Butadiene rubber-polyurethane elastomer material with ultra-low rolling resistance and preparation method thereof

A polyurethane elastomer and rolling resistance technology, applied in the field of polymer synthesis, can solve the problems of rolling resistance that cannot meet the application requirements of high-load vehicles, poor high temperature resistance, etc., and achieve excellent dynamic mechanical properties, good synergy, and reduced rolling resistance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

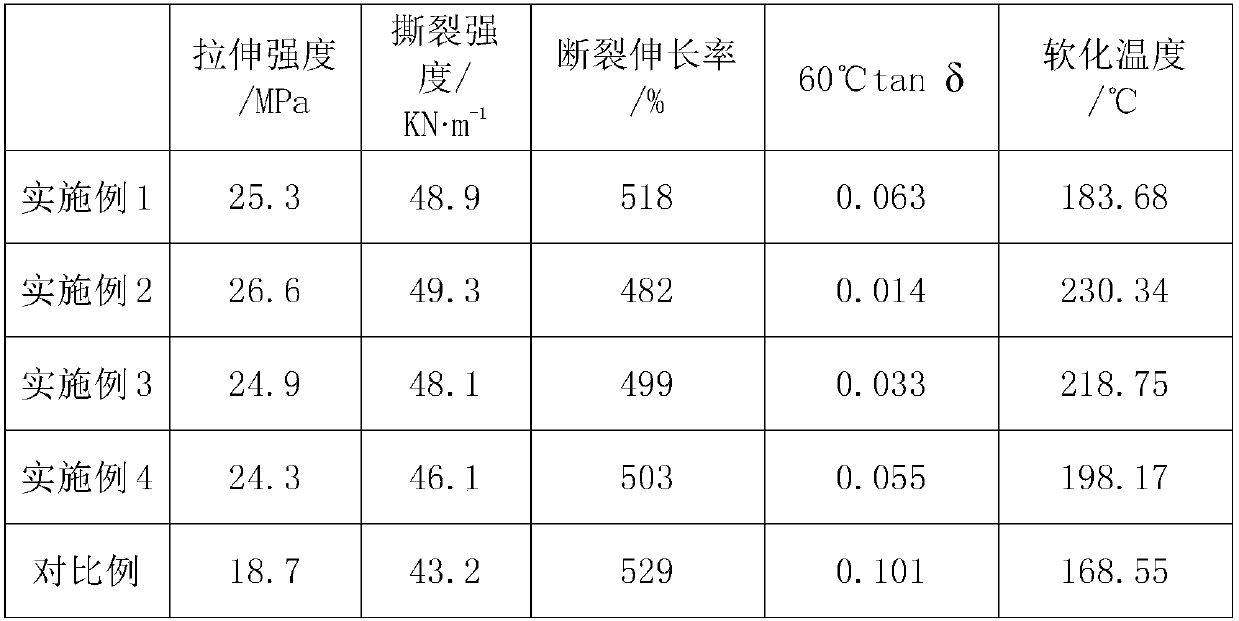

Embodiment 1

[0038] 1) Preparation of prepolymer: take 1 kg of hydroxyl-terminated polybutadiene rubber (molecular weight 1000) and stir it under vacuum conditions at 75 °C (stirring rate 150 rad / min) for 2.5 h, cool down to 65 °C, add 0.86 kg 4, 4-Diphenylmethane diisocyanate (MDI), react for 3h, cool down to 60°C, take a sample, detect the mass content of -NCO according to the standard ASTM D2572-97, when the mass content of -NCO reaches 11%, discharge and seal save.

[0039] 2) Preparation of butadiene rubber-polyurethane elastomer: Take 1.86kg of prepolymer and stir (stirring rate 150rad / min) for 2h under vacuum at 70°C, cool down to 60°C, add 0.18kg of propylene glycol and 0.03kg of trihydroxy Methylpropane (TMP), high-speed stirring (stirring rate 500rad / min) for 10 minutes, pouring molding, put in a 100°C oven for curing for 20 hours, after demoulding, place at room temperature for 7 days.

[0040] 3) Irradiation modification: using 60 The Coγ-ray source irradiates the butadiene r...

Embodiment 2

[0042] 1) Preparation of prepolymer: Take 1 kg of hydroxyl-terminated polybutadiene rubber (molecular weight 8000) at 95 ° C and stir under vacuum conditions (stirring rate 200 rad / min) for 2.5 h, cool down to 80 ° C, add 0.21 kg p-benzene Diisocyanate (PPDI), react for 3 hours, cool down to 75°C, take samples, detect the mass content of -NCO according to the standard ASTM D2572-97, when the mass content of -NCO reaches 5%, discharge the material and seal it for storage.

[0043]2) Preparation of butadiene rubber-polyurethane elastomer: Take 1.21kg of prepolymer and stir at 90°C under vacuum conditions (stirring rate 200rad / min) for 2h, cool down to 75°C, add 0.03kg of 1,4-butane Alcohol (BDO) and 0.03kg trimethylolpropane (TMP), high-speed stirring (stirring rate 800rad / min) for 12min, pouring molding, put into 120°C oven for curing for 22h, after demoulding, place at room temperature for 7d.

[0044] 3) Irradiation modification: The butadiene rubber-polyurethane elastomer is...

Embodiment 3

[0046] 1) Preparation of prepolymer: take 1 kg of hydroxyl-terminated polybutadiene rubber (molecular weight 4500) and stir it under vacuum at 85 °C (stirring rate 250 rad / min) for 3 hours, cool down to 70 °C, add 0.33 kg of 4,4 -Diphenylmethane diisocyanate (MDI), react for 3h, cool down to 65°C, take a sample, detect the mass content of -NCO according to the standard ASTM D2572-97, when the mass content of -NCO reaches 7%, discharge, sealed and preserved .

[0047] 2) Preparation of butadiene rubber-polyurethane elastomer: Take 1.33kg of prepolymer and stir at 90°C under vacuum conditions (stirring rate 250rad / min) for 2h, cool down to 65°C, add 0.08kg of 1,4-butane Alcohol (BDO) and 0.01kg trimethylolpropane (TMP), stirred at high speed (stirring rate 600rad / min) for 6 minutes, poured and molded, put in an oven at 120°C to cure for 24 hours, after demoulding, placed at room temperature for 7 days.

[0048] 3) Irradiation modification: using 60 The Coγ-ray source irradiate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com