Back squeezing device for oil-dreg separation of oil press in research of agricultural science

A technology of agricultural science and oil press, applied in the direction of fat oil/fat refining, fat production, etc., can solve the problems of low efficiency, complex structure, etc., and achieve the effect of improving intelligence, improving work efficiency, and convenient output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

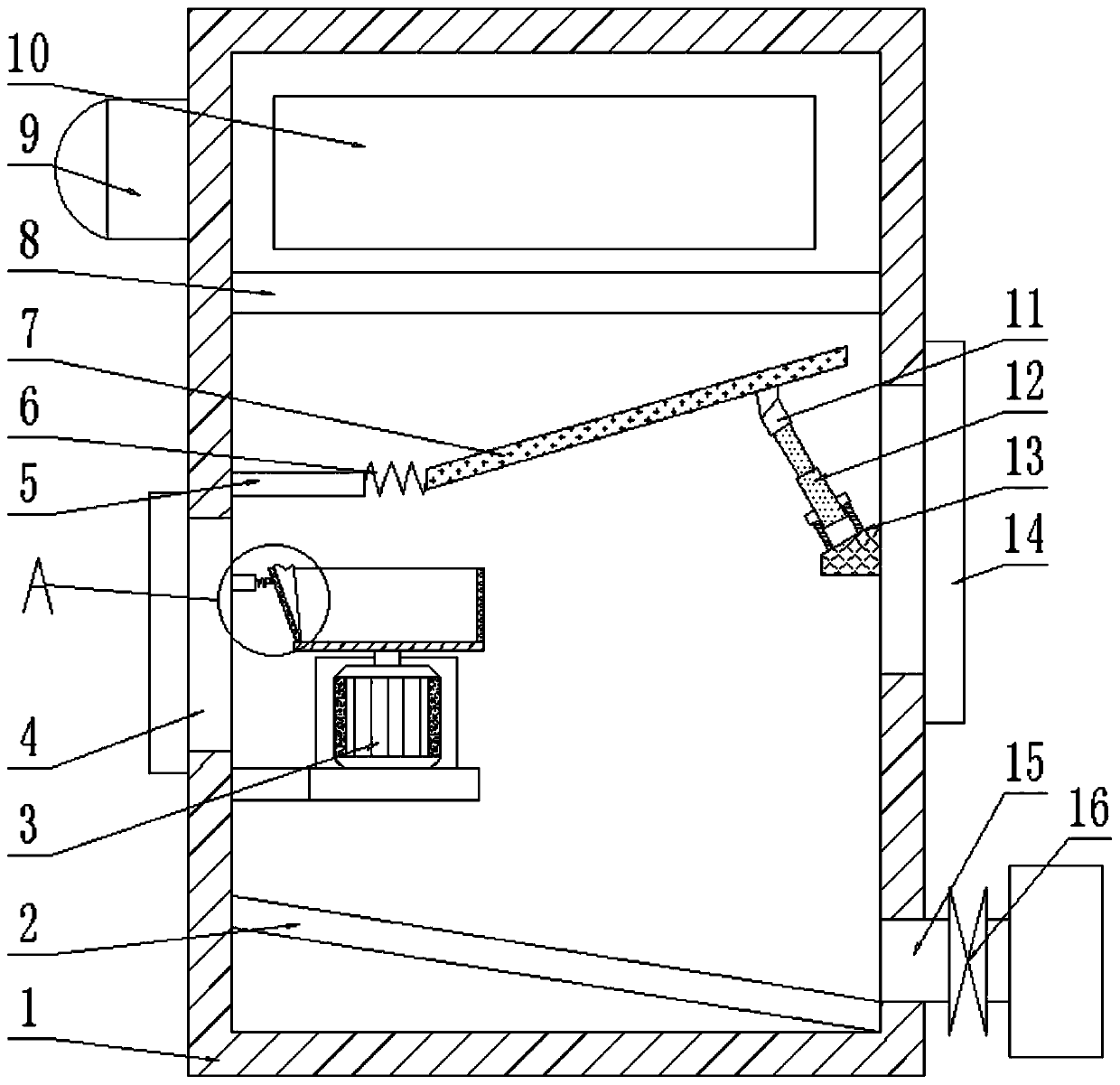

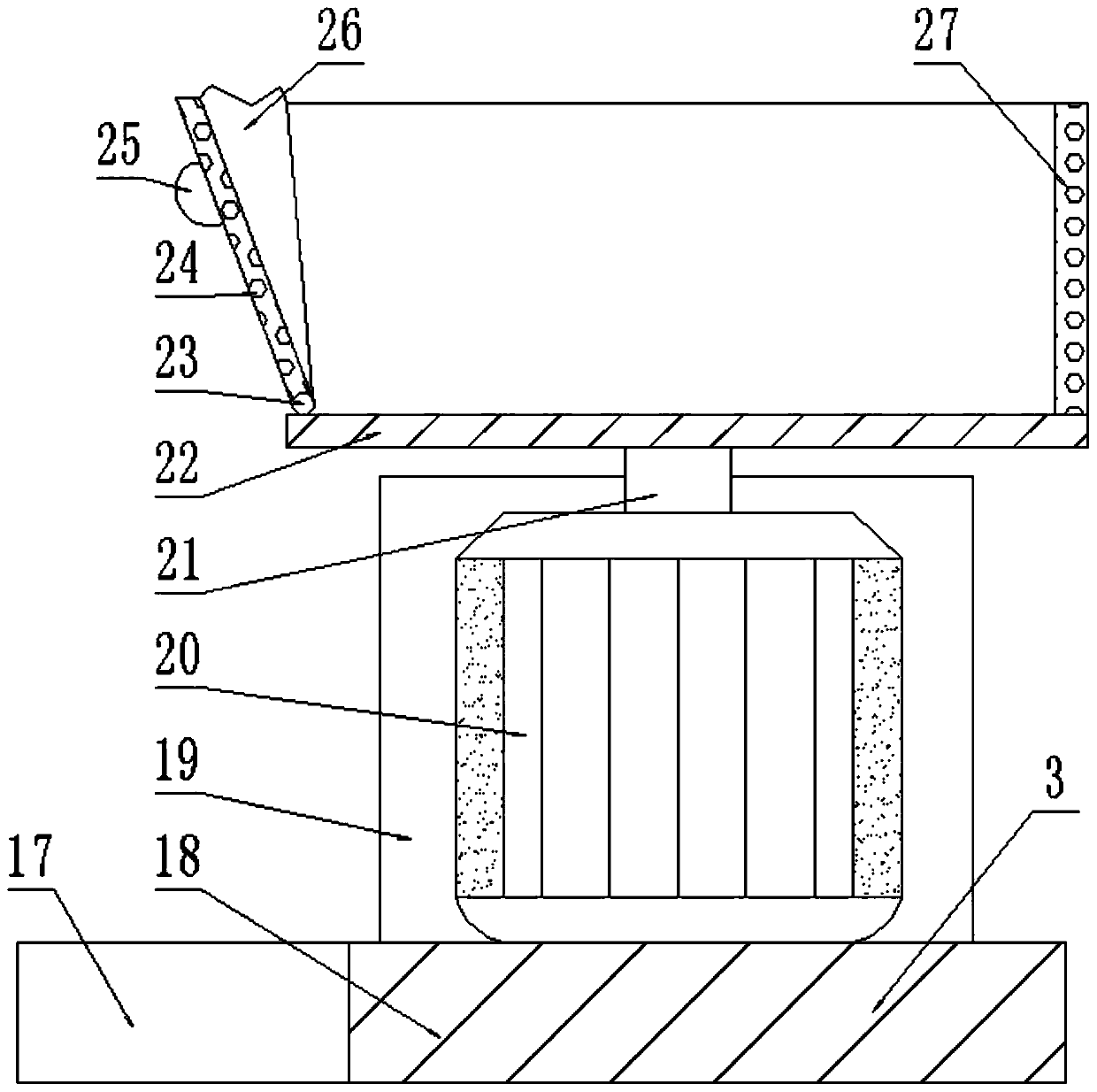

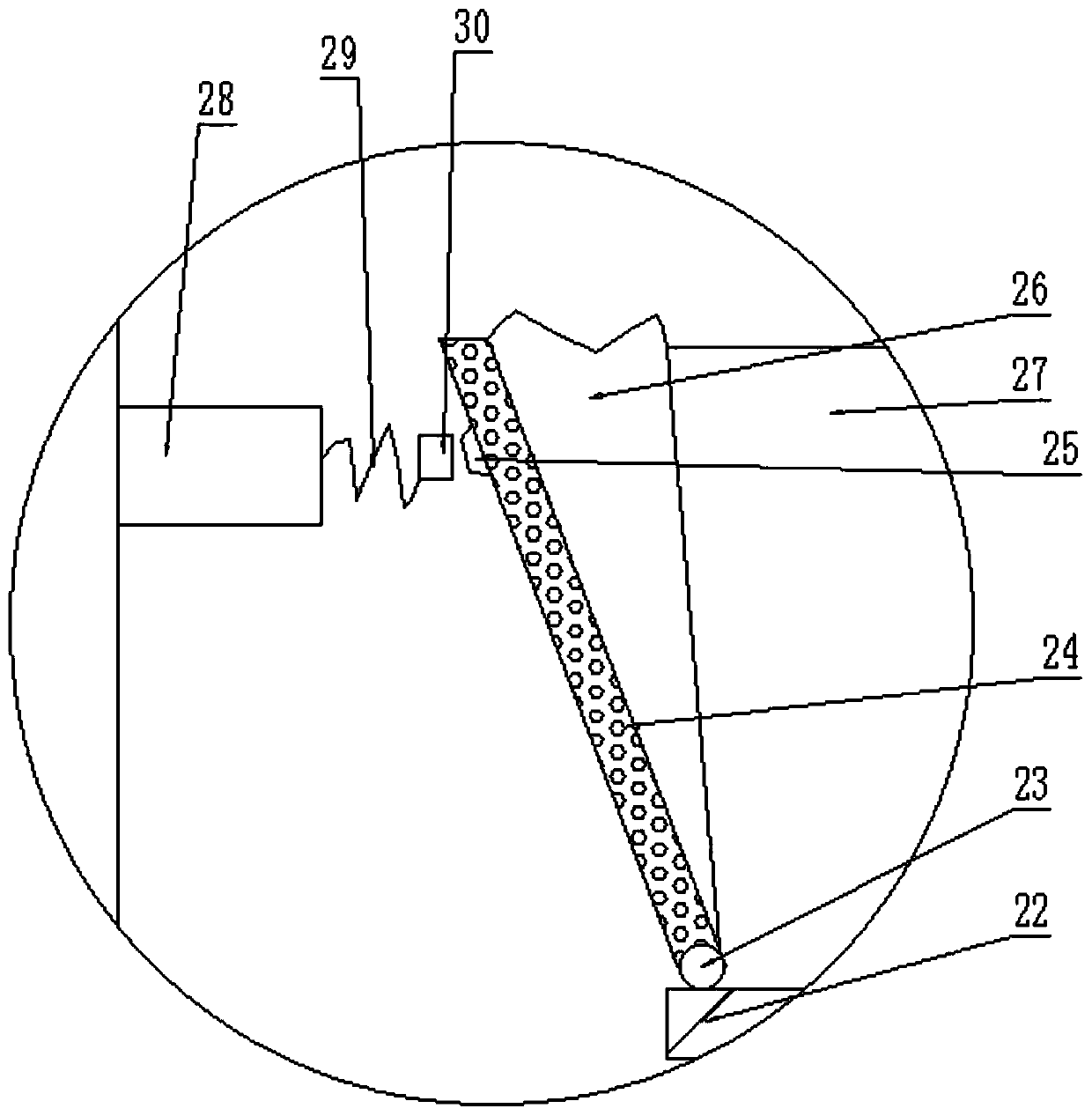

[0030] refer to Figure 1-5 , an oil press oil residue separation and return press device for agricultural scientific research, comprising an oil press shell 1, an oil outlet pipe 15 is welded at the bottom of one side of the outer wall of the oil press shell 1, and the oil outlet pipe 15 is provided with a valve 16 , the bottom inner wall of the oil press housing 1 is welded with an oil deflector 2 placed obliquely, through which the oil is quickly collected after the oil is extruded to facilitate discharging, and one end of the oil guide 2 is connected to the oil outlet pipe 15, The height of the side of the oil guide plate 2 close to the oil outlet pipe 15 is lowe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com