Extraction dephenolization device and extraction dephenolization method for coal chemical industry wastewater treatment

A technology for coal chemical wastewater and extraction, which is applied in multi-stage water treatment, chemical instruments and methods, extraction water/sewage treatment, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

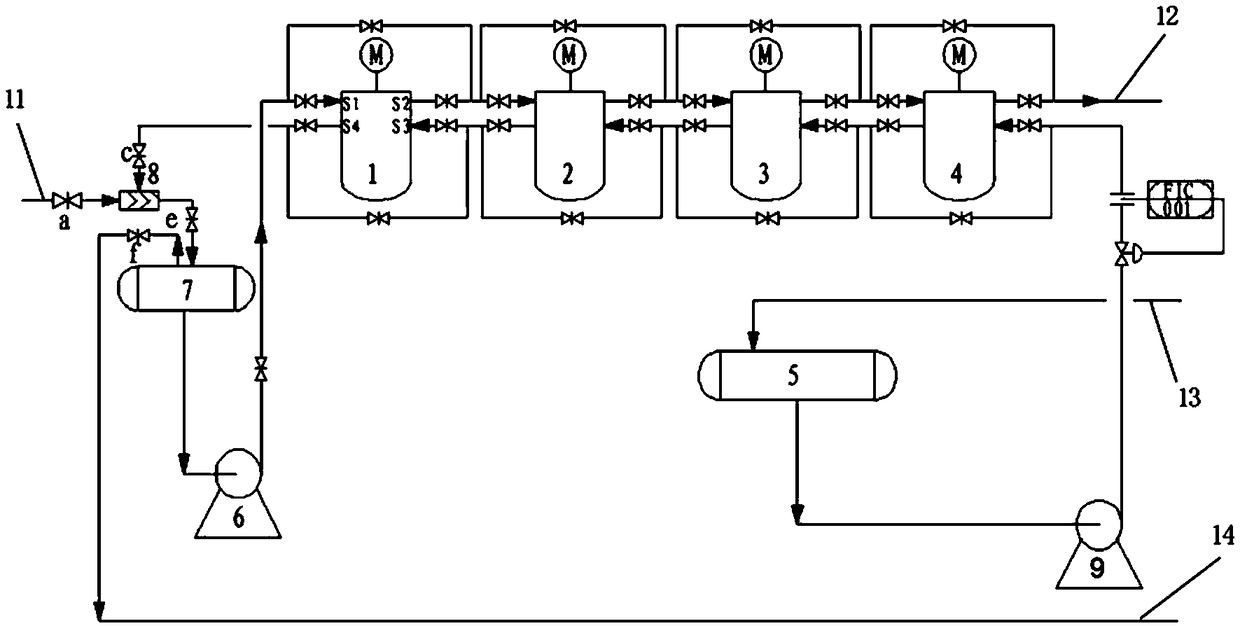

[0058] figure 1 An extraction and dephenolization device for coal chemical wastewater treatment is shown. The extraction and dephenolization device includes 4 centrifugal extractors—the first-stage CTL type single-stage centrifugal extractor 1, the second-stage CTL type single-stage centrifugal extractor 2, the third-stage CTL type single-stage centrifugal extractor 3 and The fourth stage CTL type single-stage centrifugal extractor 4, SV type static mixer 8, mixing and clarifying extraction tank 7, extraction agent circulation tank 5, first feed pump 6 and second feed pump 9.

[0059] The SV type static mixer 8 has a raw material liquid inlet, an extractant inlet and an outlet for receiving phenolic waste water, and its raw material liquid inlet is communicated with the feed line 11, and the feed line 11 is provided with a first valve a, and the extractant inlet There is a third valve c. The outlet of the SV-type static mixer 8 is communicated with the inlet of the mixing an...

Embodiment 2

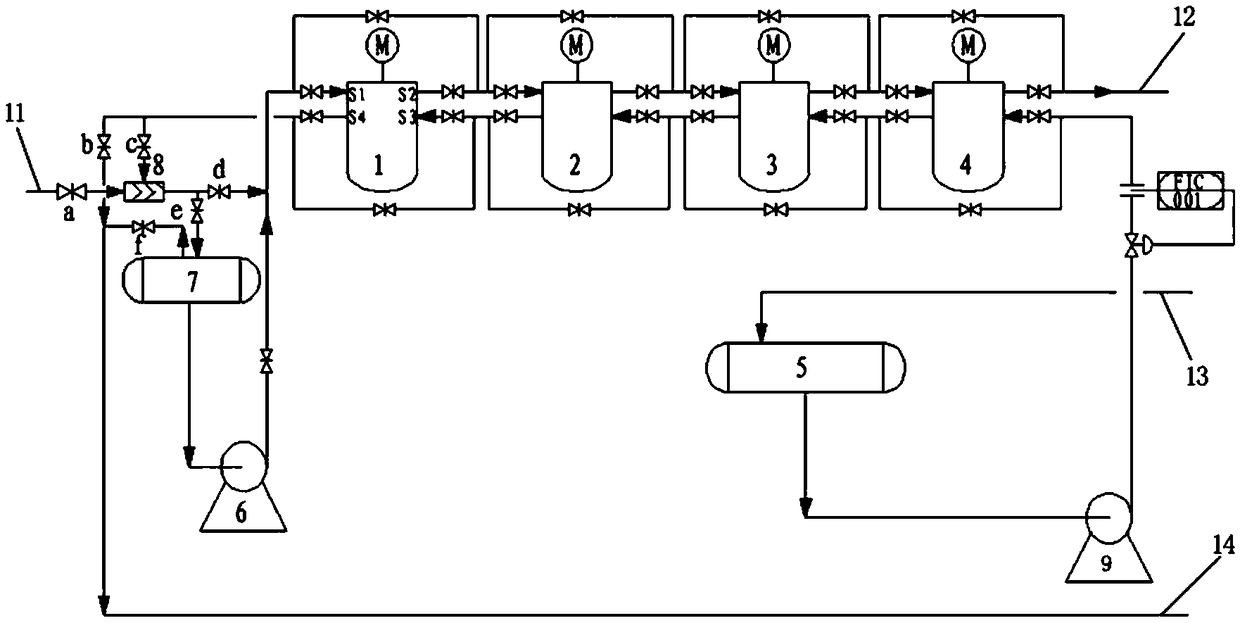

[0073] figure 2 An extraction and dephenolization device for coal chemical wastewater treatment is shown, which has all the structures described in Example 1.

[0074] Such as figure 2 As shown, the outlet of the SV-type static mixer 8 is connected to the first raw material liquid inlet valve of the first-stage CTL type single-stage centrifugal extractor 1 via a branch line, so that the outlet of the SV-type static mixer 8 is connected to the first-stage The raw material liquid inlet S1 of the CTL type single-stage centrifugal extractor 1 is connected. At the same time, a fourth valve d is provided on the branch pipeline between the outlet of the SV static mixer 8 and the first raw material liquid inlet valve.

[0075] In addition, the extract from the first-stage CTL type single-stage centrifugal extractor 1 is sent to the phenol tower for processing through the branch pipeline provided with the second valve b.

[0076] When the phenol-containing wastewater in the mixing...

Embodiment 3

[0078] The device of Example 2 was used to treat the deacidification and deammonification wastewater (phenol-containing wastewater).

[0079] Coal gasification wastewater is phenol-containing wastewater (deacidification and deamination wastewater) obtained after degreasing, deacidification, and deamination treatment. The content of unit phenols in phenolic wastewater is 3100mg / L, the content of polyphenols (dihydric phenols and trihydric phenols) is 1200mg / L, the pH is 6.5, and the temperature is 40°C.

[0080] at 100m 3 Under the flow rate of / h, the phenol-containing wastewater is sent to the SV-type static mixer 8, and by controlling each valve, the phenol-containing wastewater flows through the SV-type static mixer 8, the mixing and clarifying extraction tank 7, and the first-stage CTL-type single-stage Centrifugal extractor 1, second-stage CTL single-stage centrifugal extractor 2, third-stage CTL single-stage centrifugal extractor 3 and fourth-stage CTL single-stage cent...

PUM

| Property | Measurement | Unit |

|---|---|---|

| separation factor | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com