Floating-type oil absorption device of oil-water separator

An oil-water separator, floating technology, applied in the direction of liquid separation, separation methods, chemical instruments and methods, etc., can solve the problems of polluting the furnace, soft spots of parts, affecting the appearance of workpieces, etc., to prevent the entry of air and impurities, and facilitate Installation and disassembly, the effect of a high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1)

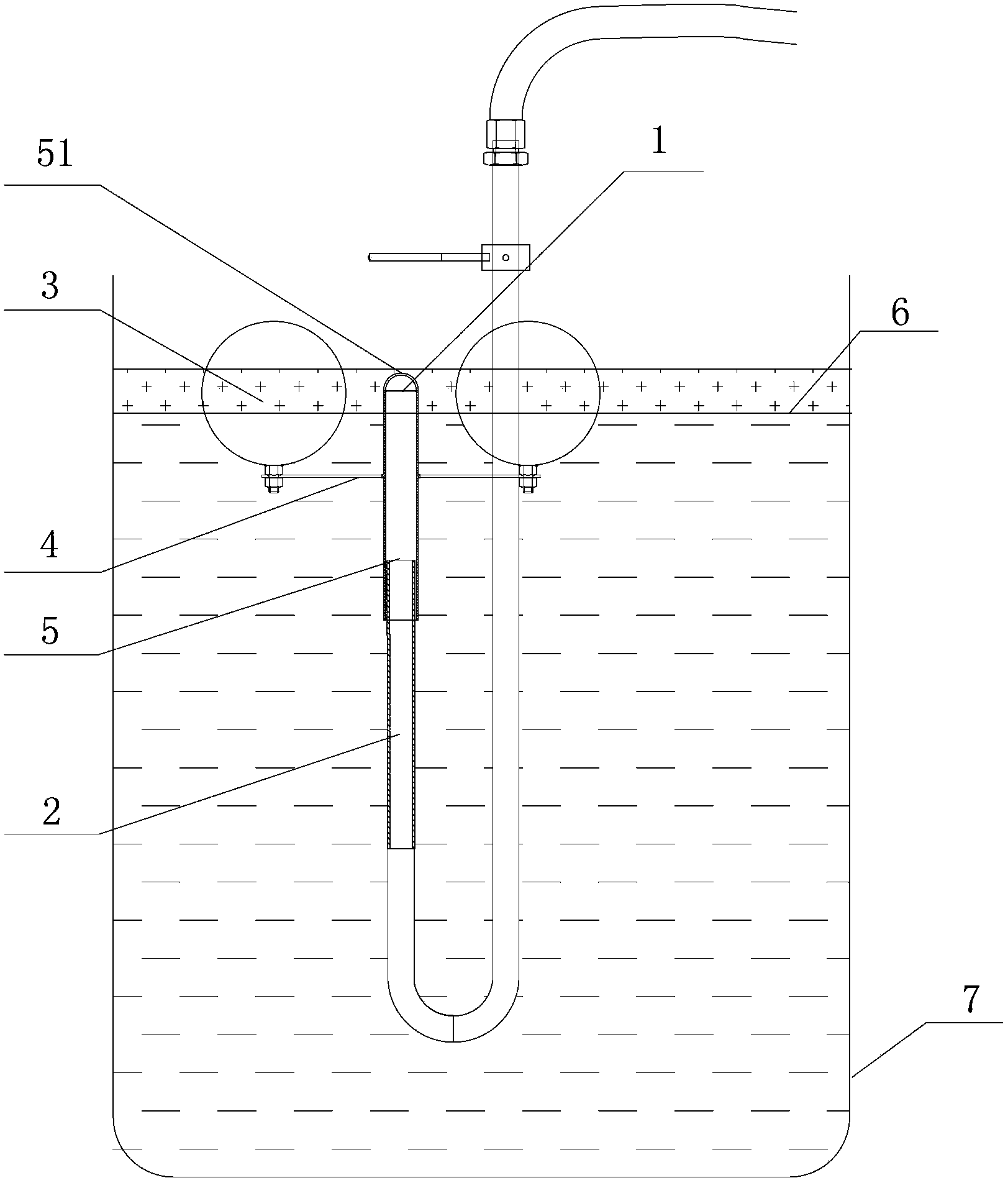

[0017] See figure 1 , the present invention has an oil suction port 1, an oil suction pipe 2, two stainless steel floating balls 3 and a connecting rod 4 located at the lower end of the stainless steel floating balls and fixedly connected thereto; The oil suction sleeve 5 is slidingly connected with the oil suction pipe 2, fixedly connected with the middle part of the connecting rod 4, and the other end of the oil suction pipe is connected with the oil suction starting device.

[0018] In order to prevent water from entering the pipeline from the port of the oil suction pipe 2, preferably, the oil suction sleeve 5 and the oil suction pipe 2 are cylindrical, the diameter of the oil suction sleeve 5 is larger than that of the oil suction pipe 2, and the oil suction pipe 2 is inserted in the oil suction sleeve 2. The upper end of the oil suction port 1 is provided with an arc-shaped baffle 51 to prevent the oil suction pipe 2 from passing through the oil suction sleeve 5 .

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com