Counterweight system for elevator with tractor ratio of 4:1

A traction ratio and elevator technology, which is applied to elevators in buildings, lifting equipment in mines, transportation and packaging, and can solve problems such as high cost, complex structure, and poor versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described below in conjunction with accompanying drawing.

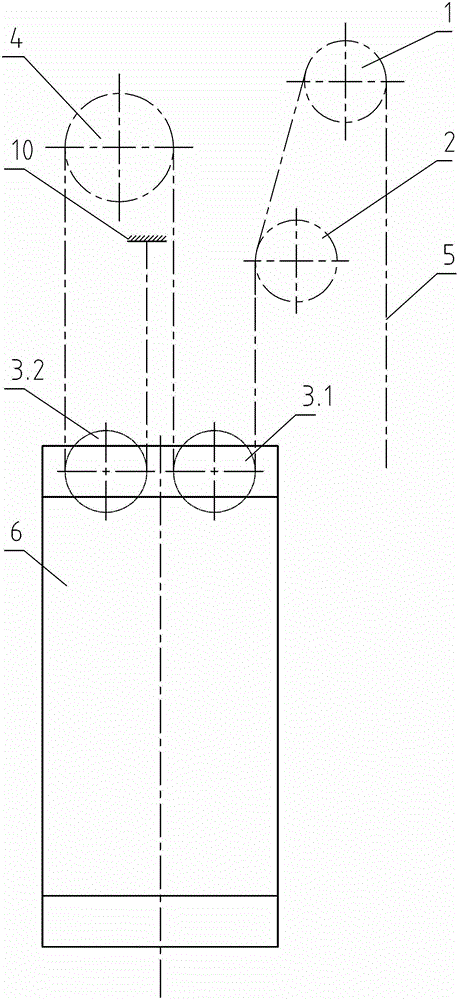

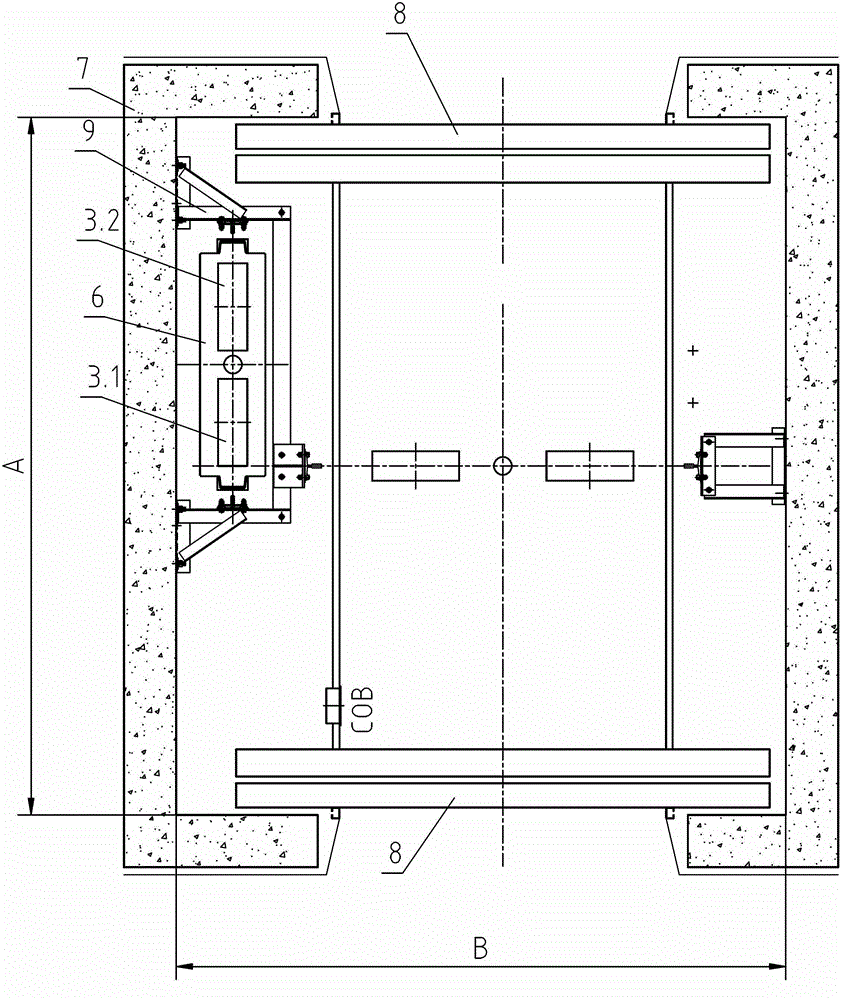

[0013] The elevator counterweight system with a traction ratio of 4:1 in the present invention includes a counterweight guide wheel 4, a first counterweight reversing sheave 3.1, a second counterweight reversing sheave 3.2 and a counterweight body 6, the first counterweight reversing The rope wheel 3.1 and the second counterweight anti-sheave 3.2 are installed on the counterweight body 6, and the traction rope 5 enters from the first counterweight anti-sheave 3.1, and then passes through the counterweight guide wheel 4 to the second counterweight anti-rope pulley. Sheave 3.2 goes out and is connected to fixed rope end 10, and described fixed rope end 10 is positioned between the second counterweight reverse rope wheel 3.2 and counterweight guide wheel 4, and described fixed rope end 10 is positioned at counterweight guide wheel 4 Projecting downward.

[0014] The second co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com