Clearing and cover-bottle separating device after waste plastic bottle label paper stripping and application thereof

A technology for waste plastics and separation devices, which is applied in the direction of plastic recycling, recycling technology, mechanical material recycling, etc., can solve problems such as separation and adverse effects, and achieve the effects of complete separation, low production cost, and improved selection efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

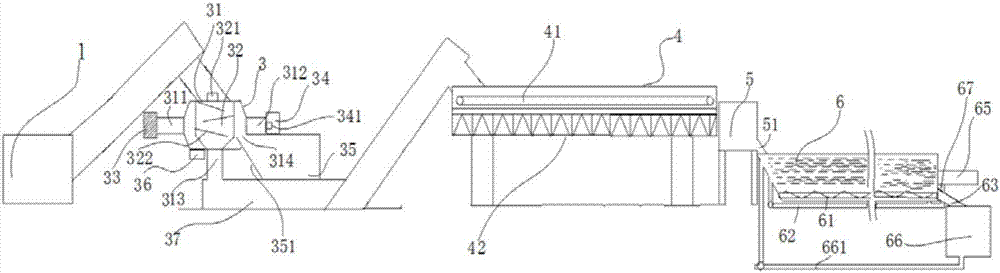

[0040] After the waste plastic bottle label paper of the present embodiment is peeled off, it is cleaned and the cap and bottle separation device are as follows: figure 1 As shown, it includes a paper bottle body temporary storage box 1, a winnowing mechanism 3, a selection platform 4, a crusher 5 and a separation tank 6 arranged in sequence and connected by a feeding auger; the selection platform 4 includes The horizontal conveyor belt 41 and the walking platform 42 on one side of the horizontal conveyor belt 41; the end of the horizontal conveyor belt 41 is blanked into the crusher 5; the crusher 5 communicates with the beginning of the separation tank 6 through the discharge port 51; the separation The end of the pool 6 communicates with the plastic pellet collection box 66 through the plastic pellet outlet 63; the separation pool 6 is filled with separation liquid.

[0041] The waste plastic bottle label paper of this embodiment is peeled off and cleaned and the cover and ...

Embodiment 2

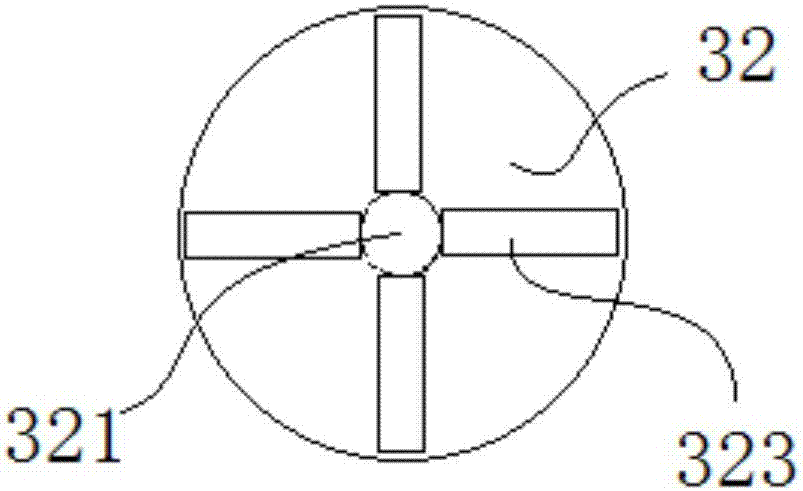

[0043] The waste plastic bottle label paper of the present embodiment is peeled off and cleaned and the cap and the bottle are separated. Roller net cylinder 32, the upper end of the roller net cylinder 32 is externally connected to the discharge opening of the feeding auger, and the lower end is externally connected to the waste bottle collection and transfer mechanism 37 through the waste bottle discharge pipe 313; one side of the horizontal barrel body 31 is also passed The air inlet pipe 311 is externally connected to the blower 33. Through the difference in the density of the bottle and the label, the label paper is blown out of the roll-type mesh cylinder by the way of horizontal wind blowing, and the bottle body falls freely into the waste bottle collection and transfer mechanism. It only needs to control the wind speed. It can solve the problem that the bottle and the label are not easy to separate after the waste plastic bottle is off the label. Picking efficiency: Th...

Embodiment 3

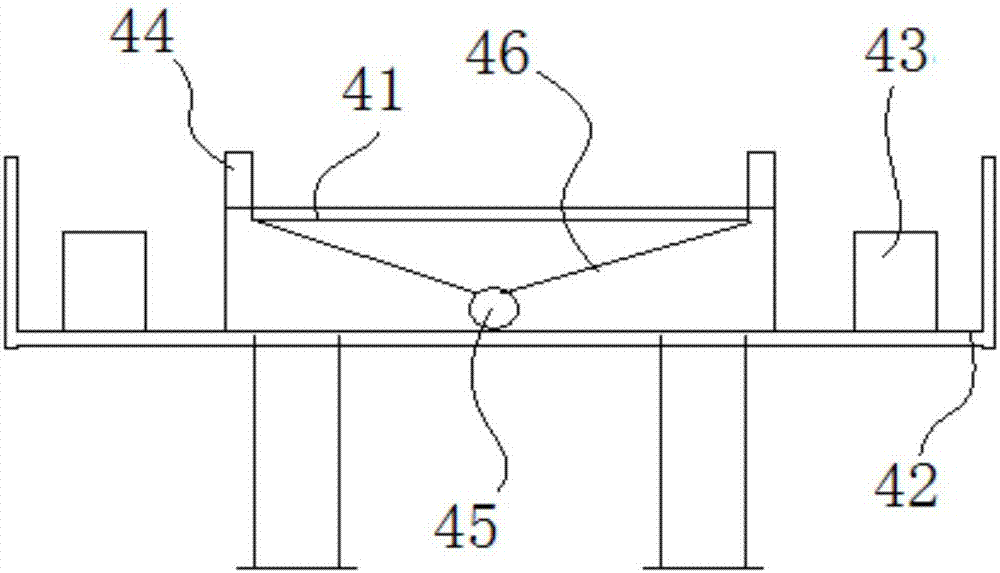

[0045] The waste plastic bottle label paper of this embodiment is peeled off and the device for cleaning and separating caps and bottles has the same basic structure as that of Embodiment 2, the difference and improvement being that in the winnowing mechanism 3, the other side opposite to the air inlet pipe 311 is connected externally. Air outlet pipe 312; at the bottom of the air outlet pipe 312, the horizontal barrel body 31 is connected to the waste standard collection box 35 through the waste standard outlet 314 opened on the side, and the waste standard is collected to avoid flying around and pollute the environment; the horizontal conveyor belt 41 At the bottom, a high-pressure air duct 45 is arranged vertically; Figure 4 As shown, the upper part of the high-pressure air pipe 45 is evenly opened with an air outlet 451 facing the horizontal conveyor belt 41, which is convenient for drying the residual moisture of the bottle body and is conducive to the post-processing cru...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com