A production process for improving the mechanical properties of tungsten-nickel-copper alloy

A production process and copper alloy technology, which is applied in the field of powder metallurgy, can solve the problems of low mechanical properties of tungsten-nickel-copper alloys, achieve the effects of stable production process state, stable performance, and improved mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

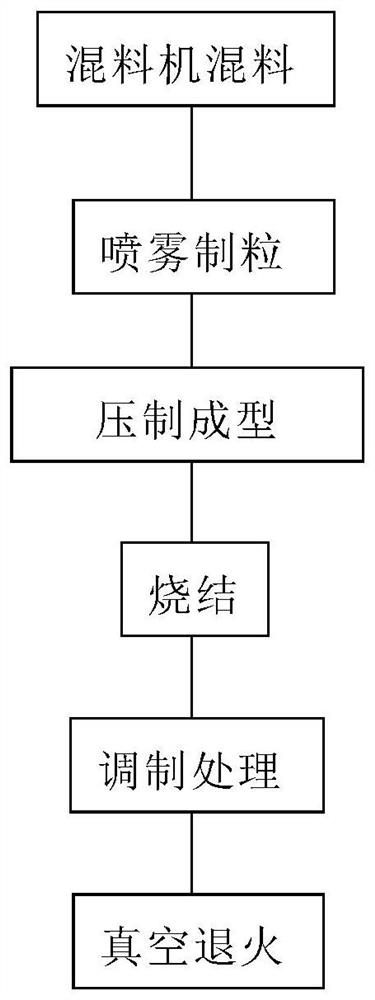

[0031] like figure 1 As shown, this embodiment includes the following steps:

[0032] Step 1. Mixing: According to the nominal composition of the target product 90WNiCu alloy, tungsten powder, cobalt powder, nickel powder and copper powder are selected as raw materials to weigh and put into an inclined mixer for dry grinding and mixing to obtain mixed powder; the The ratio of ball to material mixed by dry grinding is 4:1, and the time is 7h;

[0033]Step 2, granulation: adding polyethylene glycol to the mixed powder obtained in step 1, then wet grinding and mixing, and then using a spray drying tower for spray drying granulation to obtain 40-120 mesh granules; The added mass of ethylene glycol is 2.0% of the mass of the mixed powder; the wet grinding and mixing are carried out in a ball mill, the medium used is ethanol solution, the ratio of ball to material is 3:1, and the time of wet grinding and mixing is 12h;

[0034] Step 3, pressing and forming: the granulated material...

Embodiment 2

[0040] like figure 1 As shown, this embodiment includes the following steps:

[0041] Step 1, mixing: According to the nominal composition of the target product 92WNiCu alloy, select tungsten powder, cobalt powder, nickel powder and copper powder as raw materials to weigh and put them into an inclined mixer for dry grinding and mixing to obtain mixed powder; The ratio of ball to material mixed by dry grinding is 4:1, and the time is 8h;

[0042] Step 2, granulation: adding polyethylene glycol to the mixed powder obtained in step 1, then wet grinding and mixing, and then using a spray drying tower for spray drying granulation to obtain 40-120 mesh granules; The added mass of ethylene glycol is 2.0% of the mass of the mixed powder; the wet grinding and mixing are carried out in a ball mill, the medium used is ethanol solution, the ratio of ball to material is 4:1, and the time of wet grinding and mixing is 8h;

[0043] Step 3, pressing and forming: the granulated material obta...

Embodiment 3

[0049] like figure 1 As shown, this embodiment includes the following steps:

[0050] Step 1. Mixing: According to the nominal composition of the target product 93WNiCu alloy, tungsten powder, cobalt powder, nickel powder and copper powder are selected as raw materials to weigh and put into an inclined mixer for dry grinding and mixing to obtain mixed powder; the The ratio of ball to material mixed by dry grinding is 4:1, and the time is 9h;

[0051] Step 2, granulation: adding polyethylene glycol to the mixed powder obtained in step 1, then wet grinding and mixing, and then using a spray drying tower for spray drying granulation to obtain 40-120 mesh granules; The mass of ethylene glycol added is 2.0% of the mass of the mixed powder; the wet grinding and mixing are carried out in a ball mill, the medium used is ethanol solution, the ratio of ball to material is 4:1, and the time of wet grinding and mixing is 16h;

[0052] Step 3, pressing and forming: the granulated materia...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com