Octavinyl-polyhedral oligomeric silsesquioxane modified fluororubber

A technology of silsesquioxane and modified fluororubber, which is applied in the field of rubber sealing, can solve the problem of low binding force between strontium ferrite magnetic nanoparticles and rubber, and achieve excellent dynamic mechanical properties and good sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

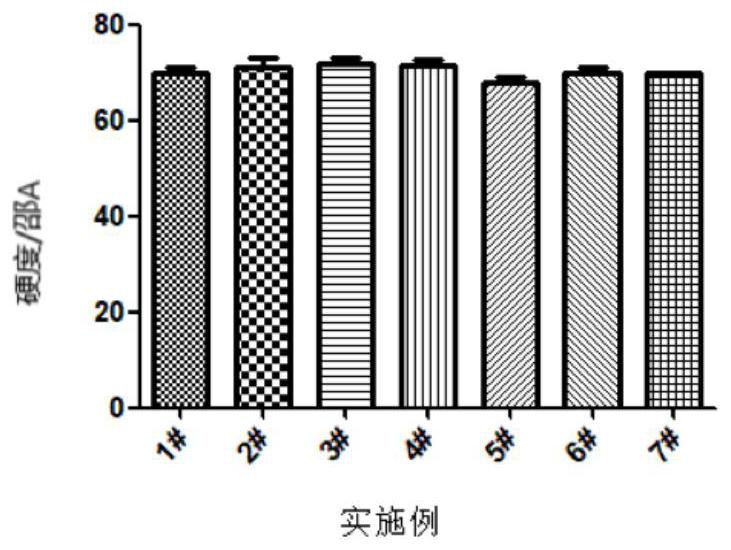

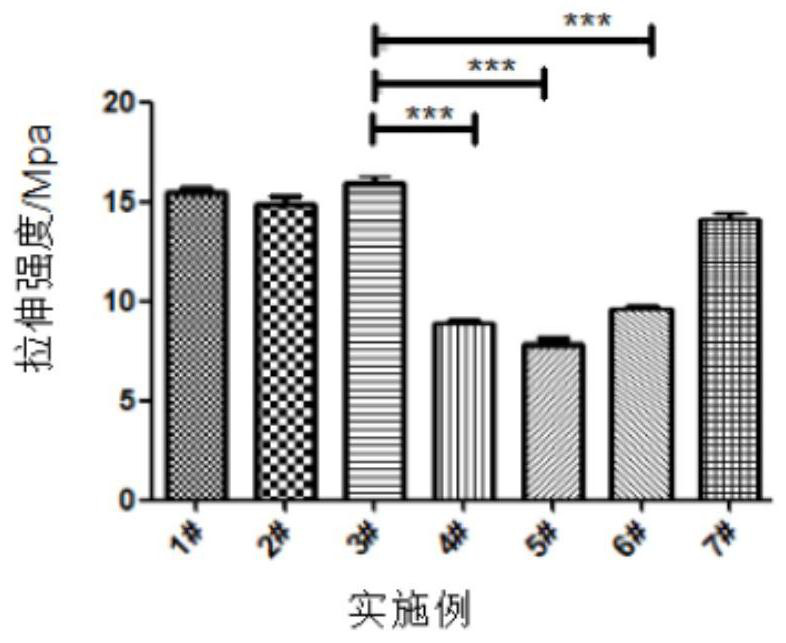

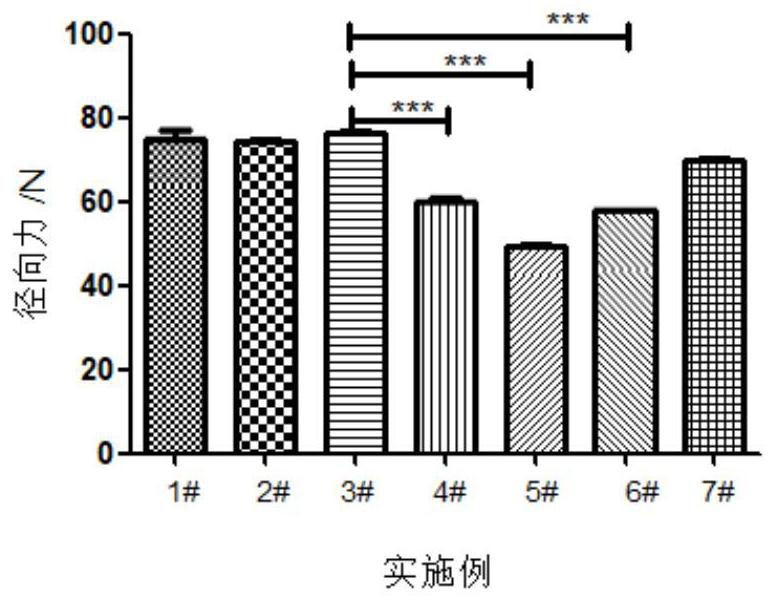

Examples

Embodiment 1

[0030] Step (1) Tested by weight of 10% by weight -2 μM hydroforms, 60 parts of octade-cage sedamine oxide, 80 parts of fluorine rubber, 20 parts of toluene, 4-dimethylaminopyridine, DMEA, 5 parts of DMEA, and 2 Ethylene triamine 5 serviles.

[0031] Step (2) A mixed solution is prepared in a container of the hydroxide, an octylene-cage sedamine oxide and a toluene, and a mixed solution is prepared, and 4-dimethylaminopyridine and DMEA were added to the nitrogen protection environment. The temperature of the container is set to 100 ° C, the reaction time is 10 h, after the reaction is completed, filtrate dried to give a modified octylene-cage multipolane.

[0032] Step (3) Put the fluororne rubber into the chamber into a mixer of nitrogen protection, mix for 5 min, then modify the vinyl triplipide sedamine oxide and diethyltride acetic acid, divided into equivalents After the 5 part, gradually add to the mesh, the temperature of the mesh is set to 150 ° C, the rotation speed of th...

Embodiment 2

[0034] Step (1) Take 60 parts by weight of 10-6 μm, 80 parts of the grain diameter, 80 parts of octiethylene-cage sedaleziloxane, 100 parts of fluorine rubber, and a concentration of 98% toluene. 4-dimethylaminopyridine 20 parts, DMEA 15 parts and 15 parts of diethylethyltride acetic acid.

[0035] Step (2) In a container of strontium ferrite, octylene-cage multiplier semi-siloxane and toluene to a nitrogen protection environment, preparing a mixed solution, ultrasound for 2 hours, and 4-dimethylaminopyridine and DMEA, The temperature of the container is set to 150 ° C, the reaction time is 20 h, after the reaction is completed, filtrate dried to give a modified octylene-cage multiplier semiciloxane.

[0036] Step (3) Put the fluororne rubber into the chamber as a mixture of nitrogen protection, mix 10 min, and then modify the octagonal-cage sedamine oxide and diethyltridine five acetic acid, divided into equivalents. After the 5 part, gradually add to the renewal, the temperature...

Embodiment 3

[0038] Step (1) Note 50 parts by weight of a strontium ferrite having a particle size of 10-4 μm, 70 parts of an octylene-cage sediment sedamine oxide, 90 of fluorine rubber, and 25 parts of toluene in concentration of ≥95%. 15 parts of 4-dimethylaminopyridine, 10 parts of DMEA10 parts and diethyltridine five acetic acid.

[0039] Step (2) In the container of the strontium ferrite, an octylene-cage multipolane and the toluene to a nitrogen protection environment, prepared a mixed solution, ultrasonic 1-2 hours, and add 4-dimethylaminopyridine and DMEA, the temperature of the container is set to 120 ° C, the reaction time is 15 h, after the reaction is completed, filtrate is filtered to give the modified octylene-cage multipolane.

[0040] Step (3) Put the fluororne rubber into the chamber into a mixture of nitrogen protection, mix 8 min, then modify the vinyl-cage sedamine oxide and diethyltridine five acetic acid, divided into equivalents The 5 part gradually added to the immanth...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| magnetic flux density | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com