Lubricating process suitable for spaceflight low-speed bearing

A bearing and process technology, applied in the direction of engine lubrication, shaft and bearing, bearing components, etc., can solve the problems of reducing lubrication performance, polluting lubricating oil, and losing lubricating oil, etc., to achieve reasonable scheme, prolong bearing life and flexible operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

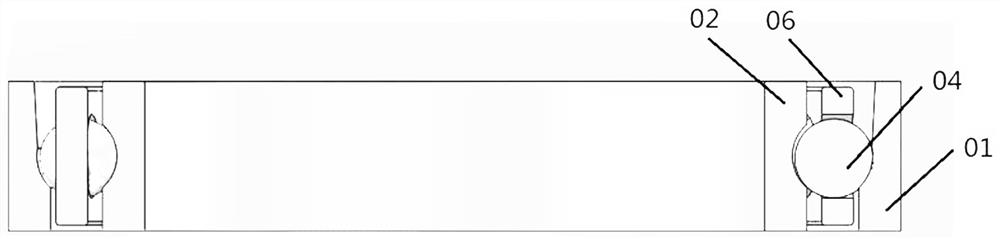

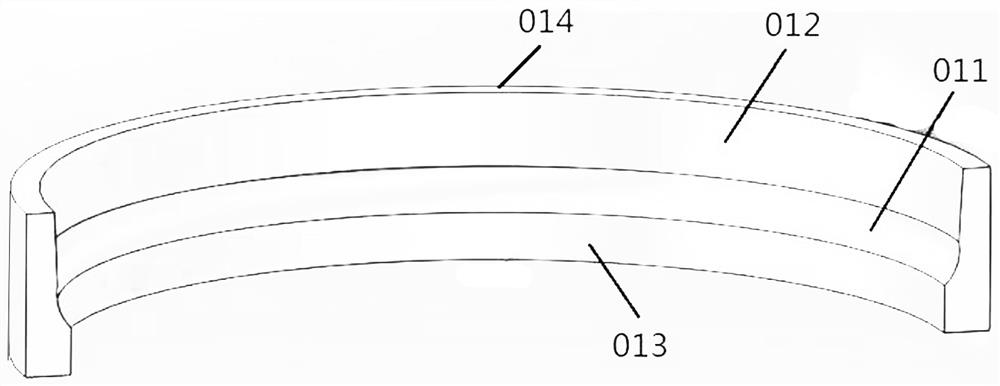

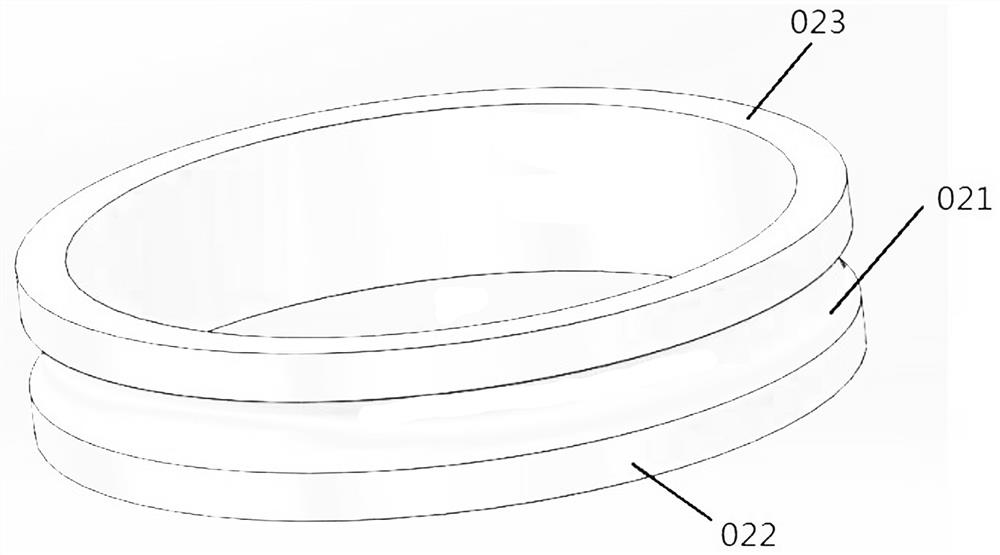

[0038] like figure 1 As shown, this embodiment provides a certain type of 7 series bearing, the main body includes: bearing outer ring 01, bearing inner ring 02, steel ball 04 and oil-containing cage 06. According to the actual working conditions of the product, the grade of lubricating oil in this case is P201, and the grade of lubricating grease is KKP201. This type of bearing outer ring 01 cavity volume is about 0.43cm 3 , the inner ring 02 cavity volume is about 0.78cm 3 , so the total cavity volume of the raceway is about 1.21cm 3 . The density of grease is about 0.8g / cm 3 , Fill and coat according to 1 / 2~1 / 3 of the volume of the raceway cavity, and the amount of grease is obtained: 480~320mg; then according to the current reaction during the running-in test and the oil film resistance measurement, the bearing rolling can be finally obtained. The total amount of grease that needs to be filled in the road (the total amount of grease filled in the bearing selected in t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com