a valve guide

A valve guide and body technology, used in the lubrication of valve devices, valve accessories, machines/engines, etc., can solve the problems of oil burning, poor lubrication conditions, shortened life of parts, etc., to prevent vibration, improve the lubrication environment, and increase the life. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below with reference to the accompanying drawings and embodiments.

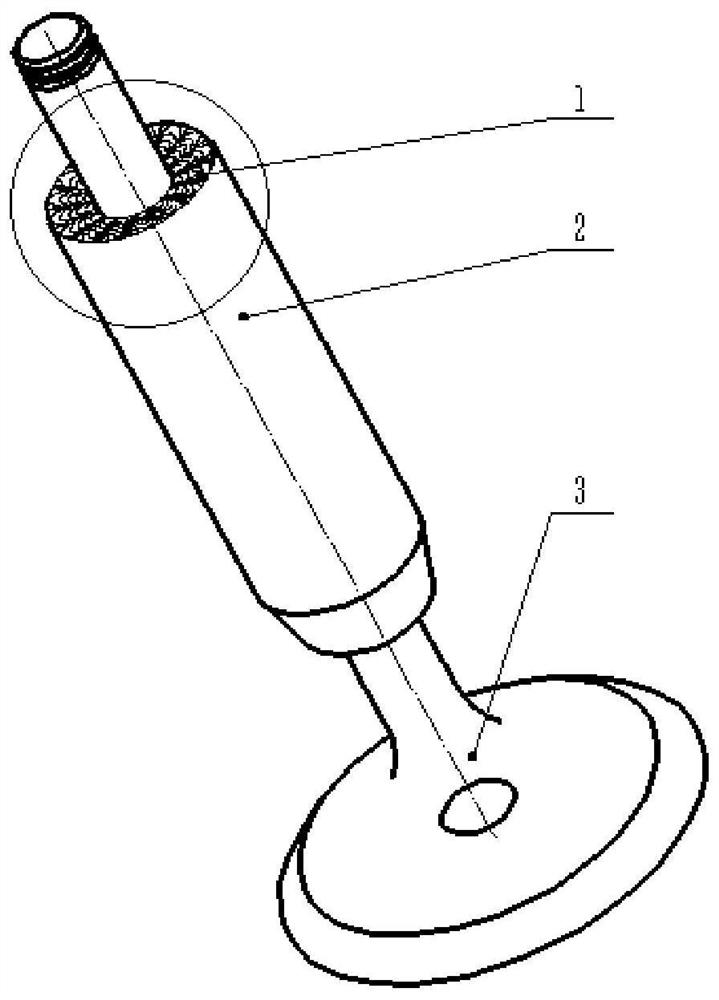

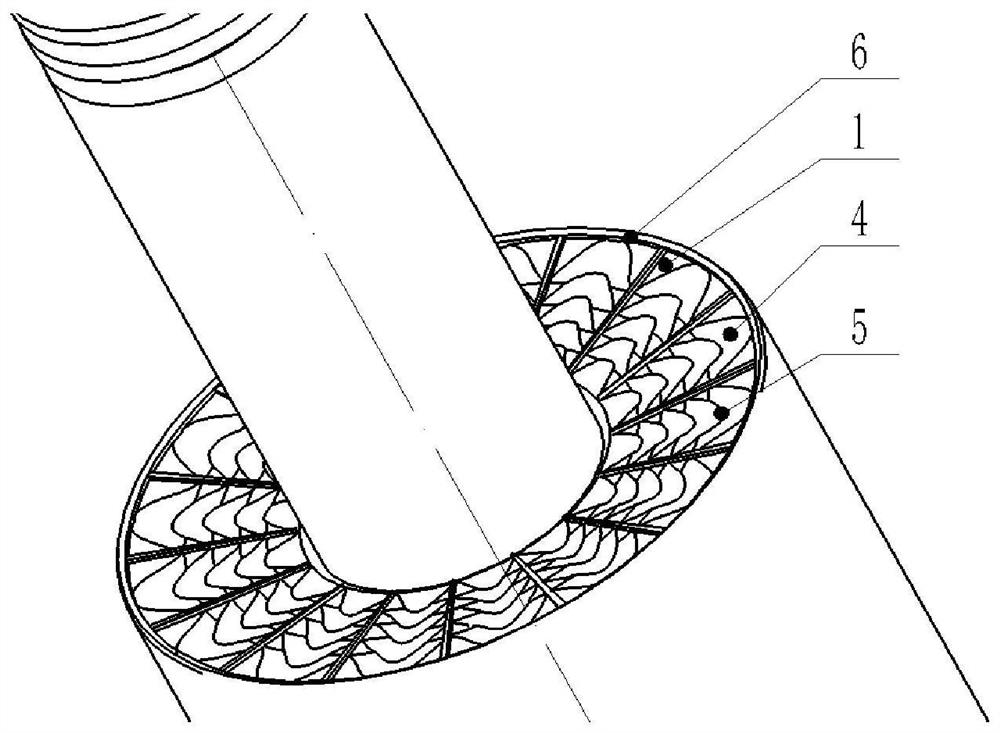

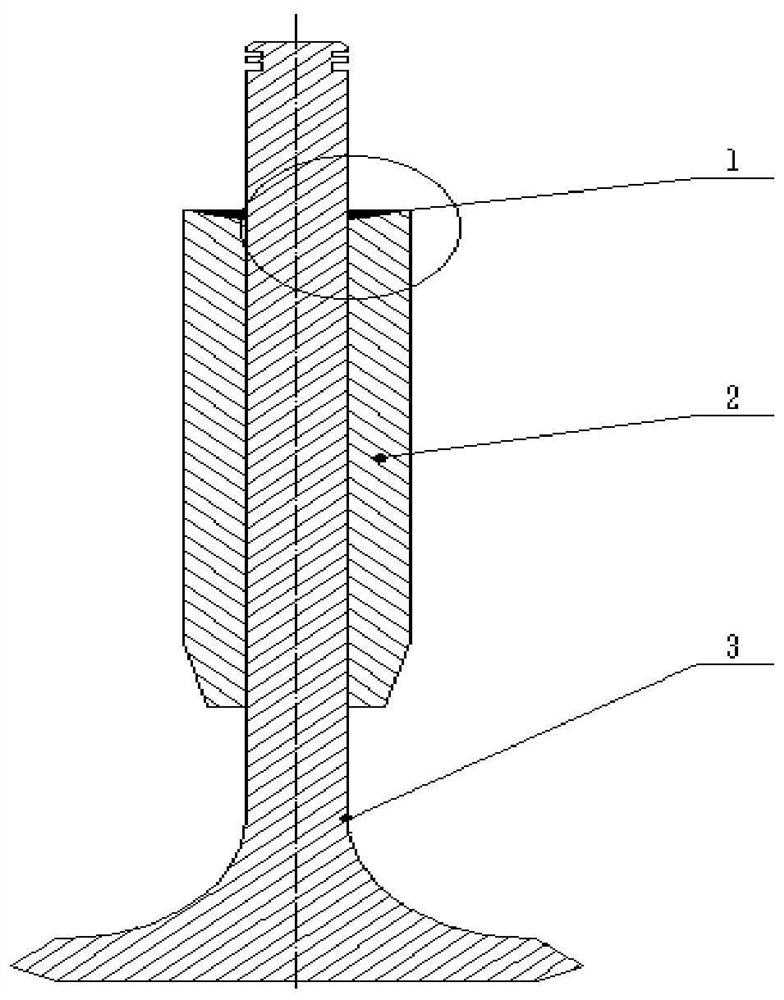

[0016] The working temperature of the valve guide is relatively high, and the lubricating conditions are poor. The oil splashed when the valve train works is used to lubricate the valve rod and the valve guide hole. The invention can solve the problem of poor lubrication caused by too little or too much lubricating fluid. phenomenon, such as figure 1 , figure 2 , image 3 , Figure 4 and Figure 5 As shown, the present invention includes a valve guide body 2 and a valve stem 3, the valve stem 3 is installed inside the valve guide body 2, the upper end surface of the valve guide body 2 is a slope inclined from the outer edge to the center, and the slope surface has a plurality of The center of the valve guide body 2 is the starting point and the secondary grooves 1 radiating outward in an array and adjacent to each other are distributed in each second...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com