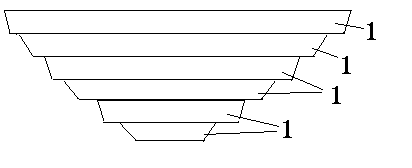

Revolving drum of conical basket type centrifuge

A centrifuge and cone-basket technology, which is applied in the drum field of the cone-basket centrifuge, can solve problems such as filter blockage and achieve the effect of ensuring thoroughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with the accompanying drawings. The following examples are only used to illustrate the technical solution of the present invention more clearly, but not to limit the protection scope of the present invention.

[0014] Such as figure 1 As shown, the drum of a cone-basket centrifuge includes several rotating frames 1 arranged sequentially from top to bottom. The shape of the rotating frames 1 is an inverted truncated cone, and the central axes of all the rotating frames 1 On a straight line, two adjacent revolving frames 1, the area of the bottom circular surface of the upper revolving frame 1 is larger than the top circular surface area of the lower revolving frame 1, and the side inclination angles of the two adjacent revolving frames 1 are different, A filter screen matching the revolving frame 1 is also fixed on the revolving frame 1, and the filter screen is fixed on the revolving frame 1 throu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com