High comfort performance independent suspension for new energy bus

A technology of independent suspension and bus, which is applied in the direction of suspension, cantilever installed on the pivot, vehicle components, etc., which can solve the problem of large distance from the center of the brake disc to the mounting surface of the hub, which is not conducive to the life of the hub bearing, and increases the Wheel hub bearing load and other issues to achieve the effect of improving the lubrication environment, improving stability and comfort, and increasing the inclination angle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

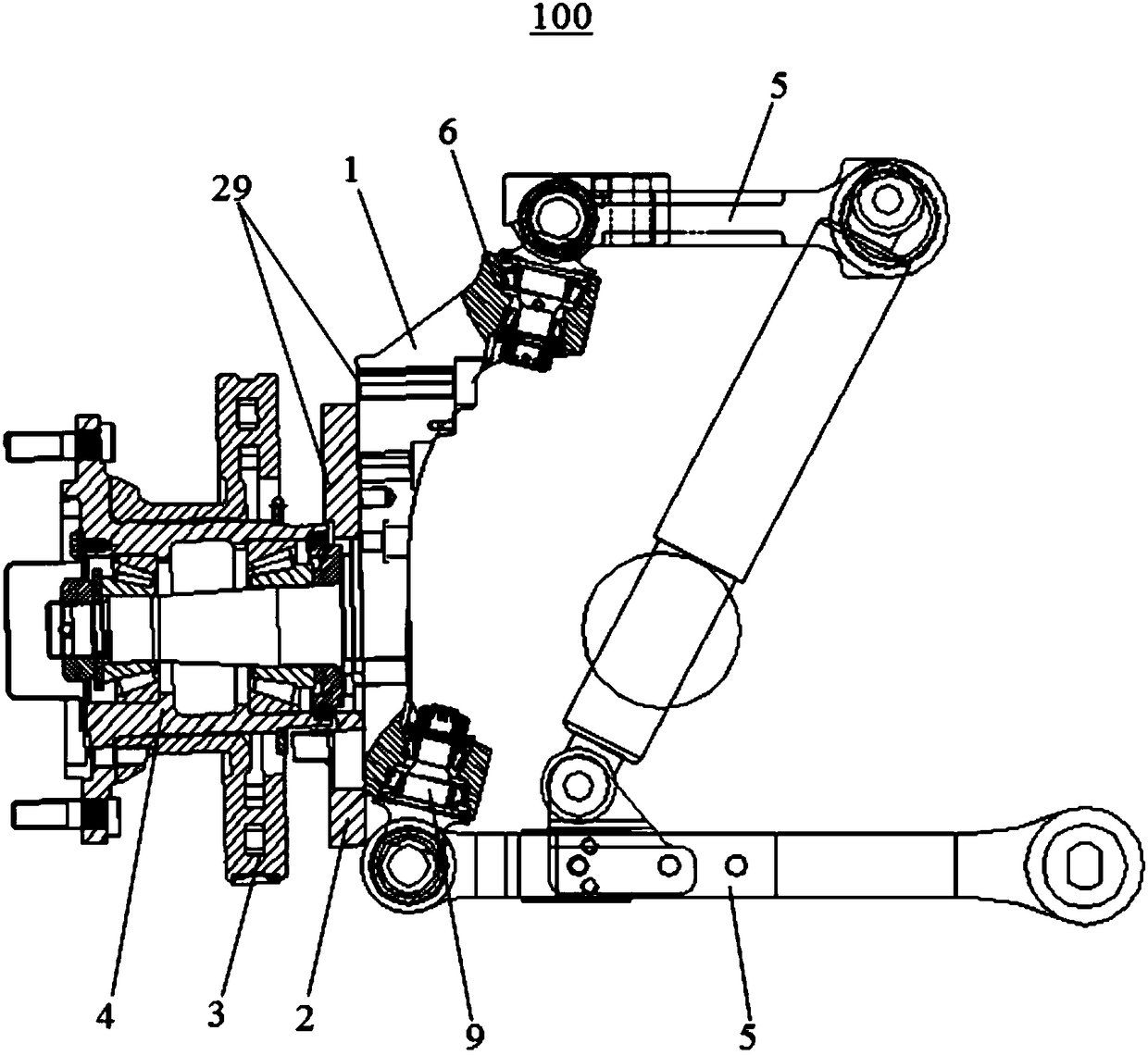

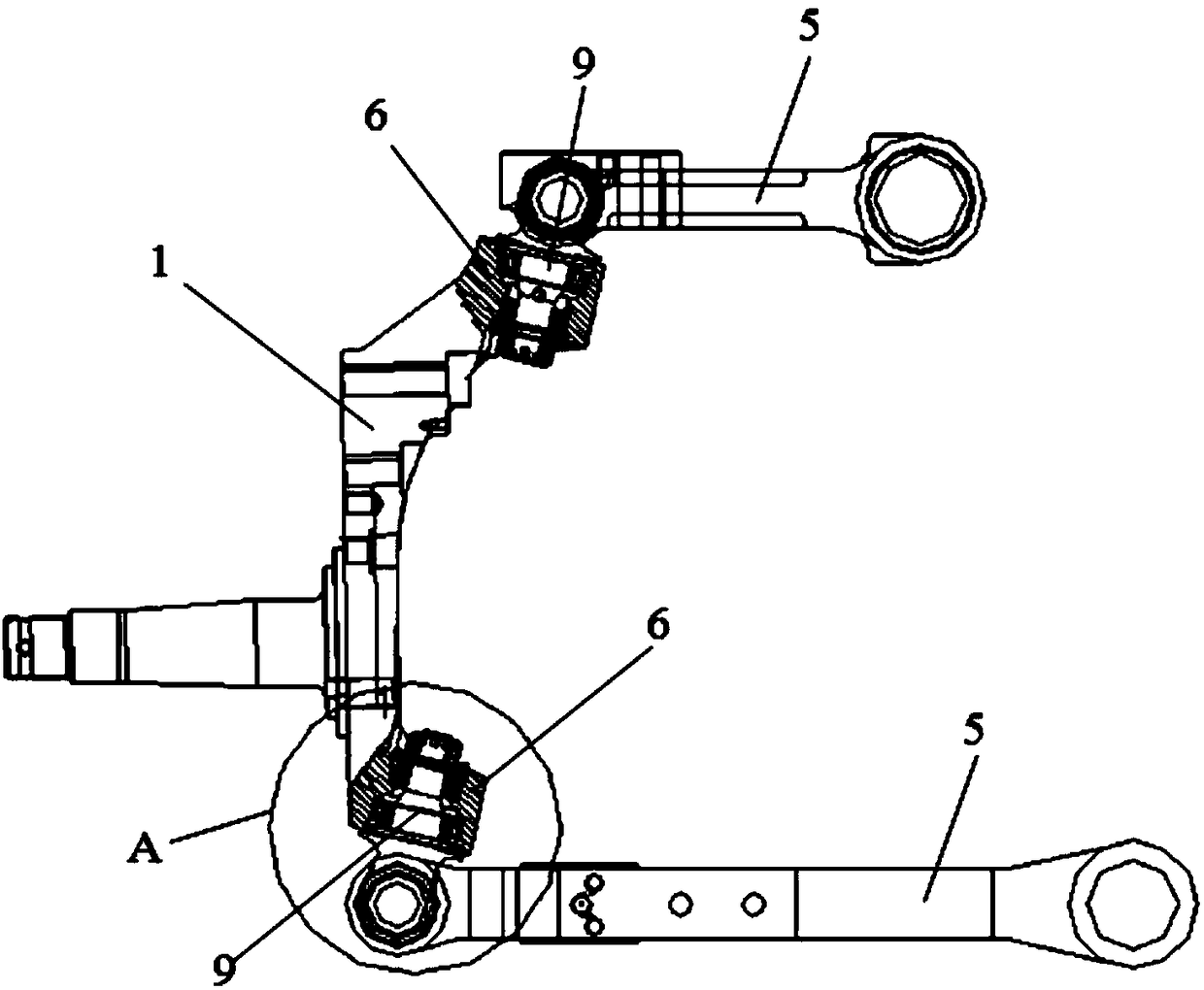

[0031] Please refer to Figure 1-Figure 6 , the present embodiment is a high-comfort independent suspension 100 for a new energy bus, which includes a steering knuckle assembly 1, a mounting plate 2 fixed on the end surface of the steering knuckle assembly 1, a brake disc 3, and a wheel hub assembly 4 And the control arm 5 connected with the steering knuckle assembly 1, the upper and lower ends of the steering knuckle assembly 1 are provided with connecting lugs 6, and the control arm 5 and the connecting lugs 6 are rotatably connected by a short pin rotary member.

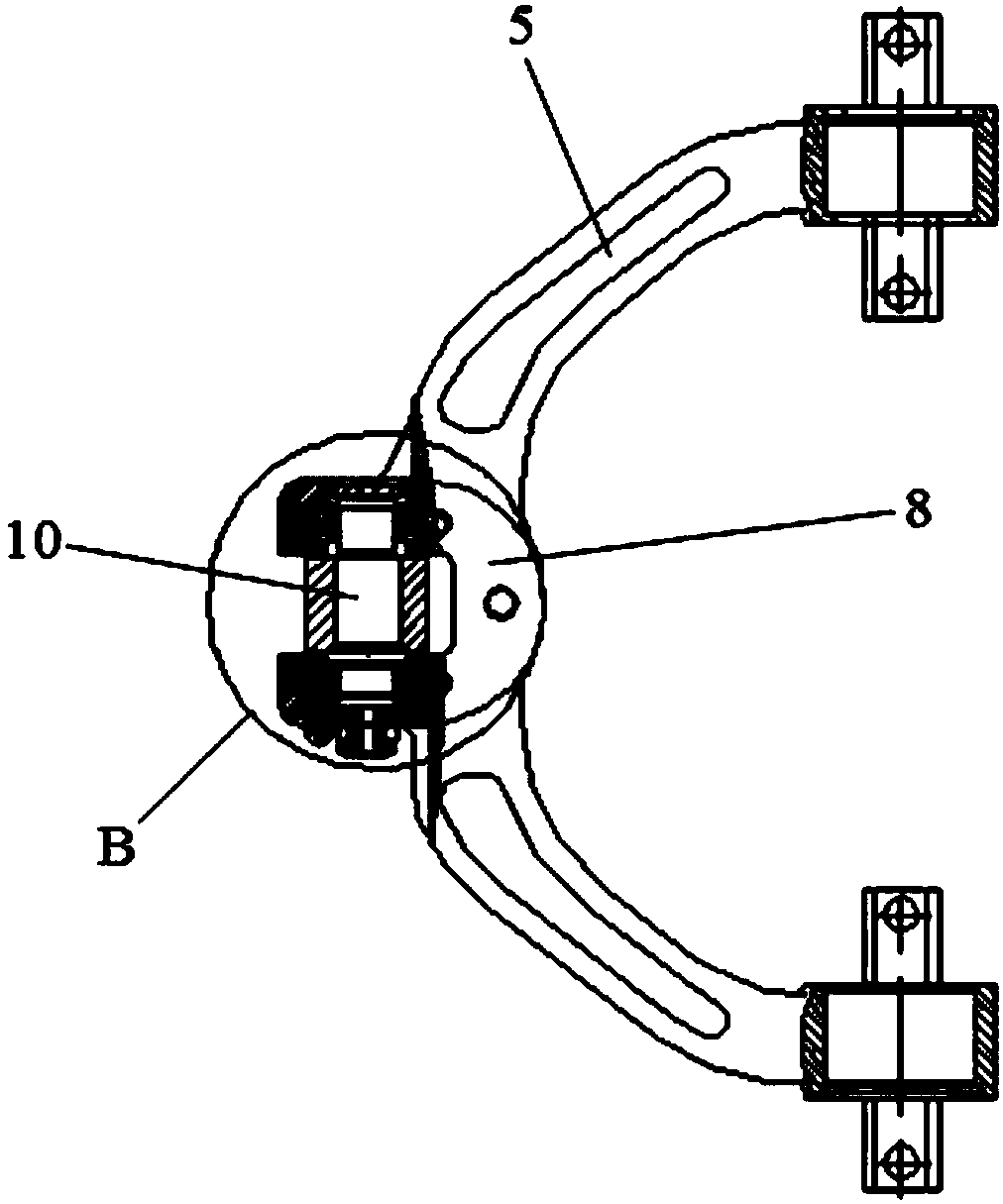

[0032] A stepped installation hole 7 is formed inside the connecting ear piece 6, a U-shaped fork 8 is provided at the end of the control arm 5, and coaxial installation holes (not marked in the figure) are arranged on both sides of the U-shaped fork 8. The pin rotary member includes a short pin connector 9 with one end connected to the mounting hole 7 bearings and a T-shaped joint 10 with both ends mounted in the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com