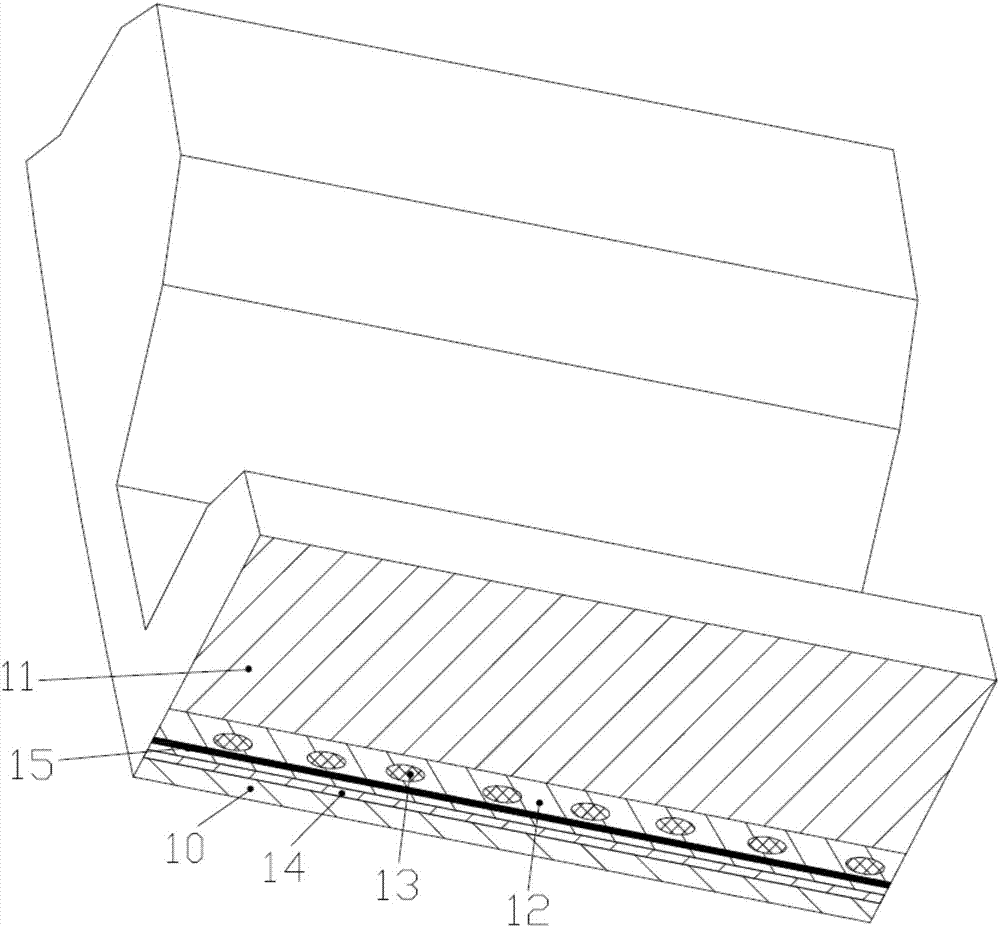

Production process of maintenance-free triangular belt with transverse fiber bundles

A technology of transverse fiber and production process, which is applied in the field of transmission belt preparation, can solve the problems of reducing product life, lack of support, and product sag, so as to improve hardness and impact strength, improve dynamic mechanical properties, and increase grip Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

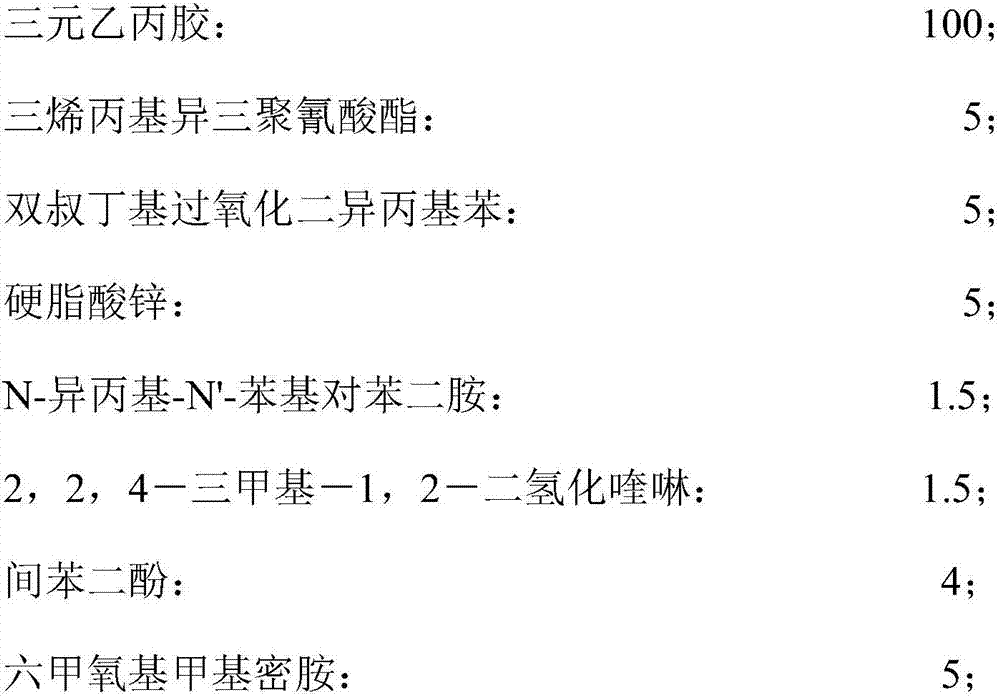

Method used

Image

Examples

Embodiment 1

[0037] Example 1: In the case that other steps remain unchanged, the temperature of mixing in step a is controlled at 100°C, while the temperature of vulcanization in step e is 130°C, the external pressure is 1.2MPa, and the external pressure holding time is 9 minutes, the internal pressure is 0.4MPa, and the vulcanization time is 45 minutes. According to the technical requirement of embodiment 1, the object of the present invention can be achieved.

Embodiment 2

[0038] Example 2: In the case that other steps remain unchanged, the temperature of mixing in step a is controlled at 115°C, while the temperature of vulcanization in step e is 145°C, the external pressure is 1.45MPa, and the external pressure holding time is 12 minutes, the internal pressure is 0.55MPa, and the vulcanization time is 35 minutes. According to the technical requirement of embodiment 2, the object of the present invention can still be achieved.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com