Novel negative pressure gas-liquid separator

A technology of liquid separator and gas-liquid mixture is applied in the field of negative pressure gas-liquid separator, which can solve the problems such as the limitation of the installation position of the separator, and achieve the effects of improving the processing capacity, convenient operation and high separation efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to make the purpose, technical solutions and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the examples and accompanying drawings. Limitations on the Invention.

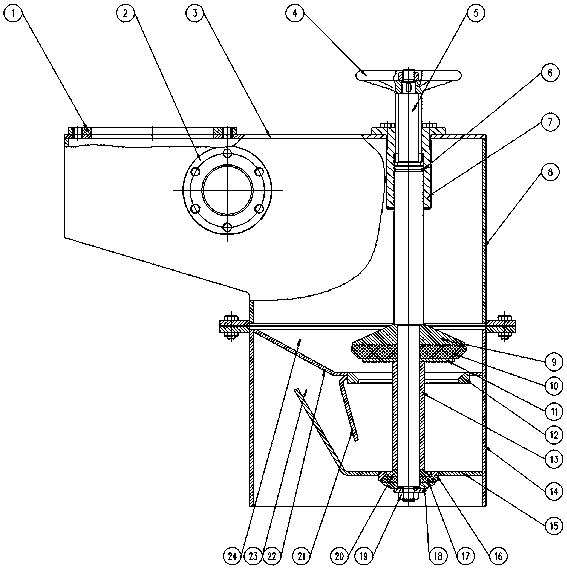

[0022] Such as figure 1 As shown, the negative pressure gas-liquid separator of the present invention is mainly composed of a gas outlet flange (1), a gas-liquid mixture inlet flange (2), a top cover (3), a hand wheel (4), and a screw (5) , screw sleeve (7), upper box (8), tapered ring (9), upper rubber valve core (10), liner (11), upper valve seat (12), sleeve (13), lower box Body (14), lower valve seat plate (15), lower valve seat (16), lower valve core (17), lower cone ring (18), upper cone ring (20), baffle plate (21), upper valve seat Plate (22) and liquid outlet (23) etc. are formed. Among them: the gas outlet flange (1) is welded on the top cover (3), the gas outlet flange is connected to the external exhaust ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com