Shaft end gas sealing device

A gas sealing and shaft end technology, which is applied in the direction of engine sealing, engine components, mechanical equipment, etc., can solve the problems of dust leakage, poor sealing effect at the outlet of the drive shaft of the plasticizing device, and pollution of the environment, etc. The effect of lowering the temperature and improving the lubricating environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

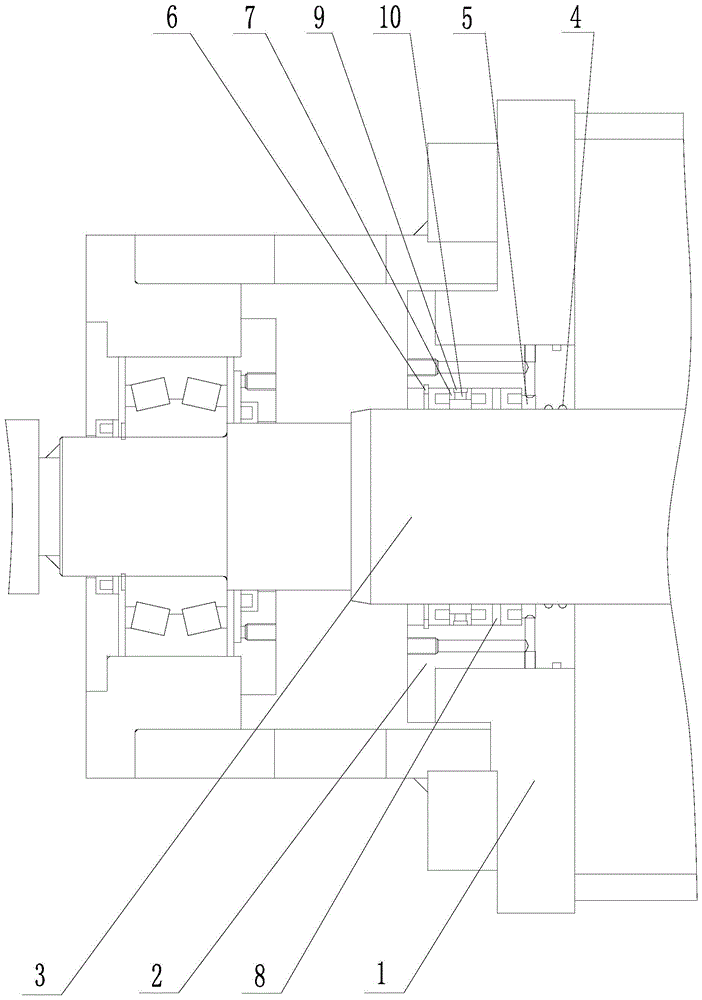

[0011] The present invention will now be further described with reference to the accompanying drawings. These drawings are all simplified schematic diagrams, and only illustrate the basic structure of the present invention in a schematic manner, so they only show the structures related to the present invention.

[0012] like figure 1 The shown shaft end gas sealing device includes a sealing seat 2 fixed on the plasticizing device 1, and a transmission shaft 3 is passed through the sealing seat 2, and the driving shaft 3 rotates through the bearing seat fixed on the plasticizing device 1. Support, the sealing seat 2 is provided with a stepped hole through which the transmission shaft 3 is inserted. The stepped hole includes a small hole, a middle hole and a large hole arranged from the inside to the outside in sequence, and two annular grooves 4 are arranged on the inner wall of the small hole. A skeleton oil seal assembly is arranged between the large hole and the transmissio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com