Automobile differential mechanism and bearing combination structure

A technology of automobile differential and combined structure, applied in the direction of differential transmission, transmission, belt/chain/gear, etc., can solve the problem of grinding iron filings, reduce the overall life of the differential, and increase the failure of the automobile differential and other problems to achieve the effect of increasing service life, improving internal lubrication environment, and reducing failures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

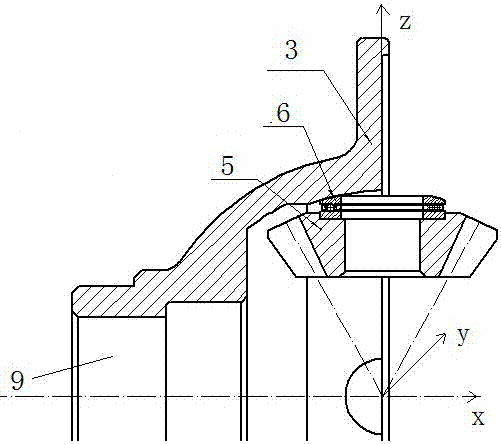

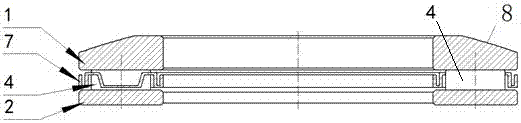

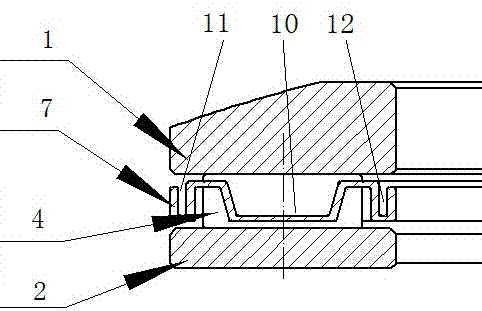

[0019] Accompanying drawing is a kind of specific embodiment of the present invention.

[0020] In the automotive differential and bearing combination structure of the present invention, a thrust bearing 6 is sandwiched between the differential case 3 and the top of the planetary gear 5, and the thrust bearing and the planetary gear are sleeved on the same shaft.

[0021] The contact surface between the thrust bearing and the differential case is a spherical surface 8 corresponding to each other, and the contact surface here on the thrust bearing is a static surface.

[0022] There are two pairs of planetary gears and a pair of side gears inside the differential case. The two pairs of planetary gears are arranged in a cross shape, located on the y-axis and the z-axis respectively. The shafts of the two pairs of planetary gears are cross-shaped shafts. The rotating shaft is located on the x-axis, and the half-shaft gear and its rotating shaft are fixed together to rotate synchr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com