Scroll compressor and heat pump system

A scroll compressor and fixed scroll technology, applied in the field of compressors, can solve the problems of reducing the reliability of scroll compressor operation, compressor wear, scroll tooth fracture, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

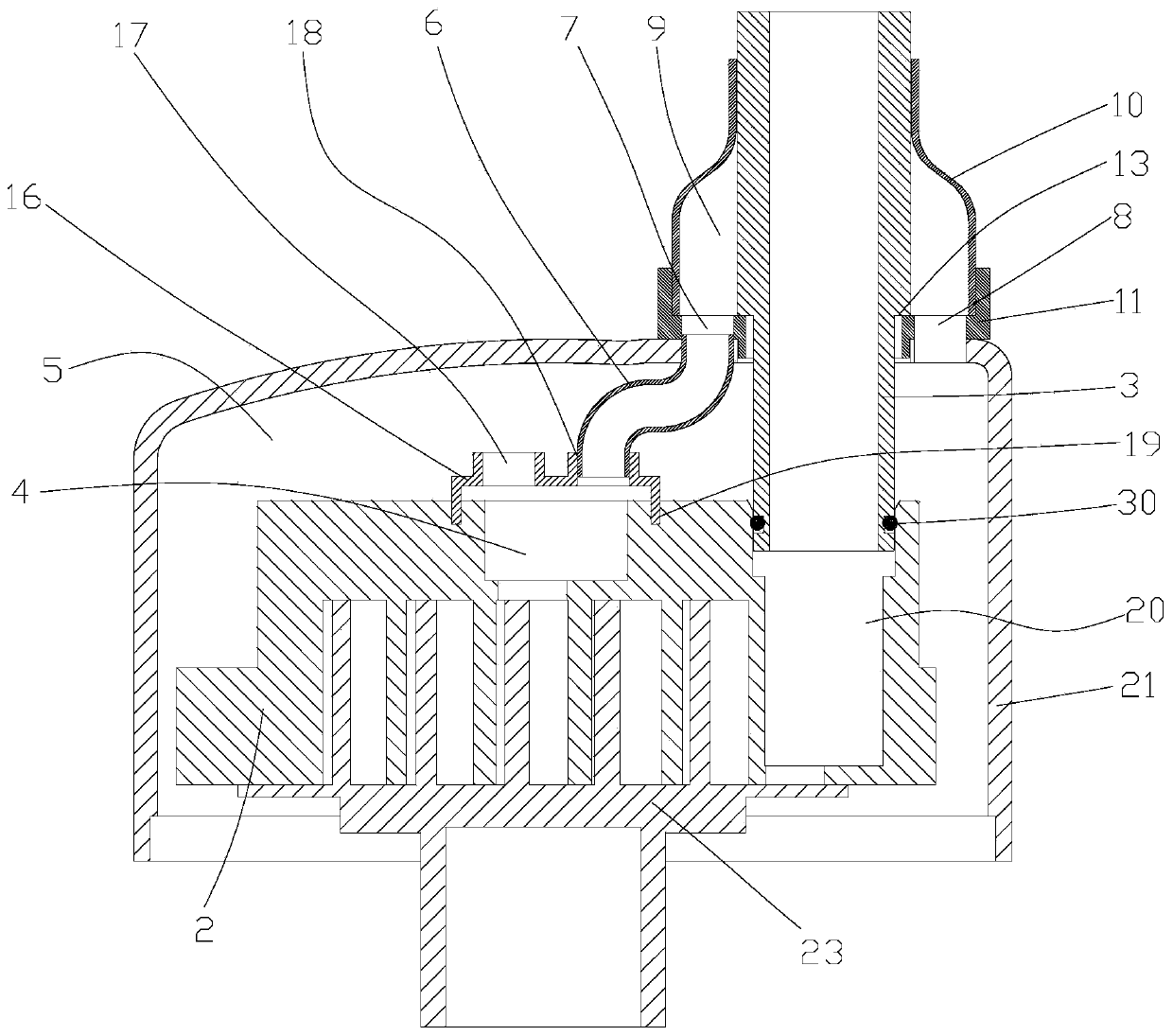

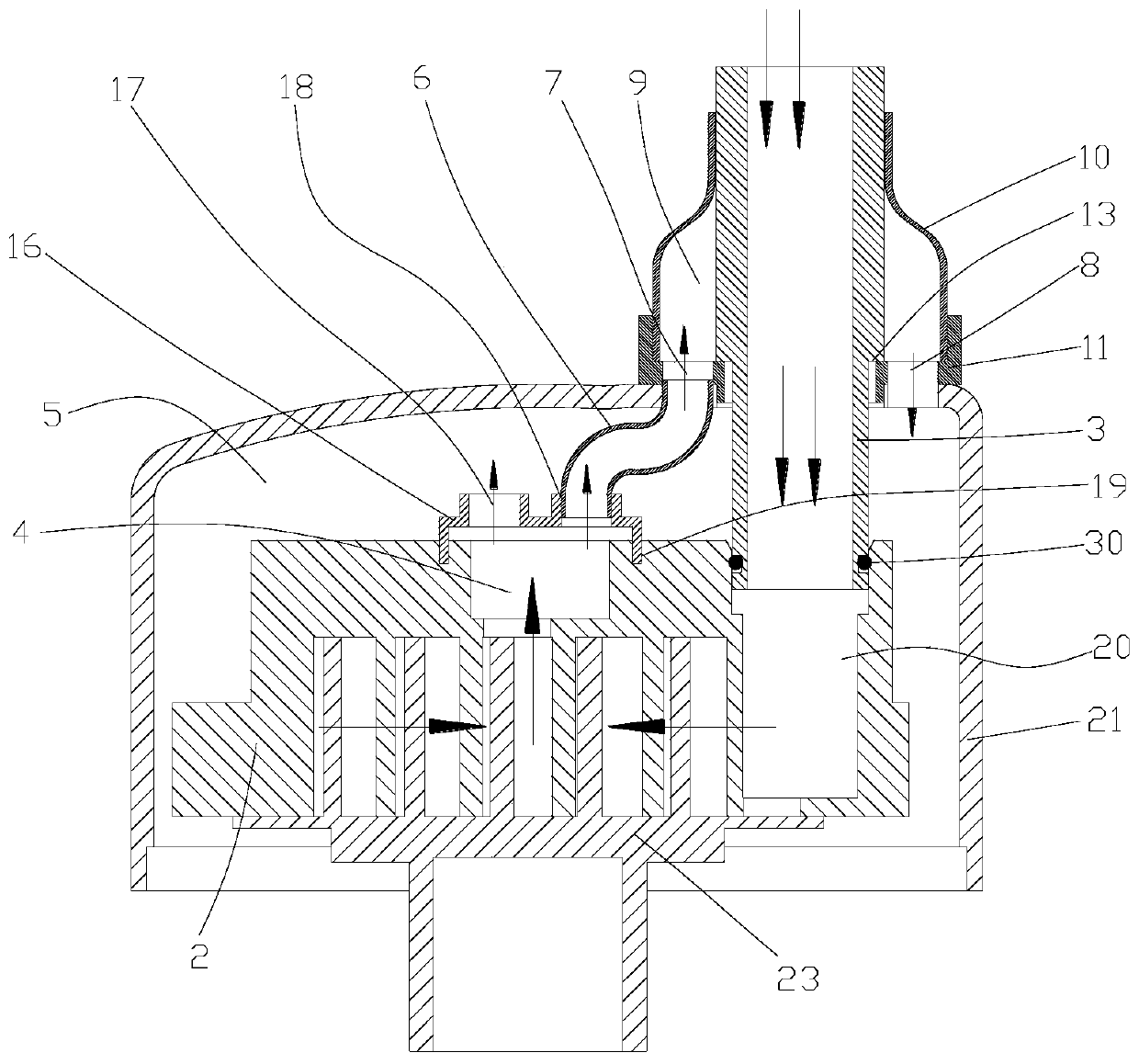

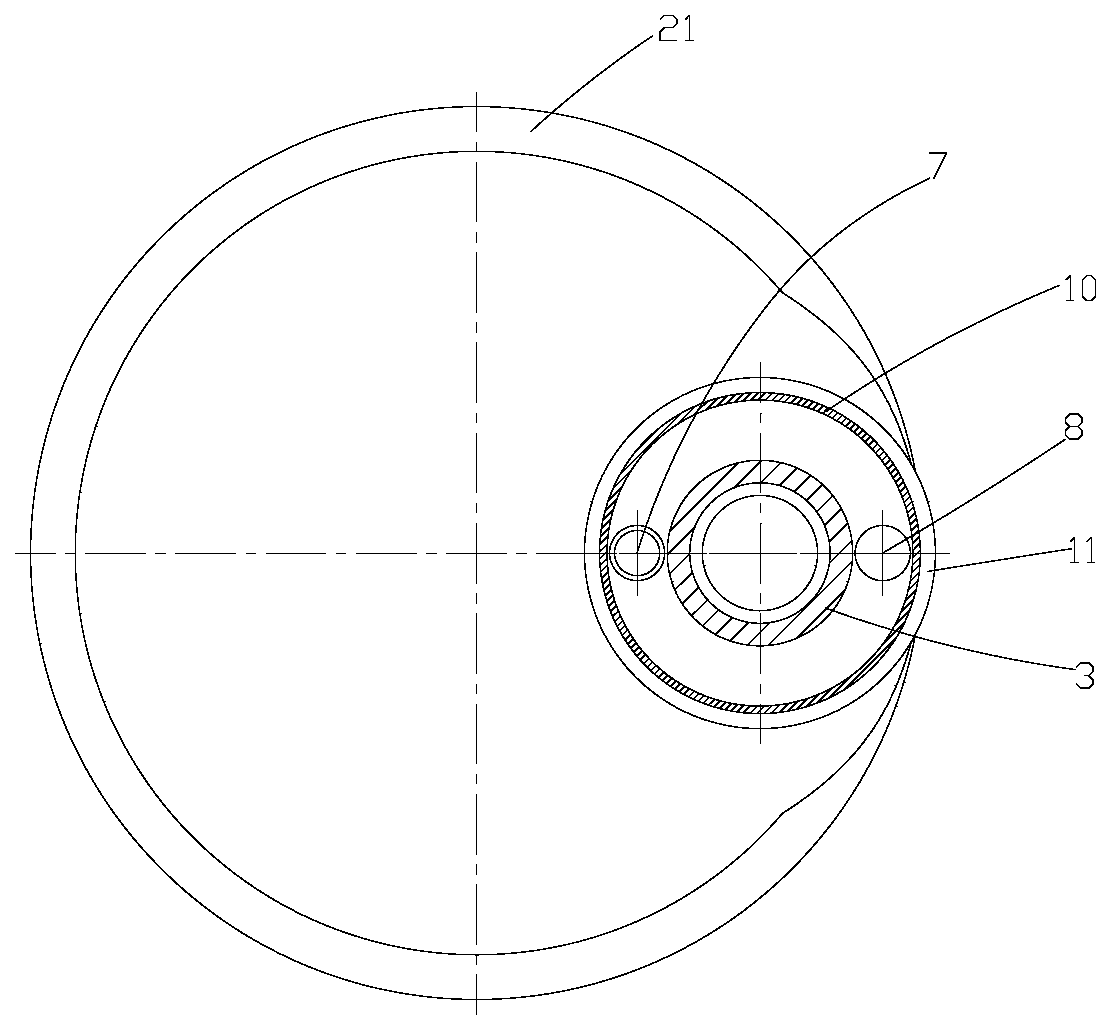

[0041] see in conjunction Figure 1 to Figure 9 As shown, according to the embodiment of the present application, the scroll compressor includes a casing 1, a fixed scroll 2 and a suction pipe 3, the suction pipe 3 is arranged on the casing 1, and the fixed scroll 2 is provided with a row The air port 4, the scroll compressor also includes a suction heat recovery component, which is in heat exchange contact with the suction pipe 3, the air inlet of the suction air recovery component is connected to the exhaust port 4, and the suction heat recovery The air outlet of the component is connected to the exhaust chamber 5 of the housing 1, and at least part of the refrigerant discharged from the exhaust port 4 flows through the suction and heat recovery assembly, exchanges heat with the refrigerant flowing through the suction pipe 3, and then flows to the exhaust chamber 5.

[0042] The scroll compressor adds a suction heat recovery component at the discharge port 4, so that at lea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com