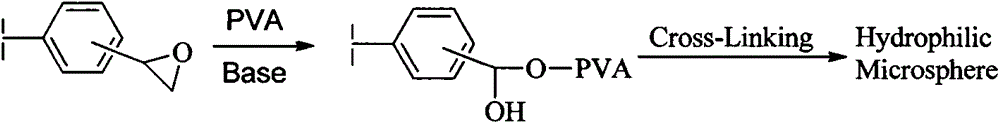

Hydrophilic modification method for PS-DVB (polystyrene-divinyl benzene) crosslinked microspheres grafted and bonded with PVA (polyvinyl alcohol)

A technology of divinylbenzene and polystyrene, applied in the field of hydrophilic modification of PVA graft-bonded polystyrene-divinylbenzene cross-linked microspheres, which can solve phase collapse, unfavorable biological protein separation, and reaction conditions Harsh and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

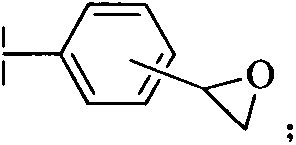

[0028] Step (a) introduction of epoxy groups on the surface of PS-DVB microspheres

[0029] Weigh 0.5g of N-bromosuccinimide in a 50mL beaker, measure 20mL of acetone and 4mL of deionized water in the above beaker with a graduated cylinder, and stir until the N-bromosuccinimide Dissolve completely; add this solution into a 50mL round-bottomed flask with 1.0g of dry PS-DVB microspheres (cross-linking degree 1%, non-porous), stir evenly, add 0.2g of ammonium acetate, and react at room temperature 3h, after the reaction was completed, sand core was filtered, washed with 10 times the amount of ethanol and deionized water respectively, and drained; the microspheres were transferred to a 50mL round bottom flask, and 15mL of deionized water and 3mL of NaOH ( 3mol / L) solution, reacted at 40°C for 6h; after the reaction, filtered through a sand core, washed with 10 times the amount of deionized water, and drained for later use.

[0030] Step (b) bonding and post-crosslinking of PVA on...

Embodiment 2

[0034] Step (a) introduction of epoxy groups on the surface of PS-DVB microspheres

[0035] Weigh 1g of N-chlorosuccinimide in a 50mL beaker, measure 15mL of acetone and 4mL of deionized water in the above beaker with a graduated cylinder, and stir until the N-chlorosuccinimide is completely Dissolve; add this solution into a 50mL round-bottomed flask with 1.0g of dry PS-DVB microspheres (30% cross-linking degree, with holes), stir evenly, add 0.3g of sodium acetate, and react at room temperature for 3h , after the reaction, sand core filter, wash with 10 times the amount of ethanol and deionized water respectively, and drain; transfer the microspheres to a 50mL round bottom flask, add 15mL of deionized water and 3mL of NaOH (3mol / L) solution, react at 40° C. for 6 h; after the reaction, filter through a sand core, wash with 10 times the amount of deionized water, and drain for later use.

[0036] Step (b) bonding and post-crosslinking of PVA on the surface of PS-DVB microsp...

Embodiment 3

[0040] Step (a) introduction of epoxy groups on the surface of PS-DVB microspheres

[0041] Weigh 1g of N-bromosuccinimide in a 50mL beaker, measure 15mL of acetone and 4mL of deionized water in the above beaker with a graduated cylinder, and stir until the N-bromosuccinimide is completely Dissolve; add this solution into a 50mL round-bottomed flask with 1.0g of dry PS-DVB microspheres (30% cross-linking degree, with holes), stir evenly, add 0.3g of sodium acetate, and react at room temperature for 3h , after the reaction, sand core filter, wash with 10 times the amount of ethanol and deionized water respectively, and drain; transfer the microspheres to a 50mL round bottom flask, add 15mL of deionized water and 3mL of NaOH (3mol / L) solution, react at 40° C. for 6 h; after the reaction, filter through a sand core, wash with 10 times the amount of deionized water, and drain for later use.

[0042] Step (b) bonding and post-crosslinking of PVA on the surface of PS-DVB microsphe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com