Beer jar liquid level detection control system

A liquid level detection and control system technology, applied in general control systems, control/regulation systems, program control, etc., can solve problems such as liquid level fluctuations and unstable control, achieve stable liquid level in wine tanks, reduce interference and fluctuations , the effect is obvious

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

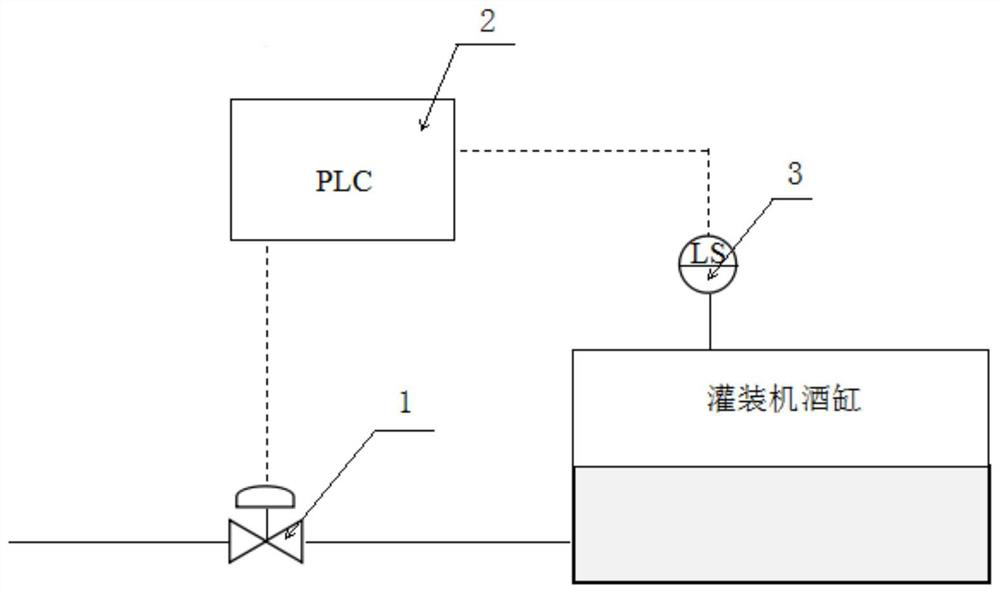

[0031] Such as figure 1 As shown, the beer vat liquid level detection and control system provided in this embodiment includes a plurality of liquid level probes 3 arranged on the vat of the canning machine,

[0032] A regulating valve 1, the regulating valve 1 is connected to the wine vat of the canning machine through the wine supply pipeline,

[0033] PLC controller 2, the PLC controller 2 is connected with the liquid level probe 3 through the control line, and the control PLC controller 2 is connected with the regulating valve 1 through the control line.

[0034] There is only one liquid level probe on the existing wine tank. If the level of the wine tank changes due to installation problems or long-term operation, it will cause periodic fluctuations in the measured value of the liquid level; in addition, the wine tank will form a vortex during rotation. It will lead to a liquid level difference during the start-up process of the wine vat. The beer wine vat liquid level de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com