Elastomeric composite body

An elastic composite and modification technology, applied in the field of elastic composite, to achieve the effect of low hardness, superior dynamic mechanical properties, and good strength and elongation properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

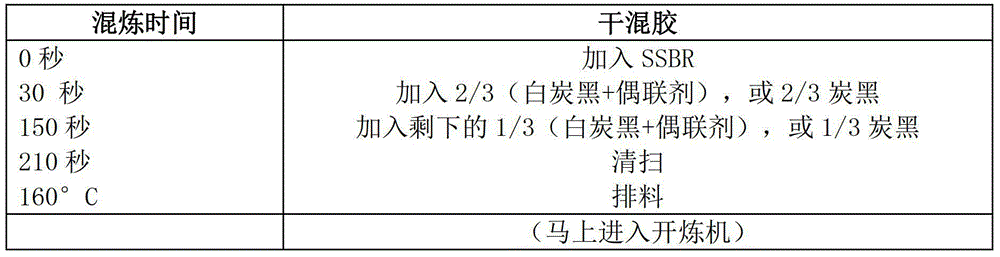

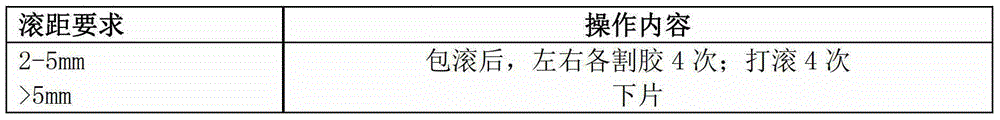

[0044] The present invention also provides a method for preparing the elastic composite, which is characterized in that it is prepared by a liquid-phase mixing and dispersing process, and the steps include: 1) making a modified white carbon black grinding slurry or carbon black in a non-polar organic solvent Grinding slurry; 2) Dispersing and mixing filler slurry or filler and rubber glue under high-energy shearing in proportion; 3) Dry removing the solvent from the uniformly dispersed composite slurry glue under dynamic conditions; 4) Removing The complex of solvents is sheared, kneaded and dried to obtain a product.

[0045] The solvent used in the filler slurry is non-polar organic solvents such as aliphatic hydrocarbons, alicyclic hydrocarbons, and aromatic hydrocarbons.

[0046] The solvent used in the rubber solution is non-polar organic solvents such as aliphatic hydrocarbons, alicyclic hydrocarbons, and aromatic hydrocarbons.

[0047] In step 1), if the filler is whit...

Embodiment 1

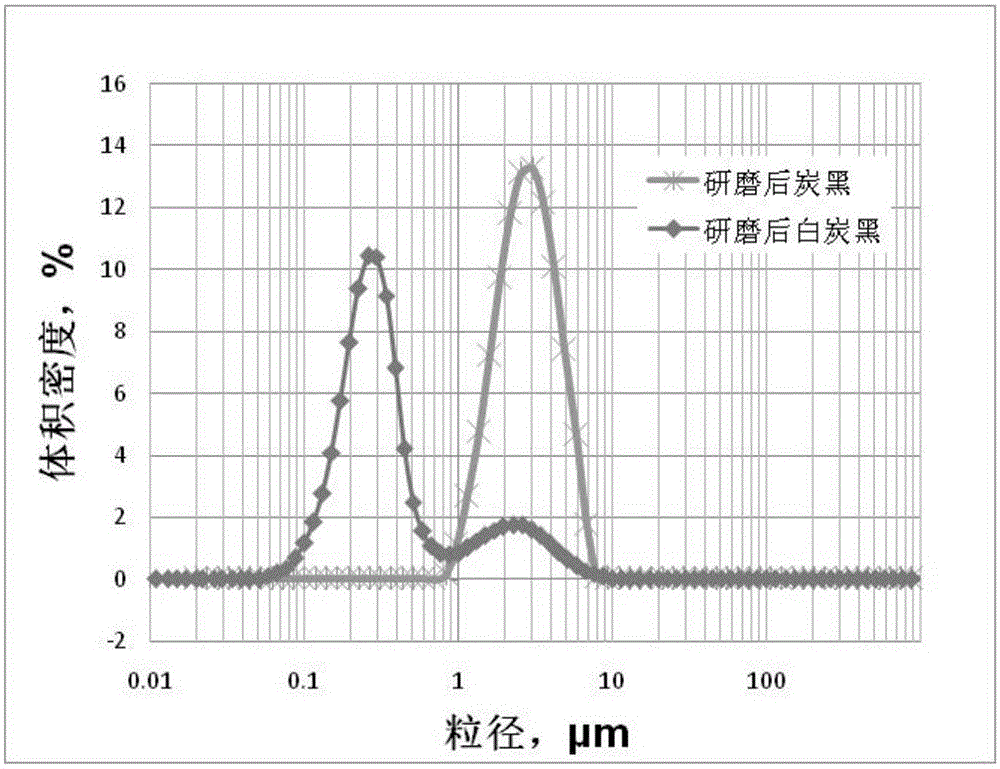

[0060] According to the preparation method of modified silica disclosed in patent application number 201410724713.2, a modified silica slurry with a silica aggregate particle size of 100nm-5μm was obtained, and the solid content was 5%wt.

[0061] In the high-energy disperser, 13.5kg of the above-mentioned modified white carbon black slurry is mixed with 6.8kg of concentration of 20%wt solution-polymerized styrene-butadiene rubber glue, wherein the ratio of the two solid contents is, rubber: white carbon black= 100:50. The high-energy disperser disperses the white carbon black evenly among the rubber molecules while grinding it to obtain a composite mixed liquid.

[0062] The composite mixed liquid is sent to the devolatilization extruder for solvent removal, and the temperature range of the eight blocks on the devolatilization extruder is set to 40-100°C, and the screw speed is 100 rpm. The compound mixed liquid is obtained through the extruder, and the volatile matter conte...

Embodiment 2

[0065] According to the preparation method of modified silica disclosed in patent application number 201410724713.2, a modified silica slurry with a silica aggregate particle size of 100nm-5μm was obtained, and the solid content was 10%wt.

[0066] In a high-energy disperser, mix 9kg of the above-mentioned modified silica slurry with 22.5kg of 5%wt solution-polymerized styrene-butadiene rubber glue, wherein the ratio of the two solid contents is, rubber: silica=100 :80. The high-energy disperser disperses the white carbon black evenly among the rubber molecules while grinding it to obtain a composite mixed liquid.

[0067] The composite mixed liquid is sent to the devolatilization extruder for solvent removal, and the temperature range of the eight blocks on the devolatilization extruder is set to 40-100°C, and the screw speed is 150 rpm. The compound mixed liquid is obtained through the extruder, and the volatile matter content is less than 1%.

[0068] The compound is knea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com