Two-stage multi-inlet dynamic pressure degasser

A technology with multiple inlets and inflow inlets, which is applied in the field of multiphase flow separation, can solve problems such as poor performance and lower fluid liquid-gas ratio, and achieve the effects of strong applicability, improved separation capacity and efficiency, and large separation factor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

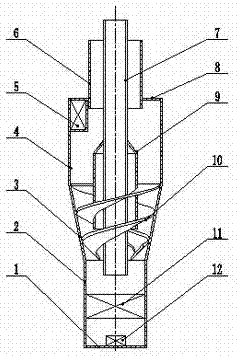

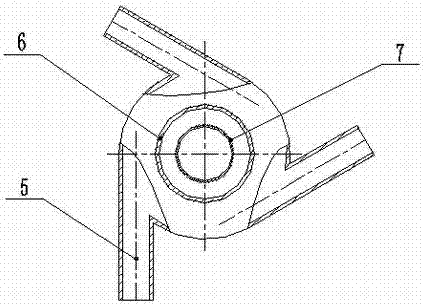

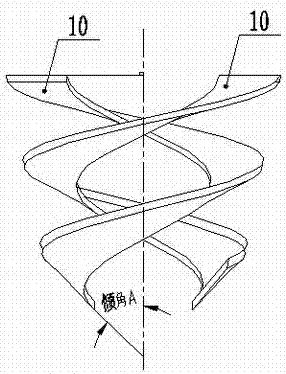

[0019] figure 1 , 2 A structural diagram of a dual-stage multi-inlet dynamic pressure degasser is shown. This two-stage multi-inlet dynamic pressure degasser includes a pre-degassing component, a fine degassing component and a two-phase outlet structure. The pre-degassing assembly includes a primary separation cyclone inlet 5 , an upper cover 8 , a cylinder 4 , and an umbrella-shaped rectifying plate 9 . Three primary separation swirl inlets 5 are evenly distributed around the upper end of the cylinder body 4 . The fine degassing assembly includes two fine-separation guide vanes 10 evenly distributed in the circumferential direction, a cone 3 matched with the fine-separation guide vanes 10 and a straight cylinder 2 connecting the cones 3 . The two-phase outlet mechanism includes a fine separation air outlet pipe 7 , a coarse separation air outlet pipe 6 , an agglomeration and anti-vortex device 11 and four circumferentially evenly distributed liquid outlets 12 . The centra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com