Periodic gear wheel spraying lubrication device and method with adaptability to displacement

A technology of lubricating device and large gear, applied in the direction of gear lubrication/cooling, transmission parts, belt/chain/gear, etc., can solve the problems of tooth profile surface failure, decrease in transmission performance, decrease in transmission efficiency, etc., and achieve uniform lubricating oil. , the effect of reducing noise and reducing consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

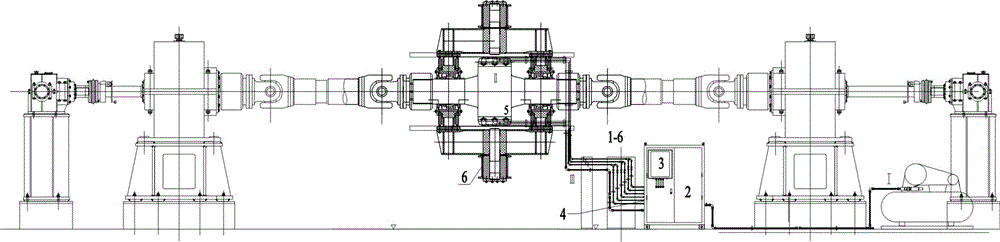

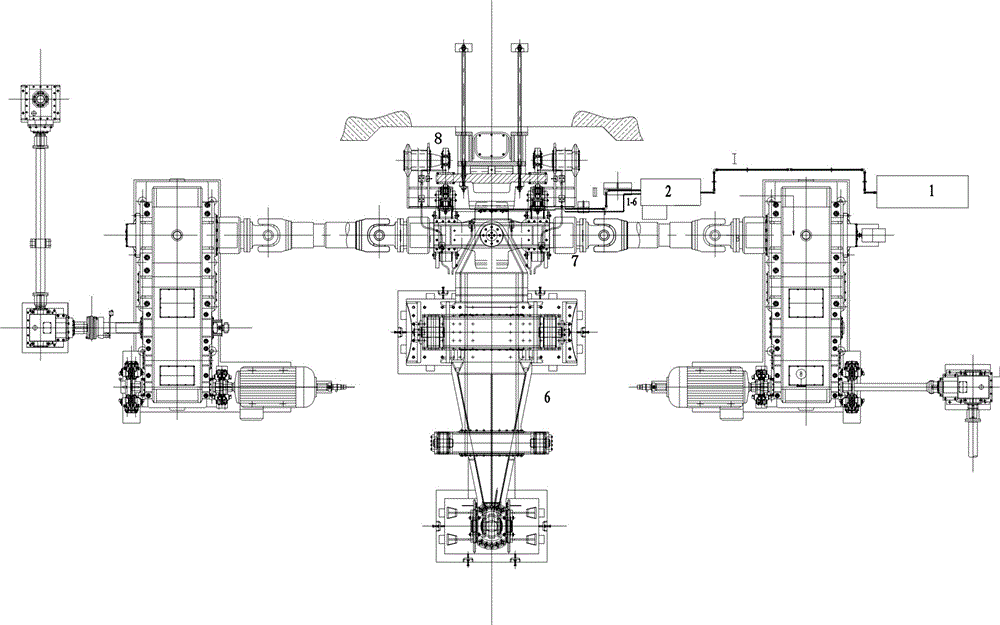

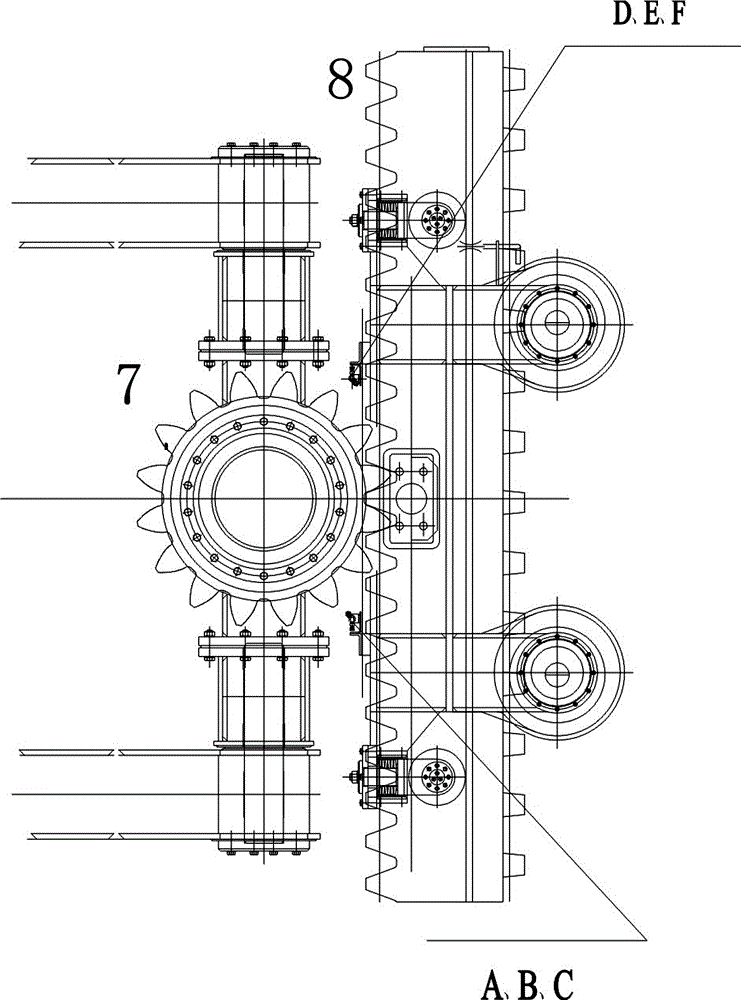

[0023] Such as Figure 1~Figure 4 As shown, the large gear periodic spray lubrication device that can adapt to displacement includes the air compressor air supply system 1, and the lubrication pipeline: the first pipeline I, the second pipeline II, the third pipeline III, and the grease pipeline 1-6, fixed lubrication pump station 2, lubrication system program controller 3, progressive double-line distributor 4, lubricating oil nozzle 5, pinion bracket mechanism 6.

[0024] The air compressor air supply system 1 enters the fixed lubrication pump station 2 through the first pipeline Ⅰ and connects to the pneumatic pump, and is divided into two pipelines through the solenoid valve and the pressure regulating switch, and the first pipeline is connected to the pneumatic triple unit , the compressed air enters the pneumatic pump to make the pneumatic pump work after being processed by the pneumatic triple parts, and the lubricating oil will output from the oil outlet of the pneumat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com