Device for separating impurities from spice for pastry

A separation device and spice technology, applied in magnetic separation, solid separation, filtration, etc., can solve the problems of narrow application range, poor separation effect, inconvenient operation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

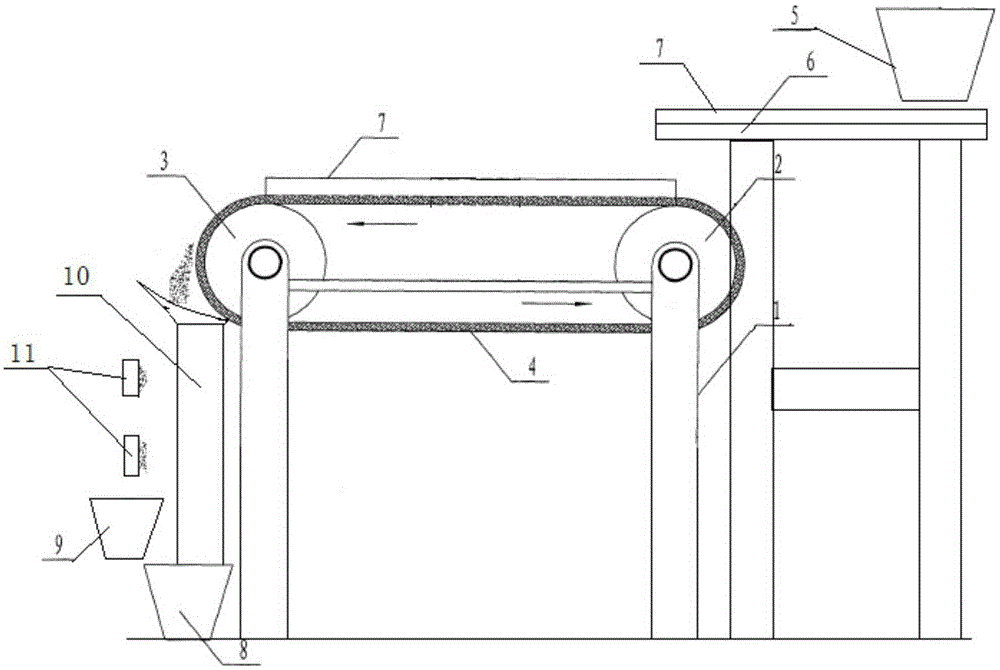

[0016] A device for separating spices and iron impurities for pasta, including a frame 1, a driving belt roller 2 and a driven belt roller 3 are respectively arranged at both ends of the frame 1, and a transmission belt 4 is wound on the driving and driven belt rollers 2 and 3, and the driving The top of the belt roller 2 corresponds to the discharge end of the vibrating screen 6, the feed end of the vibrating screen 6 corresponds to the outlet of the feed box 5, the driving belt roller 2 is driven by a power mechanism, and the bottom of the driven belt roller 2 corresponds to A flat cylindrical material receiver 10 is provided, and two horizontal holes are arranged up and down on one side of the material receiver 10 . Two horizontal holes are used, one is that the effect of absorbing iron impurities is better, and the other is that the electromagnet corresponding to one of the horizontal holes can be stopped to remove impurities, and the other continues to work without affecti...

Embodiment 2

[0020] A device for separating spices and iron impurities for pasta, including a frame 1, a driving belt roller 2 and a driven belt roller 3 are respectively arranged at both ends of the frame 1, and a transmission belt 4 is wound on the driving and driven belt rollers 2 and 3, and the driving The top of the belt roller 2 corresponds to the discharge end of the vibrating screen 6, the feed end of the vibrating screen 6 corresponds to the outlet of the feed box 5, the driving belt roller 2 is driven by a power mechanism, and the bottom of the driven belt roller 3 corresponds to A flat cylindrical material receiver 10 is provided, and two horizontal holes are respectively arranged on the two sides of the material receiver 10 up and down. An electromagnet 11 is arranged on the outside of the material receiver 10 corresponding to each horizontal hole. Two horizontal holes are arranged on both surfaces. First, the effect of absorbing iron impurities is better. Second, the electroma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com