External circulating lubricating and cooling system for coal mining machine and coal mining machine cutting device

An external circulation and cooling system technology, which is applied in the direction of household refrigeration equipment, gear lubrication/cooling, cooling fluid circulation equipment, etc., can solve the problems of poor lubrication of the transmission system, high operating temperature of high power density cutting equipment, etc., to ensure long-term Long-term reliable operation, meet the requirements of high-efficiency lubrication and continuous cooling, and reduce the effect of operating temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

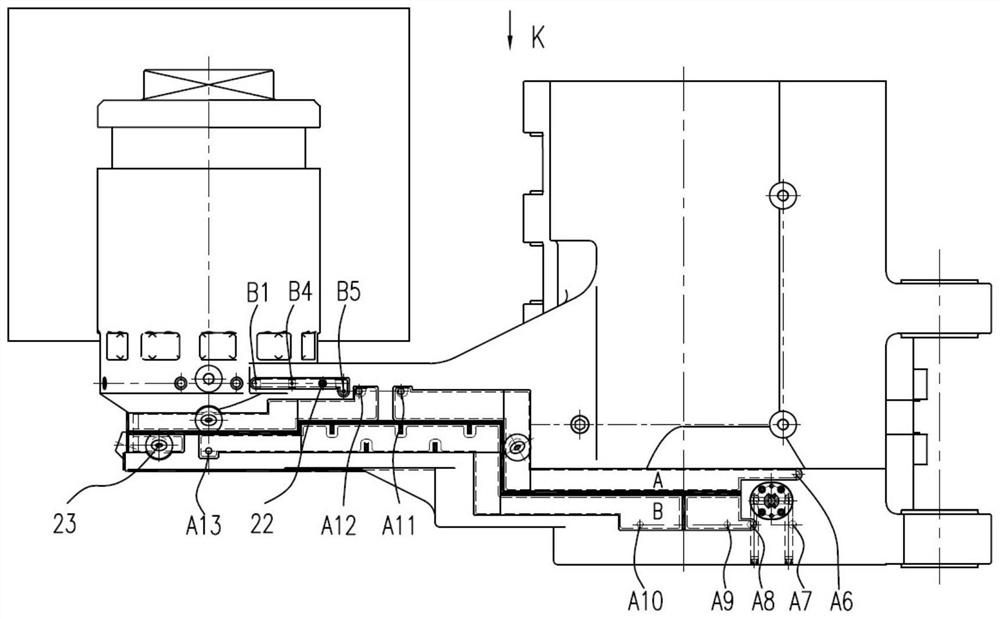

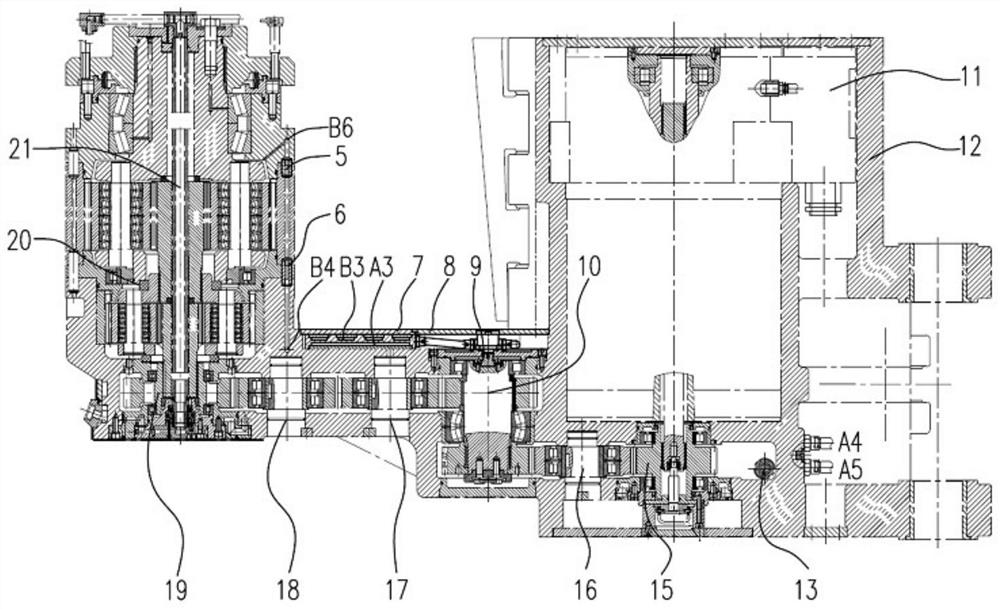

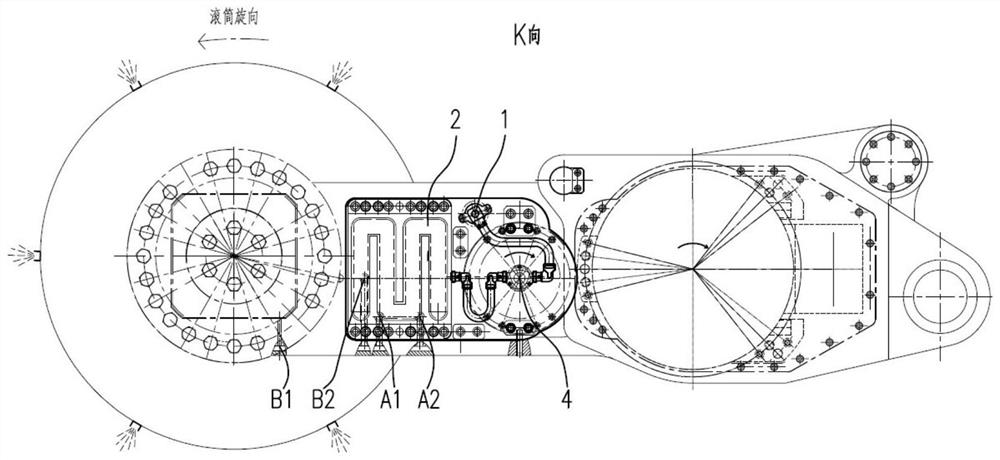

[0032] The invention discloses an external circulating lubrication and cooling system (which may be referred to as the lubrication and cooling system) for a coal shearer, such as Figure 1-5b Shown, comprise plate cooler 2, cycloid lubricating pump 4 and oil-suction filter 1, described oil-suction filter is installed in the inlet end of the oil-suction pipe of cycloid lubricating pump, and is positioned at the shearer cutting device casing (can Be called for short the bottom of the oil pool of casing 12). The outlet end of the oil return pipe of the cycloid lubricating pump is connected to the inlet port B of the circulating oil passage B3 (referred to as the oil passage) of the plate cooler. The high-temperature oil in the oil pool is sent to the plate cooler by the cycloidal lubricating pump for forced cooling. The outlet B2 of the oil channel of the plate cooler is connected with the oil pool of the shearer cutting device box. The inlet A2 and the outlet A1 of the circula...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com