Bidirectional self-shedding stripping machine for cable recovery and application method thereof

A stripping machine and self-shedding technology, which is applied in the field of two-way self-shedding stripping machines for cable recycling, can solve the problems of cumbersome operation, low cable stripping efficiency, and heavy workload, so as to improve work efficiency, improve stripping efficiency, and reduce work. volume effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

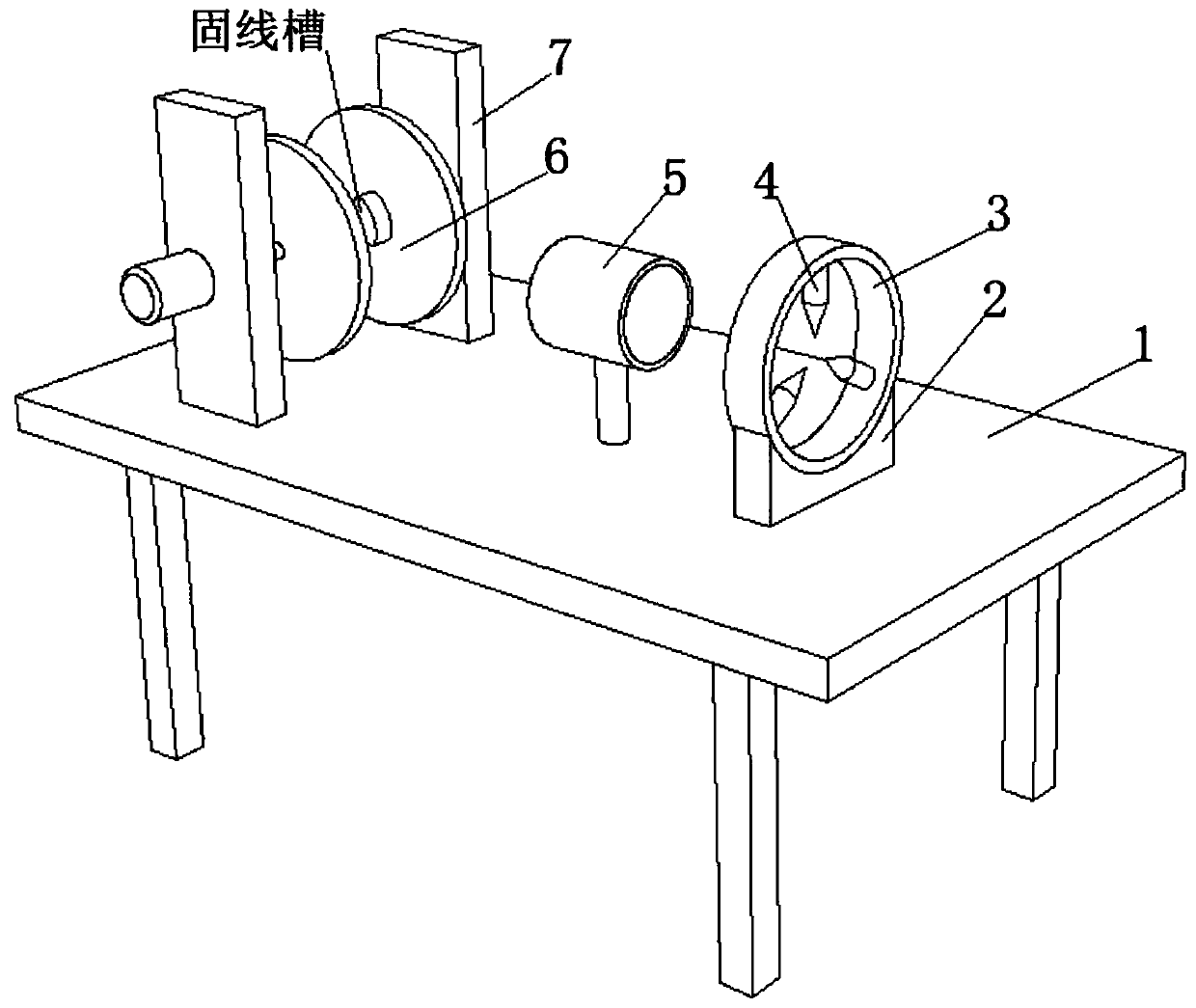

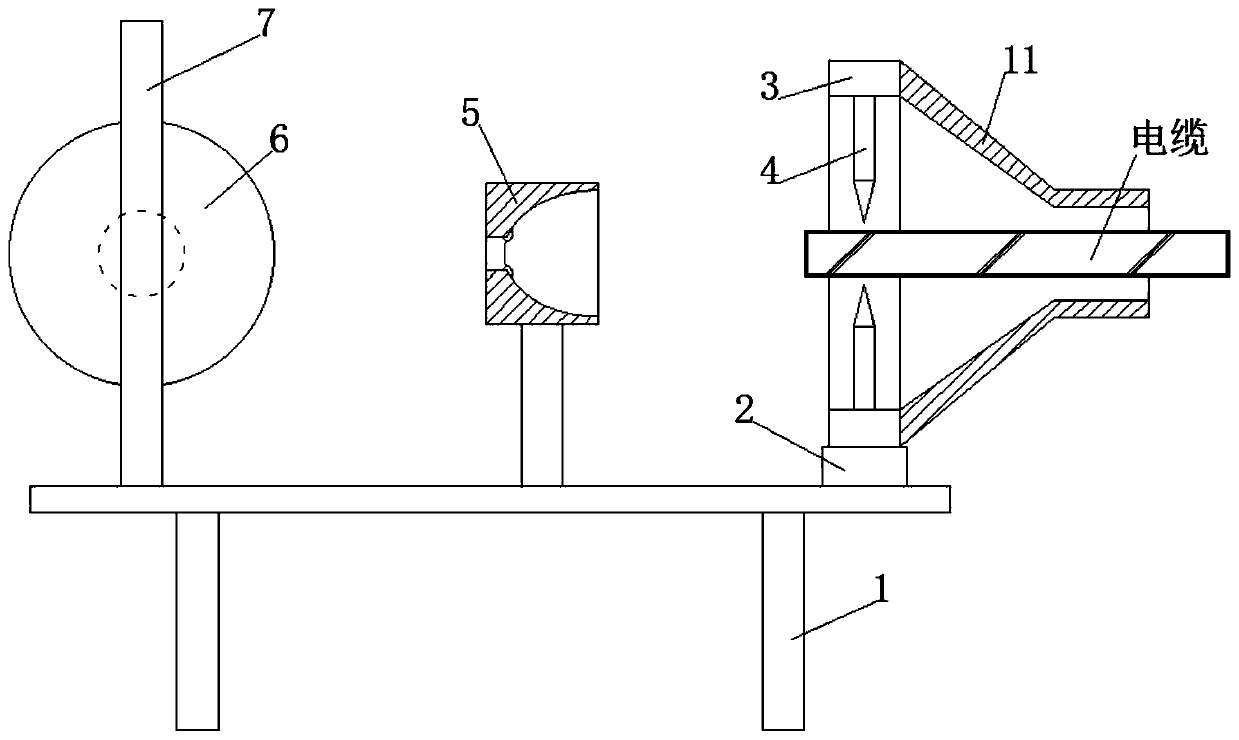

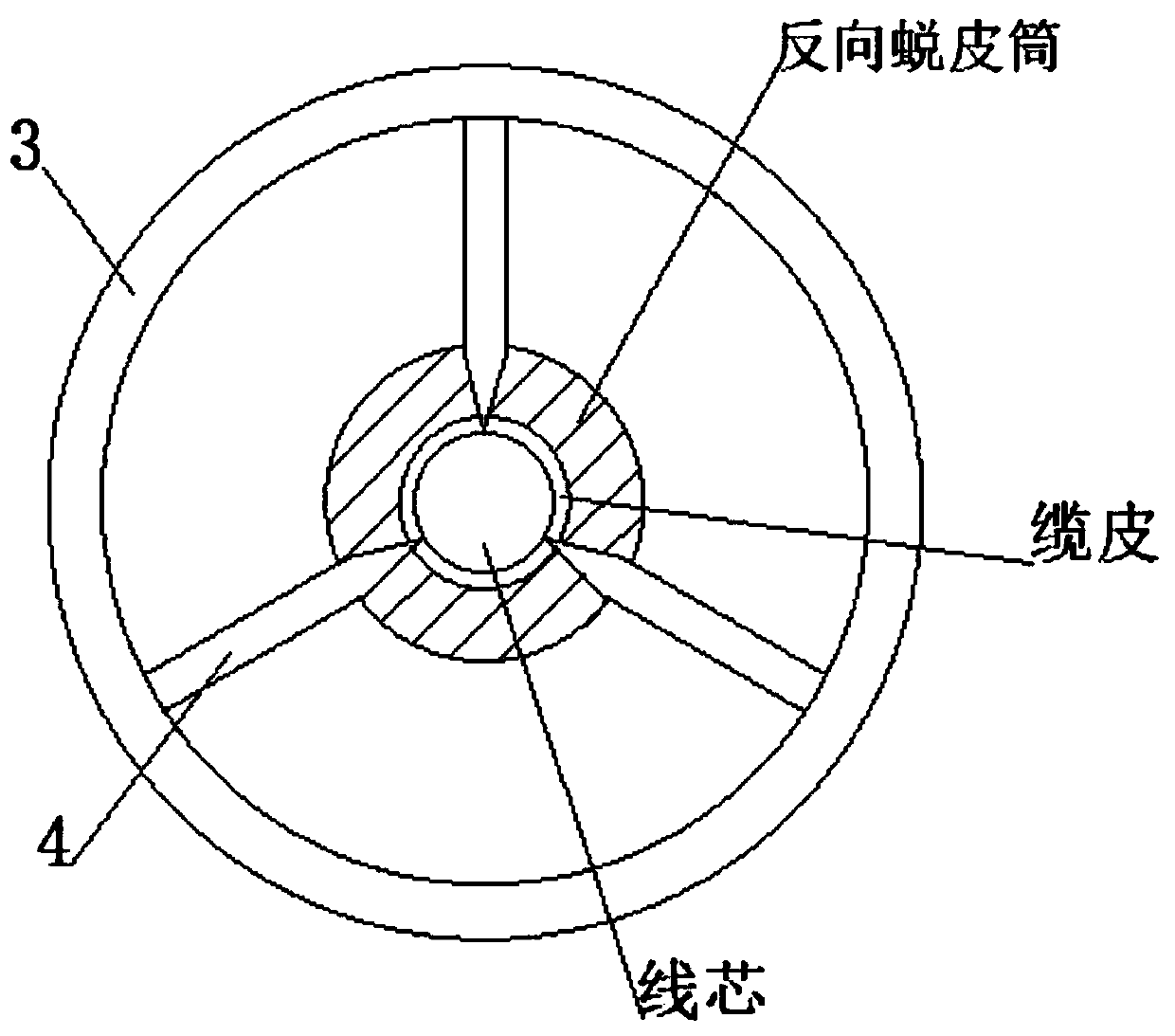

[0050] see figure 1 , a two-way self-falling type peeling machine for cable recovery, including a peeling machine body 1, a pair of columns 7 and a tool holder 2 are fixedly connected to the left and right upper ends of the peeling machine body 1, and a pair of columns 7 are rotatably connected to drive through a motor. The wire core winding shaft 6, the middle part of the wire core winding shaft 6 is dug with a wire fixing groove, the upper end of the tool seat 2 is fixedly connected with an annular tool holder 3, the straightening sleeve 11 and the inner wall of the wire fixing groove are all provided with a solid lubricating coating, and The thickness of the solid lubricating coating is 1-2mm, and the solid lubricating layer on the straightening sleeve 11 can reduce the friction between the cable and the cable, making the process of the cable advancing under the pulling force of the core winding shaft 6 more smooth.

[0051] see figure 2 , the right end of the ring knife ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com