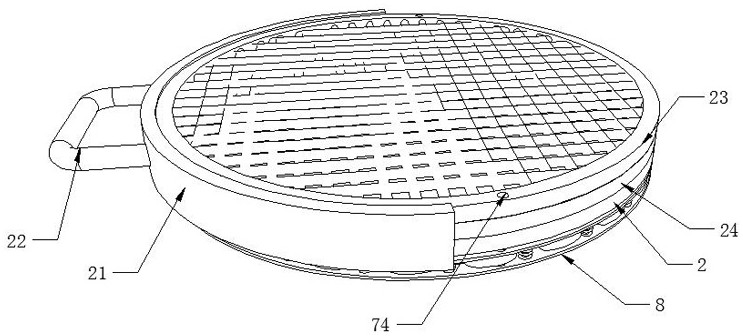

Microwave multi-effect filtering system

ActiveCN113880336AAchieve installationReduce impactSpecific water treatment objectivesTreatment involving filtrationIndustrial waste waterFilter system

The invention provides a microwave multi-effect filtering system, and belongs to the technical field of industrial wastewater treatment. The microwave multi-effect filtering system comprises a separation box, a putting-in opening, a mixing box, a connecting pipe and separation boxes, the putting-in opening is formed in the top of the separation box, the mixing box is arranged at the bottom of the separation box, the separation box communicates with the interior of the mixing box, and a plurality of separation boxes are arranged on one side of the mixing box. The mixing box communicates with the separation boxes through a plurality of connecting pipes, a notch is formed in one side of each separation box, an isolating mechanism for primarily filtering wastewater is arranged at the position, located at the notch, in each separation box, and a locking mechanism for locking each isolating mechanism is arranged in the corresponding separation box. Under the action of the isolating mechanisms, large sundries such as gravels, wood blocks and plastics contained in waste water are removed, and the primary filtering effect is achieved. Under the action of the locking mechanisms, installation of the isolating mechanisms is achieved. Under the action of a damping assembly, the impact force generated when the waste water is thrown into the separation boxes is reduced, and the situation that the isolation mechanismes are impacted by the wastewater for a long time and damaged is avoided.

Owner:ANJIEYU BEIJING OILFIELD TECHNICAL SERVICES CO LTD

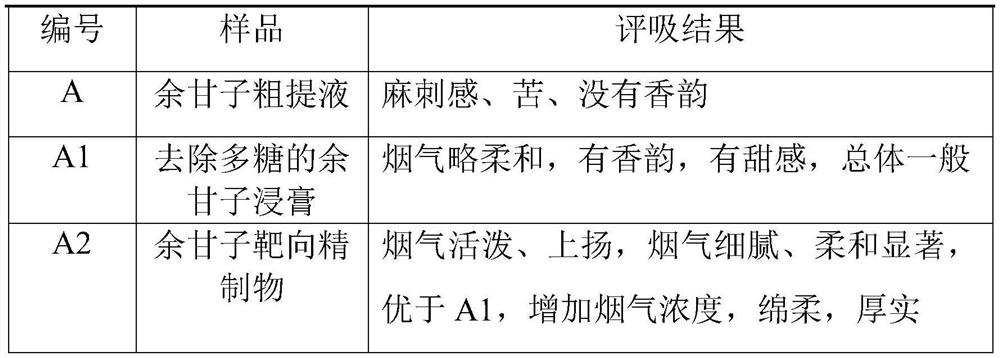

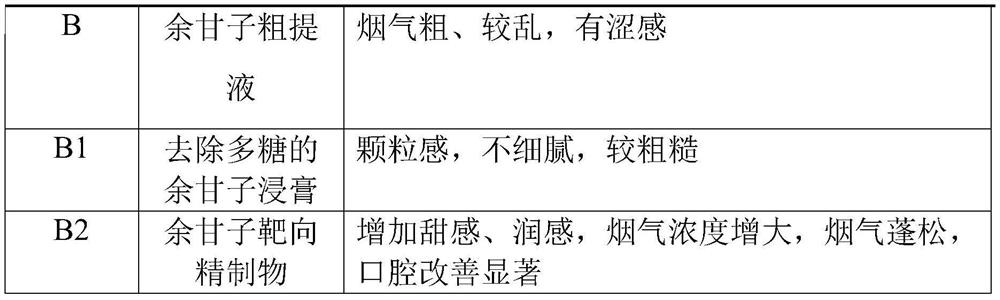

A targeted refinement of Amla emblica, its preparation method and its application in cigarettes

Owner:CHINA TOBACCO SICHUAN IND CO LTD

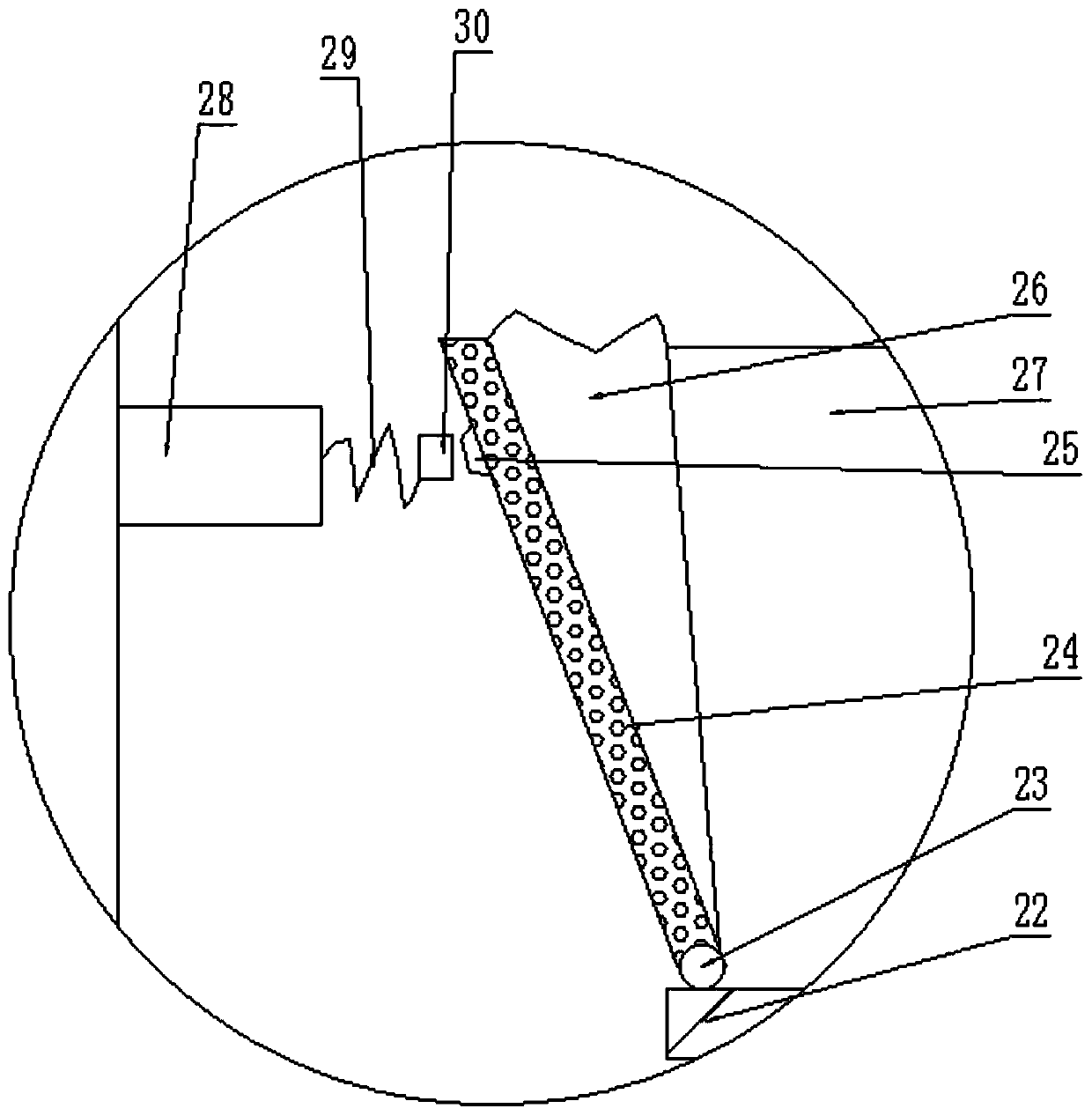

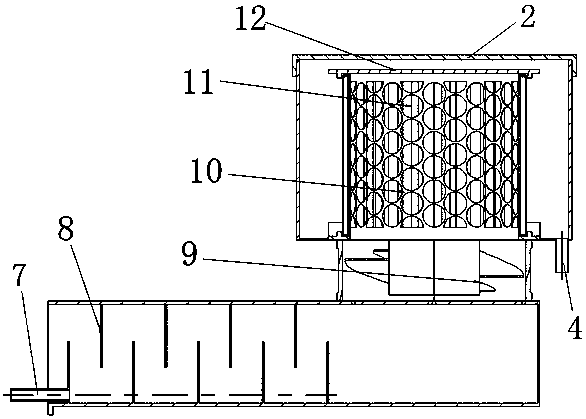

Clearing and cover-bottle separating device after waste plastic bottle label paper stripping and application thereof

PendingCN107009546AEasy to separateSolve problems that are not easily separatedPlastic recyclingMechanical material recoveryPulp and paper industryVolumetric Mass Density

The invention discloses a clearing and cover-bottle separating device after waste plastic bottle label paper stripping and an application thereof, and belongs to the technical field of waste plastic bottle recycling. The clearing and cover-bottle separating device comprises a paper stripping bottle body temporary storage box, an air separating mechanism, a selecting platform, a crusher and a separating tank which are sequentially arranged in sequence and are in communication through a loading packing auger, wherein the selecting platform comprises a horizontal conveyor belt and a travelling platform at one side of the horizontal conveyor belt; the tail end of the horizontal conveyor belt drops into the crusher; the crusher communicates with the starting end of the separating tank through a discharge hole; the tail end of the separating tank communicates with a plastic particle collecting box through a plastic particle discharge hole; and the separating tank is filled with a separating liquid. According to the clearing and cover-bottle separating device disclosed by the invention, the air separating device and the selecting platform are arranged, so that the purpose of completely separating adhered label paper from bottle bodies, and selecting out the bottle bodies with the label paper is achieved, and therefore, the covers are separated from the bottles in a separating liquid according to difference of density of the covers and the bottle bodies after crushing is performed. The clearing and cover-bottle separating device solves the problems that residual label paper on the bottle bodies causes adverse effects on post-processing crushing and the covers and the bottles need to separate are solved.

Owner:MAANSHAN HUBIN NONWOVEN CLOTH TECH

A kind of ore separator

ActiveCN109013322BPrevent affecting work performanceFirmly connectedGas current separationBrushElectric motor

The invention relates to a separator for ore, which includes a main body, a first motor and a second filter cartridge. The top of the main body is provided with a feeding port, and the top of the main body passes through a first rotating shaft. The first motor is placed on The top of the first rotating shaft and the bottom end of the first rotating shaft are connected with a first filter cartridge, the outer wall of the first filter cartridge is provided with a first outlet, and a brush is arranged on the outside of the first filter cartridge. The beneficial effect of the present invention is: the present invention is through the setting of the first filter cylinder, the second filter cylinder, the first rotating shaft, the first motor, the second rotating shaft and the second motor, and the top extension line of the first filter cartridge is connected with the second The extension lines of the top of the two filter cartridges are parallel, start the first motor and the second motor, and under the action of the first rotating shaft and the second rotating shaft respectively, make the first filter cartridge and the second filter cartridge perform rotational and centrifugal motion to ensure that the device It can classify and separate metals of different diameters.

Owner:安康市利源矿业有限责任公司

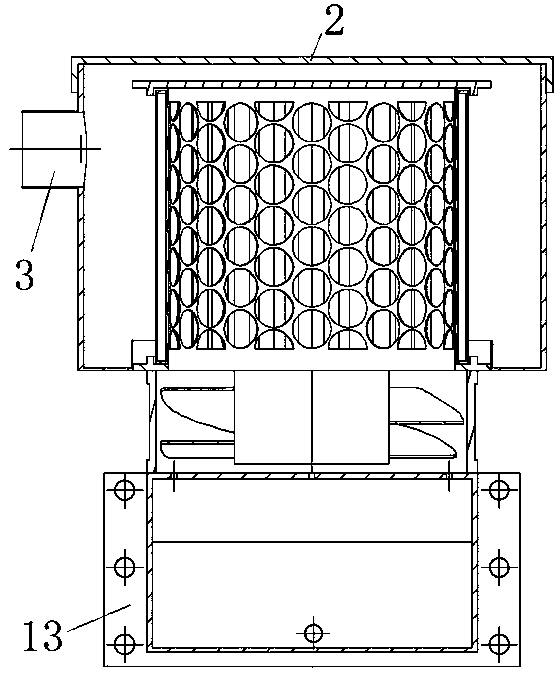

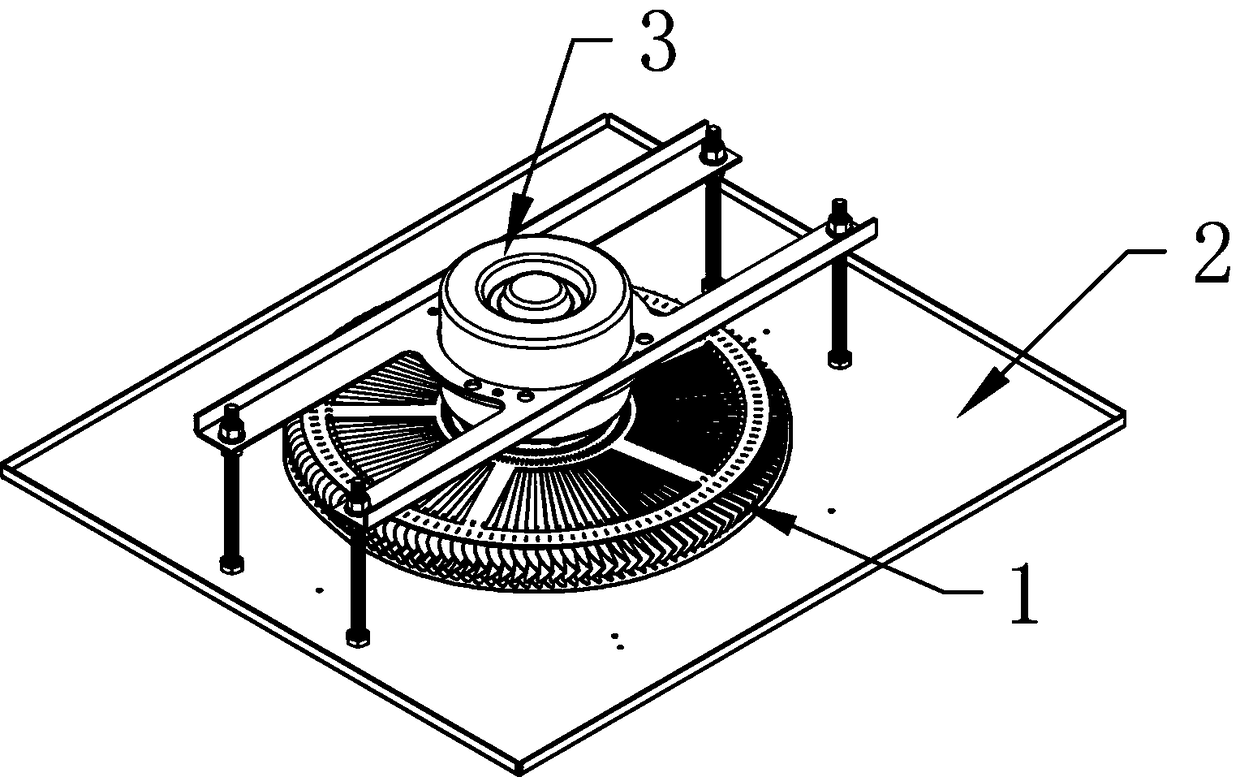

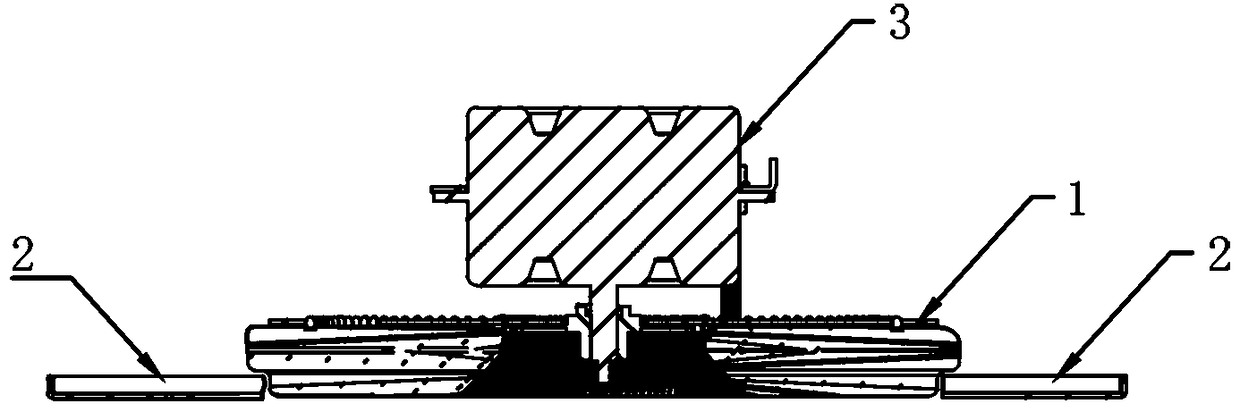

Secondary purification device for superconducting magnet

ActiveCN102179302BIncrease working areaReduce impactMultistage water/sewage treatmentMagnetic separationRoom temperatureSuperconducting Coils

The invention discloses a secondary purification device for a superconducting magnet, comprising the superconducting magnet with a room-temperature hole and a separating frame capable of moving after passing through the room-temperature hole; the separating frame is internally provided with a non-magnetic sieve, and a secondary purification member is arranged in the separating frame and below thenon-magnetic sieve; a raw material inlet is arranged at an inlet of the room-temperature hole and is positioned above the separating frame. The secondary purification device can sufficiently absorb ferromagnetic substances in ore pulp or magnetic substances in sewage so that the sewage is purified.

Owner:江苏旌凯中科超导高技术有限公司

A combined air filter

ActiveCN106512626BImprove filter qualityAvoid cloggingHuman health protectionCombination devicesAir filterFiltration

A combined air filter, which is composed of an oil-gas separation tube and a filter; the oil-gas separation tube is a square tube with one end open and the other end closed. Vertical baffle plate; the lower part of the baffle plate arranged on the lower pipe wall is also provided with a through hole, and an oil outlet hole is also provided at the lower part of the open end of the oil-gas separation pipe; the upper pipe wall of the oil-gas separation pipe near the closed end is connected with a wind The machine casing is provided with a fan inside the fan casing; the filter includes a filter casing arranged on the upper part of the fan casing and communicated with the fan casing, the upper end of the filter casing is covered with a filter cover plate, There is an exhaust hole on the side wall of the filter housing; an inner bracket is arranged inside the filter housing, and a filter screen in a cylindrical structure is provided on the inner bracket. The lower end of the filter screen is the air inlet end and is connected with The upper end of the fan housing is airtightly connected. The invention adopts a combined structure, can realize two times of filtering, and has good filtering effect.

Owner:CLFG LONGHAI ELECTRONICS GLASS

Wear-resisting grain extraction device

PendingCN110180782AExtended service lifeCutting costsGas current separationMaterial SeparationPneumatic pressure

The invention discloses a wear-resisting grain extraction device. The wear-resisting grain extraction device comprises a sorting chamber and a material discharging mechanism, wherein the sorting chamber is fixedly connected to the material discharging mechanism; the sorting chamber comprises a glass settling chamber and a concentration chamber; both the glass settling chamber and the concentrationchamber are of hollow structures; the concentration chamber is located at the lower end of the glass settling chamber and mutually communicates with the glass settling chamber; the discharging mechanism is an air seal machine; the air seal machine is fixedly connected to the bottom of the concentration chamber; the concentration chamber and the air seal machine communicate with each other; the glass settling chamber is of a triangular structure; one top end of the glass settling chamber is downward and is connected to the concentration chamber; and a feeding hole and a discharging hole are respectively formed in the two top ends of the glass settling chamber. Through the arrangement of a series of structures, the service life of the wear-resisting grain extraction device can be prolongedin the using process, when the wear-resisting grain extraction device discharges materials, the air pressure in the device is stable, thus, the effect of the material separation is ensured, and when parts in the device are damaged, the device is convenient for a user to repair or replace.

Owner:荆州市宇中粮食机械有限公司

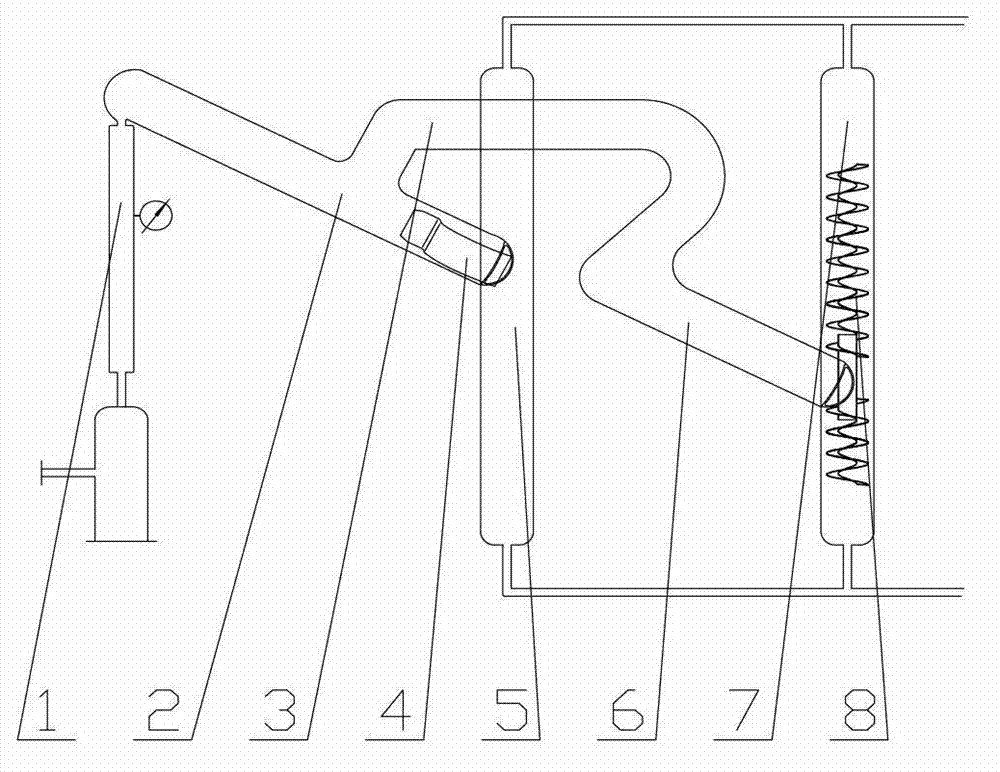

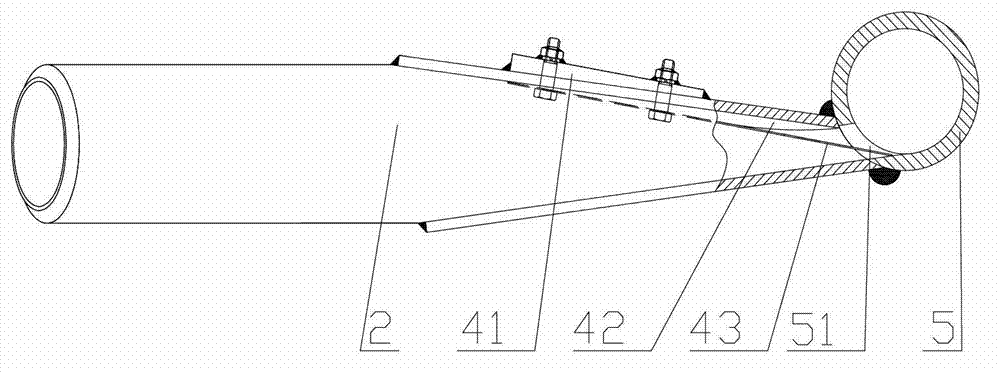

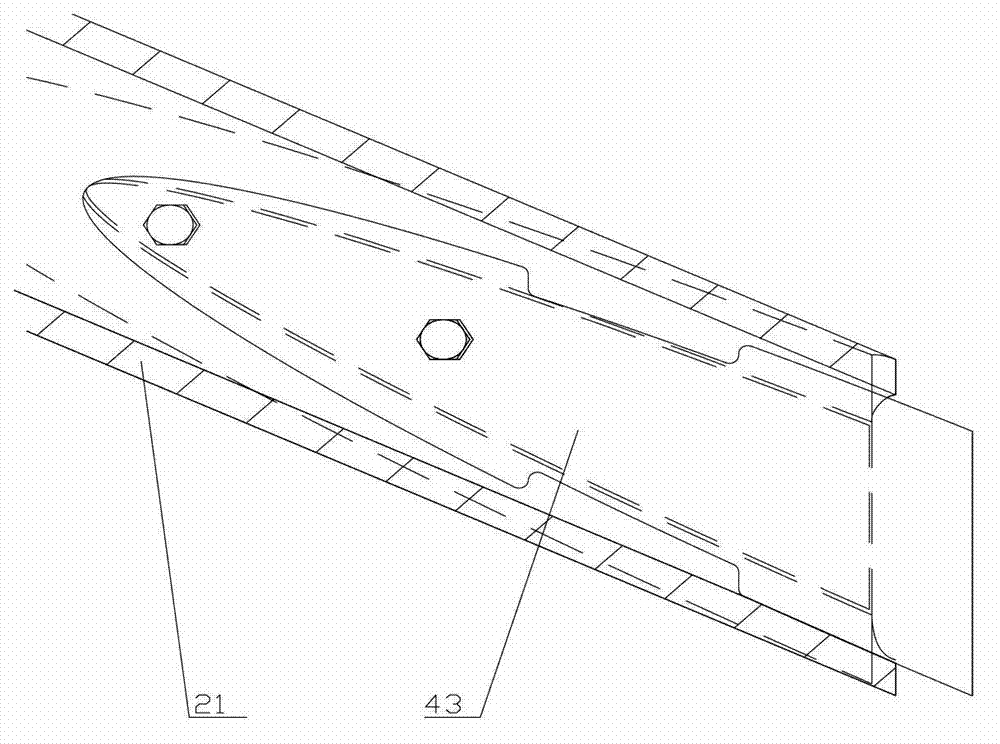

Turbulence separation device for multi-phase fluid

ActiveCN103459043BEasy to separateAvoid affecting the separation effectLiquid degasificationReversed direction vortexEngineeringMulti phase

Disclosed is a turbulence separation device for multi-phase fluid, comprising a primary oblique pre-separation pipe (2), a primary vertical turbulence separation pipe (5), a secondary oblique pre-separation pipe (6), and a secondary vertical turbulence separation pipe (7). One end of the primary oblique pre-separation pipe (2) enters tangentially into the primary vertical turbulence separation pipe (5). The secondary oblique pre-separation pipe (6)leads out from near the end of the primary oblique pre-separation pipe (2). The end of the secondary oblique pre-separation pipe (6) enters into the secondary vertical turbulence separation pipe (7) tangentially. The turbulence separation device for multi-phase fluid is a series parallel dual-ejection and dual-separation device, with high measurement precision, low tolerance, and high stability.

Owner:XIAN DONGFENG MACHINERY & ELECTRONICS

Oil smoke separation device

PendingCN108579219ARealize separation and purificationEasy to separateDomestic stoves or rangesLighting and heating apparatusPetroleum engineeringSmoke

The invention discloses an oil smoke separation device. The oil smoke separation device comprises a separation disc, a partition plate and a motor, wherein the motor is arranged on the separation disc;the size of the upper layer extending along the circumference of the separation disc is larger than that of the lower layer extending along the circumference, forming the shape of the upper width andthe lower narrowness; the partition plate is provided with a hollow structure, the separation disc is embedded on the hollow structure of the partition plate, and the lower layer position of the separation disc is flat with the partition plate, and the upper edge of the separation disc is projected on the edge of the hollow structure of the partition plate. Compared with the prior art, the oil smoke separation device can effectively separate the oil fume and effectively intercept the non-separated oil smoke.

Owner:广州特伊雅智能科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com