PH-sensitive type cation regenerated cellulose composite film as well as preparation method and application thereof

A technology of regenerated cellulose and cation, applied in chemical instruments and methods, membrane technology, semi-permeable membrane separation, etc., can solve the complex process of cellulose/chitosan composite membrane, limit the application of membrane separation technology, and unstable product quality. and other problems, to achieve the effects of good biodegradability, overcoming whether the bond is firm, and the preparation process is simple and feasible

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

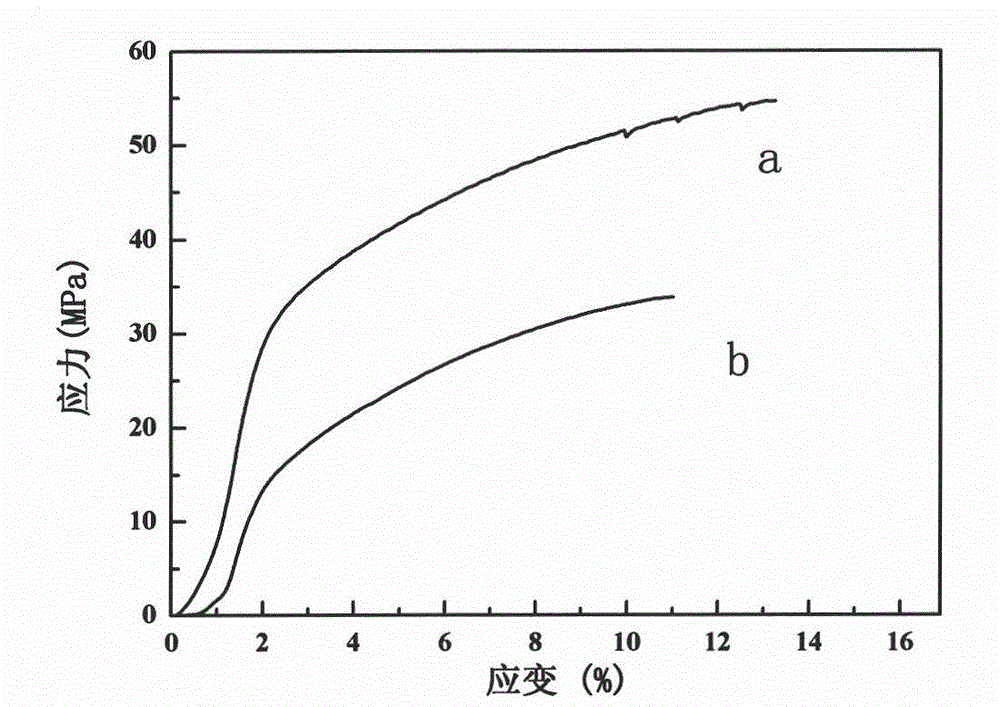

[0023] Dissolve cotton linter cellulose in 6% NaOH / 5% thiourea aqueous solution to prepare a 4% cellulose solution. After defoaming, cast it on a glass plate to form a 0.5mm solution layer, and then pre-solidify in air for 10 minutes. And then stably immersed in 0.5% chitosan solution dissolved in 2% acetic acid aqueous solution for 3 hours, take it out after removing the film, wash it with water and dry it in the air, and use an electronic universal testing machine to test its mechanical properties.

[0024] The stress-strain curves of the prepared composite membrane and pure regenerated cellulose membrane (the cellulose solution is directly immersed in 2% acetic acid aqueous solution for 3h after pre-coagulation) are shown in Fig. figure 1 . Figure 4 The scanning electron micrographs of the composite membrane (A) prepared for Example 1 and the pure regenerated cellulose membrane (B) are compared.

Embodiment 2

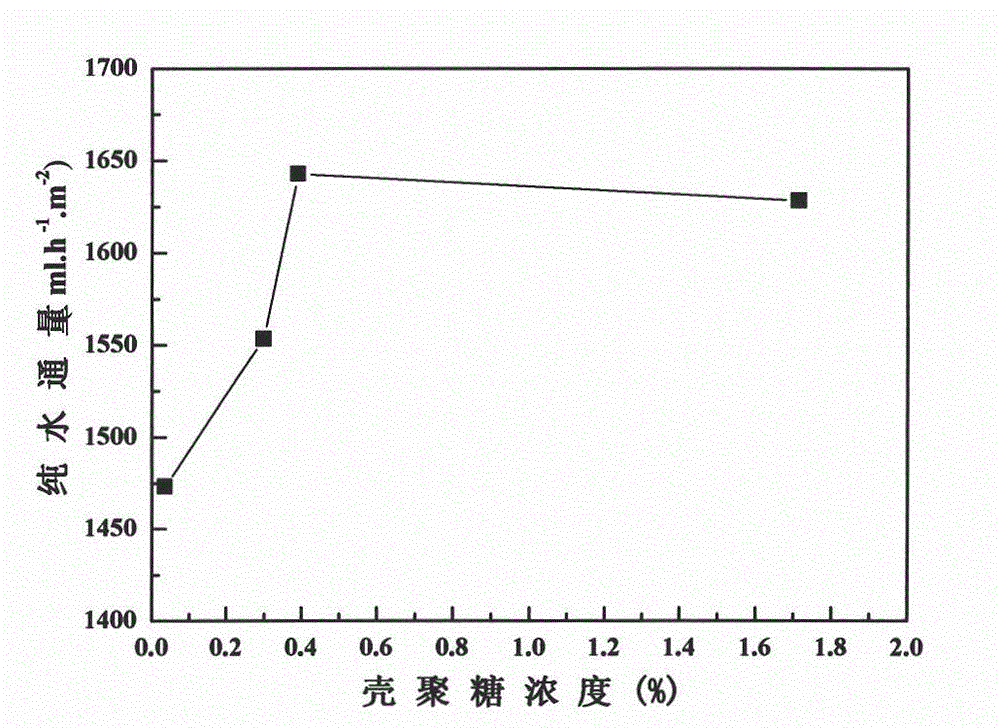

[0026] Dissolve cotton linter cellulose in 5% NaOH / 5% thiourea aqueous solution to prepare a 5% cellulose solution, cast it on a glass plate to form a 1mm solution layer after defoaming, then pre-solidify in air for 10 minutes, and then Steadily immerse in 0.5% chitosan solution dissolved in 2% acetic acid aqueous solution for 10min, 60min, 180min or 600min, remove the film and wash it with water and dry it in the air to prepare composite films with different chitosan contents. The amount varies with the content of chitosan, see figure 2 .

Embodiment 3

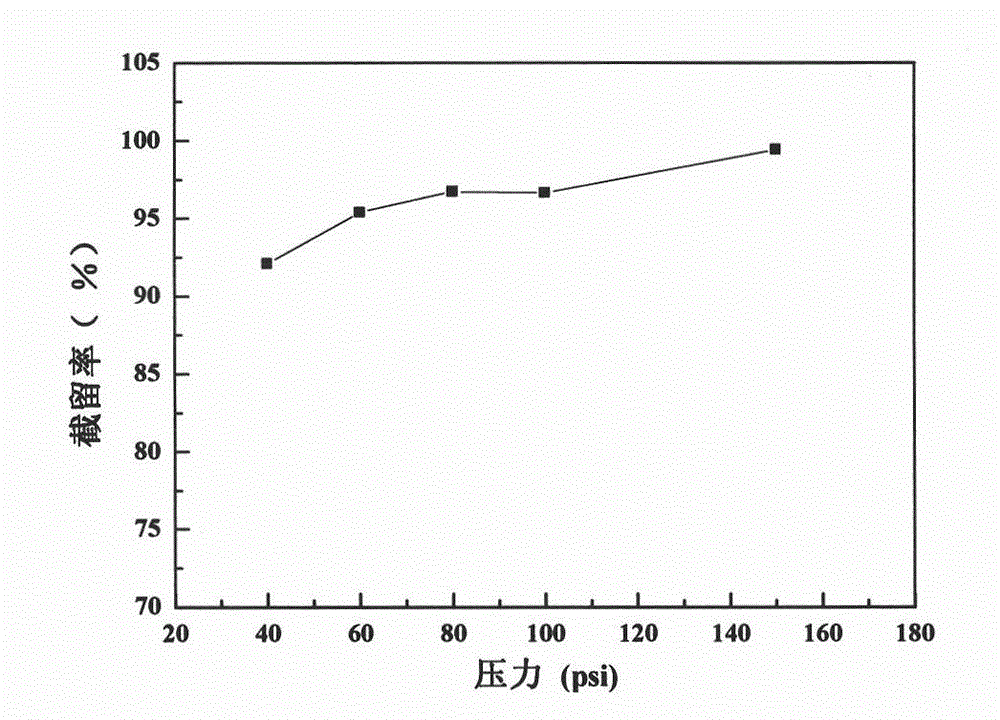

[0028] Dissolve cotton linter cellulose in 7% NaOH / 4% thiourea aqueous solution to prepare a 4% cellulose solution. After defoaming, cast it on a glass plate to form a 0.5mm solution layer, and then pre-solidify in air for 10 minutes. Steadily immersed in 0.5% chitosan solution dissolved in 2% acetic acid aqueous solution for 3 hours, took out the membrane and washed it with water and dried it in the air. 2+ retention rate. The composite film on Cu 2+ The interception rate is above 90%, see image 3 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com