Turbulence separation device for multi-phase fluid

A cyclone separation device and cyclone separation technology, which are applied in cyclone devices, liquid separation, and devices whose axial directions of the cyclone can be reversed, etc., can solve the problems of weakening the cyclone separation effect and reducing the actual separation measurement accuracy. , to achieve a good separation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

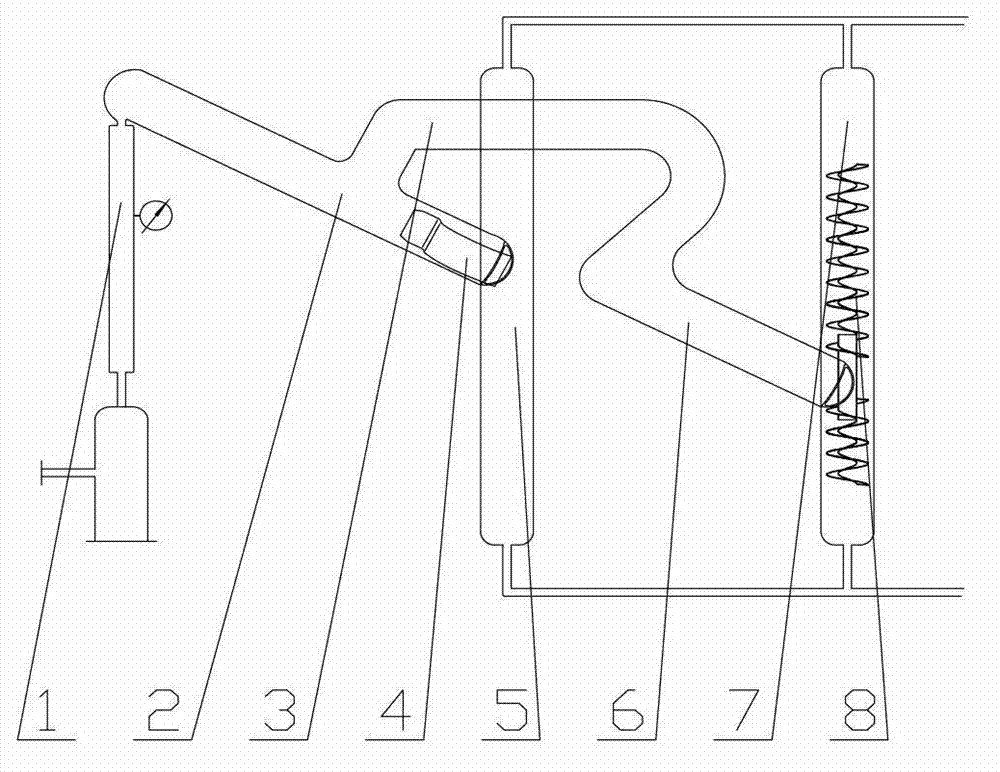

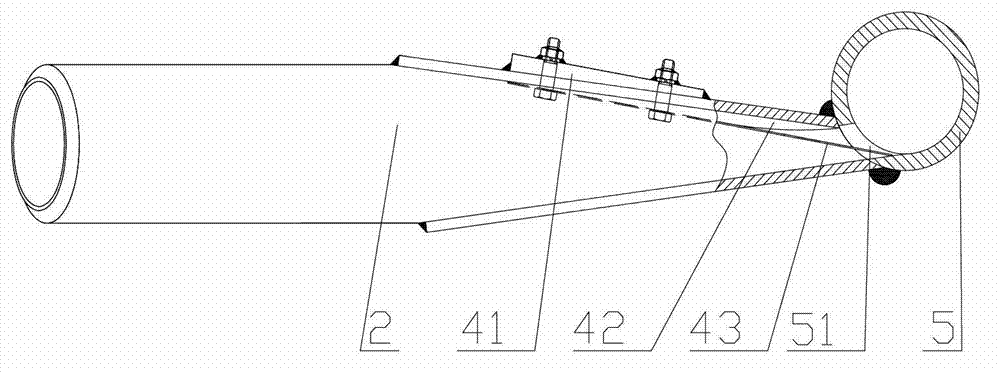

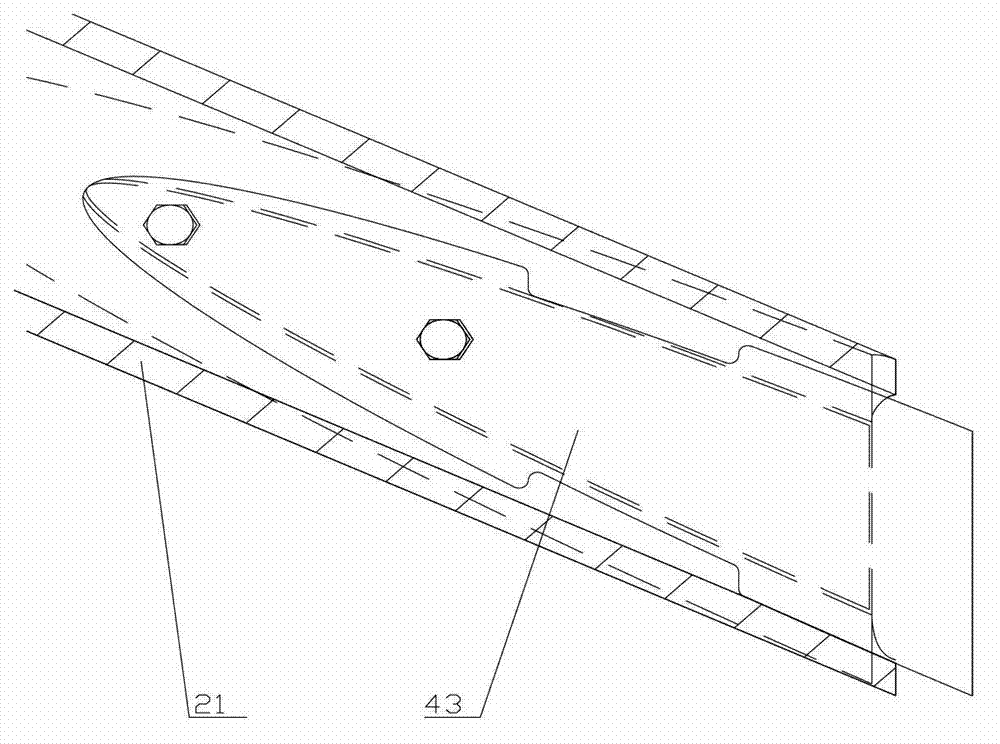

[0037] see figure 1 , the present invention provides a multi-phase fluid cyclone separation device for two-stage mixed jet two-stage separation. ), a primary vertical cyclone separation pipe 5, a secondary inclined pre-separation pipe 6, a jet linear velocity stabilizing device 4, a secondary vertical cyclone separation pipe 7 and a forced swirl helicoid 8.

[0038] The working process of the present invention is: the gas-liquid two-phase mixed fluid rises and separates in the fluid stabilization pipe 1, and then enters the first-stage inclined pre-separation pipe 2 arranged obliquely, and is gradually separated into a stratified flow of upper gas phase and lower liquid phase. At the position close to the end of the first-level inclined pre-separation pipe 2, a height difference conversion pipe 3, that is, a pre-separation consolidation pipe, is arranged upward, and most of the gas phase components that have been precipitated in the first-level inclined pre-separation pipe 2 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com