A targeted refinement of Amla emblica, its preparation method and its application in cigarettes

An emblica and targeted technology, which is applied in the field of cigarette flavors and fragrances, can solve the problems of large differences, complex types of ingredients, and unremarkable cigarette functions, and achieve the effects of outstanding functionality, improved sensory quality, and delicate smoke

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

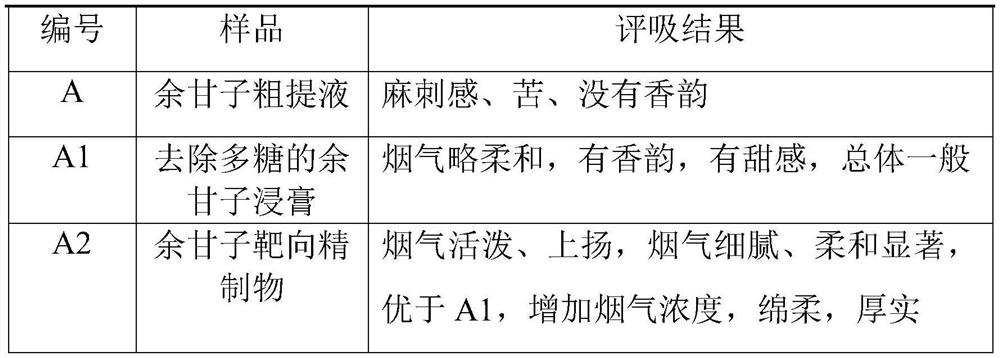

[0025] Weigh 50g of dry emblica, add 500g of pure water after crushing, heat in a water bath at 90°C to condense and reflux for extraction 3 times, each time for 2h, combine the filtrates 3 times, concentrate under reduced pressure to 50g of crude extract (code A), and after cooling Add 200g of 95% ethanol for alcohol precipitation. After standing for 24 hours, centrifuge to remove the precipitate. The supernatant is concentrated under reduced pressure until it has no ethanol smell, and diluted to 30g with pure water to obtain the polysaccharide-removed emblica extract (code A1). The polysaccharide-removed emblica extract was adsorbed by the macroporous adsorption resin AB-8 for 24 hours, and the sample was loaded according to the ratio of the crude drug amount to the resin amount at 1:10. After the adsorption was completed, 4BV was eluted with pure water, and the pure water eluate was collected to reduce Concentrated under pressure and then dried to obtain the targeted refined...

Embodiment 2

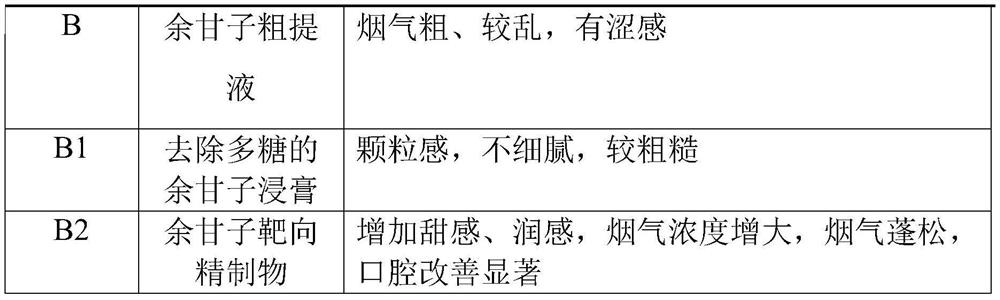

[0031] Weigh 11kg of dry emblica, add 110kg of pure water after crushing, heat at 90°C to extract 3 times, each time for 2h, combine the filtrates 3 times, concentrate under reduced pressure to 1kg of crude extract (code B), add 4kg of 95% Ethanol was used for alcohol precipitation, and after standing for 24 hours, the precipitate was removed by centrifugation, and the supernatant was concentrated under reduced pressure until it had no ethanol smell, and 4.58 kg of emblica extract (code B1) from which polysaccharides were removed was obtained. Weigh 333g of emblica extract (crude drug amount 800g) from which polysaccharides have been removed, and absorb it through the macroporous adsorption resin AB-8 for 24 hours, load the sample according to the ratio of crude drug amount and resin amount 1:10, and elute 8BV with pure water after the adsorption is completed. The pure water eluate was collected, concentrated under reduced pressure, and then dried to obtain the targeted refined...

Embodiment 3

[0038] The polysaccharide-removed emblica extract and emblica targeted refined product in Example 1 were dissolved and diluted with 10% ethanol respectively, and the diluted solution was sprayed on the sample shredded tobacco 3#, and the dosage of emblica targeted refined product was 0.05% by weight of shredded tobacco, sealed and stored for 24 hours, rolled into cigarettes.

[0039] The results of sensory evaluation showed that: compared with the cigarette samples added with polysaccharide-removed emblica extract, the cigarette samples added with emblica targeted refinement had lively, soft, transparent smoke and increased roundness, which was significantly better than Before refining.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com