Packing wear condition monitoring device

A wear state and monitoring device technology, which is applied in the direction of testing wear resistance, wellbore/well components, earthwork drilling and production, etc., can solve problems such as increasing motor power, shortening service life of packing, polluting wellhead and atmospheric environment, etc., to achieve Increase the service life, reduce friction loss, and improve the effect of lubrication environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

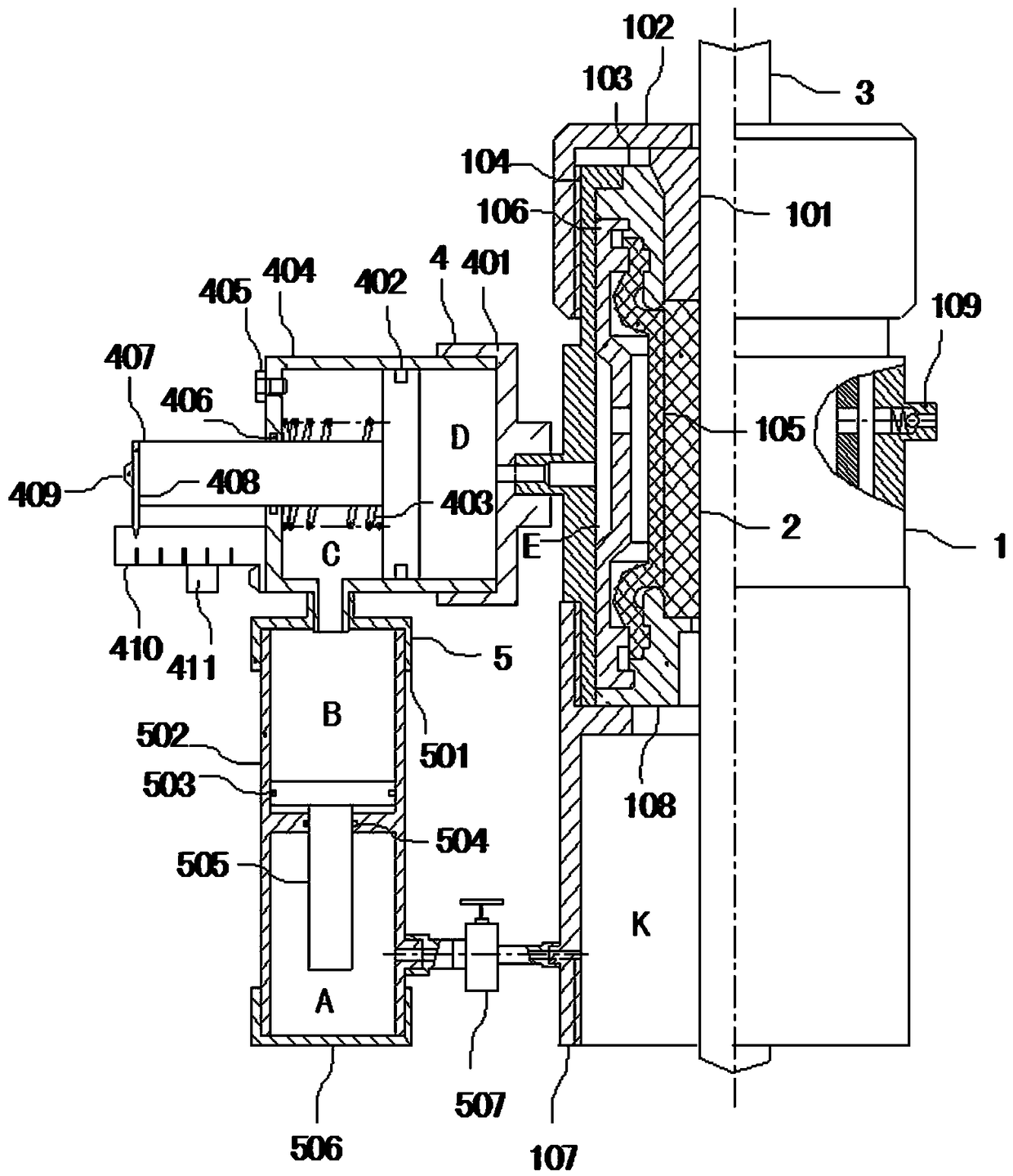

[0022] Such as figure 1 As shown, the packing wear state monitoring device includes a packing bin 1, a metering mechanism 4 and a pressure matching cylinder 5; the bottom of the stuffing bin 1 is fixedly connected to the wellhead components; the stuffing bin 1 includes a casing 104, a shield 106, The rubber tube 105 and the packing 2; the rubber tube 105 and the packing 2 are respectively placed in the housing 104; the cursor 3 is located on the central axis of the housing 104; the packing 2 and the rubber tube 105 are sequentially socketed with the cursor 3 The end of the shield 106 is fixedly connected to the end of the rubber cartridge 105; the inner wall of the housing 104 and the outer wall of the rubber cartridge 105 form a pressure chamber E; an oil filling valve 109 is fixedly provided on the outer housing 104; The oil injection valve 109 communicates with the pressure chamber E.

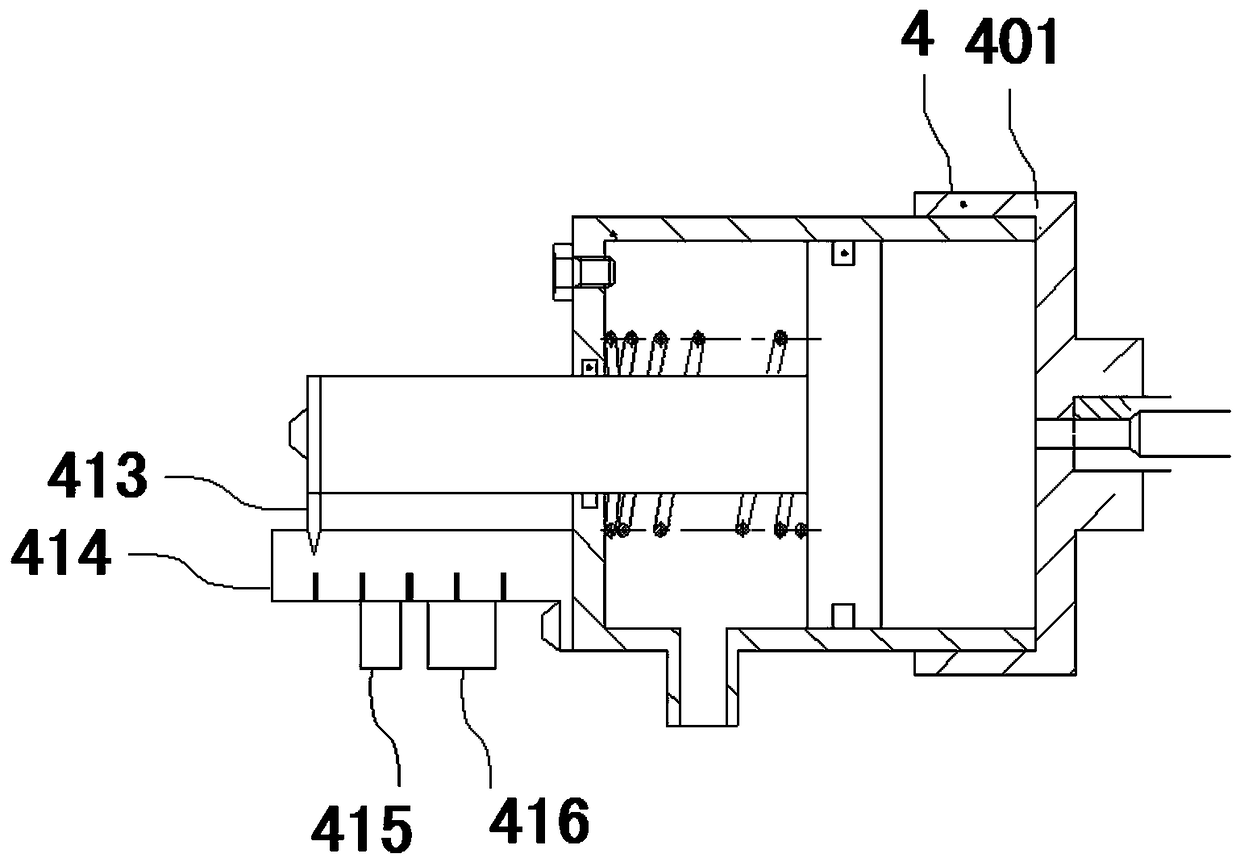

[0023]The metering mechanism 4 includes a cylinder 404, a piston 407 and a piston rod 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com