A kind of octavinyl-cage silsesquioxane modified fluororubber

A technology of silsesquioxane and modified fluororubber, which is applied in the field of rubber sealing, can solve the problem of low binding force between strontium ferrite magnetic nanoparticles and rubber, and achieve excellent dynamic mechanical properties and good sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Step (1) Weigh the particle size by weight to be 10 -2 μm strontium ferrite 40 parts, octaethylene-cage silsesquioxane 60 parts, fluororubber 80 parts, 95% toluene 20 parts, 4-dimethylaminopyridine 10 parts, DMEA 5 parts and two 5 parts of ethylenetriaminepentaacetic acid.

[0031] Step (2) Throw strontium ferrite, octaethylene-cage silsesquioxane, and toluene into a container protected by nitrogen gas to prepare a mixed solution, sonicate for 1 hour, and add 4-dimethylaminopyridine and DMEA, The temperature of the container was set at 100° C., and the reaction time was 10 h. After the reaction was completed, it was filtered and dried to obtain the modified octaethylene-cage silsesquioxane.

[0032] Step (3) Put the fluororubber into the internal mixer whose chamber is protected by nitrogen gas, knead for 5 minutes, and then divide the modified octaethylene-cage silsesquioxane and diethylenetriaminepentaacetic acid into equal parts After 5 parts, gradually add to the ...

Embodiment 2

[0034] Step (1) Weigh 60 parts by weight of strontium ferrite with a particle size of 10-6 μm, 80 parts of octaethylene-cage silsesquioxane, 100 parts of fluororubber, 30 parts of toluene with a concentration of 98%, 20 parts of 4-dimethylaminopyridine, 15 parts of DMEA and 15 parts of diethylenetriaminepentaacetic acid.

[0035] Step (2) Throw strontium ferrite, octaethylene-cage silsesquioxane and toluene into a container under nitrogen protection to prepare a mixed solution, ultrasonicate for 2 hours, and add 4-dimethylaminopyridine and DMEA, The temperature of the container was set at 150° C., and the reaction time was 20 h. After the reaction was completed, it was filtered and dried to obtain the modified octaethylene-cage silsesquioxane.

[0036] Step (3) Put the fluororubber into the internal mixer whose chamber is protected by nitrogen gas, knead for 10 minutes, then divide the modified octaethylene-cage silsesquioxane and diethylenetriaminepentaacetic acid into equal ...

Embodiment 3

[0038] Step (1) Weigh 50 parts of strontium ferrite with a particle size of 10-4 μm, 70 parts of octaethylene-cage silsesquioxane, 90 parts of fluororubber, and 25 parts of toluene with a concentration of ≥95% in parts by weight , 15 parts of 4-dimethylaminopyridine, 10 parts of DMEA and 10 parts of diethylenetriaminepentaacetic acid.

[0039] Step (2) Throw strontium ferrite, octaethylene-cage silsesquioxane and toluene into a container under nitrogen protection to prepare a mixed solution, ultrasonicate for 1-2 hours, and add 4-dimethylaminopyridine and DMEA, the temperature of the container was set at 120° C., and the reaction time was 15 hours. After the reaction was completed, it was filtered and dried to obtain modified octaethylene-cage silsesquioxane.

[0040] Step (3) Put the fluororubber into the internal mixer whose chamber is protected by nitrogen gas, knead for 8 minutes, and then divide the modified octaethylene-cage silsesquioxane and diethylenetriaminepentaacet...

PUM

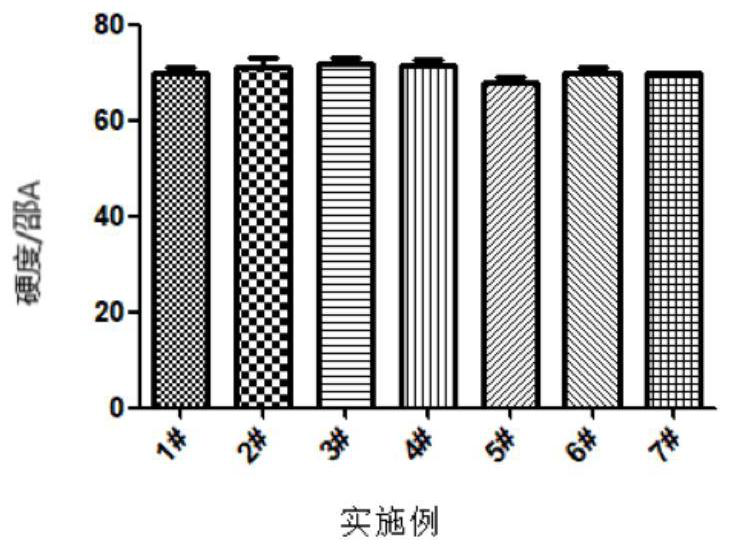

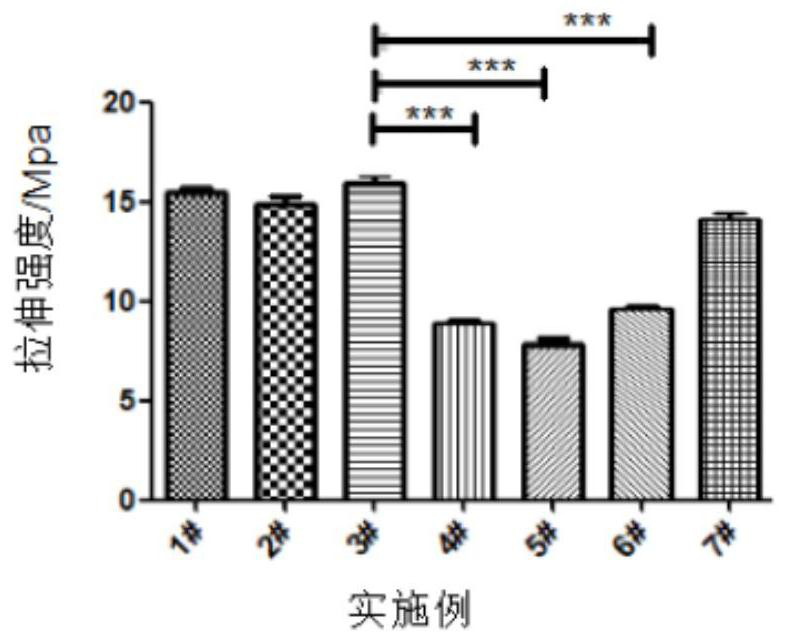

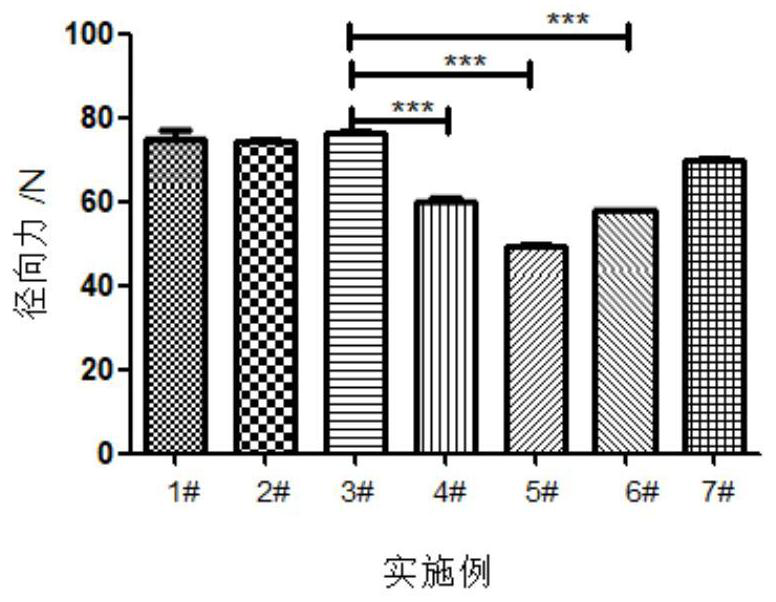

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| magnetic flux density | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com