Oil smoke separation device

A technology of oil fume separation and separation disc, which is applied in the direction of oil fume removal, separation method, and dispersed particle separation, etc., can solve the problems affecting the effect of oil fume separation, affecting the service life of oil fume separation device, etc., and achieves good effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

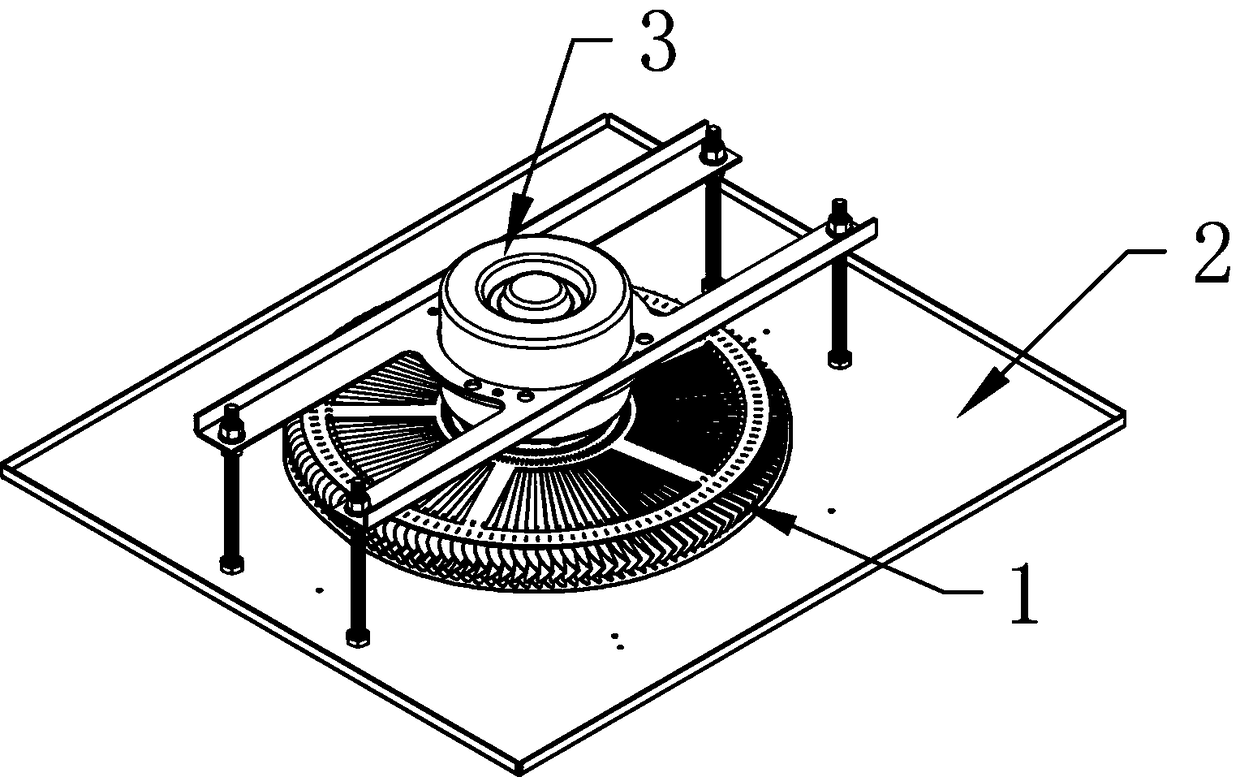

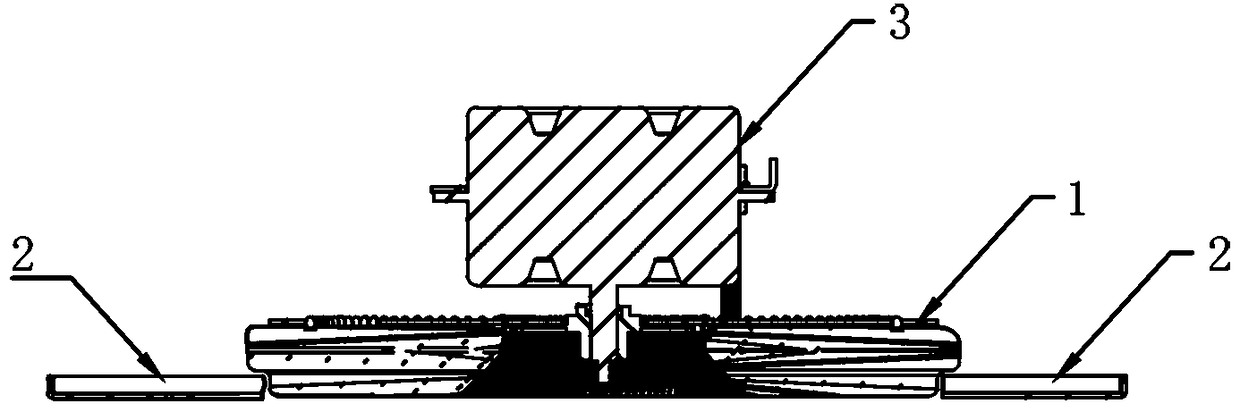

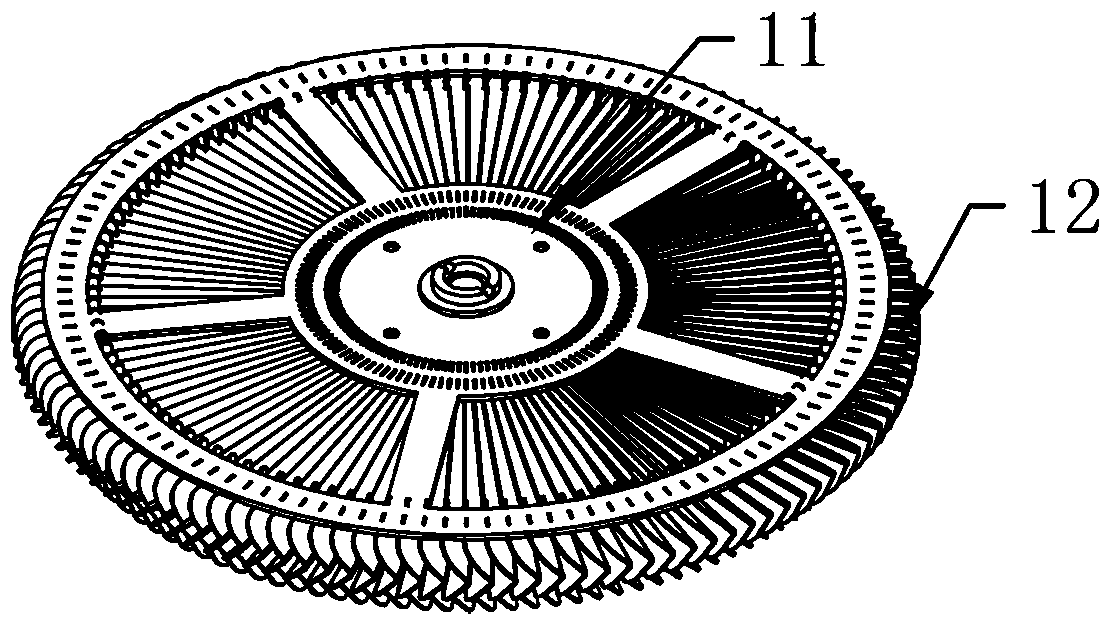

[0029] like figure 1 with figure 2 As shown, an oil fume separation device includes a separation disc 1, a separator 2 and a motor 3, the motor 3 is installed on the separation disc 1, and the upper layer of the separation disc 1 extends circumferentially larger than the lower layer along the circumferential direction. The extended size forms a shape with a wide top and a narrow bottom; the partition 2 is provided with a hollow structure, and the separation disc 1 is embedded in the hollow structure of the partition 2, and the lower layer of the separation disc 1 is in the same position as the partition 2 Flat, the upper edge of the separation disc 1 protrudes from the edge of the hollow structure of the separator 2.

[0030] By setting the separation disk 1 into a structure with a wide top and a narrow bottom, and the partition plate 2 is just flat with the narrow side part of the separation disk 1, so that the edge of the hollow structure of the partition plate 2 protrudes...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com