A combined air filter

An air filter and combined technology, applied in the field of combined air filters, can solve the problems of limited use angle, reduced filtering accuracy, waste of resources, etc., to achieve a wide range of applications, reduce replacement times, and increase use. effect of life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

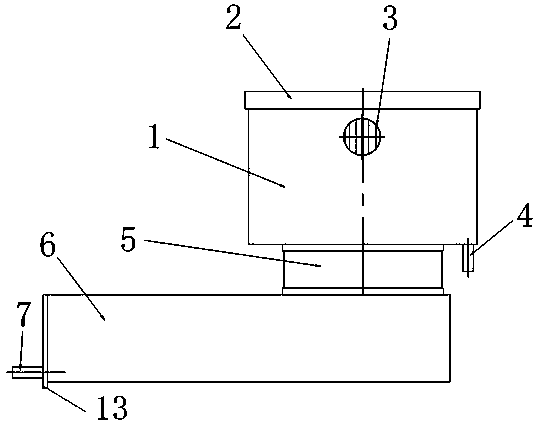

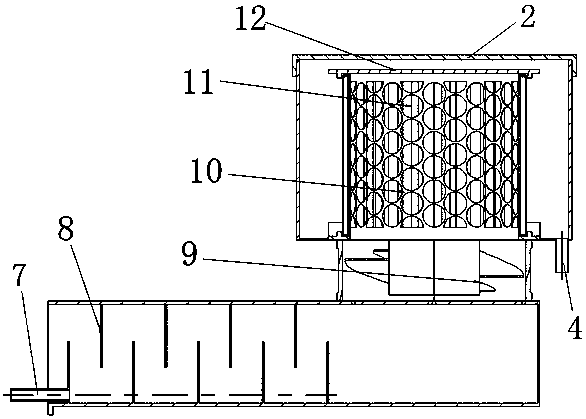

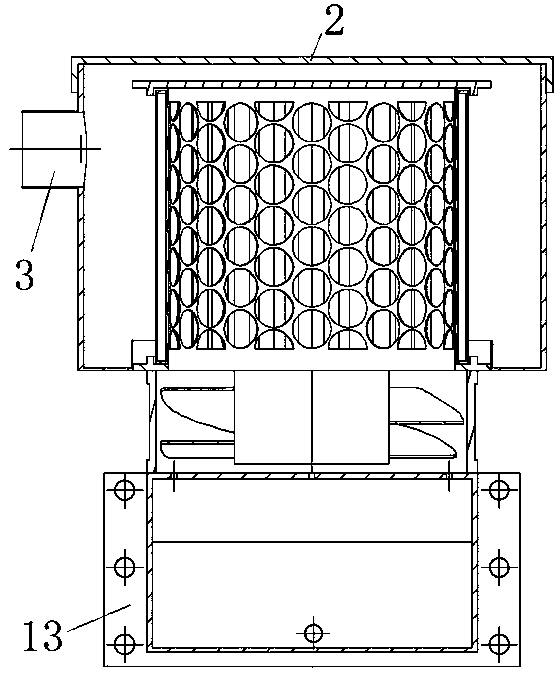

[0031] Such as Figures 1 to 4 As shown, a combined air filter is composed of an oil-gas separation tube 6 and a filter; the oil-gas separation tube 6 is a square tube with one end open and the other end closed, and the upper tube wall and the lower tube wall are close to the open end. Several vertical baffles 8 are evenly fixed and connected, and the baffles 8 on the upper pipe wall and the lower pipe wall are arranged alternately in the horizontal direction. Separation passage; the lower part of the baffle plate 8 arranged on the lower pipe wall is also provided with a through hole, and the lower part of the open end of the oil-gas separation pipe 6 is also provided with an oil outlet hole 7 . The length of the baffle plate 8 is equal to the width of the oil-gas separation pipe 6 . The through holes at the bottom of the baffle plate 8 are circular holes with equal diameters, and the axes of all the through holes are collinear. All the through holes and the oil outlet hole ...

Embodiment 2

[0040] The main structure is the same as the above-mentioned embodiment 1, the difference is that the oil outlet direction of the oil outlet hole 7 is toward the bottom of the oil-gas separation pipe 6, so that the separated oil can be directly recovered for further processing, and it is suitable for waste oil and will not be repeated. Take advantage of situations where only the emissions need to be cleaned.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com